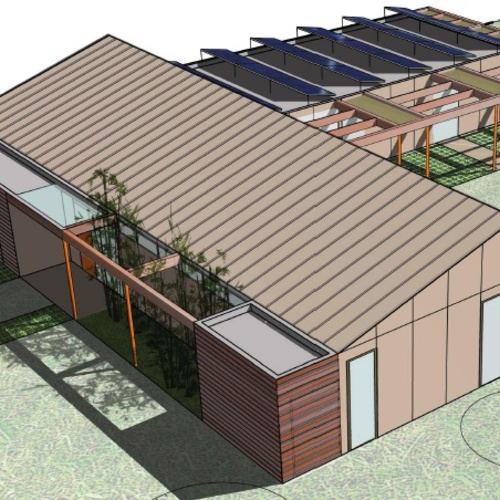

Image Credit: Wes Gerrish and Sevag Pogharian Design

Image Credit: Wes Gerrish and Sevag Pogharian Design On May 25, a fire that started in the attic of the house prompted a response by more 30 firefighters. Though the house was completely destroyed by the fire, its designer and builder, architect Sevag Pogharian, said he will rebuild it pending a settlement with the project’s insurer.

On August 29, 2007, Montreal-based architect Sevag Pogharian broke ground on Alstonvale Net Zero House, a project whose ambitious energy efficiency design earned it one of 12 berths in the 2007 edition of the Canada Mortgage and Housing Corporation’s EQuilibrium Sustainable Housing Demonstration Initiative program.

Pogharian, who founded the firm Sevag Pogharian Design in 1990 and eventually expanded its services to include not only residential design but construction, intended Alstonvale Net Zero House to embody extremely high standards of sustainability, energy efficiency, and comfort while still meeting a price target that would compare favorably to prices of other homes in Hudson, a prosperous community near Montreal. The house was designed to generate all the energy needed for its operation and for the household’s transportation needs, and it would feature home-scale agricultural components, including a greenhouse, to help feed the home’s occupants.

But on May 25, 2010, the nearly completed house burned almost to the ground. “I feel crushed,” Pogharian wrote that day in a blog entry on his firm’s website. His insurer is still investigating the incident, although Pogharian noted in a story recently published by the Hudson-St. Lazare Gazette that preliminary evidence points to combustion of polyurethane foam that had been applied in the attic earlier in the day.

Thinking through the possibilities

It was indeed a warm afternoon, reaching about 85 degrees Fahrenheit, when workers sprayed the polyurethane foam in the attic. The crew also ran a fan in the space to help ventilate it, although the fan was removed when the workers left at about 2:30 p.m. But if the foam in fact caused the fire, Pogharian observed, it’s unlikely its combustion was due solely to warm air in the attic. Instead, the lack of air circulation may have increased the concentration of combustible gases in the space, which could have caused the foam layer to thicken more than anticipated and further trap heat.

“I’ve come to learn a lot about polyurethane since the fire,” he told the paper. “It’s an exothermic reaction. You mix these chemicals, it gives off heat, and in the process it inflates. One of the things with polyurethane, if you apply it too thickly, the heat that is generated inside is not dissipated. It is an excellent insulation and it can combust.”

Pogharian’s initial responses to the disaster – depletion and inertia – changed for the better as time passed. He says he now is more motivated than ever to see the project to completion, pending settlement with the insurance company, which has already covered demolition expenses.

“I want to push this thing so it sees the light of day – the whole concept – the house, the car, the edible landscape, the net-zero greenhouse,” he told the Gazette. “I can walk away, or I can plunge in and try to get it done. If the insurance stuff gets worked out, there is no reason not to do it.”

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

20 Comments

Exothermic Reaction

I thought that foam installers were informed about this danger as part of their basic training?

Training...

John,

You're in a very hot attic on the hottest day in May -- you're dressed in a Tyvek suit and you're breathing through a respirator. Afternoon comes along, and you're dripping sweat. This job is taking forever and you really want it to be done.

When you were trained, you were told, "Only spray a maximum of 2 inches per lift or the foam can overheat." Really, now -- wouldn't you be tempted to spray it on just a little thicker? What harm is there in that?

Just say no

We've done new construction w/ foam and without, I've come to the conclusion that there's just no compelling reason to use any foam (spray or rigid) in new construction other than sub-slab and perhaps the basement rim. Double wall with cellulose is no more expensive, and has a variety of advantages that Robert will be happy to beat you over the head with. Especially with more and more data on the blowing agents, I hope that Pogharian finds an alternative next round.

Closed Cell vs Open Cell

I have heard of the 2 inch maximum per "lift" for Closed Cell.

I have asked foam suppliers about Open Cell .. but never got an answer for a Maximum "lift" thickness on Open Cell.

They usually just ask me "why would you ever want more than 5 or 6 inches?"

Is there a maximum safe "lift" thickness for open cell?

Foam Salesmen Driving Me Nuts

John - I just had the same conversation and got a very long response that did not answer my question. I have a homeowner that wants to use foam so I of course recommended 8" in lieu of 5" for the open cell to meet our code minimum of R-30. When I asked our salesman to price the extra 3" inches, all he did was try to talk me out of it and told me about diminishing returns and how 8" will not perform any better than 5". I had to stop him and ask - are you really going to try to talk me out of paying you more money to install more of your product? How could you possibly say that R-32 is not better than R-20. I think these guys are getting brainwashed by their manufacturers and loosing their common sense.

Sad story about that house but thanks for posting this article - will really pay attention when they are installing this stuff.

Response to John Brooks

John,

You can find the answers to your questions in the ICC-ES evaluation reports. (Here's one for Icynene:

http://www.icynene.com/assets/documents/pdfs/Architect/ESR-1826Report.pdf .)

According to ESR-1826, "Where Icynene LD-C-50 is used as an air-impermeable barrier, such as in unventilated attic spaces regulated by IRC Section R806, the insulation must be installed at a minimum thickness of 3.5 inches. Icynene LD-C-50 can be installed in one pass to the maximum thickness. Where multiple passes are required, the cure time between passes is negligible. ... Thicknesses of up to 7 1/2 inches for wall cavities and 11 1/2 inches for ceiling cavities are recognized based on room corner fire testing in accordance with NFPA 286, when covered with minimum 1/2-inch thick gypsum board or equivalent thermal barrier ..."

In Canada, Go to CUFCA Website for Information on Spray Foam

As the Chair of CUFCA, (Canadian Urethane Foam Contractors Association) I would encourage all Contractors, Architects, and Inspection Officials to go to our website for unbiased information and continuing education on 2 lb. closed cell spray foam products. At http://www.cufca.ca

While occurences such as this are unfortunate and also discredit the entire industry , they do occur and will continue to occur as more and more contractors become active spraying foam without the proper training or necessary respect for the science involved in the installation process. CUFCA is the only fully independent third party administered Quality Assurance Program coupled with an industry leading training system for the installation of 2 lb. Closed Cell Spray Foams. As the industry expands, (no pun intended) new foam manufacturers are entering the Canadian market. Some of these companies do not wish to restrict their marketing to only our Certified Installers. Also many off the shelf foam systems are marketed as DIY kits without proper training or PPE. Working with Isocyanates requires understanding of the process and the health risks associated with it. CUFCA promotes Continuing Education and has independant auditing and field testing and inspections. Bottom Line, do your homework on the products and the specs. CAN ULC 705.1 and CAN ULC 705.2 are the published material and installation specs for 2 lb. Foam. You need to ensure that installers are complying with these standards. It would be premature to speculate what was the root cause here. Certainly if the foam was installed too thick in a single pass, it can ignite.

When installed correctly, 2lb. Closed Cell Spray Foam is a great insulator, great air and vapour barrier, and adds structural support to conventionally framed structures.

Response to Andrew

Andrew,

The most important sentence in your post was this one: "Certainly if the foam was installed too thick in a single pass, it can ignite."

My advice to builders: have fire extinguishers on hand, and don't leave the job site until four or five hours after the spray foam installer has completed work.

Heat of reaction

As to the maximum lift for open cell foam vs. the nominal 2" lift for closed cell, a purely speculative answer would be the 2" for CC times the density ratio. So for 2 pcf CC vs. 0.5 pcf OC you might figure an 8" lift with OC is feasible. This guesstimate is based on the questionable assumption that the heat of reaction of the polymerizing material, on a weight basis, is the same for both CC and OC.

Open Cell Foam Heat Issues

In response to your note Dick, the comparrison of heat generated by exothermic reaction in 1/2 lb open cell foam is not a linear path from 2 lb. Foams.

Half Pound Foams use water as the blowing agent. Known as "Water Blown" foams, these include Icenyne which are generically a .5 lb foam product.

These foams expand at 100 times volume and dissapate much of the heat right away due to the open cell formation during rapid expansion. The material has an R3/inch LTTR as opposed to the R6/inch LTTR of 2lb. foams. Closed Cell SPF's use a patented blowing agent developed by Honeywell. As a background on the evolution of the 2lb. foams, we use to use a blowing agent called R141. As of December 2009, the industry moved to a new blowing agent called R245a. This is a zero ODS system but has a lower reaction temp. Also some foam manufacturers use a higher water index in their resin formulations which compound the temperature issue. Hence the heat generated gets trapped and as it continues to react the heat is magnified due to the thick insulation around the core. It can crack and allow oxygen into this area and you then have a flashpoint. Again, I would stress that as long as an experienced and well trained operator works within the guides, there is no problem with foam systems. It is when short cuts are taken that bad things happen. This can be said of many products and industries.

A Bit of Clarification

I am a spray foam insulation contractor and try to check in from time to time on the chat in the blogs of the Green Building Advisor.

I would like to begin by thanking Martin for the excellent presentation that he gave at The 14th Annual Westford Symposium on Building Science. For those of you who did not attend you missed an excellent presentation.

I have read the chain of responses about this particular fire and felt absolutely compelled to address some of the things that have been said. I am aware as I write this that the majority of posters on this site have a strong bias against spray foam which is evident from the very tone of most of the threads. It is unfortunate since spray foam is the best practical insulation available for a variety of reasons. This battle was won long ago. You don't see refrigerated trucks, industrial tanks and pipelines, igloo coolers etc., etc. insulated with cellulose and fiberglass for good reason. I understand that everybody has an opinion and that to many of you mine probably stinks so I shall digress and address the immediate topic at hand.

1) IF (and I stress IF) indeed the fire was caused by too much exothermic heat build up, it would likely be for 1 of 2 main reasons. The first reason is just as the posters have stressed - that lifts may have been too thick ( generally 2" to 3" maximum for 2lb closed cell foam - check the manufacturer data sheet if you really want to know and are willing to invest 5 minutes online). The second just as likely possibility is that pass thickness was correct but not enough time was allowed before a second pass was applied. Once again you can simply check the data sheet.

2) It is my opinion that warm attic temperatures or lack of ventilation (as noted in the article) are unlikely to have played any significant role. Perhaps this would have made it necessary to wait say 21 minutes versus 20 minutes between passes but the role of these 2 factors would have been incredibly negligible.

3) I do take a bit of offense to Martin’s implication that a conscientious SPF contractor would jeopardize the safety of themselves or others to get out of an attic faster. I know he meant no offense, but I still have not gotten used to the general lack of respect for the skill and pride of a quality insulation contractor (any type of insulation). I can tell you from experience that price rules and insulation is treated as a commodity the vast majority of the time. It is sites just like this that should be trying to change that prevailing perception and not propagating it.

4) If you would like to know the proper maximum pass thickness for any type of foam then this is really simple. 1- Go to the website of the foam manufacturer. 2- Open the data sheet. 3- Read it. Only 1 or 2 pages. 4- Bonus. You will probably learn some other stuff too!!! If the manufacturer does not make this readily available on their website then I highly recommend that you use another brand of foam. Generally pass thicknesses for open cell foam are much greater but all foam formulations vary and the simple blanket answer that everybody seems to want cannot be given. If your SPF contractor does not know this answer for the brand they are spraying – then get another SPF contractor!!!

5) Mr. Russell – There is no need to speculate - just go to the manufacturer website. Speculating is not scientific, creates misunderstandings and in my opinion has no place in any forum that supposedly seeks to provide actual knowledge.

Response to Eric Machemer

Eric,

Thanks for your excellent post.

I would like to respond to your comment -- "I do take a bit of offense to Martin’s implication that a conscientious SPF contractor would jeopardize the safety of themselves or others to get out of an attic faster. I know he meant no offense, but I still have not gotten used to the general lack of respect for the skill and pride of a quality insulation contractor."

1. I don't believe that a conscientious spray-foam contractor would knowingly jeopardize their safety or the safety of others. If exothermic heat from spray foam was indeed the cause of this disastrous fire, it was clearly a tragic accident, not something done knowingly.

2. I have tremendous respect for spray foam contractors, who do a difficult job in very difficult circumstances. I worked for several years as a contractor -- in tight crawlspaces, hot attics, and below-zero temperatures. Contractors need skill and patience and the ability to work in very difficult circumstances. I have the greatest respect for contractors; in no way to I disparage their knowledge and skill.

3. Although I greatly respect all of the skills necessary to climb into that Tyvek suit and respirator every day, that doesn't mean that I can't consider whether the inherent difficulties of the job are properly balanced with an insulation system that is adequately forgiving and safe, even when installed by tired workers in hot conditions. I'm asking, what's the margin of error?

foam vs cellulose

Eric,

You wrote, "This battle was won long ago. You don't see refrigerated trucks, industrial tanks and pipelines, igloo coolers etc., etc. insulated with cellulose and fiberglass for good reason."

These are very different applications than a house. Different applications have different requirements. I don't think the comparison was fair - or even very meaningful.

Bob

SPF foam

The real reason we shouldn't use SPF foam is simply described in this GBA article:

https://www.greenbuildingadvisor.com/blogs/dept/energy-solutions/avoiding-global-warming-impact-insulation

One Thing at a Time

Are there any other spray foam contractors reading this website or has the hostility towards your livelihood scared you all away? No matter. I’m not a scared. I shall try to carry our torch.

Bob,

I am referring to the straight up qualities of the 3 major and currently practical insulation products. It is meaningful in that these applications require very high performance insulation. Any insulation is used to keep hot and cold either in or out. Thermos’, coolers, tanks and even houses use insulation for the exact same thing.

I shall make the case for my position based on a pure performance basis. I will refer to closed cell spray foam, as it is my insulation of choice, although several of the following also apply to open cell spray foam.

1- Aged R-value of 6-7 per inch

2- Classifies as an air barrier material per ASTM test standards <0.02 L/sm @ 75 Pa

3- Classifies as a vapor retarder (the brand we use is 0.8 perm at 1”)

4- Bonding to substrate stops convective looping

5- Adds structural racking strength to wall and roof assemblies

6- Increases wind uplift of plywood/roof rafter connection from 75 psf to 175 psf with a 3” fillet bead on both sides of the rafter/plywood connection and to 250 psf with a continual 3” application.

7- Can be used as a continuous insulation

8- Water resistant

9- Can be used below grade

10- Can be used under concrete slabs

11- Manufactured on site to produce a perfect fit regardless of shape. Air leakage in the bay stopped without additional measures.

12- Can be used on the exterior of roofs as both the insulation and roofing material

13- Air impermeability allows for use in unvented attic assembly where roof ventilation would otherwise be difficult and/or when heating and cooling equipment is located in attic space.

14- Fungi resistance rating: Zero (ASTM G-21)

I welcome you to now make a case why other insulation products are superior to closed cell spray foam on a performance basis.

Next Reply

Martin,

“If exothermic heat from spray foam was indeed the cause of this disastrous fire, it was clearly a tragic accident, not something done knowingly.”

Please re-read your original post. It seemed to imply that this particular hypothetical sweaty contractor: a) Was trained. b) Knew the danger. c) Took a risk anyway.

Clearly, in this scenario that you laid out, the hypothetical SPF applicator did take this risk knowingly. It is my contention that a trained applicator would not have taken this risk knowingly.

Once again Martin, I am certain that you meant no offense. I have followed your writings for several years and it is clear that you have a great deal of understanding of the need for quality insulation installations and a respect for those who endeavor to do it properly. I am however regularly disappointed and frustrated whenever the topic of spray foam insulation comes up on this website as it seems to become an all out bashing fest of a fantastic insulation product.

As to your question “what’s the margin of error?” I would contend that it is an exceptionally safe technology. Tens of thousands of buildings are insulated with spray foam every year and this kind of an event is an exceptionally rare instance.

Causes of house fires in the US from 2003-2007

Cooking 40%

Heating Equipment 18%

Arson 8%

Electrical distribution and lighting 6%

Smoking 5%

Clothes dryer or washer 4%

Candles 4%

Add to this: air conditioners, fans, Christmas trees and a plethora of other causes.

Now I shall re-pose the same question – Based on the margin of error, are all of the above things “adequately forgiving and safe” that we should allow them to be in homes?

Fires caused by spray foam are so rare that I have never been able to find them on a list of fire causes. Perhaps somebody can tell me how many of the 1,900,000 house fires that occurred during 2003-2007 were caused by spray foam? While you are investigating, please try to find out the same answer for cellulose. http://www.askthebuilder.com/054_Cellulose_Vs_Fiberglass_Insulation.shtml

YES. The margin of error is pretty darn safe.

Response to Eric

Eric,

Closed-cell spray polyurethane foam is an excellent product and I often recommend it. Long-time readers of GBA will recognize the truth of this statement. GBA does not encourage spray foam bashing.

Here are links to the GBA Encyclopedia pages on spray-foam insulation; I wrote most of the material:

https://www.greenbuildingadvisor.com/green-basics/insulation-choices

https://www.greenbuildingadvisor.com/green-basics/spray-foam-insulation-open-and-closed-cell

Some quotes:

"Closed-cell spray polyurethane foam performs better than any other insulation. It has a high R-value per inch (R-6.2 to R-6.5), it's impervious to moisture, and it's an effective vapor retarder. It is also an excellent air barrier."

"Spray foam Is the king of insulations."

"Spray polyurethane foam (SPF) is better than any other type of insulation at reducing air leakage."

Now that I've point out these quotes, I'm sure that I'll be criticized by some readers.

Eric, please understand that I wasn't attacking the integrity of the contractor. I identify with contractors.

Here are some facts:

1. Every time a builder buys a new tablesaw, the first thing he does is remove the blade guard.

2. When I was a contractor, I occasionally broke most safety rules. Sometimes I stepped on the top step of a stepladder.

3. Sometimes I reached far beyond the safe reach while at the top of a ladder.

4. Sometimes I extended a ladder that barely reached to the eave of a house and climbed it.

What's my point? That I'm an idiot? No, I'm just honest. Any honest builder or contractor will recognize himself in these examples. Contractors are human beings. That's my point. When we're tired, we cut corners and make mistakes. A good safety program aims to minimize these bad decisions. But we can't eliminate them.

One More

Kathy,

I have read the entire report and I cannot accept that it has true scientific basis. I would be curious to hear if Alex currently feels that all the facts and assumptions that he made in the article are still 100% fair and valid.

I would encourage you to read the responses that FOLLOW the article at the link that you have referred all of us to: https://www.greenbuildingadvisor.com/blogs/dept/energy-solutions/avoiding-global-warming-impact-insulation

I would point specifically to the posts made by Allison A. Bailes PhD. I am not sure who this obviously wise (and likely also handsome and debonair) man is but he is absolutely spot on. Please also check out his analysis http://hub.am/an7fDi

I would add a couple of glaring flaws beyond Dr. Bailes analysis.

Mr. Wilson has assumed an amount of blowing agent used that is TWICE what is actually used in SPF.

Mr. Wilson states that “we do not account for any change in airtightness”. This is utterly absurd. The amount of energy saved/used is a MAJOR factor in an analysis of this type. Does anybody out there not yet understand the importance of air barriers and the enormous role it has in wasted energy?

Mr. Wilson assumes that every wall starts with R-13 fiberglass insulation and his calculations begin with insulation added after this baseline. It almost appears as though he is trying to skew the results in favor of the conclusion that he wishes. This is absolutely unfair. I should think that nearly everyone who reads this website understands that initial insulation application provides the biggest energy savings. Mr. Wilson starts off with an R-13 fiberglass which may provide heat loss reduction of 85% +/- (where total heat loss is considered to be 100% in a baseline un-insulated wall). He then applies 1” of closed cell foam with a value of R-6. If the total heat loss reduction is now 90% +/- then he is only crediting the closed cell foam with a 5% +/- reduction in energy loss. (Note: to be honest I don’t know what reductions he has assumed since he did not seem to think that it was important for readers to know what these assumptions were) Most SPF applications use spray foam as the only insulation. If we start with the same baseline un-insulated wall and start with the same 1” of closed cell foam the SHAZAM – that same 1” of SPF now provides 75% +/- heat loss reduction. By my math this is a 1,500% difference!!! What would this do to his calculated payback times?

This is a very, very, very flawed study. The conclusion that we should stop using SPF and XPS based on these results would be laughable in my opinion if it were not for the fact that many readers are treating this as real science without knowledge of the tremendous inherent flaws.

to Eric

Hi Eric,

Although there are some who are strongly opposed to foam, I am not one of them. I have used foam in the past and will use it again. I just don't think it is always the best choice, and, as I said, there's a world of difference between a tank truck or pipeline and a house.

I have read all your responses to the others and you make a lot of good points. I am not an expert, nor am I as well-informed as you, but from what I have read, densepacked cellulose is very effective insulation for a house. The air movement within it is very very small and with even a poorly applied vapour barrier would give an 'effective' R value (admittedly with a thicker wall!) equal to blown in foam. And at a MUCH lower price. Double walls - two 2x4 walls instead of a single 2x6 or 2x8 wall will eliminate the thermal bridging whether using cellulose or foam, and will improve the 'effective' R value.

My next project will be insulated with 12 inches of beadboard - white styrofoam - which I get free - used hottub covers which I have to store up and dry out in the sun. Given that these were destined for landfill, I think it is safe to say that it would be extremely green - no environmental cost at all except the gas I use to bring it home, and that should be offset by the fuel used to deliver any insulation product to my site.

There will be labour costs in cutting and fitting it, but that money goes to me and my friend, keeping it in the community rather than giving it to the oil companies, Dow, Dupont, etc. And it will still be cheaper.

But I think you would admit that while cellulose can be a reasonable alternative for a house, it is not even a remote consideration for a tanker truck or a pipeline, and an igloo cooler that was twice as large and twice as heavy for the same capacity would be a non-starter. That was why I said the comparison was unfair.

I, also, have read the article Kathy referred to - and the responses. As one of the responders said, it was a blog, not a scientific study.

While I understand you wanting to stand up for your trade, I think you will admit that often it is not the contractor who is applying the foam, and 'everyone' makes mistakes - builders, doctors, architects - and even worse, there are incompetent practitioners in every field.

OTOH, as you pointed out, how often has there been a fire with this suspected cause? Whatever the cause, it is unfortunate, and if it was the insulation, it is an extremely rare occurance.

In closing, I would like to thank you for informed, polite responses to all the posts. You've added to the knowledge base for many of us, Ideally, we should all be looking to increase our knowledge of materials and uses, not just to defend what we have already decided is best. (That comment was not intended to point a finger at anyone. We all do it.)

Bob

Published Paper On FPF XPS

I would like to contribute this link to a scientific paper written by Dr. Danny Harvey from the University of Toronto. I think Alex's report reaches similar conclusions and presents the material in a much more approachable manner. Note: Dr. Harvey's paper was published in "Buildings and Environment"

Net Climatic Impact of Solid Foam Insulation Produced with Halocarbon and non-Halocarbon Blowing Agents. 2007. Buildings and Environment 42(8): 2860-2879.

I would like to contribute this link to a scientific paper written by Dr. Danny Harvey from the University of Toronto. I think Alex's report reaches similar conclusions and presents the material in a much more approachable manner. Note: Dr. Harvey's paper was published in "Buildings and Environment"

Net Climatic Impact of Solid Foam Insulation Produced with Halocarbon and non-Halocarbon Blowing Agents. 2007. Buildings and Environment 42(8): 2860-2879.

For a free version of the paper go to this link:

faculty.geog.utoronto.ca/Harvey/Harvey/papers/Harvey%20%282007c,%20BAE,%20Climatic%20Impact%20of%20Insulation%29.pdf

Log in or create an account to post a comment.

Sign up Log in