Image Credit: Building Science Corporation

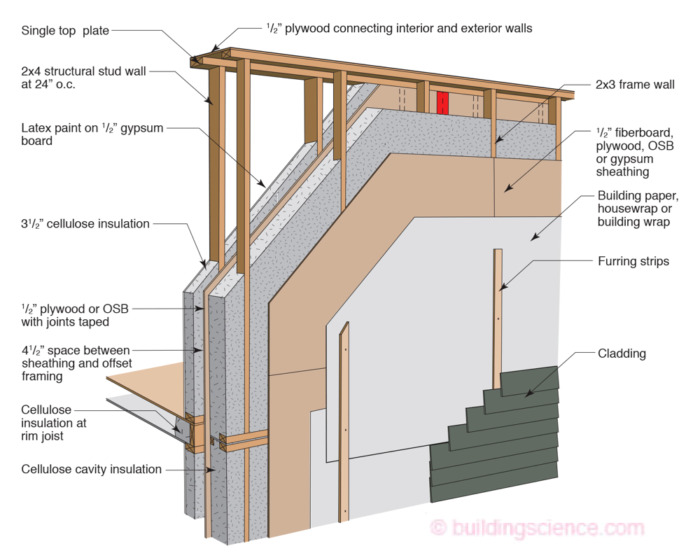

Image Credit: Building Science Corporation BSC's double-stud wall, side view

Image Credit: Building Science Corporation

Joe Lstiburek called me last week to set the record straight. I had written an article about a study of moisture in double-stud walls in a Massachusetts home, and his company, Building Science Corporation (BSC), had done the research as part of the Building America program. They found elevated moisture content in the cold, exterior sheathing, and Joe wanted to make sure everyone knew, “I would never build that wall because I consider it too risky.”

The BSC study redux

The reason he called is I that I hadn’t done my job as a journalist. Of course, I’m not really a journalist; I just play one in this blog. But that doesn’t absolve me from the duty to dig deeper, especially when I ascribe a conclusion to a person when that conclusion came from third-party sources. In this case, the conclusion was that buildings are more robust than we give them credit for, a statement I had initially ended that article with.

Because of that conclusion and because I hadn’t made it clear that BSC only monitored the project, some readers had the mistaken impression that BSC had at least endorsed, if not designed, that double-stud wall. As mentioned above, Joe considers that wall too risky, and the excessive moisture content in the exterior sheathing confirms his misgivings. Although the sheathing wasn’t damaged when they deconstructed the wall sections after three years, the amount of moisture they saw during winter and spring was a concern.

As for the debate about where the moisture came from, Joe said it’s coming from inside. The perfect correlation between indoor relative humidity — low in winters 1 and 3, high in winter 2 — and sheathing moisture content — also low in winters 1 and 3, high in winter 2 — indicates that the moisture is from indoors.

“None of this is unknown,” Joe told me. “None of it is a surprise — none of it. Which is why on our website, we recommend don’t build this wall; build ’em this way.” (See the diagrams above and below.)

The problem is the lack of adequate vapor control. Both cellulose and open-cell spray foam, the two types of insulation they looked at, are Class 3 vapor retarders (1-10 perms). With lots of insulation in the walls, 12 inches in this study, the exterior sheathing stays colder. Cold materials are generally wetter than warm materials.

“The wall design I’m talking about solves the problem of inside moisture and it solves the problem of outside moisture,” Joe said.

Lstiburek’s ideal double-stud wall design

The diagram at the top of the article shows Joe’s ideal double-stud wall design. (For more details, see High R-Value Wall Assembly: Double Stud Wall Construction on the BSC website.) It’s got two layers of framing, which is why it’s called a double-stud wall or double-wall construction, but there’s an important difference between his wall and the one in the BSC study. He specifies a layer of OSB or plywood on the outside of the inside wall when using an air permeable insulation like cellulose or fiberglass.

That extra sheathing serves as the primary air control layer as well as the vapor control layer. That method works in a cold climate, like the climate zone 5 where the BSC study took place. It also works in other climates. “Plywood or OSB work in every climate zone,” Joe said. “Both of them act as a rigid, smart vapor retarder and air control layer.”

Some builders in cold climates put a layer of 6 mil polyethylene inside a double-stud wall instead of the OSB or plywood that Lstiburek prefers. I asked Joe for his thoughts on that technique: “In terms of the physics, it’s great. In terms of practicality, it’s a very fragile way of doing things. That’s why I like sheet goods. We did this in the early ’80s and it was difficult to build.”

Another thing Lstiburek likes is to have the structural part of the double-stud wall be the interior wall. “I also think it’s colossally stupid to have the second wall of a double-stud wall be on the inside of the structure. That’s an incredible waste of floor area and materials and very, very difficult from an airtightness perspective,” he said. In the BSC diagram below, you can see the exterior wall is clearly outside the structure.

On the exterior of the wall, he specifies a vented rainscreen to aid drying. The first diagram shows furring strips, but any method that provides at least a 3/8″ gap should work. A ventilated cladding, like vinyl siding, would also work.

Lstiburek’s ideal double-stud wall has all the thermal, air, and vapor control that it needs to make the wall perform well and avoid moisture problems. “I think the walls that I’m recommending are not risky, regardless of whether we’re talking about interior or exterior moisture,” Joe said.

According to Lstiburek, the current hullabaloo over double-stud walls is a distraction: “Here’s what’s frustrating about this: We figured all this stuff out thirty years ago!”

External Resources

BSC: High R-Value Wall Assembly: Double Stud Wall Construction

BSC: High R-Value Wall Assembly: Double Stud with Spray Foam Wall Construction

Allison Bailes of Decatur, Georgia, is a speaker, writer, energy consultant, RESNET-certified trainer, and the author of the Energy Vanguard Blog. Check out his in-depth course, Mastering Building Science at Heatspring Learning Institute, and follow him on Twitter at @EnergyVanguard.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

53 Comments

A few comments on Lstiburek's wall

Allison,

Thanks very much for this blog, which is an important contribution to this ongoing discussion. My thoughts:

1. Joe's comment, "Here's what's frustrating about this: We figured all this stuff out thirty years ago!" seems a little flippant and disingenuous (although it's hard to judge his intended meaning without knowing the context). Yes, Joe, I know what you mean: Canadians were building walls with intermediate air/vapor barriers (following the old 1/3 to 2/3 rule) thirty years ago. But the issues we have been discussing here were not resolved 30 years ago, which is why Joe gets paid to do research on Carter Scott's walls. Anyway, this is not a fundamental disagreement -- just a comment.

2. Exterior 2x3s? Really? Count me out. It's hard to buy 2x3s, and they often cost just as much as 2x4s, and they tend to warp and twist.

3. Joe's detail conveniently avoids showing how his non-load-bearing outer wall integrates with the foundation. This detail can be tricky, especially if you want a good load path from the inner wall down to the foundation. There are solutions, of course -- but it would be nice if BSC included this detail in their drawings.

Now that we know the moisture

Now that we know the moisture in the test house was coming from the inside conditioned space, it raises the question of how it got there. Any failure of the air barrier has been ruled out, so we know that vapor was not transported outward by airflow.

Also ruled out is adsorption from the outdoor air. So that leaves outward diffusion as the only possible explanation. Yet, we are told that diffusion is fundamentally so minor, that it is not capable of causing any wall cavity moisture accumulation unless there is some abnormally high source of interior humidity such as a swimming pool or greenhouse; and there is no such abnormal humidity condition in the test house.

So, what is the explanation of how the indoor vapor encountered the cold sheathing?

Response to Ron Keagle

Yes, it's vapor diffusion. Both cellulose and open-cell foam are vapor semi-permeable (~2 perms for 12" ocSPF, ~5 perms for 5.5" ocSPF, and 7-10 perms for 12" cellulose). Water vapor can move through them, and when it gets all the way to the exterior sheathing, it finds a pretty cold surface. When the sheathing is really cold, you don't need a swimming pool for this to happen. The graphs of moisture content and relative humidity (included in last week's article) show excellent correlation, so the source of the moisture isn't a mystery.

Response to Ron Keagle and Allison Bailes

It's true that some building scientists (including, to the best of my knowledge, William Rose) report that wall failures due to vapor diffusion are very rare, outside of buildings like swimming pools and greenhouses.

This recent study of Carter Scott's walls does not contradict that generalization. "They found no damage here and no evidence of mold or rot," and the sheathing was "basically undamaged."

Wall design

It looks very similar to what Martin has been suggesting here for years. I'm not as concerned as the building scientists as to where the moisture comes from as this wall deals with all possibilities.

For those of us in temperate climates where the gap between the two walls will probably be designed to be quite small, the foundation problem disappears.

What's left is the outer sheathing. I'm not keen to install what is largely a redundant second layer on the exterior. The labour and materials for this are what might well sway me to use another approach - like exterior mineral wool. Eliminating the sheathing in favour of a robust WRB might be the best solution.

Exterior insulation

Malcolm, yes, exterior insulation is the better way way to go. It eliminates more of the thermal bridging, is less expensive, and keeps the sheathing warm. The diagrams in this article show Joe's preferred double-stud wall, but the superinsulated wall he likes best of all is one with exterior insulation. It's what he used on his own home. (See his article, Leiningen versus The Ants Redux, where he talks about what caused it to fail the first time and shows drawings for how he rebuilt it.)

Allison

Thanks, I read Joe's article in FHB a few years ago. Having had extensive experience with carpenter ants here in the PNW I found his explanation for their presence, and dismissal of the problem of pests in foam, less than convincing.

What makes the double wall most compelling for me is the way it buries the air-barrier/ vapour retarder in the assembly, making it so much more resilient than either interior membranes, air tight drywall or relying on the exterior sheathing.

I've watched a lot of houses being altered by either their owners or pros, sometimes quite soon after construction, and it's make me a believer in wall systems that don't rely on exotic or fragile techniques for their robustness. You can do a fair amount of monkeying with Joe's double wall on both the exterior and inside without compromising it.

The Role of Diffusion

Martin,

I understand Bill Rose’s position on ruling out diffusion as being a problem, but as I recall, Joe Lstiburek has also claimed that diffusion is not a problem that needs to be addressed in a building. Wasn’t it Joe who published the rule of thumb on diffusion claiming that it transfers only 1/3 cup of water through a 4 X 8 sheet of drywall during the entire wintertime heating season?

I understand your distinction between wet walls that do not become damaged or grow mold, and wet walls that do become damaged or grow mold. However, they are both manifestations of the same problem, and I think it is too close of a call to design for that distinction. Any wetness is slowly causing damage whether it is apparent at first or not. Thus, I believe the only practical way to assure no damage or mold will occur is to keep the walls dry. In your blog piece called: “Do I need a Vapor Retarder,” you said this:

***************************************************

“Most textbooks and magazines explained that a vapor barrier was needed to keep the walls dry during the winter, and that walls without vapor barriers would get wet. This was bad advice, for several reasons. First of all, outward vapor diffusion through walls during the winter almost never leads to wet walls. When interior moisture causes moisture damage in walls or ceilings, the problem is almost always due to air leakage (exfiltration), not moisture diffusion.”

****************************************************

When you say that outward diffusion “almost never leads to wet walls,” it seems that you subsequently explain what you mean by “almost never” when you say this:

****************************************************

“Q. Can I just ignore vapor diffusion? A. Not quite, but almost. There are a few circumstances where builders need to pay attention to vapor diffusion: Vapor diffusion can be a significant moisture transport mechanism in certain rooms with high humidity — for example, greenhouses, rooms with indoor swimming pools, or rooms that are deliberately humidified…”

*****************************************************

So I conclude that since this tested house did not have unusually high humidity such as might be the case with indoor swimming pools or greenhouses, we can conclude that the moisture in the wall of this test house should never have occurred according to the principles that have been explained many times here in the past.

Response to Ron Keagle

Ron,

Whether the findings of this study (the BSC study of sheathing moisture levels in Carter Scott's homes) should lead to changes in specifications by builders depends on the builders' appetite for risk.

When it comes to double-stud walls, we've been looking for dead bodies for years -- and we still haven't found any. The sheathing on this house had no damage, no mold, and no rot.

What we do know -- as I reported several years ago -- is that the wall sheathing on this type of house gets damp in February and dries out in April. Whether or not that fact worries you depends, as I said, on your appetite for risk.

The findings from this report may lead some builders to install a smart vapor retarder on the interior side of their double-stud walls. It's fine if they do that, and I may begin advising cautious builders to do that. However, we still don't have any examples of mold, rot, or sheathing damage.

Around and around we go

My, how we all like to talk about walls!

Lstiburek's suggestions do, indeed, nudge the double-stud wall concept in the direction of the Larsen truss wall and the Klingenberg wall.

For those who want a refresher course in all the options -- most of which are between 10 to 30 years old -- here are some links:

The Klingenberg Wall

All About Larsen Trusses

Risky Wall Questions

Martin,

I don’t perceive any risk involved with cold sheathing as long as outward-moving vapor is stopped at the inner plane of the interior walls. I conclude that vapor adsorbing into sheathing or framing from outdoor air is not enough to cause damage or grow mold inside of the wall, so I see no risk with that.

But I have one more question about the tested house where moisture was found as covered in the other blog. Regarding the air barrier, what exactly did it consist of? Was the inside living space surfaces of the walls covered with drywall that was taped and finished? Was it installed as air-tight drywall? Or was the air barrier comprised only of the sheathing and cellulose? The photograph shows the wall with no drywall, and open to the cellulose. Is that the condition that existed during the test?

Finger jointed 2x3s...

Finger jointed 2x3s are straight than milled 2x3s, and even straighter than milled 2x4s. While there are availability issue (can't pick 'em up at the box store, and aren't normally stocked at most building supply outlets catering to contractors), it's just fine to specify them, they're not expensive, and they're just fine to use in any application that a milled 2x3 would be suitable. Sure, there is overhead to the special order, but for most high-R houses that would not be the only thing that needed to be special ordered.

Leaving out the detail of how the exterior studs interfaces to the foundation is indeed unfortunate, but isn't necessarily complicated.

Using intermediate layer OSB/ply as the primary air barrier and for vapor control is a standard practice commonly used in PassiveHouse designs, and has many merits. It's more expensive than smart vapor retarders (which is really CHEAP insurance in any double-studwall assembly), but they're rugged- far less susceptible to degradation / damage over time than air-tight wallboard or interior side smart vapor retarders. (I like it.)

The differences between a Larsen Truss and a double studwall aren't huge, though the details of a Larsen Truss are perhaps less understood by the average framing carpenter. But a Larsen Truss with an intermediate layer of OSB on the exterior side of the structural chords makes it more complicated. OTOH, the very original exterior trusses installed by Larsen back in the 1980s were retrofitted on the outside of the sheathing of an existing framed wall, which puts the OSB/ply exactly where Lstiburek specifies for the double studwall stackup he endorses.

But it seems like a more expensive build than some alternative methods that are still likely to have better moisture level margins than Carter Scott's double studwall.

Using fiberboard or gypsum for the exterior sheathing (as the alternatives to OSB in Lstiburek's stackup) gives it significantly higher drying rates toward the exterior too. If Carter Scott started using fiberboard or gypsum sheathing rather than OSB, that modification alone (without any other design changes) would likely render the whole discussion moot, and would meet IRC 2012 chapter 7 prescriptives for walls of any thickness with class-III vapor retardency on the interior for all US climate zones up to Zone 6 (but not 7 & 8):

http://publicecodes.cyberregs.com/icod/irc/2012/icod_irc_2012_7_sec002_par025.htm

"Vented cladding over fiberboard.

-Vented cladding over gypsum. "

Any assembly that requires wintertime conditioned space RH to be below the established standards for human health and comfort (30% is the low end of the human-healthy range) to have any margin for moisture in the structural wood doesn't feel like the right way to go. In construction there may be good / better / best, and there is no "perfect". The persistence of the 20%+ MC sheathing in the tested wall (particularly in the cellulose insulated bay) doesn't necessarily even rise to the "good" level. But it probably wouldn't take the full-on Lstiburek stackup to get it there. My inclination would be to price out the sheathing specification change against the installed cost of smart vapor retarders, and do at least one or the other, or maybe even both. (YMMV) In Carter Scott's case changing the sheathing spec would also mean adding a separate WRB and changing air sealing methods- I don't mean to trivialize how big a change that change is from the prior methods he has standardized into his house builds.

We don't yet have a 50 or 100 year track record on thousands of OSB clad double stud wall houses with only latex paint as the interior vapor retarder. Just because there aren't a lot of bodies yet doesn't mean there won't be- the sample size and duration is still too small. But elevated moisture levels are not a good symptom, and may be the harbinger of less benign symptoms to come.

BTW: From the previous blog describing the testing:

----------------------------

When I asked Kohta Ueno, the author of the BSC report, about this, he said low relative humidities are typical in New England. "I have very seldom seen houses running 40% RH through the entire winter around here." Most homes, he said, run at about 20-30% RH through the winter, and he considers 40-50% RH to be "crazy-dangerous levels in a New England/Zone 5 type of climate."

----------------------------

The levels in that test house did exceed 50% RH indoors at least part of the winter, and the "...20-30% RH..." is below what health professionals recommend. I live in US climate zone 5 and don't have the tightest house in town, and 35% is probably about the wintertime average. I could easily ventilate to bring it under 30% without a huge energy penalty, but it would come at the cost of health compromises for at least one member of my family. Ueno's observations about most homes may be true of leakier houses or houses running higher ventilation rates, but would not likely be true of most homes built to IRC 2012 levels of tightness without dedicated mechanical ventilation.

Illinois Lo-Cal House

From the 1970s, designed by Seichi Konzo and Wayne Schick. It was double wall construction. I recall talk around our office in the 1980s about putting a poly vapor barrier in the middle of the wall, which made sense to me. I checked, and no, they had it on the inner face.

Martin, we need more data

You said, "The findings from this report may lead some builders to install a smart vapor retarder on the interior side of their double-stud walls. It's fine if they do that, and I may begin advising cautious builders to do that."

I don't think there are studies that support this advice yet. Certainly not this one. All the previous studies had an unknown amount of air exfiltration, and this one didn't even test a smart vapor retarder. Don't repeat the same old mistake.

Response to Ron Keagle - the intended air barrier in the present BSC test is also the WRB...the taped green surface of the Zip System sheathing.

Response to Dana and Malcolm Taylor

I like that you guys are brainstorming simple and cheap ways to make the double stud wall's sheathing drier. Dana, you said, "But it probably wouldn't take the full-on Lstiburek stackup to get it there." I agree. In zone 5a, the full-on stackup is off the chart but probably 3 or 4 inches to prevent any condensation in a 12" double wall. That's borderline impractical, and worse in colder climates.

If mineral wool is used as Malcolm suggests, 1 or 2 inches will make the sheathing much warmer and drier, and still promote drying to the outside.

Here's another simple cheap idea stolen from attic design and field proven -- Add a ventilation channel: https://www.greenbuildingadvisor.com/articles/dept/musings/site-built-ventilation-baffles-roofs

Response to Kevin Dickson

Kevin,

You wrote, "We need more data."

GBA loves data. We'll continue to publish new data as it becomes available.

In the meantime, here's my advice:

1. As I wrote in my 2010 and 2013 articles, builders of double-stud walls should choose plywood, boards, fiberboard, or DensGlass Gold for the exterior sheathing -- not OSB -- and should include a ventilated rainscreen gap between the siding and the sheathing.

2. As GBA has recommended since Day One, builders should pay attention to airtightness.

3. If the data showing that exterior sheathing gets damp in February makes you nervous, you should probably choose a different type of wall assembly -- one with insulation on the exterior side of the sheathing. Alternatively, you can install a smart vapor retarder on the interior side of the wall -- which (in spite of the fact that we need more data) will do no harm and may do good.

4. Lstiburek's suggested wall, which falls somewhere in between a classic double-stud wall and the Klingenberg wall, will work just fine, and builders can choose that approach if they like it.

5. Your suggestion to add a "ventilation channel" -- usually referred to as a ventilated rainscreen gap -- is one that GBA has consistently endorsed for years.

Ventilation Channel vs. Rainscreen Gap

Martin,

The rainscreen gap on the outside of the plywood sheathing is a given. I was brainstorming a ventilation channel like you would find in a properly insulated cathedral ceiling. On second thought, it would be too hard to ventilate, and probably wouldn't do its job if it's unventilated.

Response to Kevin Dickson

Kevin,

The purpose of a properly vented rainscreen gap -- with air inlets at the bottom, air outlets at the top, and a depth of 3/4 inch -- is very similar to the purpose of a ventilation channel in a cathedral ceiling. It's true that roof assemblies are very different from wall assemblies, as many experts have noted -- roof assemblies can be covered with snow, while walls rarely are; and roof assemblies with air leakage are subject to moisture problems arising from the stack effect in a way that most walls aren't.

That said, the principle is the same. And while you write that a rainscreen gap "would be too hard to ventilate," you're wrong. Building scientists have measured rapid drying of sheathing and siding in walls with a ventilated rainscreen gap -- and this is ventilation drying, not diffusion -- driven by sunlight, wind, and the stack effect.

I would echo Ron's questions

I would echo Ron's questions and observations. It's interesting that years of hearing that vapor diffusion is not a risk to then see that diffusion is a reoccurring reality on a 3 year old wall. one has to wonder how this pattern over 20 or 50 or more years affects materials like OSB or even plywood. Additionally creating wall systems which require multiple insulation strategies instead of a single dense pack visit by the cellulose installer is by its nature somewhat inefficient. Of course builders have to weigh the relative cost of various air sealing systems but reading these reports makes me feel that the "classic" combination of an interior membrane like intello, combined with lessco boxes and maybe a dropped sidewall looks pretty good as an option.

Response to Mark Klein

Mark,

As far as I know, this type of seasonal cycling -- whereby wall sheathing gets damp in February and is dry by April -- occurs in the vast majority of American homes. It is not restricted to double-stud walls.

I'm not sure that this study changes our understanding of whether outward vapor diffusion is a risk. The wall sheathing in this home shows no side of damage, mold, or rot.

But Martin it actually didn't dry out by April- or even by May.

If you look at the sensor data for the north facing cellulose wall (N2) the moisture content of the sheathing stayed above 20% late into May in the winter when the interior RH was running above 40%, and even in the 12" ocSPF wall (N1) and 5.5" ocSPF were above 20% MC into May. The cellulose wall was even above 30% on May Day that year. Only in the first year when the house was unoccupied was the cellulose insulated north wall at safe levels by April Fools day. Even in the third season where the ventilation kept the interior RH below 30%( and thus below human standards) the cellulose wall was still above 20% well into April. See p. 31 of the PDF:

http://www.buildingscience.com/documents/bareports/ba-1501-monitor-double-stud-moisture-conditions-northeast

In the Arena/Steven study cited on P5 (p 16, PDF pagination) of Ueno's full report, a similar cellulose double-wall assembly with Class-II vapor retarder on the interior the moisture content of the peaked at 17% MC, in a house with interior RH comparable to the third season in Ueno's study. That is well below the 25% peaks seen in Carter Scott's cellulose wall during the third season. How expensive is vapor-barrier latex (or better yet, MemBrain for even faster drying) as insurance?

Vapor retarder paint

So would a Class II Vapor retarder paint on 1/2 gypsum with vented rainscreen vinyl siding over plywood work? This would be in zone 4/5 with double stud cellulose. Or should a smart vapor retarder be added inside the wall?

Response to Dana Dorsett

Dana,

OK, fine — let's say May rather than April. In most cases, the drying occurs by April. But if the interior RH is over 40% (which is of course possible but which is less common than you imply), we'll say May. This doesn't affect my argument.

You ask a rhetorical question: "How expensive is vapor-barrier latex ... as insurance?" I assume you are talking about vapor-retarder paint (primer). The answer is, of course, not very expensive. I'm not sure why you are even asking the question; a vapor retarder isn't optional in Massachusetts — it is code-required. According to section R702.7 of the IRC, "Class I or II vapor retarders are required on the interior side of frame walls in Climate Zones 5, 6, 7, 8 and Marine 4."

The class-II vapor retarder is INDEED optional...

The Class 1 & 2 vapor retarder really IS optional in Zone 5A for wood structural sheathing, when the siding is ventilated, per the Class-III allowance exceptions listed in table R702,7.1 :

http://publicecodes.cyberregs.com/icod/irc/2012/icod_irc_2012_7_sec002_par025.htm

------

TABLE R702.7.1 CLASS III VAPOR RETARDERS

Vented cladding over wood structural panels.

------

That exception is the only reason Carter Scott's stackup is even LEGAL to build, since there is only standard latex paint (a class-III vapor retarder) on the interior side. That explains the difference in sheathing moisture content peaks & averages between Ueno's data and the Arena study, where vapor barrier latex was used. Ueno's data indicates that the vented cladding over wood sheathing exception may in fact be too lenient for Zone 5A, given just how long the high moisture content persists into spring, and the differences in drying rates between ocSPF & cellulose.

The notion that April dry-out vs. May dry-out is irrelevant is a bit misplaced too, since the outdoor temps in Devens MA (25 crow miles from my house) from mid-April into mid May are well into the mold-activity range. (My sinuses give me first-hand feedback on that.) Ueno also notes in the text of that study that the south walls experience mold activity temp & humidity levels both earlier in the season and for longer periods than the north walls, despite the higher peak moisture content.

Even in the third season when the winter average interior RH was south of 30%, the cellulose wall's sheathing moisture content didn't drop to 20% until the beginning of May. That is not an unrealistically high interior moisture at all, even for older construction that has been tightened up a bit. eg:

My house rarely drops below 30% RH in winter (monitored in multiple locations, but not with dataloggers) even during extended cold snaps. This is an early 1920s plank-sheathed 2x4 house that has been retrofitted with 3lbs+ cellulose. I make it a point to not let it rise above 35% RH in winter (I leave the bath exhaust running when it rises that high) but it's arguable that I'm being too lax, given that there isn't much back ventilation on the 9" cedar clapboards. The vapor retardency of the multiple layers of paint on the horsehair plaster may be working in my favor, but air leakage at as-yet-undiscovered/unremedied cracks in the plaster can't be ruled out.

A discussion of Arena's monitoring & simulation-verification can be found starting on p.23 (PDF pagination) here:

http://www.buildingscience.com/documents/bareports/ba-1403-guidance-modeling-enclosure-design-above-grade-walls-expert-meeting

"Vented cladding" definition

Dana,

The "vented cladding" definition is one of the most mysterious exceptions in the International codes. As far as I have been able to determine, it isn't defined anywhere in the code.

What does it mean? I'm not sure. Do you think any local code inspectors know what it means?

Is vinyl siding considered a "vented cladding"? Many of us who have considered the issue might think so -- but the issue is far from clear in the minds of most code officials. After all, Carter Scott's vinyl siding is (as far as I know) nailed directly to the sheathing.

In any case, the code definitely needs to clarify this issue. Some building scientists only consider a rainscreen gap to be "vented" if there are openings both at the bottom of the gap and at the top of the gap. How big do these openings have to be? Who's going to verify the nature of the openings, if any, at the top of the rainscreen gap?

More on vapor-retarder paint

Dana,

I think we are on the same page when it comes to vapor-retarder paint. I have always informed GBA readers that the code calls for a vapor retarder on the interior side of most walls in Climate Zones Marine 4, 5, 6, 7, and 8.

I have never urged GBA readers to try to claim an exemption from installing this code-required vapor retarder based on the poorly defined "vented cladding" exception. I have only advised taking that exemption if they install an adequate thickness of rigid foam or mineral wool on the exterior side of the wall sheathing.

If vapor from outdoor air

If vapor from outdoor air adsorbing into the sheathing is a problem, why isn’t Joe Lstiburek’s ideal double stud wall risky? Won’t that outer sheathing get wet and transfer wetness to the insulation?

Yes, I think there is some consensus...

Ueno's text suggests membrane type smart vapor retarders (second paragraph, p.65, PDF pagination) as a potential solution to Scott's wall stackup.

Ueno believes (as do I) that vinyl siding is generally construed as "vented cladding" from a code compliance point of view:

"In zone 5, allowable assemblies include vented cladding (such as vinyl siding) over OSB, plywood, fiberboard, or gypsum sheathing. However, a double-stud wall has different behavior than conventional (2 × 4 or 2 × 6) construction." (top of p49, PDF)

That is also spelled out in R702.7.3:

http://publicecodes.cyberregs.com/icod/irc/2012/icod_irc_2012_7_par030.htm

The only specified rainscreen depth in the current code for a specific siding type is for masonry & stucco, found in TABLE R703.7.4 (way down the page):

http://publicecodes.cyberregs.com/icod/irc/2012/icod_irc_2012_7_sec003.htm

Other prior versions of the code (including some state versions) had higher air gaps required for stucco & masonry, but also spelled out different depths for different siding types, eg:

http://publicecodes.cyberregs.com/st/ny/st/b1200v10/st_ny_st_b1200v10_4_par039.htm

But note, even those include:

"6. Vinyl lap siding applied directly to a weather resistive barrier."

I'm satisfied that Carter Scott's siding meets the IRC definition of "vented cladding", even without the rainscreen. But then again...

One thing I've been curious about for some time is whether that standard should be applied in the same way to ZIP siding, which has no capillary break AT ALL between the WRB and the sheathing, since it's an integrated product.

The primary benefit of the rainscreen gap is the high degree of capillary break, which is protective over a wide range of actual drying rates. Vinyl siding may not have the identical drying rate as a top to bottom convecting rainscreen gap, but it's still pretty effective capillary break, and no moisture reservoir capacity to be concerned about. But the secondary capillary break offered by a separate housewrap or felt WRB, however slight that break might be, isn't necessarily something that can be discounted. There are thousands of houses being built with ZIP + vinyl every year now- we'll probably know if it's a problem or not within a decade or two.

The 5.5" ocSPF is pretty close to conventional construction, and you'll note that in the N3 graph on p.31 the peak moisture content even during the high-humidity winter is barerly higher than the 12" cellulose wall during the subsequent lower-than-human-healthy RH winter, and has never breaks 15% during the the low humidity winter. The 12" ocSPF comes pretty close to 20% during the low-humidity winter. (The first winter data for any of them is irrelevant- it was an unoccupied house with low interior RH.) If at 30-35% the sheathing moisture roughly splits the difference between the high & low humidity winters, the "conventional construction" 5.5" thickness ocSPF wall probably still makes, it, but it's not quite as clear that the 12" ocSPF wall does. When the ocSPF thickness doubles the differences are subtle, but real.

Response to Dana Dorsett

Dana,

Thanks for sharing the reference to section R702.7.3. I have looked for a code definition of "vented cladding" for quite a while, and never found it. Maybe this was added in the 2012 code, and I didn't realize the addition? Or maybe I just missed it. In any case, many thanks.

Even though I'm glad to see that the IRC has included a definition of "vented cladding," it's worth pointing out, for the record, that the definition is pretty lame -- and still leaves many questions unanswered.

R702.7.3 Minimum clear air spaces and vented openings for vented cladding.

For the purposes of this section, vented cladding shall include the following minimum clear air spaces. Other openings with the equivalent vent area shall be permitted.

1. Vinyl lap or horizontal aluminum siding applied over a weather resistive barrier as specified in Table R703.4.

2. Brick veneer with a clear airspace as specified in Table R703.7.4.

3. Other approved vented claddings.

Ideal Double stud wall

I have been reading and looking up as much information as I can find to target a net zero home.

We are seniors on a budget and we would love to have our first new home which we have been dreaming about for over 40 years. We are located 150 miles north of Edmonton Alberta on Island Lake, 15 mile northwest of Athabasca which is probably a zone 7 - 8 location.

We have a lakefront lot and looking at building a 1 1/2 story hillside home with a walkout basement. We are

Looking at building a wheelchair accessible home approximately 1200 square feet on main floor.

Here is the my idea!!!!!!

Build basement using BASF Neopor ICF blocks as they have a higher R insulation value.

Build an Athabasca double stud wall using 2x4 studs 12 inches thick. Install plywood on the inside wall and under scissor trust cathedral ceiling which we could finish with either wood or gyprock. Install plywood fire block on top of double stud wall.

Insulate with BASF walltite high density foam in multiple passes from the outside to a thickness of 11 inches to allow venting under rain screen and install siding directly onto the outside studs. Insulate the wall from the outside and also the roof from the top of the roof before sheeting it in. We could also vent the roof above the foam. No vapor barrier required, simple and straight forward. We are talking about a house that would be air tight and no moisture or drying problems

I know the insulation cost will be higher but we will address that problem and also we are building a home that will last hopefully over 100 years so we should build it right.

I would appreciate your thoughts on this design.

Response to Joe St. Denis

Joe,

First of all, you need a water-resistive barrier (WRB) on the exterior of your wall. I don't recommend that you nail your siding directly to the studs. For more information on this issue, see All About Water-Resistive Barriers.

Second, closed-cell spray foam is an expensive way to accomplish your goal, and the insulation has a high global warming potential. I advise you to abandon your plan and instead to build a house using the PERSIST or REMOTE system, using EPS or mineral wool for insulation.

For more information on these systems, see Getting Insulation Out of Your Walls and Ceilings.

Again, experts choosing a terrible method and choice of materials to argue over useless details that we never serve anyone but themselves. Readers want the best options available but they never get to see them because of self-interest. What's wrong with using the Simple Perfect Wall System? A system that will give the owners and occupants a cost-effective option while having the ability to survive natural and man-made disasters, like those proposed by many of these experts. Systems that insulate, are Structural, Impervious, Rot, Fire, and Mold resistant. The Envelope should also be Easy and Cost-Effective to construct without argument of detail that fluctuates with the wind generated by experts and suppliers. No reinventing required, the products already exist.

George,

I don't know about the rest of the GBA community, but I'm sure getting sick of your scatter-gun insults. Where is the self-interest for me or the "experts"?

If you feel strongly about any topic why not engage, lay out your point of view, make your case? The way you post here now helps no-one. You are a text-book troll.

Hi George.

Maybe this is a better article for you: Walls that Work.

It includes double-stud walls as an option, but have a few other common wall assemblies as well.

Sorry but I'm not a Prime Member so these articles are not available to us. From what I see is that most of the wall systems are mostly Wood Frame and this is where I get annoyed because Wood Framing has always been the major problem with House Construction. Short lifespan and extream maintenance is not what people really want for their hard-earned dollars. Water and Wood give experts in wood construction endless opportunities to offer solutions that never work and add to the cost of homes. The Simple Perfect Wall like this will achieve better function and reduce costs and worry about failures.

Please explain your problem with more detail so I can offer you some better detail.

I was a little late on discovering "Lstiburek’s Ideal Double-Stud Wall Design" when designing my own home...so my version was conceptualized and designed a little different: Two 2x4 walls with the studs at 24" o/c and staggered with R15 rock wool batts in each wall. I planned to sheath the inside of the exterior wall with plywood, tape it, then stand the interior wall against it.

The outside of the exterior wall is already sheathed with plywood (I'm building the house now). Over that will be house wrap, furring strips, and siding.

I'm not sure how to handle the inside of the interior wall though. Rather than sheet rock, I will be using reed privacy fencing, and then trowling an earthen plaster over that. No paint.

Joe specifies sheet rock and latex paint. I believe the earthen plaster is quite "breathable" and the reed fencing I'm using instead of sheet rock won't stop anything. Does this mean I will need to use an independent permeable membrane under the reed fencing and earthen plaster?

I was thinking kraft-faced rockwool would be the ticket....IF I needed anything at all. However, I don't believe there's a kraft-faced rockwool available...and I really don't want to use fiberglass.

I am building in zone 5. Cold.

Thoughts?

Could use more information on the wall thickness and the exact detail you are considering. You get into the 1/3, 2/3 debate on locating an air barrier.

It's just two 2x4 stud walls against each other, studs staggered. No gaps between the two walls. R15 rockwool in each wall for a total R30. I was also planning to use 1/2" plywood between the two walls as the air control layer.

On the exterior, I also have 1/2" plywood for my sheathing. Wood siding will go over that. So minus the wood siding, the thickness would be as follows: 1/2", 3.5", 1/2", 3.5"..... which totals 8". The earthen plaster on top of the reed fencing on the inside would add roughly 3/4" to that.

user...121,

There is no rule around the location of an air-barrier. They can be anywhere in a wall. The 1/3, 2/3 recommendation concerns vapour-barriers.

Also worth remembering that the 1/3, 2/3 rule of thumb isn't found in Canadian building codes. Instead that they require the the vapour barrier "shall be installed sufficiently close to the warm side of the assembly to prevent condensation at design conditions."

I would not be comfortable building Dean's wall as he has described. I see the possibility of trapped moisture between the plywood sheathings.

User ...121,

You did see that Joe Lstiburek's ideal double-stud wall that the article is about has the same two plywood layers?

I appreciate the thoughts. My posts and inquiries may not be clear though. Malcolm Taylor is on the right track. My inquiry is specifically about Joe Lstiburek's ideal double-stud wall that the article is about here.

For the sake of simplicity, lets just say my wall is the same as Joe's illustration at the top.....except one detail. Instead of "latex paint over 1/2" gypsum board" as the illustration shows....I will be using earthen plaster (clay) over reed fencing.

My question then becomes: Do I need some sort of barrier behind my earthen plaster (clay) and reed fencing since I'm not using latex paint and gypsum board?

deanbowman,

Where your wall differs for Joe L's (and what I suspect worries User ...121), is that your warm side vapor-retarder - the mid-wall plywood - is too far towards the exterior and might accumulate moisture. An interior variable perm membrane would alleviate those concerns - or you could model the wall and see if it really is a problem.

I personally would not be comfortable with it as described, the interior finish is quite unusual and I think some further research is warranted.

Thanks, Malcolm! Good catch on my mid-wall plywood being closer to the outside compared to Joe's example. I hadn't thought of that.

I looked up the perm ratings on earthen (clay) plaster and painted drywall. The only thing I found on the earthen plaster is 11 perms per 2" of plaster. My plaster would only be 1/4"-1/2" thick. Presumably, I would see far higher perm ratings with the thinner plaster.

Regarding painted drywall, it was rated at 3 perms by one lab and between 8-10 perms from BSC. I got those ratings from energy.gov which came from BSC.

So........if I'm interpreting all this correctly, it looks like my wall would be far more permeable than that of Joe's example using painted drywall. I guess that would make your observations correct in me needing to add a vapor barrier.

If I do indeed need more vapor control, then how would I best achieve that? Any specific product?

Very much appreciate the input on this. Keep it coming, please. I could use as much as I can get.

Response to Malcolm:

After rereading user-723121's comments, and yours again too Malcolm, I'm sorta thinking the same as you in regards to their concern. Maybe user-723121 will chime in again.

At any rate, I'm still torn...and not overly sure what to do. This is my personal home that I've put my lives savings into, as well as my heart and soul. I'm not contracting it out but building it with my own two hands. I'm 54 yrs old and plan to pass there at an old age. So....I really want to get this right and not have any major problems.

Looks like the thickness of the wall in Joe's example illustration above is close to 11" where as mine is 8". Maybe I'm overthinking this but a part of me says just do it as I planned with the addition of a smart vapor retarder under the reed fencing and earthen plaster, as you suggested. But then I begin to question other aspects of the wall....as in the 1/2" plywood between the two walls. Is that "air barrier" as Joe calls it even needed in my thinner wall?

deanbowman,

If it were me I'd tape the sheathing as a primary air-barrier, skip the layer of plywood between the two walls, and add an interior variable-perm membrane detailed as a secondary air-barrier. We know that wall, with the rain-screen you are adding, performs well.

The longer I build the more risk adverse I become. Don't include any assembly or detail in your house that you will ever wake up in the night worrying about.

I agree with Malcolm on the wall design. Make sure your exterior drainage plane details are sound with proper door and window flashings. Have built a couple of 2x8 R-30 double walls with plywood exterior sheathing and they performed well in a 7,800 hdd environment. I used a cold climate warm side 8mil Teno for the primary air barrier, you want a variable perm membrane for Zone 5.

Long live the double wall !!

Response to Malcolm and user-723121: (I'm not used to the format here where I don't see an option to reply to most recent posts)

Thank you both for your input!!! It would be a huge, huge relief to me to not have to install the plywood between the two walls as I originally planned. And like you, Malcolm, I'd rather not take risks. I prefer tried and proven....even if it's possible I could be missing out on some performance.

So, if I'm understanding correctly, a double wall like I describe but WITHOUT the plywood between them....it could just be treated like a regular (& proven) wall that happens to be thicker. Is that correct?

The "variable perm membranes" you both speak of are otherwise known as Smart Vapor Retarders...correct? If so, from what I can find on the Net, I have three to choose from in the U.S.: Certainteed’s Membrain, Pro Clima’s Intello and Siga’s Marjex. Does this sound right?

As far as having a good rain-screen and window flashings.... I plan to do my best. Both will have the benefit of being more protected from rain and snow than the typical house (we don't get much rain either). My smallest overhang is 3.5' ....on the south solar side. The rest of the house will be protected with 6' overhangs and 8' porches.

deanbowman,

Yes. The problem with double stud walls - or any thick walls - is primarily that the sheathing can stay too cold and accumulate moisture during the winter. With good air-sealing, and the protection afforded by a rain-screen, the concern is greatly reduced. https://www.greenbuildingadvisor.com/green-basics/double-stud-walls

Variable-perm membranes are also known as smart-vapour retarders. I'm afraid I'll have to defer to other posters on which one to choose.

You can find good exterior details in this Best Practices Guide: https://hammerandhand.com/best-practices/manual/

Thanks for the additional info, Malcolm. That's a good link you shared too.

Hoping someone will chime in on variable-perm membranes.

Your air barrier placement would not be typical in a double wall as I know it. OK if you had R-30 outside of your interior plywood. One rule of thumb for placing an air barrier mid wall is to have 2/3 of the R-value to the cold side. This came from cold climate construction in Canada originally as I remember. This was in the earlier days of superinsulation and double walls. There have been some existing homes superinsulated in Canada where the existing house was wrapped with a low perm air barrier. A Larsen Truss wall system was added to the exterior from the footing to the upper top plate. The new wall system was sufficient in R-value to meet the 1/3, 2/3 rule. A zone 5, mixed climate may have differing guidelines utilizing a smart retarder and the like.

Log in or create an account to post a comment.

Sign up Log in