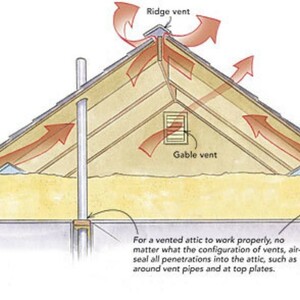

Roofs often require ventilation channels directly under the roof sheathing — either for a short section of the roof (for example, near the eaves) or for the entire roof, from soffit to ridge. When the wind is blowing, these ventilation channels allow air to move from the soffit vents to the ridge vents.

To establish a ventilation channel, it’s usually necessary to install some kind of baffle. A baffle performs three functions: it defines the depth of the air gap; it keeps insulation from intruding on the air gap; and (if properly installed) provides an air barrier to limit wind-washing of the insulation. (Wind-washing degrades the thermal performance of air-permeable insulation materials like fiberglass, mineral wool, and cellulose.)

The value of providing ventilation channels under roof sheathing is often exaggerated. To a limited extent, these air channels can help keep roof sheathing dry and can reduce the chance of ice dam formation. However, ventilation channels aren’t able to perform the miracles that some ventilation advocates claim. For more information on this issue, see All About Attic Venting.

Where the baffles belong

In a house with a vented unconditioned attic, ventilation baffles are only needed near the eaves. The baffles should begin above the ventilated soffit — just to the exterior side of the plane of the wall sheathing — and should extend far enough into the attic that they terminate above the top of the insulation on the attic floor. The deeper the insulation, the longer the baffles have to be.

In a traditional Cape Cod house with 4-foot kneewalls, there are two ways to install ventilation baffles. The preferred way is for the baffles to begin above the ventilated soffit and extend all the way to the small attic above the second-floor ceiling. (This approach is used when the triangular…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

57 Comments

Brentwood industries

Frustrated with common cardboard and foam baffles not being job-site tough, I was impressed when I saw this product at a tradeshow.

http://www.brentwoodindustries.com/products/building/roof-ventilation/accuvent-accublock.php#accuvent2

I never used them in the field, but they were impossible to tear, puncture and were very resilient, even when crumpled up and stepped on. They have one specifically for deeper attic insulation, "The AccuVent High Energy."

About the AccuVent

Kris,

I agree that the AccuVent is a good product. That's why I mentioned it, and provided a web link, in my article.

Soffit dam question

Martin,

I've been working on my attic insulation lately so your topic is very helpful to me. The problem is that I cannot physically get to the eaves to install a baffle because of the impossibly shallow roof with these funny 2 x 6 supports that I cannot crawl over. I was going to glue the spacer sticks made out of offcuts of polyiso on the rafters as far down as I can reach. Then apply foam sealant to a piece of polyiso cut to fit the rafter bay and slide it down as far as it can go as well. Does that sound reasonable even if I can't get a good seal at the soffit side of the rafter bay?

I've got a relatively new metal roof (about 10 years old), new Hardiboard siding and soffits, gutters (about 4-5 yrs old) so I really don't want to take the soffits down to install the baffles. The guys who did the work did put a piece of those pretend (meaning they only pretend to do the job) foam baffles in there, but they aren't secured to any thing. So I think they are useless. I didn't know better when I had that work done. I was new to GBA at that time.

Response to Lucy Foxworth

Lucy,

Q."Does that sound reasonable even if I can't get a good seal at the soffit side of the rafter bay?"

A. Under the circumstances, that sounds entirely reasonable.

Our method might help Lucy

A technique I developed for low slope retrofits uses 3/4" polyiso and vinyl F-channel cut into 4" pieces. The 4" clips, as I call them, fit tightly over the polyiso. Put the clips at the heel end of the baffle up so the nail fin acts as a 1" stop and the top clips down so you can staple the baffle in place. Measure and score a flap on the end to make up the remaining heel height as a wind-washing dam. Leave this flap folded while sliding the baffle in place, staple the topside nail fins, and then carefully wedge the flap snug using the end of a long barrel foam gun (or stick) at the very outside of the top plate. Then seal in place with the same foam gun. I realize the long barrel gun is the key to this working really well, but even with out it you can reinforce the flaps with tape and wedge them in place tight with a stick and it still does a better job than anything else I've used in a tight heel. Either way you can do the whole thing from 5 feet away. Seal the plate to wall board connection with duct mastic and a long handled trowel, it's the most reliable thing I've found at such a tight angle. A crew of two makes this much easier with one in the heel and one in the middle clipping and trimming (16 o.c. is apparently nominal?). We've installed these as long as 8 feet in a really low slope with success. There's my trade secret, good luck.

Pictures

Here's some picture for clarity.

Response to Andy Kosick

Andy,

I'm grateful for your comments and photos. This type of tip, shared by someone with lots of field experience, is very valuable. Thanks.

a variation on Mike Guertin’s technique

Martin, thanks for a very informative article. Would you comment specifically on the YouTube video showing a variation on Mike Guertin’s technique. I'm concerned about the fact that the baffles do not span the entire width of the rafter cavity, and the lack of air sealing at the top plate. I was however very impressed with their assembly line technique! Andy's approach seems both more effective and practical to me, and if you had access from the soffits it could go quickly with someone working at both ends of the baffle.

Response to Armand Magnelli

Armand,

Although the video I linked to shows an installation that doesn't follow my advice, there is always something to learn from observing other people's methods. The installation tools developed by Andy to hold the baffles in place as the glue dries are clever.

It's possible to learn a few tricks from this video, and use the tricks in a different way -- ideally, to install baffles that span the entire width of the rafter bay and that are installed in a more airtight manner.

Agreed

Martin, you are of course correct. I appreciated both the assembly line approach and the use of simple tools to get the adhesive to hold the baffles in place.

In an attic used for storage,

In an attic used for storage, do baffles built with rigid foam meet code? A similar question was asked in a 2009 GBA Q&A (link below) but wasn't addressed, other than a general reference to Dow Thermax.

https://www.greenbuildingadvisor.com/community/forum/energy-efficiency-and-durability/14545/fire-code-concerns-rigid-foam-panels

Response to Stewart Akerman

Stewart,

Q. "In an attic used for storage, do baffles built with rigid foam meet code?"

A. The brief answer to your question is yes. That said, I'm not exactly sure what your concern is.

Some building inspectors do not allow rigid foam to be left unprotected, and insist that it be covered by other materials for fire safety reasons. But attic ventilation baffles are always covered by insulation.

If you install fiberglass batts between your rafters, the fiberglass batts protect the rigid foam baffles from igniting. That said, it's always a good idea to have an air barrier on the interior side of the fiberglass batts, and it is illegal to leave kraft facing exposed.

Thanks for the reply, Martin.

Thanks for the reply, Martin. I was asking about the part of the rigid foam baffle that extends *above* blown attic insulation and is not covered.

I'm sorry I wasn't more clear. The storage I was envisioning was in an attic accessed by pull down stairs, where a portion of it is a decked plywood storage platform. The remainder of the attic floor is insulated with blown cellulose.

Response to Stewart Akerman

Stewart,

I have never heard of any code official objecting to a little bit of rigid foam peeking out above the insulation on an attic floor. But the only person who can definitively answer your question is your local code official -- since he or she is the one who interprets the code locally.

Site build or accuvent?

I'm getting ready to install site-built or Accuvent baffles. My house is new construction and my trusses are 16" heels. I took the sheathing all the way up to the bottom of the top truss chord. I have used the pre-made plastic baffles before, but they seem flimsy. Thinking about ripping 7/16 OSB and building baffles myself. My question is whether I need to air-seal those site-built baffles if it is a vented attic with continuous soffit and ridge vents. I will be very meticulous with attic air sealing. Any advice would be appreciated!

Response to Adam Emter

Adam,

If you are building a vented unconditioned attic, these ventilation baffles will be short. They will extend from your wall sheathing to a few inches above the top of the insulation installed on your attic floor.

It's always a good idea to pay attention to airtightness. In this region of your attic, you want to limit the effects of wind-washing. (Wind-washing is the degradation in your insulation's thermal performance due to the movement of outdoor air through the fibers of your insulation.)

If I were installing these ventilation baffles, I would try to seal the perimeter of each baffle. If you don't do the air sealing, it's not the end of the world. But if you are up there in the attic installing baffles, and you have the materials you need to seal the edges of the baffles, you might as well do a good job.

Thanks for your advice,

Thanks for your advice, Martin. I didn't fully understand the reason behind air sealing the baffles, but now I know. Whether I build my own baffles or opt for the Accuvents, I'll be sure to use sealant.

Cathedral ceilings and baffle material

The article says,

"There really aren’t any reports of failures or problems resulting from the use of vapor-impermeable materials — for example, polypropylene, vinyl, or foil-faced polyiso — to make ventilation baffles."

People considering impermeable baffles in cathedral ceilings might want to know about a failure reported in a recent Q&A discussion. A homeowner reported major condensation problems that resulted from the combination of impermeable baffles and poor air sealing of the ceiling drywall. (Comment number five in this thread https://www.greenbuildingadvisor.com/community/forum/gba-pro-help/99296/insulation-vaulted-ceiling)

The primary advice to the homeowner was that air sealing of the drywall is critical, and that advice would hold whether or not the baffle was permeable. So that doesn't necessarily invalidate the position taken by the article --most of us would primarily attribute the failuer to inadequate air sealing, not to the use of impermeable materials. But if it can be that bad with major air leaks, it seems like it could be a little bad with a little air leakage. And one of the themes that I hear repeated here a lot is that a good design is one that takes into account the fact that perfect construction is unlikely in practice, and designs that depend on it aren't very wise.

I think that if I were building a vented cathedral ceiling, I'd want to either use a vapor permeable baffle material, or use a thick enough foam layer to meet the guidelines for exterior rigid roof foam.

Of course, that doesn't contradict the article, which also says:

"Anyone worried about this possibility should probably make their ventilation baffles out of a vapor-permeable material."

So I'm not disagreeing with the article--I'm just saying that this story is a little more reason join the camp of people who do worry about it and do use vapor permeable materials. I think that's especially true in cathedral ceilings because there are other ways for moisture to escape in an attic with insulation on the floor and baffles only up a few feet on the sides.

Benefit of vents

My project has 6' of slope insulated from the top plate to the collar ties where the insulation continues on the flat. I installed site built rafter vents (2") rather than filling the entire cavity because I can inspect the vented space for leaks from the deck installed on the collar ties. Having built two homes that are both capes I've come to see the greater benefit of insulating the flat for several reasons, one of which is the ability to detect any leaks which are impossible to see prior to damage that eventually reveals itself in the living space once it's too late to prevent. I can't imagine filling the rafters to the peak, closing it all in from below and resting comfortably, assured that I'd suffer no water damage in the closed off and inaccessible space.

> "...embracing the Energy

> "...embracing the Energy Star Homes principle calling for air-permeable insulation to be enclosed by an air barrier on all six sides."

Would be interesting to see more discussion of this. Most discussions on GBA refer to single air barriers in a partition.

OK, I do see this:

GBA: musings/one-air-barrier-or-two

And this (singular):

GBA: questions-and-answers-about-air-barriers

Response to Jon R

Jon,

I guess you found the answer to your own question. In case you have any lingering confusion: The Energy Star requirement (namely, that in most cases fiberglass insulation needs to be enclosed by an air barrier on "all six sides") was developed to address insulated kneewalls and skylight shafts (where many builders were omitting the attic-side air barrier).

The exception to the "all six sides" rule is for insulation on an attic floor, where no top-side air barrier is required. (Researchers and builders agree that it is cheaper to blow a little more cellulose on top of the insulation than it is to unroll a layer of Tyvek.)

Great article!

Im struggling to understand how sealing the baffles at the perimeter makes them air tight if they are open at the top and terminate inside the attic above loose fill insulation.

Do they only need to be sealed air tight only in the sections where they press against insulation?

Is air tightness on all but the top and bottom of the baffle important to maximize the flow of outdoor air through the baffle in the direction of the ridge vent?

Cody

Cody,

I'm not as sure as Martin that in cases where the baffles aren't necessary to keep the vent channel clear that they (or sealing them) are worth the effort.

Of course any secondary air-barrier helps an assembly by adding redundancy, but that has to be weighed against what is a very labour intensive process. Wind-washing appears to degrade the R-value of batt insulation by between 5% and 8%. If that's important to you then maybe adding baffles makes sense. Sealing them as another air-barrier I'm just not sure about.

Cody,

The air that moves through your ventilation channels is separate from the indoor air (the air inside your house). You don't want these two types of air to mix or dilute each other.

Of course, the air that moves through your ventilation channels is connected to soffit vents at the bottom of the channels, and is connected to your ridge vent (or your vented attic) at the top. Basically, this is outdoor air.

The air under your ventilation baffles -- including the air found between the fibers of your fluffy insulation -- is warmer than outdoor air during the winter. So it makes sense to try to create an air barrier to separate the air in these fibers from the air in your ventilation channel.

Without baffles (ideally, baffles installed with sealed seams), the performance of the fibrous insulation can be degraded by wind-washing. Wind-washing refers to the phenomenon of outdoor air blowing through fibrous insulation, and pulling heat from the air surrounding your fibrous insulation.

Q. "Do they [the baffles] only need to be sealed air tight only in the sections where they press against insulation?"

A. Yes, that's basically the idea. But in most cases, if you don't have insulation, there isn't any need for baffles -- so wherever the baffles are, it makes sense to pay attention to airtightness at the baffle seams and baffle perimeters.

I've been reading and researching a lot about air sealing the baffles (I'm using semi-permeable foam board with a perm rating of 2.) Are you suggesting air sealing ONLY for the sake of preventing wind washing of the insulation and degrading R value?

1. Seeing as I'm using rockwool which isn't incredibly susceptible to wind washing in the first place, and I live in Southern California with very mild climate, and my roof is already R38, it seems like the extra labor will be wasted by air sealing these vents.

2. In my particular instance, it also seems like leaving the edges a "little leaky" would be another guarantee any moisture (likely condensation from the baffles) would easily find its way out.

Am I overlooking something? Will leaving the baffles "leaky" allow extra moisture into my roof assembly or are we only worried about wind washing? Thanks for your articles on cathedral roofs. I've learned a lot

What is the minimum pitch this strategy can be used in on and why?

M Hunt 11,

Generally, the minimum pitch for a conventional vented cathedral ceiling is 3 in 12. As Malcolm noted, further information can be found in this article: "Insulating Low-Slope Residential Roofs."

Do you have any pictures that show how to insulate between 2x8 joists with a low slope roof?

M Hunt 11,

Are you talking about joists or rafters? If you are talking about joists, and you have an adequately high mini-attic, this article explains what you need to know: "How to Insulate an Attic Floor."

If you are talking about 2x8 rafters, and you want to put the insulation between the rafters, your only choice is to create an unvented roof assembly with closed-cell spray foam. For more information, see Assembly #4 in this article: "Five Cathedral Ceilings That Work."

MHunt11,

You may find this article helpful: https://www.greenbuildingadvisor.com/article/insulating-low-slope-residential-roofs

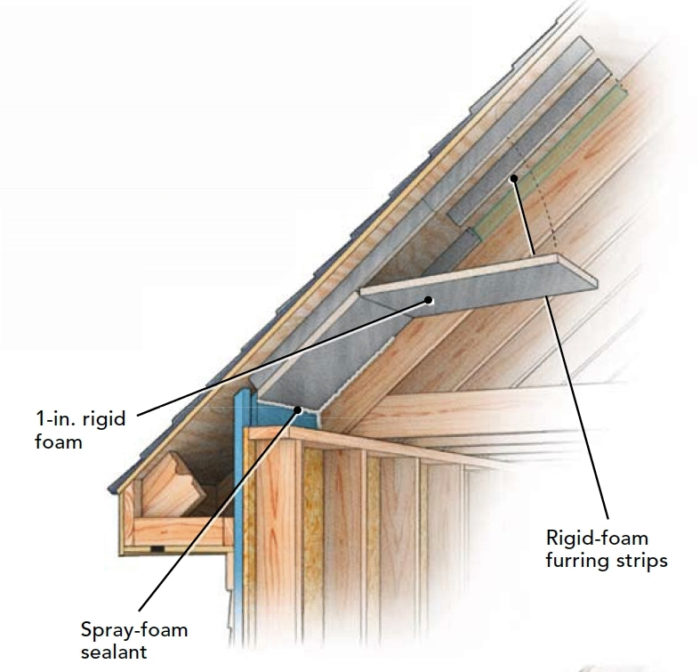

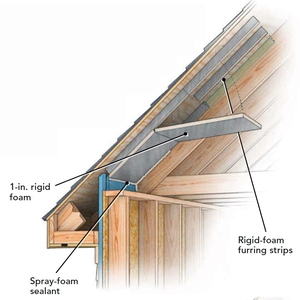

How the foam furring strips and foam (as baffle) is attached to each-other, and to the roof sheathings and trusses?

(Background info: Am to-be-homeowner; working with a builder to build a single family home in Vermont (CL 6a). My builder have used manufactured vents, which staple on to truss or sheathings. Use of plywood seems straight forward. But the rigid foam seems to bring bonus insulation when used as baffle surface). Thank you for your attention.

Rajib Roy

I would second this question! I really like the vinyl F channel approach described in the comments by Andy Kosick, but I am hoping to use 1" foam for my baffles, and I can't seem to find F channel bigger than 3/4. I would love any other suggestions that allow for quick foam installation using staples, like the F channel approach allows. I see in the other video that Mike Guertin hand nails them in. I will resort to this if necessary, but would love to avoid it.

Sean,

I would use the minimum number of nails required to hold the rigid foam in place. A few nails here and there should do it.

The nails can be installed sideways into the rafters, if desired, and left proud to form "ledges" to prevent the rigid foam from slumping due to gravity. These nails can be bent upwards after being nailed at a slight angle.

I am looking to improve the insulation and air flow in the knee wall attic of a 1950’s cape by making this space part of the interior space. The plan is to use 1” polyiso for the joist cavity blocking, 1” polyiso for the 2” vent baffle, and either fiberglass or Rockwool to fill the remaining space in a 6” rafter. Joints are to be sealed as possible in the space.

I was hoping to add another 1” polyiso layer to cover the batt insulation and bridge the rafters. Knowing that vapor barrier will not be perfect, I’m concerned about condensation on the batt side of the baffle and trapping moisture within the batts between the two moisture barrier layers. Location is in upstate NY. Air conditioning with a focus on dehumidification is a possible future addition. A complex roof structure also prohibits the use of foam insulation above the sheathing. This structure also creates some dead end rafter bays. There are soffit vents and a ridge vent for the main roof.

I’m concerned about creating a moisture issue by reducing the free flow of air in the space and adding the different layers of insulation.

Some advice regarding these concerns would be appreciated.

Can polyiso be left exposed in this space?

Monica

Hi Monica,

I am pursuing a similar approach, and have a lot of similar concerns. I am definitely no expert, but can share the conclusions I've come to via all my research.

- Relying on soffit -> ridge venting is dubious with a complex roof structure

- I personally have opted to use a more vapor permeable foam for the baffles (unfaced EPS, ex), and a impermeable foam for the interior (foil faced EPS or Polyiso), encouraging drying to the outside. (more discussion on some of this here https://www.greenbuildingadvisor.com/question/vapor-permeability-of-polyiso)

- Air sealing is key for the interior foam. Taping/sealing all joints and edges. It acts as both the air and vapor barrier. Other discussions on this site about this topic have continually enforced that air sealing is more important than vapor permeable baffles. (I think there is much discussion on that topic on this post and in the comments)

Like I said, I'm an amateur and just learning all this myself, but this is what I've gathered from this site.

Sean

Does anyone have an updated link to the video referenced in this line:

"A YouTube video shows a variation on Mike Guertin’s technique."

The video no longer exists at that link.

Thanks for this helpful article! I'm in the process of sourcing materials for site-built baffles. I was going to go with OSB but it's so expensive right now. Would hardboard be a suitable material for this purpose? Thanks!

Aciarn,

Hardboard would work.

Great, thank you!

“[Deleted]”

We're building a ventilated cathedral ceiling with a 2 inch air gap. The rafters are 2x10, so we were going to install site-built baffles, then fill the rest of the rafter bay with batts, and install one layer of rigid foam under the rafters. Since our plan is to dry to the outside, we are looking at vapor permeable options for our baffles. Here's an idea: what about using Tyvek as our baffles, stretched tight between the rafters, attached with continuous furring strips, and sealed with Tyvek tape? It seems like it would be strong enough to keep the batts out of the air gap, and has very high permeability. Plus it would be cheap... Any thoughts about this idea?

Sarah,

It works and is done regularly. I'm not as convinced as Martin that making the baffles air-tight is that important, and would skip the taping.

Another variant that has been used on projects featured on GBA recently is to stretch a permeable WRB (like Tyvek) over the rafters and attach the 2"x2"s on top of that.

This gives you a continuous air-barrier, and you can fill the entire rafter bay with batts. It is a bit difficult to install, but working on each rafter bay from the underside installing strips isn't much fun either.

Thanks! The roof is already on, so working from underneath is the only option. About the baffle: with friction-fitted mineral wool batts, I wonder if a baffle is needed at all? I saw diagrams somewhere online where no baffle was used and the mineral wool batts were exposed to the vent channel. I understand the concept of wind-washing, and that a smooth surface would also permit better air flow, but I'm curious whether it makes an appreciable difference with this product.

Sarah,

The standard detail up here in BC is only having baffles at the exterior walls - and then only if the insulation is compressed. Above the exposed batt insulation we leave a 3" gap to ensure the ventilation isn't blocked.

As far as I can see wind-washing doesn't degrade the R-value enough to be a worry.

I'm looking for suggestion for an easy to cut/trim wind dam /soffit baffle sheet that will withstand reflected UV. The first choice was 1/2" foil faced ISO but supply is an issue.

The largest span is 24"

It's for a 110yo home with open (4x8 Cedar) rafters tails so the material needs to last.

Picture is taken from the inside. The soffit board with the pattern cut into it is on the outside of the wall. EPS blocks are 2"

John,

The ventilation baffle doesn't need to extend beyond the wind-washing dam or the top plate of the wall. It doesn't need to extend "outside," so it doesn't need to be able to resist ultraviolet light.

Hi Martin

Here's a picture of reflected sunlight coming through the soffit.

John

John,

The usual method for detailing this area is to install a wind-washing dam (a vertical piece of blocking directly above the wall's top plate). The wind-washing dam extends from the top plate to the underside of the ventilation baffle.

The baffle need not extend to the outdoors. It won't see any light.

For more information on these details, study the illustrations on this page.

John, looks like you're worried specifically about UV light degrading foam baffles by reflecting off something outside and angling up through the soffit. This is not a thing. Your pic shows reflected light but that's the visible spectrum. UV light is 90% or more absorbed by most surfaces it first encounters. Unless you've got some highly UV-reflective roofing or something just below and outside, your hidden baffles are not vulnerable.

Hi Andy

I always wear a hat when I'm hiking but my face which is never in the sun will get sun burned on a 6-8hr hike if I don't use sunscreen. The first time I thought it was wind burn but after the 2 time I looked into it.

https://uv-blocker.com/en-ca/blogs/sun-protection/can-you-get-a-sunburn-in-the-shade

https://www.uvdaily.com.au/blog/reflected-uv/

I know this is an old thread but it is the perfect place to ask my question - I want to build 2" vent channels in a cathedral roof that can withstand dense packed cellulose. Zone 6 coastal. Cutting all that plywood/MDF for the 18' long rafter bays sounds awful. I was thinking of doing the Tyvek baffle idea but what if I used a smart vapor barrier instead of Tyvek? I'm using Siga Majrex for the walls. That would keep the summer humidity out of the insulation and let any winter humidity dry out through the vent channel, correct? My plan was to fill the remainder of the 2x12 rafter bays with DP cellulose, then 2 layers of taped 2" foil faced polyiso underneath, strapped with 2x4's below that to hold either sheetrock or tongue and groove wood ceiling and create an electrical channel. My goal is R60 roof but I need to conserve ceiling height as much as I can because this is an apartment over a garage and I don't want the dormer ceilings to get too low at the low point, where it will interfere with kitchen cabinets etc. It was originally planned as a spray foam + DP cellulose roof but the spray foam quote came back way too expensive so now I am changing my plan. Any problems with that assembly? Thanks!

I haven't used Majrex in that application but I think it would work well for the reasons you describe.

jwalker,

Another alternative you may want to consider is covering the rafters with a variable perm membrane, and then running 2"x4"s on top of the rafters as vent channels. This saves all the monkeying around with individual baffles, and also gives you a tight upper surface on the bays to contain the cellulose. Josh Salinger explains it much better than I could:

https://www.greenbuildingadvisor.com/article/building-a-vaulted-high-performance-and-foam-free-roof-assembly

I agree, the "sarking membrane" system is a great approach. I've gotten tired of recommending it due to those who say it's too hard to install the membrane without the sheathing in place--I've done it, it's not that hard--but it is an ideal way to vent a roof. It's usually done with a high-perm European membrane but I don't see why a variable-perm membrane wouldn't work.

Micheal,

Does the membrane need to be high perm? Baffles often get built from plywood or foam. Wouldn't any house-wrap, like Tyvek Commnercial (28 perms), work?

Malcolm, that's why I think a variable permeance (low-perm) membrane would be ok in this situation, especially in a humid environment. I've only done it using Pro Clima Mento, which is somewhere around 40-60 perms but that's probably not necessary, and may even be detrimental.

Thanks Malcolm, that would be a great idea except the roof is already sheathed. :-)

Log in or become a member to post a comment.

Sign up Log in