Image Credit: Jeffrey Sauls

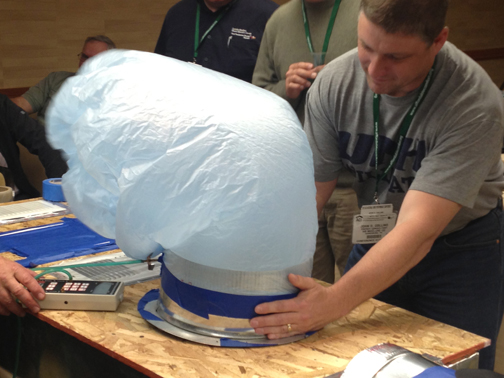

Image Credit: Jeffrey Sauls Bruce Manclark is discussing a flow hood. I'm in the background, holding my head. (I'm standing next to Jeffrey Sauls of Energy Vanguard, who appears to be praying.)

Image Credit: Allison Bailes

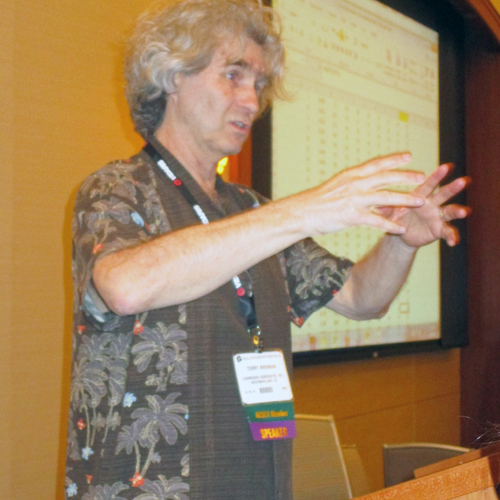

Among the multitude of sessions at the ACI conference in Denver recently (a total of at least 180 sessions by my count), there was a very interesting half-day workshop on airflow testing hosted by Bruce Manclark and Paul Francisco. Their setup included simulated HVAC ducts of various shapes and sizes, and they used a Minneapolis Duct Blaster to provide air flow to test various measurement tools.

They demonstrated various methods of air flow measurement, including the use of flow hoods, large-vane and hot-wire anemometers, pito tubes, and, probably most interesting, the surprisingly accurate garbage bag method.

Before we get to the various measurement methods, a note on the “hosing” mentioned in the title of this post. In order to provide a specific amount of airflow to be measured, Bruce and Paul used the aforementioned Duct Blaster, connected to a manometer with a hose to provide air flow at a specific CFM to the ducts to be measured. While one attendee watched the flow rate on the manometer, several methods of measurement were demonstrated on rectangular and round supply registers.

Unfortunately, regardless of the method used, the amount of flow coming out of the registers never quite matched what was coming through the fan. After over an hour of testing and retesting, Bruce opined on the problem, suggesting that the Duct Blaster fan could be incorrectly calibrated. One of the attendees pointed out that whenever he has trouble with flow measurements he uses a different hose. Although the session leaders were skeptical, they agreed to give it a try.

Success!

In a matter of seconds the hose was changed, and like magic, the flow measurements started matching up and making sense. Although a little embarrassed by the episode, Bruce and Paul rallied and continued with their workshop.

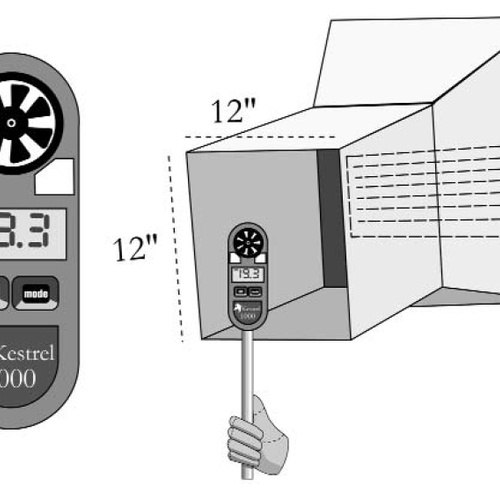

Disregarding the hosing and resulting problems, one of the main takeaways from the session was that it is pretty hard to accurately measure airflow in duct systems and exhaust fans, something that reinforces my admittedly limited experience. Devices available to measure airflow include the previously mentioned anemometers, flow hoods, a pressure pan, a True-Flow air handler flow meter, and garbage bags.

Wide-vane anemometers can be moved around over grilles to obtain an average airflow or attached to a hood that fully covers a register, a method that appears to provide better accuracy. Hot-wire anemometers are used most often to measure pressure inside a duct through a hole drilled in the side, moved back and forth to obtain an average pressure throughout a duct.

Flow hoods appear to have varying degrees of accuracy, and can be difficult to hold in place. Pressure pans, used to measure exhaust flow only, are fairly simple, but it is critical to open the small door on them to the correct location for the airflow, and to match the manometer setting to obtain an accurate reading.

Simple and cheap = Accurate

Which leaves us with the garbage bag. By simply calculating the volume in a standard plastic garbage bag, and timing how long it takes to fill up or empty completely, you can fairly simply calculate the CFM of almost any supply or return register or exhaust fan. This method works best with two people – one to hold the bag and one to time it – but man, it sure is cheap and simple, and apparently, pretty accurate.

My takeaway from this session is that flow measurement is a difficult and somewhat inexact science. In my experience on building certifications, I have done a minor amount of flow testing, primarily of exhaust fans, and I have reviewed third-party test and balance reports provided to me by clients. In almost all cases, air flows are not close to the design and, since most residential ductwork is inaccessible, air flows are difficult if not impossible to adjust to meet designs.

I know that there are people out there meeting Energy Star 3.0 certification that requires HVAC systems and exhaust fans meet designed air flows. I would be very interested to find out if in fact they are really meeting the requirements, and how they are doing it.

I both look forward to and slightly fear the opportunity to test and verify these conditions myself on upcoming projects.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

7 Comments

Carl,

Did they test both

Carl,

Did they test both powered(flow blaster) and unpowered hoods(alnor)? What was the most accurate method? I have a hard time charging contractors to test the air flow with a garbage bag regardless of how accurate it is. Is there an explanation as to what caused the hose to give a less than accurate reading? thanks for your input

Flow hoods

They did demonstrate both powered and unpowered hoods. I don't recall the test data but it was discussed that the powered hoods are more accurate as well as really heavy and a pain to hold over your head for very long. They did point out that avoiding the shrouds on flow hoods and placing them directly over registers gives a more accurate reading.

Interesting

We routinely use a flow hood and room-by-room Manual Js to diagnose and resolve individual room comfort issues. While I can't speak to absolute accuracy of our methods, we bat 1000 resolving the client's comfort issues. That is probably because comfort issues tend to arise only when rooms' air flows are grossly out of whack, 30-200% or more. Dampering as necessary to get flow to within 10-20% tends to resolve the problems.

My gut reaction (perhaps wrong) is that a flow hood shroud helps to "condition" the register air by dissipating and averaging high velocity regions.

I haven't dipped a toe into E-Star 3 yet.

Photo

Allison Bailes shared this photo from the above mentioned session with Bruce Manclark discussing a flow hood and me in the background holding my head standing next to Jeffrey Sauls of Energy Vanguard who appears to be praying.

http://www.flickr.com/photos/affordable_comfort/8734725995/in/photostream/

Accuracy

First off Bruce Manclark is a great trainer. I have learned much from him over the years and encourage colleagues to attend his sessions when they can.

Carl “difficult and somewhat inexact science” I don’t know what your definition of difficult is but holding a device over a register and pushing a few buttons, really. Plus or minus 5% – 10% for testing airflow IMHO is close enough for residential design. If you’re seeing larger disparities then that something’s probably wrong, maybe try a different method or put it into context with the situation. The problems not with the tools it’s in getting people to use them. Some easy method of calibrating the tools would also be good step in the right direction. If you’re looking for accuracy EC’s kit with your duct blaster is hard to beat, the 12 pounds will be a good work out for you.

“In almost all cases, air flows are not close to the design and, since most residential ductwork is inaccessible, air flows are difficult if not impossible to adjust to meet designs. “ I assume you’re talking about bath fans? It’s pretty easy to look and see if it will work at the rough in stage. A 90 right off a bath fan is sure to kill its flow. HVI has the fan curves for most fans and calculating duct resistance isn’t exactly rocket science. Quality manufacturers like Panasonic also provide good recommendations in their installation manual. If you’re talking about forced air ducts the balance dampers need to accessible to balance, no?

Folks that are looking for more empirical data on the accuracy of airflow measuring devises both in the lab and field can read about work done by LBNL.

Measuring Residential Ventilation System Airflows: Part 1 – Laboratory Evaluation of Airflow Meter Devices

http://buildings.lbl.gov/sites/all/files/lbnl-5983e_0.pdf

Measuring Residential Ventilation System Airflows: Part 2 - Field Evaluation of Airflow Meter Devices and System Flow Verification

http://homes.lbl.gov/sites/all/files/lbnl-5982e.pdf

Difficult and Inexact

Richard - Thanks for your input. I agree that Bruce is a great trainer and incredibly knowledgable on the subject of air flow. The difficulties I was referring to include both exhaust fans and duct flow and balancing. I agree that ducts from exhaust fans need to be designed to provide adequate flow or they won't meet specs. I see more problems with HVAC supply and returns in homes not meeting specs, and since they are almost always hidden behind drywall with few if any dampers installed, balancing them to meet the design is a huge challenge. I don't do this work myself, but I typically review 3rd party T & B reports provided to me for LEED and other certifications, and rarely find one that meets the design specs within the allowed margin of error.

As to the challenges in measuring the flow - as demonstrated in Bruce and Paul's session, different devices will deliver different measurements of the same register. Two different brands of flow hoods come up with different CFM rates. Wide vane and hot wire anemometers some up with still different figures - the these are challenging to hold the right place long enough to get an accurate reading. My point was that there are many options available to measure flows and to the relatively inexperienced professional in this sub set of building performance (such as myself) it is a challenge to decide which, if any device to purchase, and have confidence that the readings it provides are consistently correct.

Our findings

The upshot of the two reports cited by Richard is that most flow hoods can measure RETURN flows with acceptable accuracy (plus or minus 10%).

However, SUPPLY flows are much more difficult to measure. Based on 400+ field measurements and 1000+ laboratory measurements, we determined that only the powered flow hoods can reliably measure supply flows with sufficient accuracy (plus or minus 10%). We were considering their use for measuring ventilation airflows; for other applications the accuracy criteria may be different. The question "How accurate is accurate enough?" should always be considered.

My sense is that the garbage bag method can yield accurate results. However, its accuracy is heavily contingent upon the skill of the practitioner at using the measurement technique. And there's also the issue of client perception that Chaz brought up.

Log in or create an account to post a comment.

Sign up Log in