Image Credit: Colby College

A recent comment posted at a Vermont news web site called VTDigger read, “Just a single 25 megawatt (MW) woodchip plant could/would provide some 4 percent of Vermont’s [electricity] consumption, 24/7, and would contribute to the Vermont economy in the form of jobs and money in circulation from the wages [and] taxes — wealth created in the state that stays in the state.”

My response: Some of the main reasons wood burning is advocated by proponents are: 1) give work to the logging industry, 2) money is spent in Vermont, 3) create jobs in Vermont, 4) generous federal and state subsidies are available, etc.

The commentator is right about jobs, wages, taxes, etc. — but these are not the real issues.

Expensive renewable energy is an economic headwind for Vermont’s economy

Subsidized renewable energy systems inefficiently producing variable, intermittent energy at two to five times New England wholesale prices, as did SPEED projects for about five years, are the real issue. Vermont needs to have low-cost renewable energy (RE) to make not just the RE sector but all sectors of Vermont’s economy more viable — so they can expand, be profitable, create jobs with good benefits, pay good wages, and pay taxes.

Vermont is one of the poorest states in the U.S. based on family income and per capita income, with a fragile, near-zero-growth economy, and with a high cost of living index (120 with the U.S. set at 100). Vermont cannot afford to turn over a major part of its economy to expensive renewable energy production.

With more and more subsidized renewable energy projects diverting valuable capital from more profitable activities, and more mandates for increasing consumption of their expensively produced energy, Vermont’s entire economy could be facing increasingly stronger headwinds for many years.

CO2 emissions of wood-burning power plants

Wood-burning power plants would require cutting trees and burning them, which emits just as much CO2 per kWh as coal. This may have an immediate adverse global warming impact. Moreover, burning wood emits at least as much airborne health-damaging particulates as burning coal.

Wood-burning proponents and governments claim that burning wood is “CO2-neutral.” They purposely forget to add, “over a period of about 100 years.” Global warming is a problem now. Forests from which wood is taken would require about 100 years to recover from the damage, based on numerous studies. Wood-burning power plants are an inappropriate 100-year “solution.”

Mary S. Booth addressed this issue in 2011. Deforestation is discussed in this University of Michigan presentation.

Other types of biomass, such as corncobs, cornstalks, various grasses, bamboo, etc., can be harvested each year, or every few years, but those would require more land area. Such biomass can be claimed to be renewable, although the soil would likely become too depleted for future food-growing purposes.

Taking, taking, taking from the land, without giving back, is not a long-term, sustainable option. Even taking 0.5 cord/acre, considered “sustainable” by government and other foresters, would merely slow the soil depletion rate. In practice, the 0.5 cord/acre is often greatly exceeded for expediency and due to a lack of oversight during logging.

In Vermont, most of that land area would need to be created by shifting land from other uses, e.g., from open spaces, meadows, etc., to ensure that biomass would be available in the required quantities.

Capacity factors and efficiencies of biomass power plants

Theoretically, it is possible for base-loaded biomass-fired power plants to achieve capacity factors of 100 percent. (Base-loaded means operating at a steady output near rated plant capacity.) In practice, plants do not operate at these levels because of scheduled and unscheduled outages. As a result, capacity factors of such plants are about 85 percent to 95 percent.

The usual annual three-to-four-week scheduled outage would reduce the plant capacity factor (CF) to about 94 percent. It is likely that a plant would have several unscheduled outages ranging from a few hours to a few days, which may total one to two weeks for the year. This would reduce the CF to about 91%. As a plant ages, it likely would be operated at less than its rated output, which would reduce its CF.

In Vermont, the average net electrical efficiency of existing base-loaded wood-burning power plants is around 25 percent, after accounting for fuel handling and various parasitic losses. Below are some calculations regarding a 25-MW base-loaded wood-burning power plant similar to existing Vermont plants.

Energy production, wood chip input and capital cost

A 25-MW wood-burning power plant is assumed to have a CF of 0.90 and operate at 25 percent efficiency. You’ll find more information here.

Plant energy production = 25,000 kW x 8,760 hr/yr x CF 0.90 = 197,100,000 kWh/yr, or about 3.52% of Vermont’s 5,600,000,000 kWh/yr consumption.

Required heat supply to plant = 197,100,000 kWh/yr x (3,413 Btu/kWh)/0.25 plant efficiency = 2,691 billion Btu/yr.

Required wood chip supply to plant = 2,691 Btu/yr/(23,139,667 Btu/cord) = 116,286 cords/yr, or 290,714 tons/yr.

Estimated capital cost = 25,000 kW x $4,000/kW = $100,000,000.

CO2 emissions

Usually, laypeople are surprised to learn that wood-burning CO2 emissions/kWh and particulate pollution/kWh are at least as bad as those from coal. Particulate pollution is linked to a wide range of serious health effects, including heart attacks, strokes, and asthma attacks.

Recently, the EPA proposed reducing the particulate emissions of new residential wood stoves by 80 percent. The proposal covers wood stoves, fireplace inserts, forced air furnaces, masonry heaters, and indoor and outdoor wood boilers (also called hydronic heaters).

Smoke from residential wood stoves, which are used around the clock in some communities, can increase toxic air pollution, volatile organic compounds, carbon monoxide, and soot, a.k.a. particulate pollution, to levels that pose serious health impacts.

The estimated CO2 emissions would be as follows:

CO2 emissions due to harvest, process, and transport: 2.09 gal diesel fuel/green ton x 290,714 green ton/yr x 22,384 lb. CO2/gal = 13,600,341 lb. CO2/yr, or 6,800 ton CO2/yr.

CO2 emissions due to combustion: 195 lb./1,000,000 Btu x 2,691 billion Btu/yr = 524,707,794 lb./yr, or 262,354 ton/yr.

Total CO2 emissions = 1) + 2) = 538,308,135 lb. CO2/yr, or 269,154 ton/yr.

Truckloads and harvested area

Required truckloads per year (assuming 32 tons per truckload) = 290,714 ton/yr./(32 ton/truck) = 9,085/yr., or 36/day, based on 250 hauling days.

Required harvest area = cords/(0.5 cord/acre) = 232,571 acres, or 363 sq. miles.

Radius of harvested area = square root of (363 sq. miles/pi) = 10.76 miles, if only harvestable forest were in that area.

In the real world, the harvested area is 9 to 25 times greater, corresponding to a radius of about 30 to 50 miles. Beyond 50 miles, the hauling cost would be uneconomical. As a result, Vermont could accommodate only a few additional 25 MW wood-burning power plants.

No. 6 fuel oil emits 33 percent less CO2

Because No. 6 oil-fired power plants have efficiencies of about 35 percent, versus 25 percent for a wood-burning power plant, the heat input to the boiler needs to be only 71 percent of the wood-burning power plant. The estimated CO2 emissions would be as follows:

| CO2/million Btu | Factor | Billion Btu/yr | lb CO2/yr | Tons of CO2 emitted per year (for a plant burning No. 6 fuel oil) | |

| Combustion | 173.906 | 0.71 | 2,691 | 334,248,475 | 167,124 |

| Fuel oil production | 12.5244 | 0.71 | 2,691 | 24,071,979 | 12,036 |

| Fuel oil transport | 0.62622 | 0.71 | 2,691 | 1,203,599 | 602 |

| Total | 359,524,053 | 179,762, which is only 67% of the wood CO2 emissions/yr. |

If natural gas were used, the emissions would be only 117.08 lb. CO2/million Btu and a 25 MW gas-fired power plant would have an efficiency of about 38 percent. The resulting emissions would be 58% less. Emissions for burning various fossil fuels can be found here.

Better alternatives than renewable energy build-outs

Hydroelectricity from Hydro-Quebec: Getting more low-cost (5 to 7 cents/kWh) hydroelectricity — steady, not variable, not intermittent, near-CO2-free — from Hydro-Quebec would be the best way to get all the sectors of Vermont’s economy moving again.

Energy-efficient buildings and vehicles: Building net-zero-energy buildings and encouraging the use of high-mileage light vehicles are much more effective measures to reduce fossil fuel consumption and man-made global warming than wood-burning power plants, and they have near-zero adverse environmental impacts.

Willem Post is a retired engineer who writes about energy issues. He is a founding member of the Coalition for Energy Solutions. This post originally appeared at VTDigger and is republished here in a slightly different form with the permission of the author.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

19 Comments

One sided debates suck

William would have my ear if he also gave equal thought to both sides of this subject.

Two decades of us verses them in discussions needs to stop.

We live in the middle. Let's discuss from that point.

Some #'s are missing here

With someone with a Bias towards these "subsidized renewable energy systems" I find it hard to believe your claims that they are [inefficient, variable, intermittent, expensive] without some numbers for comparison, and some other source of energy to compare them with. You essential ask us to take for granted that it is so, with no reference to back it up. I'm not suggesting you go into the same detail you did for the main point of the article, but at least creating some baseline for people to understand where you're coming from might have been useful.

I like the detail you went into on the main point of your article, but i honestly took a while to get past the first two sections due to the "us vs them" tone AJ referenced. People do like to jump towards wood as a renewable resource. It might be true, but the devil's in the details, and things like this are never as straight forward as we want them to be.

No power plants run 100% capacity factors.

A combined cycle gas plant could theoretically run a 95%+ capacity factor too, but the US average is about 45%, so what?

Most of the wood burned in New England biomass powerplants is logging slash and other low commercial value residues, a good fraction of which would otherwise be burned for disposal with NO energy output applied.

The more important number for biomass plants in terms of net carbon footprint is it's operating thermal efficiency, and how the forest resource is managed, which affects the both rate at which replanting and regrowth (re-sequestration of atmospheric carbon) happens, and the amount of soil-carbon and methane are released in that harvested/replanted woodlot.

The carbon-accounting of wood burning was studied in depth in Massachusetts a few years ago, and anybody who really wants to dig into this issue should probably read it, and understand the methodologies used:

http://www.mass.gov/eea/docs/doer/renewables/biomass/manomet-biomass-report-full-hirez.pdf

The thermal efficiency of burning wood for power turbines are fairly low, about 25% efficiency. The compared very unfavorably to combined cycle natural gas (~55-60%, some are over 60%), or supercritical coal (40-45%), but even at 25% efficiency it's less carbon-intensive than sub-critical coal (30-35% thermal efficiency, higher carb per kwh.) Unfortunately there are no simple ways of getting biomass generation thermal efficiencies out of the 20s, limited by low peak burning temperatures well below the critical point for the working fluid (water/steam).

To be atmospheric-carbon neutral while using good forest management practices, biomass burning needs to reach thermal efficiencies of about 30% or higher. While that is at the theoretical fringes of what is possible in an electricity-only powerplant (and with no commercial power plant existence proofs that it's even possible), for a heat & power co-generation it's actually quite easy, and 75%+ net thermal efficiency is not too tough in a well engineered properly scaled. In Massachusetts if the net thermal efficiency of a biomass plant hits 40% it is given half a renewable energy credit (REC) per megawatt-hour, to be traded on the renewable credits auctions, it requires a minimum of 60% thermal efficiency to earn a full REC.

But it's also a matter of whether and how much net carbon reduction it is achieving on it's own, it's also important to look at how much grid-carbon it may be offsetting, which is a function of the regional power generation mix (and the thermal efficiency of it's carbon burners.) In the ISO-New England grid currently about 1/3 of the power comes from legacy nukes, about 10% is hydro (both local and imported), 5% comes from other renewables (about half of which is biomass cogenerators), a few percent from supercritical coal, and the rest (a bit more than half, annualized) is from natural gas (predominantly combined-cycle 50%+ thermal efficiency.) The amount of other emissions a biomass co-generator is displacing is actually pretty small, compared to what it would be in, say, West Virginia, where more than 90% of the power is supplied by thermal coal, about half of which is older sub-critical coal plants.

So, from a policy point of view, what makes sense in a state like Vermont that has NO fossil fired power plants? There is still a place for biomass cogenerators where the thermal output is offsetting low efficiency fossil burning. But that's not to say it's a slam-dunk everywhere, and it's not necessarily going to be economic.

At current installed prices, medium scale solar is already nearing par with the grid wholesale price of power on a lifecycle levelized cost basis, and that cost is dropping by about 25% every two years. By 2025 residential rooftop PV will be cheaper than the grid wholesale price of electricity. Before advocating new mid to large scale generation of ANY type, or powerline expansion to tap more hydro from existing powerplants from across the border, it's important to bear in mind that those assets will not be needed even fairly early into what would be a normal lifecycle, but someone still has to pay for them. Load defection (if not outright grid defection- going off-grid) will start slowly, but that is just the thin-edge of a solar tsunami (or solar + battery tsunami), which is going to wreck the business model of a utility with large capital expenditures that need to be paid of by the ratepayers over the next 30-40 years. Grid electricity demand has been flat to slightly falling in New England for a decade now, even though economic expansion periods. But the droop in kwh sales is bound to become more pronounced, not less over then next 10-15 years, as PV (with or without storage) on the ratepayer's side of the meter hit's "no-brainer" status as an investment.

Response to Dana Dorsett

Dana,

Thanks for your comments, which are well researched and helpful, as usual.

One quibble: I rather doubt your statement that "Most of the wood burned in New England biomass powerplants is logging slash and other low commercial value residues, a good fraction of which would otherwise be burned for disposal."

I'm fairly familiar with logging practices in northern New England. Around here, no logger burns "logging slash" (usually called brush in Vermont). Once a tree is felled and the log is skidded to the landing, the brush (tops and limbs) is left in place to rot.

I agree with the author

I read this earlier today

http://thinkprogress.org/climate/2015/04/16/3644889/woody-biomass-is-thicket-of-trouble/

And its nuts, causing one problem to "solve" another is foolhardy and we can't afford to fail.

That said Dana is correct that capacity factor is not an issue to consider here.

Where do I begin?

Phew! There is a lot to say on this topic. Some wild claims about particulate etc. It would be good to look at some Scandinavian combined heat and power biomass plants. They are in the 80% efficiency range. Electricity from wood is a stop gap as we look for adequate wind, and pv resources for winter time in Vermont. Currently winter is the only problematic season. The direct use of wood for heat can be very clean and efficient if we use the best modern gasification units and high end wood stoves. Wood stoves are good for low density rural areas but they need to be rated at 80% and above. Gasification can be used in Urban areas and compares well with the cleanest gas plants. The University of British Columbia in Vancouver uses bio fuel gasification in one of the greenest and most conscious cities in the world. One needs to catch up with this technology, it is not your fathers wood stove.

Dead wood or live harvest? Dead trees release methane as they decompose. It is much better to burn them as the CO2 is 5% of the warming effect of methane. Live harvest is another matter. It is quite likely that Vermont forests are about to experience disease kill offs beacause of warming. You will have to deal with this through burning. I talk from ground Zero of the largest pine beetle kill zone in the world. I am surrounded to the horizon with dead pine rotting and producing methane that will cancel all the carbon savings of Canada for 20 years. It is no small matter. Any forest in the world could be next. By the way, B.C. where this happened still has no idea what to do with this Saudi Arabia of dead wood, will you know what to do?

Ven

I enjoy your posts immensely but can't let your description of Vancouver as "one of the greenest and most conscious cities in the world" pass without comment. UBC may fit that description, but Vancouver is just another city swamped by suburban growth. I'm also not sure you aren't mistaking the residents predilection for outdoor sports for "consciousness".

There's more than enough slash to go around (response to Martin)

In some places & times it's too volatile to just leave the slash, which can lead to fast spreading fires during forest fire seasons. But I haven't seen how they do it in New England- could be that slash burns are rare. But if it's just left in place the ground, it is essentially sequestered carbon, with a modest amount of associated methane emissions, which is better for the climate than burning it.

Ven: Are you SURE that the methane emission rates in dead-tree stands are higher impact than the CO2 emissions from burning it, on any time scale? My understanding from multiple sources was that a felled tree emitted methane slowly enough that it was better to leave it than burn it due to the longer atmospheric lifecycle of the CO2 and the slowness of the methane release. I'm not sure that would apply in the same way to standing dead-wood under severe & rapid insect attack though, since the insects do speed up the methane-emissions. If you can point to a good reference study on those issues, I'm up for it!

Living in a lower-density low-rise urban location I thought long and hard before installing a wood-burner at my house. The factors that tipped the balance for me was that the city is under a long standing wood-boring insect quarantine (Asian Longhorned Beetle), any host species trees that come down in the city have to either stay in the city, or be run through chippers and shipped in sealed containers to a nearby biomass generating facility (the sub-30% thermal efficiency type, not a co-generator), and one of my neighbors is a tree maintenance & removal contractor with a tree-disposal problem. (Prior to the ALB quarantine he had been able to get rid of it most of it for free or even get some decent cash for some of it from cordwood vendors.) Disposing of the city's scrap trees at ~80% thermal efficiency in a < 3 grams per hour rated wood stove seemed like the lesser crime. But if everybody in a neighborhood of ~1/4 acre plots was doing the same they would be in for some SERIOUS air-pollution at times.

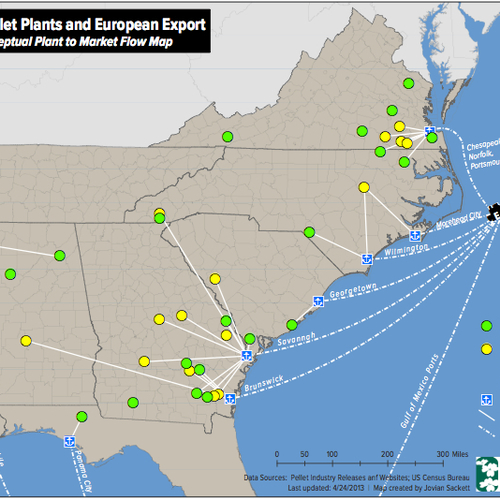

Ven, sell it to europe

it solves two problems, yours and theirs

http://thinkprogress.org/climate/2015/04/16/3644889/woody-biomass-is-thicket-of-trouble/

Correcting myself...

It's not impossible to design & build a super-critical biomass burner that delivers thermal efficiencies north of 40%, but it's a more complicated and expensive thing to do than with a simpler-purer (dare I call it "cleaner"? :-) ) fuel like coal. The lower flame temperature is just one of the factors that make it harder.

And, I've been advised that MA requires 50% thermal efficiency (not the 40%) for a biomass burner to qualify for RECs. To capitalize and fuel a biomass cost-competitively with other New England grid sources requires the REC subsidy in MA, and I would expect some subsidy would be required in VT as well. But co-generators may be able to make a financial case even without the subsidy.

Does anybody have the financial &/or performance scoop on how Montpelier VT's biomass district heating + power co-generation system is working out, now that it's 6 -8 months into full operation?

Response to Dana Dorsett

Dana,

As far as I know, it's just district heating -- not cogeneration.

It's up and running. Construction costs appear to be $3 million over budget.

Some links:

http://www.montpelier-vt.org/group/99.html

http://vtdigger.org/2013/10/30/biomass-heating-project-budget-3-million/

Hydro Quebec

Thanks for bringing up the MA biomass studies and standards above.

Regarding the cleanliness gasification, in CT we have a new gasified wood burner (forest wood and scavenged construction debris) that seems to have had a lot of difficulty functioning properly and generated many resident complaints to the state over dust and air pollution.

I am perplexed that Hydro Quebec is listed as a main solutions. I don't see where the basis of cost of incremental hydropower comes in at 5-7c/kwh. Is there a US-based project about to contract with them for that amount? Aren't there also transmission constraints into New England? Large scale hydropower is hardly free of environmental impacts, and just because someone else bears the cost of them doesn't mean they don't exist..

I also don't get why large hydro is seen as preferable to New England (or even maritime Canada) wind. Yes it's a variable resource. So what? It's good enough for Texas.

reply to Malcolm and Dana

Malcolm, Vancouver as a "conscious city" is only relative to other unconscious cities. A recent announcement by the mayor that they aimed to be 100% renewable by 2030 is quite a startling aspiration. There are a few downtown gasification district heating plants in B.C. running on scrap wood. Victoria has one providing heat for a cutting edge green condo complex called "dockside green" and a nearby sheraton hotel. As clean as natural gas apparently. Also university of northern BC in Prince George same gasification heating system from scrap and pine beetle killed.

Dana, I am have a close view of a pristine pine forest dying and falling over and rotting all within about 8 years right outside my door. It is crazy how fast it happened. They die then fall in high winds. The rot time for release of carbon and methane is twenty years. The carbon is not merely returned to the soil but also is released into the atmosphere with the methane at 20 times the effect of carbon and lasting a century. The carbon is less of a greenhouse gas but lasts longer. "We might as well burn it for heat or electricity" they say, but strangely it is not profitable enough. Live tree harvesting is profitable, dead trees are a nightmare for logging machinery. Voila, we do nothing.

on dead-wood emissions...

http://www.greenfieldbiomass.info/uploads/The_methane_myth.pdf

http://www.cbmjournal.com/content/3/1/1

Live forests emit more methane than dead forests, but dead forests don't remove atmospheric carbon:

http://www.theguardian.com/science/2006/jan/12/environment.climatechange

It's a balancing act, with no simple models that work in every location & climate.

Dana Dorsett,

The Montpelier, VT, wood chip burning heating plant results for the partial 2004-2005 heating season are below:

Project cost:

Plant ……………………………$15 million

Distribution…………….....…….. $5 million

“Financing”:

USDOE grant………….…...…….$8 million

Montpelier bond……….......…$0.25 million

State, City, CEDF, etc…........$11.75 million

Service charges: capacity $4.84/1000 Btu/hr; energy $8.82 million Btu.

http://vtdigger.org/2015/05/01/montpelier-declares-first-district-heating-season-a-success/#comment-229014

http://www.districtenergy.org/blog/2014/08/05/city-of-montpelier-vt-finalizes-district-heating-rates/

The cost of the fuel mix, wood chips and No. 2, is about $9.37/million Btu and that is about the price at which the heat is “sold” to users. This is a very good deal for users, but a very bad deal for other Vermonters.

According to the city, from October through February (not a full heating season), the heating plant consumed 4,820 tons of wood chips and 27,500 gallons of fuel oil, at a cost of $265,100 for wood chips, and $82,500 for fuel oil, for a total of $347,600. Fuel oil is used during periods when the biomass boilers can’t be operated sufficiently. About 411,000 sq ft of buildings are heated with a steam loop and a hot water loop.

http://www.timesargus.com/article/20150502/NEWS01/705029909/1003

Plant revenue for 2004 - 2005 heating season; October 1 - February 28; not a full heating season!!

Revenue estimate:

State........................ $46,996 capacity, $98,414 energy, $145,410 total

City and others.......$131,859 capacity, $151,522 energy, $283,381 total

Total...................................................................................$428,791, or $1.04/sq ft/yr

Cost estimate:

Wood chips, partial heating season...................................$265,100

No. 2 fuel oil, partial heating season....................................$82,500

Total....................................................................................$347,600

Available for O&M, incl, staff, utilities, etc.............................$81,191; this likely is at least $250,000 less than actual costs.

The cost of financing the project is completely ignored.

If this were a private, unsubsidized project, servicing a loan of $20,000,000, at 5% interest/yr, would require annual payments of $1,604,851.74/yr for 20 years!!!

http://www.calculatorsoup.com/calculators/financial/amortization-schedule-calculator.php

I spend about $1/sq ft to heat my house, which is about 3 – 4 times more efficient than those buildings. It looks like the owners of the buildings are getting a very good deal at the expense of other Vermonters.

This is an extremely uneconomic project; a perfect example of the state’s wasteful meddling in energy. More such uneconomic wood chip plants in Vermont would be another adversity for Vermont’s fragile, near-zero-growth economy.

Roger Smith

Green Mountain Power's existing contract with H-Q for steady, 24/7/365, hydro energy expires in October 2015.

H-Q has about 3,000 MW of underused hydro capacity and is building 1,550 MW more.

The GMP is negotiating a NEW contract. The likely price will be 5 - 7 c/kWh for 20 years, adjusted based on average New England grid prices, which have averaged 5 c/kWh for the past 5 years, and are not likely to increase much, because of abundant nearby gas.

This is far less costly than any renewable energy project in Vermont.

Solar and wind energy is low quality energy; it is variable, intermittent.

Here are the energy costs of Vermont's SPEED program for RE systems less than 2.2 MW

Here are the production results for the SPEED Program, 2.2 MW or less:

Year..........Production............Paid to Owners..........$/kWh.........% VT Use

Units............kWh............................$

2010...........5,980,779...............829,832.88.............0.1387...........0.11

2011..........20,172,973............3,329,269.05............0.1650...........0.36

2012..........29,666,592............5,093,237.71............0.1717...........0.53

2013..........44,820,516............8,692,440.70............0.1939...........0.81

2014..........62,865,075..........13,190,927.86............0.2098..........1.13; after 4.5 years!

http://vermontspeed.com/speed-monthly-production/

http://vermontspeed.squarespace.com/project-status/

What, another energy project that's over budget & uneconomic?

I'm shocked...

... or maybe not.

As I stated, even biomass cogenerators aren't a slam-dunk and not necessarily economic, and a fraction of the output of those is a premium high value product (the electricity), rather than just low grade heat, as in a district heating project.

But, the initial capex for district heating will always be high compared to a replacement program for pre-existing individual oil boilers. It's not exactly a fair comparison given the lifecycle of district heating plumbing is several times the useful lifecycle of a boiler. A 20 year financial analysis is ludicrous, given that there are existence proofs of century-old district heating infrastructure that is still quite functional. Shall we do a 20 year financial analysis on a TVA dam project next?

The argument is a bit of a straw man, as is the 5% interest financing. About 3-4% is a more realistic discount rate on energy infrastructure projects, and the terms are never as short as 20 years, (though some can be as short as 30.)

So, would it make financial sense in a 4% 50 year analysis? Who knows? That kinda depends on what your assumptions are on energy cost inflation risk over that time frame, including carbon taxes or other methods of pricing the externalities of burning fuel oil vs. those of burning wood chips, etc.

I spend less than half what you do to heat my house, and as completely irrelevant as that is, it's still more relevant than comparing your house to a district heating scheme. Shall we compare the past and projected capital expenditures on our heating methods over a 50-100 year period too, not just the marginal cost? Whether the district heating project is a net win for the VT taxpayer over the actual lifecycle of the infrastructure won't be known for decades. I'm not particularly optimistic on that- I'm more of an agnostic, since predicting future energy pricing is a dubious business to get into. But comparing the marginal heating cost of your house for one season to the capitalization & marginal cost of a district heating system isn't apples to apples, it's more like night & oranges. A better comparision would have been comparing the district heating system to a "business as usual" capex + marginal cost of the same buildings on a 50 year basis.

Dana Dorsett

Dana,

The 20-year amortizing is just for illustration. You can go to this website and choose 30 or 40 years and choose 4% or 3%.

http://www.calculatorsoup.com/calculators/financial/amortization-schedule-calculator.php

The connected buildings are assumed to use up to 60 Btu/hr.sq ft, just for heating!! That is energy hog.

Service charges:

- Capacity $4.84/1000 Btu/hr;

- Energy $8.82/million Btu.

These charges were set much too low. No wonder users have been so happy. Everyone else is paying most of their heating bill.

It turned out my assumption was rather close to do my original analysis.

This became clear after the data for a partial heating season were released.

My 25-year old, not-super-efficient, house uses about 12 Btu/hr/sq ft, just for heating, about 1/5 th.

New England wholesale prices, at which utilities buy some of their energy, have averaged about 5 c/kWh for the past 5 years; those average prices are likely to remain steady, as there is an abundance of domestic, nearby, low-cost, natural gas for decades.

ISO-NE: “With plentiful, inexpensive supply from the Marcellus Shale in Pennsylvania and New York right at New England’s doorstep, natural gas continues to be the fuel of choice for new power plant construction in the region.”

There is nothing to celebrate having such a wood burning plant. Such building heating systems are based on, 100-year-old, bygone technology.

This is not “leading”. This is going backwards AND IN A WASTEFUL MANNER!!! Only government beaurocrats would call it a “success”. It is not THEIR money they waste.

It would be less costly, in the long run, to spend the $20 million on energy efficiency improvements to the building envelopes and systems, which would be nearly CO2-free. It would be much better to retrofit these buildings with solar panels, high R-value doors and windows, much more sealing and insulation, and heat pumps.

The comparison to a house is still pointless...

It's not clear why your house keeps getting dragged into the discussion. It's simply irrelevant- just additional heat load of required ventilation rates for many types commercial & industrial buildings result in a per square foot heating load adder as high or higher than the total per square foot load of a single family residence. It really is night and oranges, not even apples and oranges, even if BTU/ft is a number that can be applied to both, and they are both classifed as buildings.

That's not to say that spending the same amount of capital on building efficiency, heat pumps and better ventilation control &/or HRVs wouldn't have been a better investment than the district heating infrastructure, only that it's ridiculous to be talking about a house in this context. That is, unless all of the buildings using the district heating are single family residences. Are ANY of them single family homes?

I'm much less impressed with the economics Marcellus shale than many people, which is only profitable when the liquids fractions of the well are high, and liquid fuel prices are high, and the externalities of using the fuel are not being priced in. At the current wholesale cost of natural gas NONE of those plays would be profitable on just the natural gas product. The cost proposed major infrastructure build-outs for utilizing even more Marcellus gas in New England do not make economic sense even at recent $2-4/MMBTU wholesale pricing, which is why the developers are only interested if the costs get rate-based. It's a very risky bet. If you start pricing the climate and other externalities of burning natural gas it gets even worse. Rate-basing the cost of more gas distribution infrastructure seems like a dubious investment for the ratepayer. But there is probably a case for rate-basing a subsidy for distributed gas heat & power cogenerators or micro-cogens where gas heating is already in use. And spending the transmission pipeline money on more enhanced building efficiency is still a FAR better expenditure for the ratepayers. Only the folks drinking the frack-water truly believe that shale gas is going to be trading at $2-4/MMTU for decades. (Not even my in-laws in the gas & oil exploration biz are betting on that.)

I've never been impressed with the simple-economics of biomass district heating against the alternatives at US energy pricing, even though it makes economic sense in some European countries. But to correctly assess this particular project the broader economic effects of exporting the cash and employment out of VT to Quebec or NY for the gas & hydro alternatives would also have to be included to know if it could ever become a net-win for the VT taxpayers.

Log in or create an account to post a comment.

Sign up Log in