Image Credit: Image #1: Charles Bado

Most energy-efficient homes include a mechanical ventilation system — often an HRV or ERV that brings in fresh outdoor air while simultaneously exhausting an equal volume of stale indoor air. The main problem with introducing outdoor air into a house is that the air is at the wrong temperature — too cold during the winter and too hot (and often too humid) during the summer.

HRVs and ERVs address this problem by passing the outdoor air through a heat-exchange core designed to take the edge off extreme temperatures. (For more information on this type of ventilation system, see HRV or ERV?) While the tempering function of the heat-exchange core helps, it isn’t a perfect solution. Unless the outdoor air is already at room temperature, the air delivered by an HRV or an ERV will always be cool in the winter and warm in the summer. Moreover, in cold conditions an HRV core starts accumulating ice. Manufacturers have developed a variety of solutions to the frost problem. For example, a cold HRV core can be warmed by temporarily closing the outdoor air damper and circulating indoor air through the core (that is, by putting the HRV into “recirculation” or “exhaust only” mode). Another way to address ice buildup is to include an electric resistance heater that raises the temperature of the incoming outdoor air.

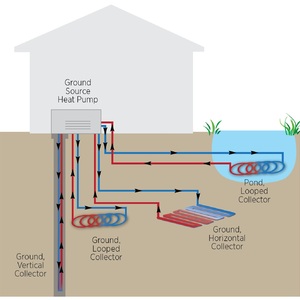

Some HRV and ERV manufacturers (including Zehnder and Ultimate Air) offer a third option: a system which conditions incoming outdoor air by blowing it through copper heat-exchange coils connected to a buried ground loop. This buried ground loop consists of hundreds of feet of PEX tubing (usually between 3/4 inch and 1 1/4 inch in diameter) filled with a glycol solution; operation of the system requires a pump to circulate the…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

24 Comments

Humidity

Thanks for the collection of data!

Did any of the analyses consider humidity removal in the summer? For my zone 6 central NH location, that looks to me like it will be the biggest benefit, and was the tipping point for deciding to install a system. I'm cheating though and using my existing geothermal wells, rather than running new tubing. Ideally that cuts the cost some, but it requires adding a heat exchanger, so I can use a higher-glycol mix in the air-to-water coil than in the ground loop, to prevent freezing.

Dehumidification in the summer and avoiding defrost energy in the winter seem to me to be the only good arguments for it. Preheating or pre-cooling air that is going to run through an HRV system anyway has little benefit. Your numbers show that avoiding defrost energy is a small effect, and would be even smaller if a better defrost cycle was used. So it seems like dehumidification might be the best argument.

a few thoughts

In the second paragraph, you wrote:

"For example, a cold HRV core can be warmed by temporarily closing the outdoor air damper and circulating indoor air through the core (that is, by putting the HRV into “recirculation” or “exhaust only” mode)."

Most North American HRV/ERVs use the recirculation method - the exhaust air is recirculated through the incoming side of the core. This keeps the house in a balanced pressure condition. The exhaust-only mode is simpler - it turns off the supply air fan, so the exhaust air melts any ice out of the core on its way outdoors. It puts the house into a negative pressure condition with respect to outdoors.

People can (and will, this IS the Internet) debate endlessly about the desirability and drawbacks of each of these methods - recirc, exhaust-only, preheater, ground exchange. The Zehnder has a back-up control feature that puts the unit into exhaust-only if the preheater doesn't work properly to implement defrost control (and presumably this is also true if the ComfoFond fails). Exhaust-only puts the house at a pressure lower than outdoors which has potential to backdraft a combustion device such as a wood stove, so that defrost method is my personal least favorite.

I wouldn't say that I "refuse" to put in a ground exchange loop - there's no sense in being that hard line - but every time I look at the cost I choose another approach. In budget-driven buildings, a choice such as the Renewaire EV90P, which has very good thermal performance, decent electrical efficiency, and no defrost requirements, is worth considering.

Finally - it's worth noting that the higher the thermal efficiency of the heat exchange core, the more time it is at risk of frost in the core, so these issues are exacerbated with the very high efficiency Paul cores in the Zehnder and other European products, Zehnder has announced an ERV core advance that they say gets closer to the HRV core's thermal efficiency, which may be a good choice, because overall cores that can transfer moisture spend fewer hours in a defrost mode.

Response to Charlie Sullivan

Charlie,

You're right, of course, that a coil connected to a ground loop will cool ventilation air during the summer and provide a limited amount of dehumidification. It's hard to quantify the energy saved by these systems during the summer, however. I welcome any data or calculations on this issue from GBA readers.

In a dry climate, the amount of dehumidification may be minor or unneeded. In Vermont, where most homes aren't air conditioned, there may be a small improvement in comfort, but no energy savings. (In fact, there will be an energy penalty -- because the circulator energy use during summer months is an added load that isn't present in most homes.) In other words, it's complicated.

Because most ventilation systems move between 50 cfm and 100 cfm -- not much air flow -- I suspect that the summer energy savings attributable to a ground loop are minor. But I invite GBA readers to pull out their psychrometric charts, sharpen their pencils, and post their energy savings estimates here.

Response to Marc Rosenbaum

Marc,

As usual, I am grateful for your comments. And thanks for clarifying the offhand remark you made during your presentation in Portland; it's good to correct the record.

It's almost time to stop comparing system efficiency costs to PV

The cost of PV is crashing fast, and rarely are equipment & building efficiency upgrades purely an energy cost play. Nor are the full lifecycle costs typically included in the analysis.

For example: It makes sense to install an R65-75 attic/ roof in central NH no matter WHAT the energy savings are over a code-max U0.026 attic would be. The energy cost savings are truly tiny, but the difference in ice-dam potential in a location that gets that much snow is significant.

Another example: It makes sense to install U0.25 or lower windows in any US climate zone 7 or higher location instead of a code-max U0.32 window independent of the cost any cost of energy, for both window condensation and human comfort reasons.

At the decades long ~20-25% per doubling learning rate of PV , it will become the cheapest form of energy of ANY type by 2030. In Saudi Arabia it is beating $10/bbl oil fired power generation on full lifecycle costs right now, based on recent bidding into that market! When PV was still by fa the most expensive form of energy out there , the statement, "The savings of that feature is more expensive than PV" had some weight.

In 2015 the lifecycle cost of residential rooftop PV in New England is substantially less than the cost of purchased power from the utility in most of the region, but so what? It doesn't mean there aren't reasons to hook up to the grid (or to remain hooked up). Nobody (yet) is shaking their head and saying, "The cost of using grid power is more expensive than PV", with the implication that paying to be grid-tied it's a silly or a bad investment.

The comparison has lost it's punch- time to get rid of it.

The versatility of the product returned by an investment in rooftop PV is much higher than any Rube Goldberg style ventilation system's defrost/pre-conditioner, and that can't be ignored. Criticism of overly complex & expensive mechanical systems is apt, but it's independent of the cost of PV.

Given that the PV may last longer than the glycol loop ventilation defrost/pre-conditioner, is the lifecyle of a Zehnder or Ultimate Air unit as long as a PV system? And, no matter how (or even if) you defrost/pre-condition the air, is a Zehnder or Ultimate Air ever a financially rational decision, based on the net-present-value of future energy savings, or any other factor? If people want to go that route for the marginal comfort uptick or have their own $/ton pricing for the marginal carbon footprint offset that's their business, and it has nothing to do with the cost of tea (or PV) in China.

Dana makes some good points

I will stipulate to the fact that PV cost comparison on energy saving strategies has declining utility.

On the topic of how long various items last -

We have good data PVs last 30 years or more. The interesting question is whether newer products of any type with digital electronics will last nearly so long as their simpler predecessors. Recently I went to a solar house I designed in VT that was built over 30 years ago. The simple HRV still runs. The simple solar fan system, using a Honeywell line voltage thermostat, still runs. No electronics. When I picked a heat pump water heater for my own house, one reason I picked the Stiebel Eltron was no electronics (the new smaller one has digital elements).

I have the Olympus rangefinder I bought in 1977, which has been with me on four continents and been dropped enough that it's dented. Still works. Meanwhile, I've been through three or four digital cameras since I bought my first about 10 years ago.

HRV/ERVs are good in superinsulated houses because they deliver air close enough to the comfort conditions that the occupant doesn't turn them off, and one can set the desired amount of air supplied to each space and verify it (at least until the owner neglects to change the filter for a few years)

And, the residual value of PV past it's prime...

... is still likely to be WAY more than zero, as discussed in this very recent GTM blog piece:

http://www.greentechmedia.com/articles/read/where-is-solars-emilio-estevez

The residual value of a complicated HRV system gone south is pretty much it's scrap value.

Electronics are not necessarily short-lived- the greater number of electromechanical parts of a system are a better predictor of mean time between failure than the number of microprocessors or power-semiconductors are involved.

Modern PV inverters & chargers have a lot more "smarts" in them and run at higher efficiency than goods sold back in the 1980s, (and they cost less too.) Consumer goods like cameras aren't really a great thing to compare with HVAC equipment or power handling equipment, most (but not all) of which GAIN reliability with smarter semi-conductor based controls.

In the middle are the nickel-cost engineered sorta-durable-goods items like hot water heaters & clothes washers, where a whiz-bang programmable user interfaces with cheap keypad switches can make them wretched things to own for the long haul. Simpler and more rugged really is better, but that can be had with electronics too. Automotive spark ignition and fuel injection systems are FAR more reliable than the electromechanical equivalents of yore, often (but not always) lasting the full lifecycle of the car (which has also nearly doubled since 1980.)

But then, I'm an electrical engineer, I have certain biases. :-)

We need a "Pretty Good" ground loop system

It seems to me that the costs associated with the ground loops is the sticking point. We should be able to install these systems for less than a $1000....If your foundation hole is already open the biggest cost is already taken care of.

Alright all the mechanical engineers out there, can we build one of these with of the shelf parts? Grainger?

Let's see.

1.Pex

2.Pump

3.Controller

4.Cheaper water/air exchanger. Would a radiator work?

Pretty Good

Response to Dana Dorsett (Comment #5)

Dana,

You wrote, "It's almost time to stop comparing system efficiency costs to PV." I agree that we may have almost reached that point. But until we do, I imagine that I will probably still find the comparison useful, because it is a good stand-in for discussions of whether an energy-saving measure is cost-effective.

You provided a few good examples of features that are desirable even though they aren't cost-effective from an energy-savings standpoint: insulation that is thick enough to prevent ice dams and windows with a low U-factor that are chosen for reasons of comfort. Of course, homeowners choose features like that all the time -- and we can stretch the discussion to include granite countertops, whirlpool tubs, and a wet bar on the patio if we want. It's OK to choose house features for reasons other than energy savings.

A ground loop isn't like a whirlpool tub or a wet bar, however. There is no obvious reason why a homeowner would want one -- so if any green building guru is going to step forward and suggest the installation of a ground loop, or any other feature that isn't cost-effective from an energy standpoint, we need the guru to explain why anyone would want to buy one. You've provided examples of how that might be done: "This insulation will prevent ice dams," for example, or "These expensive windows will be comfortable to sit beside when the thermometer drops to -10°F."

So, here is a logical framework: (a) if any feature smells a little like an energy-saving feature, we assess the cost-effectiveness of the investment with the PV comparison, and (b) if the feature fails the PV comparison test, we ask our green guru why the feature is desirable.

Response to Kye Ford (Comment #8)

Kye,

You wrote, "We should be able to install these systems for less than a $1000." This is a fairly common response whenever a discussion of cost-effectiveness comes up. The argument is often used when I discuss solar thermal systems: "Martin doesn't like solar thermal systems that cost $6,000. But these systems should only cost $3,000. In fact, I think I can install one myself for about $2,900."

My usual response to these discussions is: "The real price is what a contractor needs to charge to install it." And yes, contractors need to cover all of their overhead expenses and also make a profit.

Kye, if you can install a ground loop for $1,000, go ahead. If you do, you will have shortened the system's simple payback period from 4,400 years to 2,200 years.

Payback?

Why the idea of being able to install a cheap ground source heating loop is appealing to me is that it seems like a simple straightforward application that would do two things.

1. Preheat incoming cold air

2. Reduce or eliminate the defrost recirculation cycle for HRV

My biggest problem with my Venmar EKO 1.5 ERV is that when the unit goes into its recirculation defrost cycle, escpecially during the middle of the night, is that its really annoying. It kicks into high speed and makes the otherwise silent system loud.

We ended up turning the unit off many nights this past winter.

If I could avoid this, preheat the air, due this more efficiently than say a electric preheater, for say $750, why wouldn't you do this.

To compare a payback period of $1000 or $750 when you are spending $200,000 plus to build a house seems funny.

I'm all for PV but it isn't going to make my ERV quiet. You could argue that you could install an electric preheater with the off set savings but then you are making things much more complicated.

I'm thinking for a simple solution during the construction process that will get the highest and best use of the mechanical systems we are putting in. Pex, pump, controller, exchanger. Doesn't seem like much more work for what you are going to get out of it.

On the cheap

Martin is right that "possible in theory for $1k" and "can hire a contractor and get it done for $1k" are very different things. However, which of those to pay attention to depends partly on what we are trying to achieve. In the short term, if you can't get it done cheaply with what is available now with the skills available among contractors, it's not of interest. But 10 years ago that was the situation with PV. Stubborn idealists installed PV anyway, and now it's mainstream and cheap, partly because those stubborn idealists (including the German government) helped pay for the learning curve. So I would argue that if something makes sense in the long run, it is worth installing and promoting when you can, to help it get to the tipping point. On the other hand, if it's never going to make sense because of some fundamental problems, pushing it only diverts attention and investment from the approaches that have a better chance of success.

So I do think it's worth looking at the fundamentals of the cost. The first two are prices from "outdoor furnace supply"

300' 1" PEX: $155

12" x 12" water-to-air heat exchanger: $70

Circulator: $100. Doesn't need to have the high-temperature or high pressure operation capability of a hydronic circulator, but it would be good to have a high-efficiency motor.

Electronic controls $150 (could be $20 in volume production but I'm being conservative.)

Misc. plumbing parts $100

Insulated box and condensation pan. $100

That's $675 of parts. A contractor who installs these routinely should be able to do it for $250. So that leaves a thin profit margin to install a system for $1000, and perhaps a decent profit margin if it becomes higher volume operation. That's assuming we use a trench that is already open for other purposes.

Based on Martin's chart, above, that's a good deal relative to PV, even if it's not a clear win. But as others point out, electricity from PV is more versatile and probably more reliable--the circulator will fail eventually, for example. So we probably need another argument, such as comfort.

Kye's argument is silent defrost vs. the Venmar high-speed recirculation. But that could work at low speed too, and fixing the controls to do that at low speed should cost Venmar almost nothing. So I don't buy that argument as a reason in general, only for his particular case.

My argument above is that the summer dehumidification is the biggest benefit in a New England climate. I see this as a three-fold benefit:

1) Comfort, including avoiding a "muggy" feeling at moderately warm indoor temperatures, and avoiding a hospitable climate for dust mites, mold and mildew. Also, at moderately warm temperatures, running a dehumidifier leads to uncomfortable heat, whereas running an air conditioner leads to excessive cooling.

2) Energy savings from not running a dehumidifier or air conditioner, and

3) Cost savings from not needing to install an air conditioner, or as large an air conditioner (doesn't apply to minisplit owners), or a dehumidifier.

I think I'll use a large bucket for condensate from my system this summer, so I can collect data that could be used to compare to what it would cost to do that with a dehumidifier. I did run an analysis of how many hours a year the outdoor dew point exceeds 55 F and by how much, which might be the point at which I'll turn on the system for dehumidification purposes, but I didn't follow through to calculate how much water I'd expect to collect. The bucket will be a more definitive test anyway.

The other argument that will eventually be important is that electric pre-heaters only use electricity during the absolute worst peak hours of the year. So the electricity they use would be very expensive electricity if that consideration were properly reflected in consumer bills. A ground loop system can mitigate that peak, whereas PV can't. So in that sense a kWh of electricity saved by a ground loop is much more valuable than a kWh of electricity generated by a PV array.

DIY and Costs

Charlie wrote:

"A contractor who installs these routinely should be able to do it for $250. So that leaves a thin profit margin to install a system for $1000, and perhaps a decent profit margin if it becomes higher volume operation."

With all respect these numbers simply help illustrate the problem. No contractor can stay in business with margins like that. The higher the volume the quicker they would go feet up.

The larger problem with introducing DIY costs into discussions is that they are almost invariably used to make the case for something that otherwise doesn't make sense. Removing the labour component from a process to make the numbers work can be done with almost anything - including building the whole house - and we know how often those savings materialize when clients act as their own GCs.

I agree about costs

Malcolm, I agree. I didn't explain what I meant by higher volume. I did not mean that a contractor barely making a profit would do better by doing more such jobs. I meant that if the unit becomes a commodity product and costs much less (say $350 for a box with everything I listed except the PEX), that leaves more room for profit, perhaps $250 on a job with $250 of labor and $500 of materials. And I didn't say that would be a great business model. I said only that "perhaps" it would be "decent".

The other thing I didn't mention is the assumption that this would be part of a larger HRV installation job, which means the overall profit on the job would be larger.

I certainly did not at all mean to imply that DIY costs = what it should cost.

Charlie

Sorry, my reply conflated the two issues. The DIY costs comment was not directed at your post. I guess there is a better case for your numbers if it was a small part of the larger HVAC budget, but I still find it hard to see why a contractor would tack on such an additional item and not include the same margin they make on the rest of their work.

Response to Charlie Sullivan (Comment #12)

Charlie,

I know that you have conceded most points about the cost issue. But one aspect of your estimate hasn't been discussed: Because you "assumed we use a trench that is already open for other purposes," you calculated that the cost of installing the PEX ground loop is zero.

Let's see: unloading 300 feet of PEX; talking to the backhoe operator about widening the trench; supervising the widening of the trench; unrolling the PEX and connecting it to the plumbing fittings indoors; pressure-testing the ground loop for 24 hours; and supervising the backhoe operator during backfilling to be sure that no sharp rocks are used for the first 12 inches of backfill. You're right -- the cost of that work must be zero.

And the backhoe operator throws in the extra time for free.

And then you need to calculate some amount of time for callbacks...

Good point

Thanks Martin. Given my recent query arising from the poorly done backfilling on my own project, I should know that getting even a basic excavation job done right is not easy, let along one with a new wrinkle.

Effectiveness for larger buildings, MURBs?

Very interesting article Martin, thanks for the in-depth analysis on this topic. I wonder whether there might be a better case at the commercial scale for multi-family buildings or offices with higher ventilation loads? The heat transfer needed would be a higher rate for sure, and would increase the tube length/diameter requirements, but the corresponding energy savings for the building as a whole should certainly be higher as well. Ventilation is often the 'weak link' in a larger building's energy performance.

Response to Kyle Anders

Kyle,

You're right that some systems that aren't particularly cost-effective for single-family homes (for example, ground-source heat pumps) sometimes make sense for large commercial or institutional buildings. I invite GBA readers with data on this issue share what they know.

That said, my gut tells me that these systems require such expensive hardware, and collect so little energy, that they are unlikely to make much sense at any scale -- especially when compared with PV. But I'll keep an open mind on the issue until I see some data.

what pump might work on such a loop?

say I have 300' 3/4" pipe what low wattage pump could do the job?

What flow rate

I have the area excavated just want to be sure a pump to do this is not too expensive and readily off the self.

the other choice I have are earth tubes

Response to Bob N

Bob,

As my article shows, many of these systems use just as much electricity to operate the pump as would be required to operate an electric-resistance heater to heat up the air. That's what makes these systems a bad investment.

This type of system requires the best possible pump, so if you can't be dissuaded from installing this type of system, buy a Wilo pump. You can contact Wilo to get pump sizing help. Choose the smallest possible pump (with the lowest energy use) that will do the job.

Here is the the contact info:

Wilo USA

9550 West Higgins Road, Suite 300

Rosemont, IL

888-945-6872

http://www.wilo-usa.com

thanks, I emailed them.

to

thanks, I emailed them.

to make sense the pump needs to draw 50-100 watts be on demand, cost under $100

pipe $100

air to water ex-changer $75

I'll have 3,000 watts of PV to run it during the day,

I realize the payback, but just a nice toy perhaps.

If the pump doesn't work out cost wise the earth tubes can be tried and if they don't work seal them off use outside air for make up.

It's located in the Ga mountains so it's not a real cold climate, but does get 50"s of rain.

didn't hear back Wilo yet but

didn't hear back Wilo yet but found this pump using only 55-95 watts depending on speed Wilo-4090765-Star-S-21FX about $65

http://www.supplyhouse.com/Wilo-4090765-Star-S-21FX-3-Speed-Cast-Iron-Star-Series-Circulator-1-12-HP?gclid=CIXuif3TtccCFQ8YHwodtUoP1A

"the unit uses 98 watts on speed 3, 77 watts on speed 2, and 55 watts on speed 1. Also, the pump is rated for continual use"

So now the glycol loop make sense compared to earth tubes.

<$300 all in, I'm going to spread out the pex under a 1,000 sq ft passive solar slab, which will be insulated including wing insulation, so the water temp into the ex-changer should be in the low 60 degree range in the winter.

In fact the slab may warm the pex a bit more????

there still may be a better pump if tech support emails me back but this one is used in many geo and solar applications.

thank for your advice Martin

“[Deleted]”

Log in or become a member to post a comment.

Sign up Log in