Windows have a huge impact on the energy use of our homes. Fortunately, there have been dramatic advances in window technology over the past thirty years. This column will take a look at factors that affect the energy performance of windows.

Multiple panes of glass. A single layer of glass—and the layers of relatively still air on both sides of it—insulate to about R-1. If we add a second pane of glass ( “glazing” in industry parlance) separated by an air space, we increase the insulating value to between R-1.75 and R-2. We can do this by adding a storm window or by using two layers of glass in the prime window. Two layers of glass with a sealed air space between them is referred to as an “insulated glazing unit,” and most windows sold in the U.S. today have such glazing. Providing three layers of glass or two layers of glass and a suspended plastic film boosts performance further by creating two layers of trapped air.

Thickness of the air space. Older insulated glass units often have just a quarter-inch air space. If that air space is increased to a half inch, the insulating performance of the window, measured at the center of the glass panel, increases about 15%. If the spacing is too wide, though, the air can form convection loops and the insulating performance drops a bit. Assuming air fills the space in the sealed insulated glazing unit, the optimal thickness of the air space is between ½ inch and 1 inch. We’ll see that if a gas other than air fills that space, the optimal thickness may differ.

Low-emissivity coatings. In the mid-1970s scientists at the Massachusetts Institute of Technology figured out that a very thin metallic coating on a layer of glass or plastic film would block the escape of radiant heat. These coatings allow shortwave length light to pass through (so we can see through them just fine), but they block longer wavelength heat radiation. Technically, they reduce the emittance of radiant heat—thus the name, low-emissivity or low-e. For windows sold in our climate, low-e coatings have become fairly standard.

Low-e coatings can be deposited on the glass (referred to as soft-coat low-e), or they can be incorporated into the surface of the glass when the glass is still molten (referred to as hard-coat or pyrolytic low-e). In general soft-coat low-e adds more R-value than hard-coat low-e, but it also blocks more solar gain, so may not be the best choice for south-facing windows when you want to benefit from passive solar heating—more about that in a future column.

Assuming a half-inch air space, adding a layer of soft-coat low-e to one of the panes of glass boosts the energy performance (measured at the center of the window) by over 50%.

Low-conductivity gas fill. Some gasses have lower conductivity than air, so replacing the air in a sealed insulated glazing unit with one of these low-conductivity gas fills can boost insulating performance. The most common gas-fill is argon, though krypton is even better and is used in higher-performance windows. With krypton, the optimal thickness is about a quarter-inch.

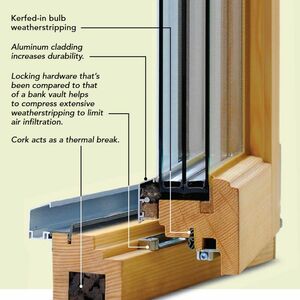

Improved edge spacers. In an insulated glazing unit, the panes of glass are held apart by a continue glazing spacer—usually a hollow channel of aluminum. Because aluminum is highly conductive, this spacer creates a “thermal bridge,” reducing the overall insulating performance of the window—and sometimes causing condensation at the window edges (because the inner glass surface will be colder there). There are some alternative “warm-edge” spacers on the market made of thinner-walled stainless steel channel, silicone, or rubber.

Frame materials. Finally, some window frame materials insulate better than others. Wood provides about R-1 per inch. Hollow fiberglass or vinyl channel that is insulated with fiberglass or foam insulation can boost the insulating performance of the entire window unit (glazing plus frame). The better the energy performance of the glazing, the more significant the heat flow through the frames. This is also why—with high-performance glazings—windows with large undivided glazing units perform better than windows with lots of small panes of glass; the latter have a higher proportion of framing.

By combining the best of these glazing and frame technologies, center-of-glass insulating values can be increased up to R-8 or even higher and whole-unit R-values (accounting for heat loss through the frames) can reach R-5 or higher. Only a few U.S. manufacturers provide such top-performing windows. Canadian window manufacturers are much more focused on energy performance.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

0 Comments

Log in or create an account to post a comment.

Sign up Log in