Image Credit: All photos: Alex Wilson

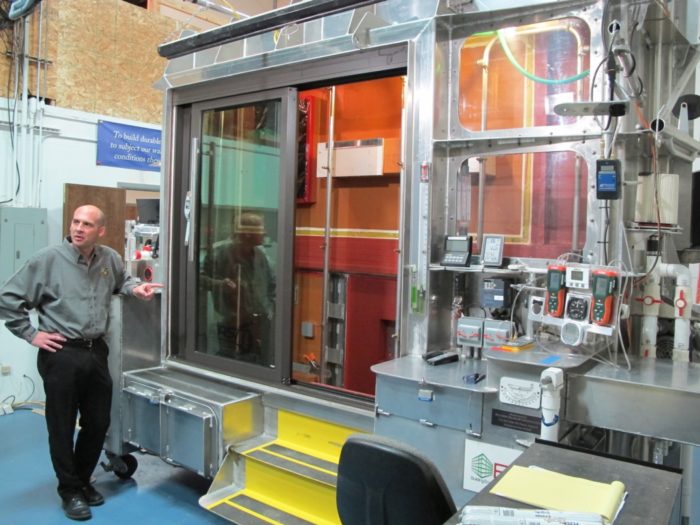

Image Credit: All photos: Alex Wilson Tom Schneider of Building Envelope Innovations explaining the operation of the test chamber, which is shown here sealed. Up to a Category 5 hurricane with winds speeds of 150 mph and high-pressure streams of water can be simulated. Manometers are used to monitor the pressure being applied to materials that are tested under conditions that simulate wind-driven rain. The smaller Clackamas test chamber is used for testing individual materials, such as sheathing or water-resistive barriers (WRBs).

When I was in Portland, Oregon, the week before last for the Living Future Conference, I had an opportunity to visit a facility in nearby Clackamas where building assemblies and components can be tested for water intrusion and water vapor penetration.

One of the high points of being a researcher and writer is the opportunity to visit really cool manufacturing and research facilities, so I usually jump at the opportunity to visit something new. I wasn’t disappointed on my recent trip.

Prosoco is a leading manufacturer of liquid-applied water-resistive barriers (WRBs), which can be thought of as spray-on Tyvek, flashing, and tape. Prosoco developed the Clackamas test facility with partner company, Building Envelope Innovations (BEI). Prosoco was at the Living Future conference because of the company’s commitment to sustainability and transparency in building products, and company president David Boyer and sustainability director Dwayne Fuhlhage invited a number of us out to Clackamas to learn how they test for moisture resistance.

A Cat 5 hurricane in a closed chamber

At the Clackamas test facility, Building Envelope Analysis (BEA) — a joint venture between Prosoco and BEI — has two specialized test chambers that can be used to simulate weather conditions as well as more insidious humidity conditions that can drive moisture into wall assemblies or damage building components like insulation and sheathing.

Along with a half-dozen other Living Future conference attendees, I watched as the submarine-like glass doors of the large chamber were closed and the fury of wind and driving rain were cranked up on the controls. We could see on manometers just how much pressure the wall assembly was having to endure, and we could watch high-pressure nozzles spraying high-velocity streams of water at the assembly.

The operator can turn a few dials and simulate 150 mph wind and driving rain, wreaking havoc on the wall assembly constituents.

David and BEI director of operations Tom Schneider explained how the test chamber can easily be configured to test everything from plywood sheathing and flashing systems, to windows and weather-barrier tapes.

When we visited, a high-tech European window that had been submitted by a local Passivhaus builder for testing was blocked off, because it had failed so miserably that we would have had water all over the place if it hadn’t been sealed off.

Prosoco’s interest in all this testing

We didn’t get into too much detail about building the test chambers, but it appeared that hundreds of thousands of dollars had gone into designing and fabricating them. Why would Prosoco and BEI go to all this effort and expense?

Because BEI developed and Prosoco manufacturers liquid-applied WRBs for building assemblies, and the companies want to show off how much better they perform than more-common WRBs (like Tyvek or Typar) and specialized building tapes, such as those made by 3M, Dow Chemical, Zip, SIGA, Pro Clima (the latter of which we used on our house).

The bottom line is that the liquid-applied WRBs, such as Prosoco’s R-Guard Cat 5 Air and Water-Resistive Barrier, do a lot better than the more common taped membrane systems. While one can question how accurately the test chamber simulates real conditions, the demonstration was compelling.

In addition to the large test chamber for testing whole wall assemblies and components, there was also a smaller chamber used for testing the permeability (or vapor diffusion) of specific materials — like plywood and WRBs.

With this discussion, I was fascinated to learn that the standard methods we use to measure the permeability of different materials to water vapor are grossly flawed. David explained that the permeability of a material that has a listed perm rating (based on standardized ASTM test methods) of 36 may drop to a perm rating of only 2 when that material gets damp from high humidity.

Prosoco and BEI have even more sophisticated test chambers in Florida and Kansas. In addition to testing the effects of wind and wind-driven rain, the Florida facility, which I’m hoping to visit sometime, can test resistance to sudden flood or tidal surges of three to four feet.

With growing focus on resilience and adaptation to climate change, dealing with storm surges in low-lying coastal areas will become more and more important.

Alex is founder of BuildingGreen, Inc. and executive editor of Environmental Building News. In 2012 he founded the Resilient Design Institute. To keep up with Alex’s latest articles and musings, you can sign up for his Twitter feed.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

23 Comments

Curious minds want to know...

What manufacturer was this high-tech European window that had been submitted by a local Passivhaus builder for testing ?

Translation:

"Lawsuits are fun. Would you like to try one?"

Double Blind unbiased research

?

great products

Prosoco makes great products and they have some cool testing equipment. The wetflash is easy to apply and seems to bond to anything. It does need i little bit of time to dry but I think its the best. it's like a gortex skin on wood.

Gordon

Why did they mention it if they weren't going to reveal who it was? Better not to even mention it because everyone will want to know who it was...

Prosoco

Can Prosoco be used to seal a recessed window install? Typically innie window installs require peel & stick tapes to bridge the gap between the window frame and window buck but can Prosoco be used instead?

Passivhaus Test Window

Peter,

I supplied the Passivhaus window to Tom for the test chamber. It was a typical triple pane tilt and turn European aluminum clad wood window (insulated wood frame). We had been shuffling this demo window around the Hammer and Hand wood shop for several years, so we decided to donate it to science. To be clear these windows perform beautifully under intended design conditions; however, Tom has been abusing this window for months, taking it far beyond its design limits. The repeated 240mph wind driven rain conditions Tom tested this window at would take a toll on any wood window.

The key takeaway here is that all windows leak, even really expensive ones. Remember the old saying, "There are two types of windows—windows that leak and windows that will leak."

Protecting the rough opening with a seamless liquid applied flashing system is a no brainier. This has been our standard protocol at Hammer and Hand for several years and there is no going back to the outmoded origami-esque flashing of the dark ages.

Something else to keep in mind, should we be insulating the gap between the rough opening and the window sill if we know that someday the window will likely leak? In most cases the answer is, "it depends", but this critical detail doesn't get discussed much.

great products

Windows engineered to handle a specified water performance should meet the specified performance benchmarks. Unfortunately, many manufacturers don’t do due diligence but that doesn’t mean that they all don’t. These test chambers are great for bringing us from theoretical to closer to real life.

In this link you can see a vid by Prosoco. The purpose was really to show the benefit of proper installation and air sealing using the prosoco system under some extreme conditions but it also shows the benefit of a window engineered to meet the conditions.

https://www.youtube.com/watch?v=UsRihA0yYfI&list=UUCJTXjAB4wC1ccvjPLdl9Ew

Window Frame Caulk

I noticed that Prosoco utilizes a white type of caulk around the perimeter of the window frame where it meets the rough opening. I was under the impression that only expandable foam seals like Tremco work in these areas since they expand and contract with the window frame movement. A "fixed" caulk will only last a few months or maybe a few years because caulk cannot take the constant expanding and contracting of the window frames and the dissimilar wood buck area.

Have any long-term tests been done on the window caulk that Prosoco uses? I don't doubt it will stop wind driven rain when installed but after a few years of expanding and contracting, how does it hold up? I was always told by building science experts that caulk is NOT a lifetime product.

white frame caulk

Peter, there are various types of "caulk" with varying durability. I have not used the ones from Prosoco but I have seen them and they are diligent about testing. From what I have seen/heard the ones by Prosoco are compressible and elastic, have good adhesion to substrates and windows and is durable. When applied to the interior around the jamb it certainly provides a good durable barrier that is inspectable once applied. it's messy business and needs to be done properly. Commercial applications and homes that are rain screened use this method all the time in my region.

Permeability changes

>the permeability of a material that has a listed perm rating (based on standardized ASTM test methods) of 36 may drop to a perm rating of only 2 when that material gets damp from high humidity.

Or, in the case of plywood and OSB, the opposite - permeability increases significantly.

Let us know if you find some independent research regarding the effectiveness of liquid-applied WRBs.

Reply to John R.

"Let us know if you find some independent research regarding the effectiveness of liquid-applied WRBs."

That's sort of where I'm at after reading this. We are left with an eye witness account and a "take it from me" testimonial. What would have been useful is a comparison with other WRBs. How important is a perfect installation of both methods? How do the two compare when job site weather is a factor or when the sheathing is dirty? How do they act as part of the whole wall assembly? How difficult is it to integrate flashing? How do the costs compare? What are the problems with conventional WRBs that liquid WRBs solve? None of that is here.

liquid-applied WRBs are better ? according to the mfg they are

Not to be too cynical, BUT -- "Because BEI developed and Prosoco manufacturers liquid-applied WRBs for building assemblies, and the companies want to show off how much better they perform than more-common WRBs ..." and THEY built & run the test chambers. Should we then be surprised that the product(s) are shown in a desirable light ? As Saint Reagan used to say "Trust, but verify."

Great discussion here

Hi all, great discussion, and we respect the comments about independent testing. At PROSOCO, we routinely use independent laboratories to test our products to current industry standards. However, those standards measure to a low denominator that we liken to today’s building codes. Because we strive to go far beyond those standards in making products that sustain real-world weather conditions, we invested in this testing chamber that measures actual conditions – the ones that are the genesis of the failure of many buildings today, and the ones that our products are built to withstand.

Test chamber rigors

Peter,

I've been at the testing facility a few times and happened to be in the same group with Alex Wilson on this trip. It's a serious chamber. The loads applied make it difficult to rig a test to have one product succeed and another fail. These folks are zealots. A group I can easily fit in with.

I've (The Small Planet Workshop) got two panels that are in line for their "day of reckoning" in the large chamber:

1- Thermacork Facade grade 100% natural cork. We recommend applying the cork over Prosoco Cat 5 for various reasons: one being self sealing for fasteners, the other as it's a perfect adhesive to adhere the Thermacork Facade to the assembly. I'm looking forward to seeing how it does in a straight up hurricane.

2- The other panel is a simple air leakage test for our tongue and groove Agepan. There has been interest in using the high perm sheathing as the primary air barrier. We think it will work. But... As you say: Trust but verify.

Full disclosure: we sell the whole line of Fast Flash products and we are really happy to do so. Our company is lucky to be able to help the market improve its skills, products and techniques with what I think are the two most advanced air barrier/WRB product lines there are to date: Siga and Prosoco.

For us, it doesn't get better.

Skylar... Mind the gap!

Skylar, it's funny that you brought the gap topic up in this thread. We've just been working along those lines with Hanno. They commissioned a study by Prof. Dr. Ing Leimer of BBG Institute Germany.

The results were presented at the PHnw 5 conference this past March. The upshot is that an uninsulated gap can collect and condense moisture and lead to poor performance and damage. The PP is pretty interesting. I'd upload it but I'm traveling with just an IPad.

We just got our first stock into The Small Planet Workshop this month and have the first projects starting. I made this change because I still feel the GAP issue is valid and the prior product we were working with was difficult for our builders to have success with. You can see it at: http://www.smallplanetworkshopstore.com/hanno-band-3e-64-6-15-23ft-4-bx/ or email

I like this for "innie windows" that are placed in a well flashed buck (Prosoco or Siga). Backing up the interior with Siga Corvum or Prosoco Air Dam is optional.

Malcolm, I agree

We need a write up on liquid applied flashings vs. tape flashings for air sealing plywood, Zip or osb. I haven't heard anyone mention using backer rod with Prosoco for panel joint air sealing. With three sided adhesion there may be potential for failure. Moisture level in panels can change and thus the gap will also change putting stress on the liquid flashing at the joint.

Albert & Debra

I concur with your comments. I really can't see using Prosoco caulk to fill a 1" - 2" gap on all 4 sides of a window with the hope that years later after everything is sealed up that it won't leak. It's not fun tearing apart a wall to access the window to try and seal it up again. As mentioned, the caulk has zero R-Value and it's better to use something that is at least a thermal break or R-Value of some sort.

Albert, do you recommend the Hanno Band expanding foam tape around the perimeter of a window and then using Prosoco caulk on the exterior portion as a belt and suspender approach to seal the window? The Hanno Band foam will remain flexible throughout its life and move with the dissimilar surfaces and provide an air and thermal barrier between the window frame and wood/concrete window buck.

Here is the build-up I think would work better:

Tremco or Hanno Band Expandable Polyurethane Foam Tape around window frame area

Prosoco caulk around the window frame and exterior window buck

Prosoco Cat5 around the entire exterior window buck area

Peter L

I have been installing windows with a 1/2" gap on all sides. Backer rod and Prosoco Air Dam works well in that case and would probably be bettor in combination with the expandable foam.

Where I was talking about was not on a window install but on an air seal where two plywood or osb panels meet. The gap is usually 16 d nail or wider it the weather is bad. This gap can close in an instant if the panels get wet. Flashing tape spans the gap. Prosoco fills the gap along with adding a 2-4" wide band of liquid flashing. I would like to understand the dynamics of this system. My concern is at the joint between the panels when the moisture content in the panels change. With Prosoco there is three sided adhesion.

Taped Tyvek and Typar WRB Perform Worse

...would be a more accurate subtitle, Martin. They are porous and are not waterproof. If they had used Pro Clima's SOLITEX Mento 1000 WRB (we sell this), which is a nonporous monolithic membrane that can hold a 30 foot water column, the liquid applied membrane would not perform better.

Response to Ken Levenson

Ken,

"...would be a more accurate subtitle, Martin."

Alex Wilson is the author, not me. I'm not sure how many brands of taped housewrap have been tested in this facility.

response to Martin

Martin, Sorry for any misattribution. I was under the impression that you wrote the headlines and subheadlines or rewrote them as it were when they appeared on GBA.

Peter & Debra

This is the hard part for me. I think these are all exceptionally good systems.

Debra, To air seal panel joints in the field of a wall at the APA suggested 1/8" gap between panels. Prosoco recommends Joint & Seam Fill, then top coated with Fast Flash or Cat 5 if there is a bulk water potential. The reason for top coating is that the J & S contains fibers that can wick moisture. If there will be no bulk water contact (like under layers of rigid insulation or interior applications) then top coating is not necessary. In this application the material is flexible enough to handle the panel movement. The aged samples we've put together are doing well.

Btw... Tape joints with good tape rock! They do stay in place for a very long time.

Peter: You would not fill the entire gap with Air Dam. It's just a bead spanning the gap. You can apply it against backer rod. Your question about applying over Hanno 3E expanding foam tape is good and that people often ask. If you feel that your physic requires a belt and suspenders, then no worries. Go for it. My feeling is that if the Hanno is applied reasonably well, then there should be no fear of plumbers butt. If a crack does show itself (sorry all) during a blower door test, then you can apply some caulking to it.

When the Hanno installation is working for the builder, it's installing windows quickly by fewer steps and providing insulation in the gap along with sealing it in permeable layers. At roughly $2 per foot it makes sense (to me) if you can instal your application with just the system elements.

Having said that... There is nothing wrong with any of these systems. These are the best out there in my opinion. It's not a choice of good and bad, it's a choice of which really good system do you want to use.

Log in or create an account to post a comment.

Sign up Log in