Image Credit: Energy Vanguard

Image Credit: Energy Vanguard A wooden floor grille has much smaller net free area than a metal grille. Notice how much of the spaces is taken up by the wooden slats.

Image Credit: Energy Vanguard The calculation from Manual T says we need a 20" x 18" return grille to move 1,000 cfm at a face velocity of 400 feet/min. Unfortunately, it isn't in the table, but 20" x 20" is. And it doesn't make the grade. The highlighted column is the one for a face velocity of 400 fpm.

Image Credit: Hart & Cooley residential catalog From the engineering data, we see that we have to increase the return grille size to 30" x 20" to get 1,000 cfm of air flow at a face velocity of 400 fpm.

Image Credit: Hart & Cooley residential catalog

You’re at a cocktail party when, as it so often does, the discussion turns to HVAC design. What do people talk about? Load calculations. Manual J. Oversizing. Maybe a little about duct sizing or location. But how many times have you been in that conversation and heard someone talk about what happens at the end of the ducts? Yes, I’m talking about the often overlooked part of HVAC design in which the designer selects the proper terminations for the duct runs.

In the protocols of the Air Conditioning Contractors of America (ACCA), this part of the design process is described in Manual T: Air Distribution Basics for Residential and Small Commercial Buildings. This step is just as important as the other parts of the design process but is often given short shrift. Here’s an overview of some of the main factors we consider when selecting grilles and registers for the systems we design.

Suck it in

First, let me say that most of our attention is on the supply outlets (the registers and diffusers). The return inlets (grilles) are important but getting them right is pretty easy. Mostly, they just need to be big and open enough for the amount of air they’re moving. If they’re not, you’ll hear it once the fan runs. Make them too small — a common problem — and they’ll be noisy and reduce air flow.

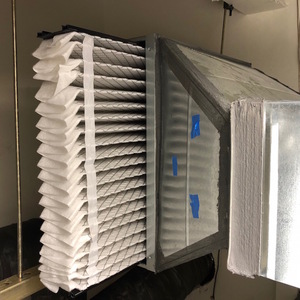

The important factor that comes into play here is net free area. It’s not just the overall size that matters. It’s the amount of open area in the return grille that matters. This is something a lot of people ignore when they switch out the metal vents in their home with wooden grilles. The net free area in a metal grille is typically 70 to 90 percent. A wooden grille might have a net free area of 50% or less. That can make a huge difference in air flow.

Then there are the DIY jobs. Just do a little search on the term “decorating a return air vent,” and you’ll see a lot of creative ways to make your system underperform — but it sure will look good!

Sizing a return grille

So how do you size a return vent? The author’s of Manual T give a pretty easy way to do it. If you’re using a non-filter grille, you divide the air flow rate in cubic feet per minute (cfm) by the face velocity in feet per minute (fpm). (Sorry, rest of the world. We use “those annoying imperial units” here in the U.S.)

But wait, you say. What the heck is the face velocity? Great question! It’s the speed of the air over the whole face of the grille. Occasionally you’ll see a reference to core velocity, which is the speed over the free area of the grille. When designing the returns, we typically use a maximum face velocity of 400 fpm for a non-filter grille.

Let’s do the numbers. Say you have a return designed for 1,000 cfm. The grille area, then, would need to be 1,000 cfm / 400 fpm = 2.5 square feet. That’s 360 square inches, so a 19″ x 19″ grille would work. Except you can’t find one with those dimensions. At 360 square inches, a 20″ x 18″ is right on the money. But…

Use real engineering data

What does the manufacturer say about their grilles? If you look at the Hart & Cooley catalog, it’s easy to see that these simple calculations don’t quite work. Take a look at the table below (see Image #3) and you’ll see what I mean. 20″ x 18″ isn’t in the table, but 20″ x 20″ is. And it doesn’t make the grade. The highlighted column is the one for a face velocity of 400 fpm.

Hmmmm. We wanted 1,000 cfm, but the 20″ x 18″ grille will give us something less than 720 cfm at those conditions.

The solution is to go bigger. The snippet of engineering data below is from further down in the table. To have a return grille that can move at least 1,000 cfm at 400 fpm face velocity, we need a 30″ x 20″ grille. The 30″ x 18″ doesn’t quite get us there so we bump it up to the next size.

That simple calculation from Manual T that I opened up the discussion of sizing with turns out to be a rough rule of thumb. To get the proper sizes for your return grilles, you must use the engineering data.

A delicate balance

At the other end, the supply duct terminations have to do a lot. Here’s the short list of what you want to accomplish with the supply air when it exits the ducts:

- Deliver the right amount of air. Of course, most of that is determined by what happens before the air gets to the end of a run but the vent type is still significant.

- Mix the supply air with the room air. That means shooting it out fast enough and in the right direction(s).

- Keep fast-moving air away from people. Drafts create comfort problems.

- Get the air out of the vents quietly. This is such an important point it deserves its own article.

- Don’t give that freshly conditioned air a short circuit to a return vent. If you put a supply just across from a return, you’re asking for trouble.

I’ll cover that important topic in the near future. In the meantime, your homework is to get your hands on a copy of Manual T, download a catalog or two , and see if you can make some sense of this stuff. (Hart & Cooley and Shoemaker are the two big names in registers, grilles, and diffusers.) When I come back to this subject, we’ll explore those design issues in some depth.

________________________________________________________________________

Allison A. Bailes III, PhD is a speaker, writer, building science consultant, and the founder of Energy Vanguard in Decatur, Georgia. He has a doctorate in physics and is the author of a bestselling book on building science. He also writes the Energy Vanguard Blog. For more updates, you can subscribe to the Energy Vanguard newsletter and follow him on LinkedIn. Images courtesy of author.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

2 Comments

Blower speed

A modern multi-speed blower is likely to be running at low speed much of the time, which reduces the velocity and throw at the registers. So I'm wondering how much we really need to worry about throw, since in practice the throw will usuallly be far less than the calculations done at full speed show. In my case I'm using old gravity-feed registers, which are much larger, for historical accuracy. So the face velocity is further reduced, but I'm locating returns high across the room to promote air flow and mixing.

This page is a bit old, but is it me or the follow up article on sizing up supply grilles to keep them quiet never came?

I looked up on energy vanguard as well and it seems the series stops at 6 when at least one more was expected.

Log in or create an account to post a comment.

Sign up Log in