Image Credit: Courtesy of Airtight Insulation

Spray-foam insulation is gaining popularity these days, and for good reason. Not only does it offer lots of R-value per inch, but it also air-seals the house. I’ve been building custom homes in North Carolina for more than 20 years, and I’ve been using spray-foam insulation for the past four. These days, all my projects get 8 in. to 12 in. of foam under the roof deck, and I often use foam to insulate walls and crawlspaces as well.

Prepping for the spray-foam crew is now just another part of the building process, but it took some time and a lot of stained shingles and concrete for me to figure out the learning curve. Along the way, I discovered that the first hurdle in using spray-foam insulation might just be working with the building inspector.

Venting, fire safety, and building officials

The first time I insulated an attic with spray foam, the building inspector asked me to supply a letter from my structural engineer stating that the roof framing was strong enough to support the weight of the foam. That might have been the most extreme case of an inspector being misinformed about the properties and benefits of spray-foam insulation, but it wasn’t an isolated case.

Code officials in my area value ventilation in attics and crawlspaces so much that they have a hard time with the thought of sealing these areas with foam. So if I’m planning to spray the underside of a roof deck or a crawlspace, I talk to the building inspector during the permitting process to make sure he’s OK with not venting either space.

The most common speed bump I run into during these conversations involves roof venting and shingle warranties. If the spray-foam insulation will void the…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

3 Comments

Spray foam insulation

Great article

A few points I missed.

Are you using open cell or closed cell foam?

Are you able to eliminate the vapor barrier?

What type of outside wall structure do you mostly use?

I live in zone 7-8

Response to Joe St. Denis

Joe,

Building codes do not require a vapor barrier in wall assemblies, although a vapor retarder (a less restrictive layer) is required in some cases in cold climates. For more information on this issue, see Do I Need a Vapor Retarder?

If your building inspector is insisting that your wall or ceiling needs a Class II vapor retarder (that is, a layer with a permeance of less than 1 perm), the requirement can be satisfied with 2 1/2 or 3 inches of closed-cell spray foam. If you are installing open-cell spray foam, and the building inspector wants evidence of a Class II vapor retarder, the usual solution is to apply a layer of vapor-retarder paint on the gypsum wallboard.

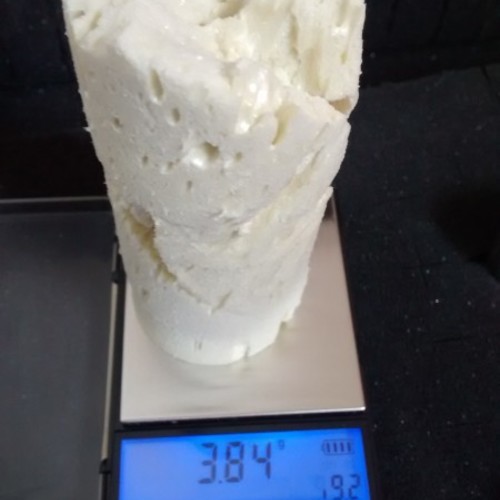

in these photos

here we were using 5-1/2" of open cell in the walls and band joists w/ 12" on the roof deck.

it's a hurricane zone so we are using continuous 1/2" OSB sheathing over 2x6 walls 24" oc w/ house wrap taped to the crawl liner run under the sill plates and over a galvanized termite / moisture break at the top of masonry.

Log in or become a member to post a comment.

Sign up Log in