Image Credit: Travis Price Architects

Image Credit: Travis Price Architects There are six of the 40-foot-long containers per floor, with six bedrooms and six bathrooms on each floor of the group housing project in the city's Brookland neighborhood.

Image Credit: Travis Price Architects Each of the three floors provides private bedrooms and bathrooms and a common area with a kitchen and living room.

Image Credit: Travis Price Architects

By the first week of September, tenants should be moving into an unusual Washington, D.C., apartment house known as SeaUA with no way of knowing whether their bedrooms and kitchens once were used to ferry bales of alfalfa to China or haul running shoes from Thailand to Los Angeles.

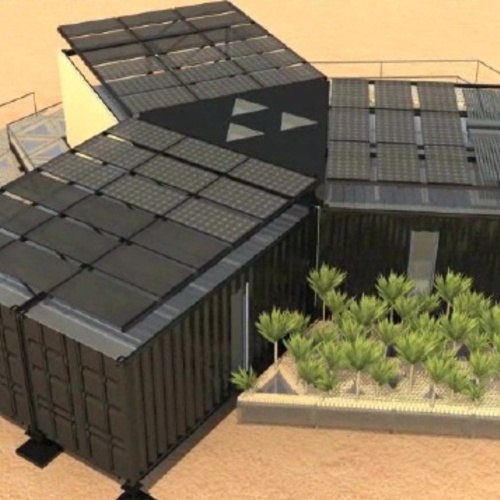

The novel housing project has a conventionally built lower level while its upper three floors are made of 18 repurposed shipping containers, each 8 feet wide, 40 feet long and 9 1/2 feet high.

Architect Travis Price calls the project the “ultimate ecological dream.”

The project got its start when two former students at Catholic University, Matthew Grace and Sean Joiner, both 31, decided last winter to tear down an investment property they owned rather than repair it. They hired Kelly Davies, now Grace’s fiancee, and Price, her boss at Travis Price Architecture, to design a replacement.

But Grace was stunned by early construction estimates.

“I was like, ‘Stop what you’re doing. What is that number?'” he told an interviewer from The Washington Post.

Well, Price countered, what about doing the project with old shipping containers?

Housing for students or young professionals

The steel shipping containers have been arranged in three floors of six containers each. Each level provides six bedrooms and six bathrooms with a common area in the middle for an open kitchen/living/dining space. A bump-out at mid-span accommodates a dining table and part of the stairwell. The basement level has been framed out to match the upper stories; it also has six bedrooms.

To create the common living areas, Price cut away some of the inner walls of adjoining containers. He also cut openings for windows in the corrugated walls of the containers, although some bracing had to be added to compensate for the loss of structure. “You can play with it all you want,” he said by telephone. “It’s a delicate game but a fun one.”

The interior walls are framed with 2x4s and insulated with closed-cell polyurethane foam insulation for an estimated R-value of 25, Davies said. Ceilings are also framed with 2x4s and insulated with spray foam, while the flat roof on the top floor gets spray foam on the inside and tapered rigid insulation on the outside. The roof assembly has a total R-value of roughly 52, Davies said.

Containers actually sit 3 in. apart, with that gap filled with closed-cell foam. “It’s like a Thermos bottle,” Price said.

Windows are a mix of fixed and operable units, and two ducted minisplit units heat and cool each floor. With all that foam insulation, the units should be very tight, but Price said the construction budget precluded a blower door test.

In all, Price said, the project should come in at about $125 per square foot, roughly half the cost of typical construction, and in a shorter amount of time.

An ideal material for building

Price says the containers are letter-made for use as environmentally friendly housing. Steel, he says, has much less embodied energy than other common building materials, particularly brick. Also, he says, because the watertight containers were engineered for utilitarian duty at sea, there isn’t an ounce in them that’s not structural.

According to the story in The Post, Price had wanted to use shipping containers for housing ever since he was in college. In the 1970s, he proposed building a 10-story steel frame to house sea-container houses. Families would be able to unplug the utilities and move the container-houses when they left town.

The project is right down the street from Catholic University. Its name is a play on words: “Sea” from the original purpose of the containers, and CU from the university. Most of the units have apparently been leased, and a similar project in the area is under consideration. There’s certainly no lack of raw materials. According to Price, there are some 700,000 used containers in the U.S. alone.

Used containers typically sell for about $2,000.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

7 Comments

Fad in the guise of

Fad in the guise of sustainability. The original house was terra cotta tile, not brick, so not sure why he's comparing the embodied cost of steel vs. brick. How does his embodied cost calculations account for the lifespan of a typical container which is 15-20 years according to the shipping industry.

Bigger picture is an old story for the sustainability field: loved buildings survive and get reused for generations. Dated or hated buildings get torn down and thrown away, which is my bet for this project.

Joe Lstiburek's take on building with shipping containers

"BSI-078: Ship Shape—The Luftwaffe, Ballast and Shipping Containers":

http://www.buildingscience.com/documents/insights/bsi078-ship-shape/

neato

Steel may not be a sustainable material, but old shipping containers as building materials are a great form of up-cycling. Some neglected buildings are just beyond repair. Just because it's old, doesn't mean it's good. Best thing to do is to salvage the wood from the old structure, and incorporate it into the new one.

Another take

http://www.treehugger.com/modular-design/does-shipping-container-architecture-make-sense.html

and

http://www.archdaily.com/160892/the-pros-and-cons-of-cargo-container-architecture/

Paul

Joe's last footnote is wonderful:

"I think the reason that so many shipping containers are insulated on the inside is that folks want other folks to know that a shipping container was used. I think a lot of folks want everyone to know just how “green” they are. What is the point of being green without being able to brag about it and rub everyone’s nose in it? Why do you think a Prius looks so ugly? Everyone needs to know it is a Prius so they know just how responsible you are"

"the construction budget precluded a blower door test"

Pretty much says it all.

Insulation?

Hi Scott,

I'm interest to know how much SeaUA cost to build? I noticed the article mentioned it was cheaper the conventional methods but didn't give a price?

Also I noticed the spray foam insulation gives an R-value of around 25. The only other place I've read about insulating shipping container homes is, http://www.containerhomeplans.org/, and they said you can use rockwool insulation; do you know what impact this will have on the R-Value?

Thanks,

Jess

Log in or create an account to post a comment.

Sign up Log in