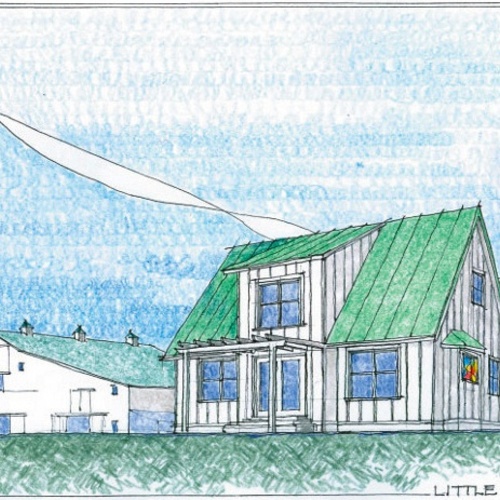

Image Credit: Procter:Rihl

Christopher Procter, a principal at London-based architecture and furniture-design firm Procter:Rihl, applied the firm’s commitment to sustainable design and energy efficiency to the construction of a home near Brattleboro, Vermont.

Nearly completed, the home, known as Pull House, is being built to perform to Passivhaus standards, according to an article published recently by U.K.-based Building Design. But it also incorporates Procter’s personal interests by offering his take on New England barn architecture and, just as important in this case, a level of comfort and clean design that would please his mother – because, in fact, the house is for his mother, who is relocating from the U.K. to Vermont to retire.

Procter’s goal, Building Design notes, is to bring the performance of the structure to Passivhaus standards while also supplementing grid-supplied power with a photovoltaic (PV) system. For the exterior walls, the architect used structural insulated panels – 7 3/4 in. of polystyrene foam between OSB sheets – that were cut at a local factory. The truss-roofed attic is insulated with a combination of 1 1/4-in. polystyrene foam and blown-in cellulose.

An anomaly in the neighborhood

One of the visually notable things about Pull House is the source of the name: the standing-seam metal that covers the roof also covers the south exterior wall, the ridgeline of which angles – or “pulls” – down from east to west to distort the home’s otherwise rectangular shape.

Building Design points out that the dark colors used on much of the exterior – most of the siding is vertical rough-sawn pine – is stained dark blue-black, in part to enhance solar gain in the winter.

The house is equipped with a Venmar heat recovery ventilator, and the triple-glazed fiberglass-framed windows come from Accurate Dorwin.

Though some finish work remains to be done and the PV system has not yet been installed, land and construction costs for the project (as it appears in the photos) have come to about $375,000.

We’ve made inquiries to Procter:Rihl for a progress update, for details about the size of the house, and for more specifics about some of its other features, and we’ll include them here when we hear back.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

2 Comments

Do the SIP's have

Do the SIP's have polyurethane rather than polystyrene cores? It seems like it would be extremely difficult to get PH certification in a climate as extreme as Vermont with wall R values in the 30's.. The only way I could see it work is if the house had an excellent exterior surface to treated floor area ratio.

short term green

Lack of eaves means no weather protection for the exterior or from excessive heat gain in the summer = bad design = poor green performance over the long term as materials will have to replaced sooner than otherwise necessary. Paper chase house.

Log in or create an account to post a comment.

Sign up Log in