Image Credit: Energy Vanguard

You can tell how energy-efficient a furnace is by its official efficiency rating, the Annual Fuel Utilization Efficiency (AFUE). It’s a measure of how much of the heat originally in the fuel that’s being burned is available for delivery to the home. The more heat that gets lost up the flue or through the cabinet, the lower the AFUE.

But that rating doesn’t capture all the ways a furnace can lose efficiency. Some, like how well the heat gets distributed to the house, aren’t related to the furnace itself. But there’s one big one that is related to the furnace.

Unlike air conditioners and heat pumps, furnaces use two sources of energy. The fuel that it burns is the obvious one. (It’s usually natural gas or propane.) The other is the electricity that runs the blower. And that’s the key to finding a high-efficiency furnace that truly operates at high efficiency.

A peek at manufacturer’s specs

I was working on a mechanical design for one of our clients recently and was going through the equipment selection process. The software we use (RightSuite Universal) has a lot of equipment data built in, so I can just find a manufacturer, set the limits for sizing and efficiency, and look at the options.

Once I get my list of options reduced to a reasonable number, I can choose a model that meets my requirements. But I have to go in and make sure to look at the blower power rating for each one or I could end up saddling the client with a furnace that looks like it should be efficient but really isn’t.

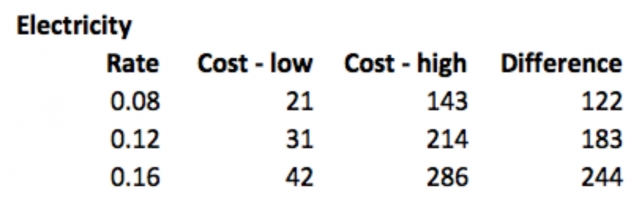

I took a look at the RightSuite listed blower power ratings for five different manufacturers. They were all in the range of 40-44 thousand BTU per hour (kBTU/hr) with AFUE ratings of 94.1 to 96.5. What I found is summarized in the table shown at right.

That’s quite a difference. The average low blower power (224 W) is about a third the average high blower power (633 W). And the worst one in there (893 W) is another 41% higher than the average high.

The effect of an energy hog blower

What this means is that when you choose a furnace, the effect on the heating bill hits two ways. A higher AFUE means you pay a lower gas bill. It does not mean, however, that your overall energy bills are lower. If you live somewhere with a mild climate, it may not affect you very much. The more that blower runs, though, the higher the electricity bill will be.

Also, remember, when you pair a furnace with an air conditioner or a heat pump, that same blower is used for heating and cooling. So if the furnace blower is an energy hog, the homeowner will pay for it year-round.

Let’s look at some numbers. To figure out how the blower’s power use affects your electricity bills, we need to know how many hours it’s going to run. If you look online for annual runtime, you’ll see some numbers that are too high. One was as high as 3,600 hours per year, implying that the system runs an average of 10 hours per day, 365 days per year.

So I checked with someone who knows and found out that the national average is probably around 1,500 hours per year, and it’s more like 2,000 hours per year in a hot climate where the air conditioner runs a lot. Since we design systems that aren’t nearly as oversized as the typical ones, I’ll use 2,000 hours in my calculations. (Right-sized systems have more runtime.)

The most efficient blower in the table above uses 131 W. Multiply that by 2,000 hours, convert from W to kW, and we find that this blower uses 262 kWh per year. The worst blower uses 893 W, so its annual consumption is 1,786 kWh. Wow! That’s almost six times more electricity use.

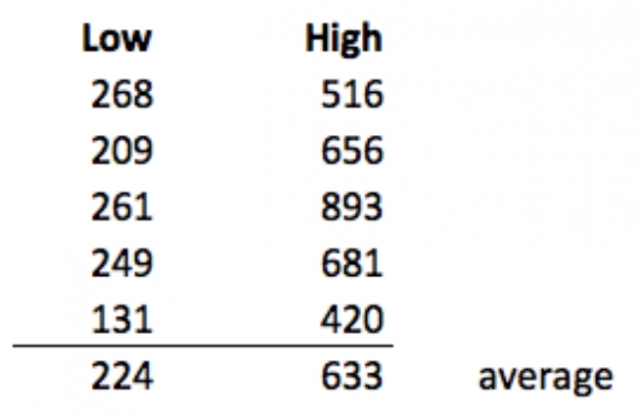

Of course, the other big factor that affects the electricity cost is the rate you pay, so I calculated the annual cost for these two blowers for three rates, $0.08, $0.12, and $0.16 per kilowatt-hour (kWh).

As you can see in the table shown at right, the difference between a low-power blower and a high-power blower can be significant. If the furnace lasts 15 years, it can cost $2,000 to $3,000 extra if you make the wrong choice.

Another way to check furnace electricity use

My little calculation above is just a simple way to show that you should pay attention to the both forms of energy used in a furnace. As it turns out, you can look up an estimate of how much electricity a furnace uses. It’s the Eae shown on the AHRI certificate from the AHRI Directory. (AHRI is the Air Conditioning, Heating, and Refrigeration Institute.)

What is the Eae, you ask? It’s the “average annual auxiliary electrical energy consumption for a gas furnace in kilowatt-hours per year. It is a measure of the total electrical energy supplied to a furnace during a one-year period.” That’s AHRI’s definition.

When you go to the AHRI Directory, you can (sometimes) find the certificate for a particular furnace. The certified data are the AFUE and output capacity. They also show some reference data, “not certified by AHRI.” Among those is the Eae, given in kWh per year. I looked at the numbers for some of the models I listed above and found the Eae numbers are significantly lower than what I calculated. The highest one I found was 732 kWh/year, about 1,000 kWh less than my high number.

Bottom line: Check your specs!

What I’ve presented here is a simplified analysis. To get to the actual effect of the blower on your energy bills, we’d need to know about the ducts. A well designed and installed duct system won’t resist the air flow as much as a typical duct system, and that affects the blower. Another real-world factor is that actual performance usually differs from manufacturer’s specifications. When you can get actual data, you can make an even better decision.

Still, using the manufacturer’s specs or the Eae is a good first step. Not all high-efficiency furnaces are created equal, and when looking for a furnace you should be aware that the AFUE is only one part of the efficiency. Be sure to look at the blower power, too, because that can have a huge effect on your energy costs. The best ones use electronically commutated motors (ECM). The worst use permanent split capacitor (PSC) motors. And if your utility is selling you dirty electricity, you pollute more as well.

Allison Bailes of Decatur, Georgia, is a speaker, writer, building science consultant, and the author of the Energy Vanguard Blog. You can follow him on Twitter at @EnergyVanguard.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

One Comment

Downside to ECM blower efficiency

As you point out, duct design is an important factor in blower performance. There's even an added wrinkle: as I understand it, newer ECM blowers respond to friction head in ducted systems differently than previous generation blower motors did. In the old days a poorly designed duct system with high friction head, for example one with inadequate supply and return, would result in lower cfm (and perhaps decreased comfort), but the power consumption of the blower would not be affected. But ECM blowers will actually ramp up in response to higher head pressure. So in the worst case you might end up paying significantly more to operate a "more efficient" blower if your ducts aren't properly sized.

Log in or create an account to post a comment.

Sign up Log in