R-30 is good and R-38 is “gooder.” That’s kind of how we sell insulation, right?

At the end of the day, when we talk about green upgrades, this is probably the one item that most consumers understand better than any other. The maxim “more is better” is, with few exceptions, pretty safe territory when it comes to insulation. Oh, if it were on that simple!

I like to tell consumers today that it is the proper installation of insulation, more than anything, which will ensure they get the realized R-value they have purchased. After all, if you compare the R-values per inch for fiberglass, cotton, open-cell spray foam, and cellulose, you just don’t see a huge difference.

The value of a third-party inspection

One of the key tenets of selling insulation upgrades, then, is to first focus your presentation on your installation processes — processes which will ensure a high-quality job regardless of insulation type. And that must include third-party inspection of the installation.

If you are already building LEED, Energy Star, or NGBS projects, this will not be a problem, as the insulation inspection will be required. But if you are new to green and want to start taking smaller steps to becoming a better builder/remodeler, this is a very good inexpensive first step to take.

Any rater/verifier/inspector with nationally recognized credentials could perform this inspection and give you a report when finished. And you can find those inspectors at your local homebuilders’ association. A minimum trip charge is all that is required, and assuming you pass and a follow-up inspection is not required, it will only cost you about $300.

HOW TO SELL GREEN UPGRADESPart One: Radiant Barrier PaintsPart Two: Tankless Water HeatersPart Three: Energy AuditsPart Four: Exhaust FansPart Five: Electrical ImprovementsPart Seven: A Few Small Things

One tip on the inspection: make sure your project manager and insulation contractor are on site so that they could learn what the inspector is looking for.

Using insulation to reduce air leakage

Now that you have successfully demonstrated to your client that they will get the R-value advertised on the insulation package by virtue of your proper installation processes, you can talk about the unseen benefits of different non-traditional insulation upgrades. That means talking about reducing the air leakage rate, which can be achieved by installing spray foam (or in some cases blown-in-place insulation). Because if you have air leaking through your parka on a cold winter day, your body is intently focused on where that air is coming in, and you could care less about the places where you are warm. Your attention is devoted to stopping that air leakage, right? Well, your house operates the same way. If cold air is leaking around, over, under or through the insulation, the insulation value of the complete home is compromised severely. Unless, of course you install an insulation that will eliminate air leakage in the first place.

Hence the exploding market in spray foams, blown insulation, and countless hybirds. Do they insulate as well as typical batts? Sure they do — in some cases even better. But not so much better they are worth the price difference. But the price difference that is worth paying for is their air-sealing capabilities.

You get to buy a parka that has no air leaks. That’s what blown-in insulation and spray foams do so well: they get into the nooks and crannies, holes and crevices, and plug them up or cover them to stop that dastardly air from leaking into or out of the house!

The homeowner benefits, and so do you

So the next time you meet with your client, talk insulation. Talk first about proper installation, and then talk about the superior air leakage elimination benefits of upgraded insulation.

That is what will make insulation upgrades such an easy sell — it has tangible benefits to the homeowner, and then, of course, to your bottom line!

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

5 Comments

batt insulation

Michael, isn't it true that only perfect installation of batt insulation will create the expected (labeled) R value? By perfect I mean zero compression is allowed for the batt, which is simply impossible. Would you say that some of the benefits of full-fill insulation (spray foam, cellulose) are actually true R value and also the air infiltration benefits?

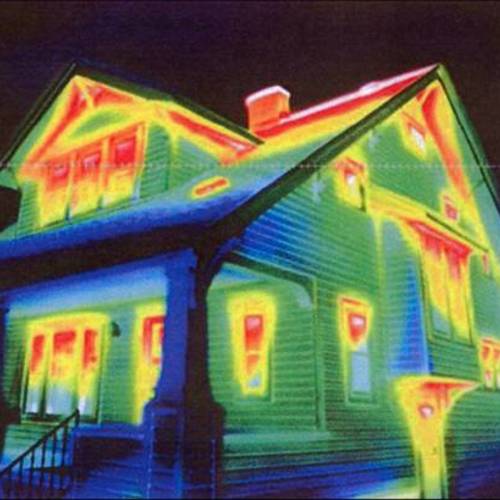

In the picture it shows a typical installation of batt insulation. Would you say that any of these wall spaces have the actual R Value that the product tested out at in the hot box test?

We operate in the Dallas/Ft Worth, Texas market and we do fiberglass batt, spray foam, and sprayed-in cellulose (I call it dense pack) and think that the sprayed-in cellulose is the best for cost and actual effectiveness of the product for remodels and new construction. What do you think in terms of price/product performance?

We also do spray foam insulation but see many downsides to this solution on many levels. We also install fiberglass loose fill, spray IRCC (radiant spray coatings), and foil Radiant Barrier with good results as part of our product mix.

Right On!

Yeah, you nailed it Steve. Let me answer one at a time. Yes, only the perfect installation (assuming all other components of the assembly were installed and operating correctly) will ensure the stated R-Value. Yes, spray foam and cellulose do a better job of realizing the stated R-Value but the former does a better job of reducing/eliminating/managing air infiltration.

The photo is of course an attempt at humor and I would hope not typical even for batts! But most assuredly the wall is not getting anywhere close to R-ll because there is too much wood and not enough insulation and because the insulation that is in the wall is insufficient and improperly installed.

You know Steve I do like the cost/value proposition of sprayed in cellulose but that questions (and answer are very subjective). We have specified open cell spray foam in all our new homes including sealed crawls and attics so clearly the market we serve views the value proposition differently. And then in our remodels we have done tons of sprayed cellulose, denim, flash and batts, everything under the sun depending on the budget, the home and the area of the home in question.

Thanks for writing!

Compressed fiberglass insulation

Actually, compressed fiberglass insulation has a higher R-value per inch than standard fiberglass insulation, that is why we heave "high density" fiberglass insulation, with higher R-values. When you look at the real R-value of insulation that is compressed around a pipe, or behind an electrical box (in a typical faulty installation) the R-value is actually higher behind the pipe or box than it would be if it had been cut and split, as in what we would consider a good installation. The real issue with the compressed insulation is with the air-space on one side of the compressed insulation, which has no R-value.

Using an electrical box as an example, if you cut the face of the insulation the size of the box, and the depth of the box, but leave that piece of insulation compressed in place behind the box, as long as the un-cut portion of the insulation surrounding the box is able to fully fill the stud cavity as intended, the installation will have a better R-value than if the cut piece had been removed, as recommended by Energy-Star and others.

The reason Energy-Star recommends the "almost right way" instead of the real right way to install batt insulation is because of the difficulty of getting it right, and verifying the installation. Another good reason NOT to insulate with fiberglass or other batts.

Cellulose

Steve - I'm not sure what you mean by sprayed cellulose, but if you mean wet-spray, it's not the same as dense pack, which is dry and blown behind some kind of membrane (mesh or woven poly).

The almost right way

And you wonder why our homeowners are confused! Geez, Ted, good point. The almost right way is deficient but the right way is impossible to verify and extremely difficult to effect. With how many boxes this would apply to? Wet or dry, open or closed I'm with you. Blown in and sprays-easy to install correctly and easy to inspect.

Log in or create an account to post a comment.

Sign up Log in