By Jim Coler

When shopping for spray foam insulation, many builders and homeowners are uncertain whether to choose an open-cell product or a closed-cell product. In my opinion, the choice is clear: for above-grade residential applications, the best choice is usually open-cell foam. In most cases, open-cell foam will be more economical, more flexible, and more forgiving with moisture than closed-cell foam.

Open-cell spray foam is often called “half-pound foam,” a reference to its usual density of 0.5 lb. per cubic foot. (The range of densities for open-cell foam actually extends from 0.5 up to 1.7 lb. per cubic foot.)

Open-cell foam was first introduced to the market in 1986 by Icynene. At that time, all of the available spray foam products on the market were closed-cell foams. Since about 2003, however, many manufacturers have been marketing both open-cell and closed-cell foams.

More volume from the same weight

Although closed-cell foams claim to add structural rigidity to a building, the structural contribution is not necessary. In fact, most structural calculations are based only on the strength of the wood or structural members, excluding any contribution from spray foam.

The weight of the raw materials required for open-cell foam is less than for closed-cell foam of the same R-value. As long as you have the cavity thickness to add more insulation depth, open-cell foam will cost less per job and per R-value measurement.

Closed-cell foam is between 3.4 and 4 times more dense than open-cell foam, so a barrel of open-cell foam fills 3 to 4 times the volume as a barrel of closed-cell foam. The R-value of open-cell foam is between R-3.5 and R-4 per inch, while most closed-cell foams are R-6 to R-7.1 per inch. Since open-cell foam uses one-third the material to produce a product which is more than half the R-value, open-cell foam is more economical than the same R-value of closed-cell foam.

It’s Vapor-Permeable

Open-cell and closed-cell foams are air barriers. But open-cell foam will absorb and release moisture vapor more freely than closed-cell foam — which is a good thing. This means it will perform much like wood. Open-cell foam is compatible with wood construction; both materials are air barriers that can absorb and release moisture.

Closed-cell foam, on the other hand, blocks most of the moisture and tends to drive it to the wood studs or rafters. This can cause the wood to expand and contract more than it does with open-cell foam. Open-cell foam provides more moisture-permeable surface area for excess moisture to absorb into and dry out of; that means the areas are less likely to become moisture-saturated if the moisture within the building is within control. Open-cell foam acts as a moisture buffer; it helps maintain a more consistent moisture level within the building, which is healthy.

But moisture in insulation is bad, right? Well — yes and no. Too much moisture in any material can cause issues. Too much moisture in wood may create an environment for mold and mildew. But foam has no food source for mold and blocks additional oxygen which is needed for mold to grow. This creates a more stable and healthier indoor air quality and environment.

Environmental strengths

There is an industry trend towards using soy oil or other bio-based oils in open-cell foam formulas. Open-cell foam uses a water-based blowing agent; in other words, water is used to cause the foam to expand. A water-blown foam is more stable and more environmentally friendly because it is a natural product. In contrast, most closed-cell foams use a hydrofluorocarbon (HFC) blowing agent. Although HFC blowing agents increase the R-value of foam, they offgas over time, causing the R-value to decrease. This slight added benefit does not outweigh the environmental effects that may be caused by the HFC. The more natural our raw materials, the safer the products.

We are all obligated to do what’s right — what’s right for our health, for our finances, and for the environment. Open-cell foam helps us accomplish all of these with a great return on investment.

To read another perspective on the issue, see “Closed-Cell Foam Beats Open-Cell Foam.”

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

26 Comments

Open versus closed cell foam

The problem with open cell polyurethane foam is that as far as I know it is failry permeable to air, so another matieral must be applied to serve as an air barrier membrane. The closed cell foam can serve as both insulation and air barrier, eliminating the need for a separate membrane.

Sorry, Greta

Greta,

You are mistaken. Open-cell spray foam is an excellent air barrier. However, it is not a vapor barrier; it is fairly vapor permeable.

When installed in a cold climate between the rafters of a ceiling to cathedralize an attic, open-cell spray foam needs to be protected with a vapor retarder to prevent water vapor from diffusing through the foam and contacting the cold roof sheathing. But it doesn't need an additional air barrier.

Open vs. Closed Cell Faom

It is nice for someone to say that open cell foam is an air barrier but what is that statement based on?

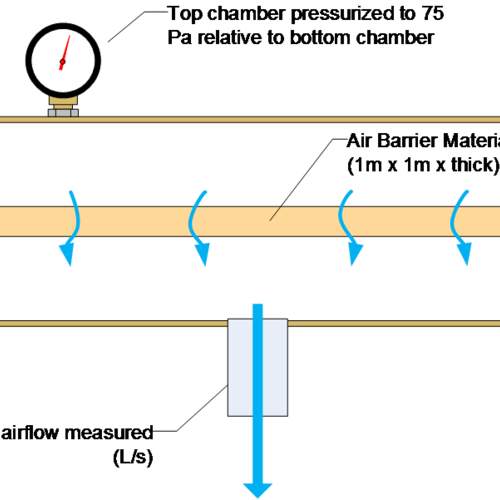

Where states have air barrier material requirments, they require 0.02 l/s/m2 at a 75 Pa pressure difference to qualify as a air barrier material. I have asked all of the open cell manufcaturers for a copy of a ASTM E 2178 test report where the test procedure has not been modified, the material has not been sprayed on a substrate, where the results of the test shows that the air permeance is less than 0.02 and where the tickness tested is identified. I have not seen one.

What I have seen is manufcaturers conducting ASTM E 283 tests on very small specimens and then exprapolating the results to a 1 meter to 1 meter specimen. As such it is very hard to get accurate air permeance results when the test specimen is 50 mm by 50 mm or even 100 mm by 100 mm. What equipment is available today that is accurate enough to get a proper value? I have hard enough time getting equipment for the ABAA research project where the test panels ate three m2.

Interesting!

Laverne,

I'm delighted that you posted; very interesting information. I hope that an open-cell foam representative comes forward with laboratory data.

Sound Control

Would love to hear some perspectives on the "sound control" attributes of open cell vs. closed cell foam. Any material differences for a spray of the same depth?

Air Barrier It Is

Laverne, et al:

I'm no advocate of spray foam of any density, but your refusal to accept the tested air resistance of open-cell foam makes me wonder what product you ARE selling.

I have a copy of an ASTM E-283 test report, dated 6/26/2000, AIR-INS inc. # AI-01645-A, which documented two 1M² samples of Icynene - 3.25" and 5.25" thick - sprayed in a wooden frame with center dividing member, backed by tar paper interrupted at the center divider (which, itself, is not an air barrier), which resulted in 0.008 and 0.0049 L/sec respectively.

To state that testing the material in an assembly that mimics real-world applications is less stringent that testing the material in isolation, suggests that you either don't understand the facts or have an agenda.

In fact, the Air Barrier Association of America allows assemblies to be ten times as leaky as materials: 0.20 l/sec-m² @75 instead of 0.02.

Ironic

Jim,

I find it more than ironic that your emphasis on the hygroscopic qualities of open cell foam is adamantly resisted by the open-cell industry. All the advertising claims that open-cell foam does not absorb and hold any significant amount of water (which isn't true), and that its value is in its hydrophobia.

If you were really concerned about moisture buffering in the thermal envelope, then you should be advocating dense pack cellulose, which has the highest safe moisture storage capacity of any commonly available insulation material. In fact, cellulose insulation is so much more hydrophilic than wood that it is protective of wood framing and sheathing materials.

And the claim that foam has no food value for mold growth is irrelevant, since mold will grow quite nicely on plastics, feeding on any dust or other organic material, and bacteria prefer plastic to wood as a growth media.

Open-cell foam more difficult to install correctly

I'm not a builder but I have done quite some research on the topic and one issue I have come across multiple times (e.g. on contractortalk.com) is that open-cell foam can easily cause major mold issues in colder climates. Essentially what happens is, in sub-30 conditions vapor entering the wall from the inside will condense and eventually freeze somewhere on the way to the outside. Simply speaking, the temperature inside the foam insulation gradually drops from indoor temperature at the inside surface to outside air temperature, with freezing point some in between.

Come warmer temperatures, all the frozen moisture will form water which seeps down and eventually out of the foam (temperatures likely won't permit a gradual evaporation but rather simply melting), causing water damage and possibly mold. So while the foam itself is no source for foam, the water build-up and leak is.

I forget what the proper procedure is but I think it was vapor barrier on the inside to prevent any moisture from entering the foam in the first place. One case I read about, the vapor barrier was done poorly in a few spots, and that's where the mold occurred.

Therefore, for all I know this additional vapor barrier necessary in colder climates will prevent most of the beneficial effects that the author cites since he specifically refers to indoor moisture and indoor quality.

So I could see how open-cell foam will likely work well in warmer climates with less need for insulation and with less complicating factors. But in colder climates I believe closed-cell foam plays out its advantages. And speaking about the R-value, In our 100year old home up here in NH, the outer wall cavities are barely 4 inches thick. With closed cell foam we almost double th R-value compared to open-cell foam.

Just my two cents, Christoph

open cell spray foam

It seems that most of the spray foam contractors are intent on applying the foam to the roof rafters even if there is no heating/AC equipment in the attic and even if the attic will NOT be turned into living space. Could it be that more material is required by that application, i.e. they sell more product. And/or does this make for an easier application than spraying the attic floor. I am reluctant to give up my soffit and ridge vents in our climate-Zone 5 near Pittsburgh. Any comments are welcome. We are checking into removing the old fiberglass and spraying open cell OR leaving the old fiberglass and covering with rigid foam panels. Any comments are welcome. RgN

Open cell spray foam

In a climate such as SC is it necessary to put in ridge vents with open cell spray foam. And if not is a vapor barrier needed?

Venting and vapor barriers

Clinton,

For more information on venting, visit:

https://www.greenbuildingadvisor.com/green-basics/vented-or-unvented-attic

For more information on vapor barriers, visit:

https://www.greenbuildingadvisor.com/blogs/dept/musings/vapor-retarders-and-vapor-barriers

Air barrier it is! Tested!

Laverne,

To answer your question, ASTM 283 does apply to the product we're talking about. This is because the air spaces and gaps it fills are typically less than the 1 meter squared sample. The gaps and cracks are typically smal gaps and cracks which are air sealed by open cell foam. It is intersting how you're touting ABAA standards as it's the only way to go, but there are other air barrier standards whcih seem to be totally applicable!

Moisture Barrier or Air Barrier???

This is a good discussion about moisture vapor transmission! A 100 sqft of air sealed drywall allows 1 pint of moisture to pass through this material. Now, putting a 1/2" hole in the drywall allows 50 pints of moisture to pass through. This is about equvalent to the gaps around your outets and switch plates. So, this demonstrates that more moisture is transferred through AIR than through any material. So, is it a moisture barrier that's required or an air barrier? Most moisture barrier materials are sheet materials like sheets of poly that are improperly sealed and not sealed around the outlets and such. So, how is this good? It's not! So, what's the alternative? A spray applied air barrier which also insulates!

This prevents condensation from occuring which happens when you have a cold surface in a warm moist environment! A glass filled with ice water will condense on the outside of it because the warm moist air is rushing to the surface to transfer the heat (which it does) but it drops the moisture on the surface of the glass. So, if you take the same ice water and put it in a foam cup, it doesn't condense! This is because you don't have a cold surface for it to condense on.

On top of this, the codes don't require a vapor retarder in the ceiling and it's actually not recommeded. So, why do we need a vapor retarder in the walls but not in the ceiling? It doesn't make sense! So, why not use a more foregiving foam which is more economical in all places? That's why we use open cell even up the in the North Country of NY and I've never had a problem that wasn't a result of install quality. This is where it is -in the quality of the install.

If it's an air seal then it provides the majority of all vapor drive concerns. Now, in special applications such a s wet basements, walk in freezers, and some buildings which tend to have more moisture and less control, we will recommend closed cell.

Insulating a brick wall

I have a client with a brick gable wall exposed in a 100 + old town house setting in Boston. I think the house next door was removed and this exposed athe gable brick wall that was not build to be exposed. The inside of the gable wall has about 2 inches of fiberglass insulation between wood studs. Moisture is present in the wall and visible moisture damage is present at the stairs to the 2nd. and 3rd. floor. QUESTION: would either open or closed cell foam insulation be a good replacement option for the fiberglass insulation? I am concerned with the exterior moisture penetrating the brick wall. The wall space is only 2 inches and with no room for a proper drain screen between the insulation and the gable brick wall.?

Response to Flemming

Flemming,

Insulating a brick wall makes the bricks colder, and therefore wetter. In some cases, insulating a brick wall makes the wall more vulnerable to freeze/thaw damage.

It takes an experienced building science consultant to assess the risk factors in such cases. Do roof overhangs protect the walls from rain? How cold does it get during the winter? Are the bricks and mortar very absorptive or only somewhat absorptive?

There is no simple answer to your question.

You should use the search function of the GBA Web site to research this issue. I suggest you use the search terms "brick insulate."

You might want to check out these pages:

https://www.greenbuildingadvisor.com/blogs/dept/building-science/how-do-you-retrofit-old-building-be-energy-efficient-and-durable

https://www.greenbuildingadvisor.com/community/forum/energy-efficiency-and-durability/16175/old-brick-house-and-little-money-whats-soluti

https://www.greenbuildingadvisor.com/community/forum/energy-efficiency-and-durability/16824/how-do-i-best-insulate-my-8-brick-exterior-wa

In addition, I strongly advise you to read "Insulating Residential Masonry Buildings In Cold Climates" by Chris Benedict (in the the current edition of Home Energy magazine, March / April 2010).

Good job Jimmy

r-Value takes a back seat to performance. Air Barrier ASTM e-283, Dead on.

R-20 closed cell foam = 3" R-20 open cell foam=5.25"

5.25" = 95.5% reduction to heat flow. 3" of closed cell foam = 93% reduction to heat flow.

Open cell foam = better value / R than closed cell foam. No brainer.

Keep up the good work.

seeking advice about OC foam and vapor

From all of my research on the net, this site seems to have the most intelligent participants! Therefore, I am seeking your advice. I have built a small "green" residential structure that I intend to frequently escape to. It has a metal roof, but no decking under the metal sheets. It has cathedral ceiling with 2x6 rafters (plus 1X4 furring strips of which the roofing sheets are attached). Every rafter is attached with hurricane clips, although I'm nowhere near coastal waters. It also has a loft so there is no attic.

I wanted a good thermal barrier so I did not skimp on the insulation cost; the entire structure is enveloped with Open Cell foam spray. The OC spray foam is adhered directly to the underside of the metal roof panels. Should I install a vapor retarder between the foam and the interior ceiling material? I was thinking about using weathered corrugated barn panels for the ceiling. I like the rustic look, but don't want to make the wrong decision and regret it later. The rustic barn tin on the ceiling seems to be the in thing in this area. Other ceiling applications are not out of the question either.

I also invested in really good vinyl windows. The exterior wall layers are; OC spray foam in 2x4 framing, OSB sheets (attached to framing), then house wrap, then plywood siding. This information may or may not be pertinent when giving your valuable advice.

Sorry to have written so much-- just seeking professional advice. Hope someone can help soon.

Floater

Response to Floater

Floater,

No one can answer your question without knowing your climate.

In cold climates -- say, climate zones 5, 6, and 7 -- you definitely want a vapor retarder on the interior side of open-cell spray foam.

By the way, your decision to spray polyurethane foam directly on the underside of your metal roofing was a mistake. When your roof begins to rust and it's time to replace your roofing, the job will be a nightmare. All your metal roofing will need to be removed; with your insulation adhered to the metal, it will be a difficult job -- and you'll have to insulate your roof all over again.

thanks

Thank you for your response and for answering my vapor barrier/retarder question. I live in Southern Missouri/Northern Arkansas area; maybe Zone 6? I really don't know.

Regarding my mistake, I figure it will be many years before my green architectural metal roofing will rust. I will probably sell the place way before then, but thank you for your concern nonetheless.

Floater

ASTM 2178

Hi Laverne, Icynene has been successfully tested to meet the requriements of ASTM 2178. i have a copy and i'm sure icynene would be happy to provide to you.

Ice damming with OC foam

I am constructing town homes in Iowa where the zone is 6. The homes are slab on grade so it requires that all the HVAC to be place in the attic. The entire envelope of the home is done with OC foam. The underside of the roof has anywhere from 6" to 8" of foam and putting my HVAC in conditioned space. I am experiencing major snow melt and ice damming on these roofs when the are completely covered with snow with an outside air temp. at as low as 0 degrees.

I'm feeling I missed a major element in the equation by not sealing the underside of the foam.

I am still able too apply the sealer and am thinking about spraying it with Suppertherm or a good latex paint. But I do not want to trap the moisture at the roof sheathing or worse yet have it raining in the attic.

Sorry to be long winded

Thanks in advance for you comments

Open Cell Foam

Has anyone ever noticed open cell foam starting to develop any sort of an odor or mold growth under any circumstance? I will be using some inside of a vehicle door for sound dampening and I can not have this happen.

Response to Iowa Builder

Iowa Builder,

The 2006 IRC requires a minimum of R-49 ceiling insulation in Climate Zone 6. That requires about 13.5 inches of open-cell spray foam, much more than you have installed. (Your roof is insulated to only R-22 or, at most, R-30 where the foam is thickest.)

Your insulation is insufficient and may be illegal.

In a cold climate like yours, open-cell spray foam installed on the underside of roof sheathing should always be protected with a vapor retarder. The easiest way to do this is to spray the underside of the cured foam with vapor-retarder paint. This paint will not trap moisture.

Response to Cole

Cole,

Mold can grow almost anywhere if the moisture level is high enough. The best way to control mold is by controlling moisture.

I'm not sure whether moisture accumulation is a problem in vehicle doors, however.

Urethane Foam Problems

I had Demilec Sealection 500 (two part open cell urethane) installed into my home this past November. It has been an absolute nightmare. Same issues as other posters. Constant odor and associated resperatory distress. Unlike other homeowners, I ventilated the space from day one (for four months now), and it has not helped one bit. I have spoken with the EPA and I am in the process of undergoing independant air testing. From my discussions with EPA it has become apparent that removal of the foam can create its own set of new problems as airborn particulates created when the foam is disturbed can present additional problems. I Am a lawyer, though I do not specialize in tort actions or product liability. I am however looking to connect with other homeowners who have had a similar problem. I have little doubt that in the end I am going to have to tear out the shingles, roof decking, and rafters to resolve this nightmare. God only knows what the long term effects of this exposure will be. I would like to coordinate a discussion group and share experiences, health problems, and test results.

This is not meant to be an attack on the industry. I am not trying to engage those of you who have had good results from properly installed foam. My concern is finding a way to help myself and those others who have experienced the nighmare of issues relating to an improperly installed product.

Pease contact me at [email protected] only if you are experiencing similar problems.

Upstate NY

I plan on re-insulating a 1960's 2"x4" wall framed house. I am removing both the interior wall panelling and cavity fiberglass and the exterior sheathing.

Would it be best to use closed cell or open cell spray foam OR BOTH? Would it make sense to just use 1" of closed cell to air/vapor seal and then pad out the rest of the cavity with open cell? In conjunction with an exterior insulation.. or just use ALL OPEN cell. in the cavity. If just open cell should I be adding an internal membrane and then would a 2" foam on the exterior be a good match for open one side closed on the outside? After all my reading I gather one side of the sheathing needs to be vapor open?

For the roof I plan on using 6.5" of closed cell. The existing roof was replaced a few years ago. I am furring down the 2"x6" rafters with 2"x4"s with a .5" gap between for thermal break. Is the .5" gap worth the trouble?

Scary to hear about your experience John, hope my installers don't mess it up!

Any input would be appreciated!

Log in or create an account to post a comment.

Sign up Log in