-

Recurring Mold in the Attic

What is the source of moisture in this cold-climate vented roof assembly with cellulose insulation?

-

Air-Sealing and Insulating an Existing Wall

What are the most effective air-sealing strategies and best insulation types for minimizing airflow through a north-facing wall?

-

Considerations When Insulating With Dense-Pack Cellulose

Is netting and strapping the ideal method? What's the best drywall thickness? How can you minimize bulging?

-

Engineering a Domestic Hot Water System to Meet High Demand

What’s the best back-up option for a big family that always runs out of hot water?

-

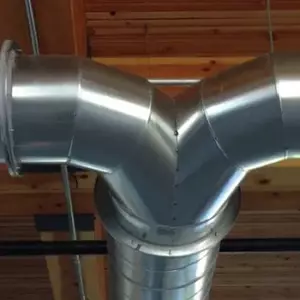

High-Velocity HVAC Systems

Are smaller duct size and the ability to dehumidify reasons enough to install a system that distributes air at high pressure?

-

Insulation and HVAC for a Detached Garage

Building scientist Kohta Ueno recommends slab, wall, and roof assemblies for a cold climate

-

Choosing Wall Insulation for a New Build

What’s the best combination of exterior and interior insulation for a “forever” home?

-

Footings for Load-Bearing Posts

A homeowner wants to fix a "bouncy" floor by adding a new beam. Do the posts need footings?

-

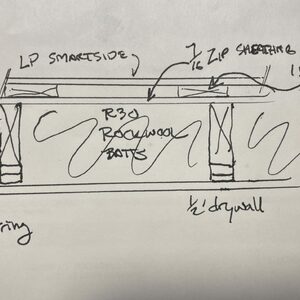

Variation on the Bonfiglioli Wall

Is this system the best choice to reduce thermal bridging?

-

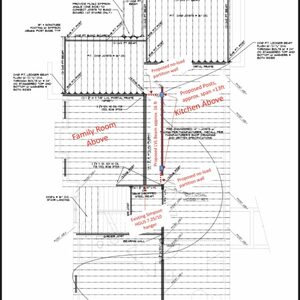

Getting HVAC Right in a New, Tight Home

The trick is to balance ventilation, dehumidification, and heating/cooling