Image Credit: All photos: Michael Trolle

Image Credit: All photos: Michael Trolle Air-source heat pumps have proved to be so efficient and flexible the author has stopped using ground-source heat pumps altogether. A single, wall-mounted fan-coil unit both heats and cools the author's Connecticut home. The indoor fan-coil unit is connected to the outdoor unit of the ductless minisplit system. An energy-recovery ventilator captures both heat and moisture of incoming or outgoing air as it provides fresh air for the interior. A condensing clothes dryer returns heated air to the house rather than venting it to the outdoors. Although there is an energy penalty during the summer, it's much more efficient in winter than a conventional clothes dryer. The dryer's heat exchanger has been removed and placed on the table.

Editor’s note: This is the fourth and last installment in a series of blogs by Michael Trolle about the construction of his Passivhaus home in Danbury, Connecticut. The first part was published as “Building My Own Passive House.”

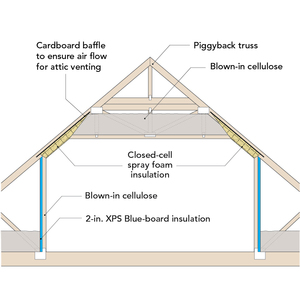

In my previous blogs, I’ve explained how the foundation, walls, and roof of my house are built using familiar American construction materials; but they are framed, air-sealed, and insulated somewhat differently from conventional building practice to create a thermal envelope that requires much less energy to heat and cool than a typical new home of the same size would use.

The four critical factors are high levels of insulation, a thick layer of continuous insulation uninterrupted by framing, an airtight envelope, and great windows and doors.

The result is a peak winter heating load (energy needed to heat the house on a cold winter day) of less than 6,000 Btu/hour. A new home built conventionally would require 22,000 Btu/hour. An older existing home might require 30,000 Btu/hour or more. My cost to heat the house for all of last winter was about $220, which kept the house at 70°F, which compares to a predicted cost of $1,000 for the same size home built conventionally and kept at 68°F.

The situation for cooling is no different. The same high levels of insulation and air-sealing work just as well in reverse to keep heat out. My peak summer cooling load is only 2,500 Btu/hour, whereas a new home built conventionally would need 14,000 Btu/hour. My cost to cool the house for the entire summer was about $84, keeping the house at 72°F, which compares to a predicted cost of $132 for the same size home built conventionally and kept at 78°F.

The savings are smaller on the cooling side because all homes have to remove a lot of heat generated by the people, lights, and appliances inside.

An air-source heat pump does the work

My house is both heated and cooled by an air-source heat pump (ASHP). This technology works by extracting heat from the outdoor air to heat the house and by dumping heat from the indoor air to cool the house. An ASHP is able to heat a house even when it is very cold outside. Mine is able to provide 92% of its rated capacity at 5°F, and it continues to work down to -17°F.

Last winter, when it was -12°F, my ASHP kept us at a comfortable 70°F, and it cost me very little to operate even then. Moreover, the outdoor unit makes less noise than a person whispering in a library!

While my single ASHP hangs on a wall and heats the entire 1,650-square-foot house, my company is using the same equipment to heat large homes with multiple zones. In these cases, we use ducted units to heat and cool zones of whatever size, wherever we want. The flexibility is so great, and the efficiency is so high that we have stopped using ground-source heat pumps (GSHP) altogether.

While GSHPs are slightly more efficient, they cost much more to install, are difficult to maintain properly, and cannot be set up for multiple small zones the way ASHP can. Moreover, our homes use so little energy that the extra efficiency of a GSHP doesn’t matter much.

Heating comfort with a simple system

Because my heating requirements are so small, my house does not need a conventional central heating system. Instead, we heat only the great room using an inexpensive wall-hung heat pump, and then use a small ducted fan system to move conditioned air from the great room to other rooms.

Heating only a single room in a 1,650-square-foot house only works in a house like mine with a highly efficient thermal envelope. A conventionally built American home — even a new one built to meet code — loses so much heat through the exterior walls and ceiling or roof that it can only be kept comfortable by distributing heated air to every room.

Last winter, I used a heat gun to measure surface temperatures all over my house. What I found was that the interior surface temperature of my exterior walls was exactly the same as the air temperature, throughout the house, on both floors. This is possible because of the superinsulation and the airtight envelope.

My European windows get slightly colder than the air but still stay within 7 F° degrees of the air temperature on a 14°F winter day. This means that wintertime window condensation is a thing of the past because the glass never gets cold enough to reach the dew point temperature.

Mechanical ventilation is a must

Airtight homes need mechanical ventilation to achieve high indoor air quality. By choosing to ventilate mechanically, we are able to bring exactly the right amount of fresh, filtered air into the house, allowing occupants with allergies or asthma to live symptom-free at home.

We built a similar home in Ridgefield for a couple with allergies who described how wonderful it was to come home, shed their allergen-contaminated clothing, take a nice shower, and then enjoy life, symptom-free. There is no secret to doing this. In fact, the first home I built 15 years ago was an American Lung Association-certified Health House, which pioneered the same strategies.

My Passivhaus, like all of our homes, uses an energy-recovery ventilator (ERV) to bring in fresh air and exhaust stale air. An ERV brings in exactly the same amount of fresh air as it exhausts stale air, which is called balanced ventilation. This helps to keep the air pressure in the house the same as the outside air pressure, which means that there is no pressure difference to induce unwanted air flows in and out of the house. This means that when doors are opened in the winter, there is no rush of cold air into the house, which is a nice comfort feature.

My European ERV transfers about 90% of the energy in the air, in the form of both heat and moisture, from the exhaust air to the fresh air during the winter months, essentially pre-heating my fresh air almost for free. In normal operation, my ERV uses between 15-30 watts of electricity, about the same as a CFL light bulb. During the summer months, when the house is closed up and I have the AC running, the ERV transfers the heat and moisture from the incoming fresh air to the outgoing stale air, essentially pre-cooling my fresh air, again almost for free.

A condensing clothes dryer wastes less energy

In order to maintain the airtight thermal envelope of a Passivhaus, you want the minimum number of holes, because each hole is a potential source of air leakage. One common hole in most American homes is the dryer vent pipe. A typical clothes dryer is essentially just a big electric hair dryer that heats house air, pulls it through wet clothes in a spinning drum, and then pushes it through a four-inch duct to the outdoors.

This works well to dry clothes, but it uses lots of electricity to create hot air, and then wastes that energy when the hot air is expelled outdoors. Moreover, the expelled hot air is replaced by cold outside air (air in always equals air out) which enters the house through the thousands of tiny holes in the thermal envelopes of most homes.

Worst of all, the vent hole in the house is never sealed well, and large amounts of cold air enter the house whenever the dryer isn’t in operation, which is 95% of the time. Depending upon the air pressure in the house, you can often feel cold, outside air as it flows into a house through the dryer. You can check yours by feeling for a draft around the door, especially when it’s really cold outside. A backdraft damper could limit this problem. Making the whole assembly airtight would help even more, but exhaust-type dryers will never be the most efficient way to dry your clothes.

My condensing clothes dryer is different. Like a normal dryer, it uses electricity to heat house air and pulls the hot air through wet clothes in a spinning drum. But then, instead of exhausting the hot air to the outdoors, it pushes the hot damp air through a heat exchanger, which causes the vapor to condense (the water is then drained). The remaining hot and dry air is then returned to the house for space heating purposes. In other words, the energy used to create the hot air that dries the clothes is also used to heat the house through the cold months of the year.

During the summer months, keeping the hot air in the house adds to the cooling load, which requires energy; but we live in a heating climate, and a condensing clothes dryer saves a lot of energy annually. To avoid the summer energy penalty, an old-fashioned clothesline is a great answer.

Michael Trolle is a co-founder of BPC Green Builders, in Wilton, Connecticut. This post, and the ones to follow, were originally published in slightly different versions at The HomeMonthly.com but also are available at the BPC Green Builders website. On October 7, 2015, BPC Green Builders was named Grand Award Winner in the Custom Home category in the Department of Energy’s Housing Innovation Awards.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

5 Comments

Look for a heat pump dryer, not just condensing

A condensing dryer does avoid the need for a vent and keeps the heat it generates inside the house. But it also uses more electricity than a regular dryer. A better option is a ventless heat pump dryer, which also keeps all the heat it generates inside the house, while using less electricity rather than more.

There was an excellent analysis here a few months back:

https://www.greenbuildingadvisor.com/blogs/dept/guest-blogs/heat-pump-clothes-dryers

In the meantime it appears that there's another ventless heat pump dryer on the US market, with even better performance than the Whirlpool unit:

http://www.blombergappliances.us/heat-pump/

ASHP

What make / model heat pump are you using, and what climate zone are you in? Thanks

Response to David Hollman

David,

Danbury, Ct. is in Climate Zone 5.

You can see from Image #2 that the heat pump is a Mitsubishi Mr. Slim.

.

Humidity control

Michael ,

There are many humid days in Connecticut without enough A/C load.

Does the ERV do a good job to manage humidity inside your house year round?

Have you ever had a need to run a dehumidifier on cooler humid days?

Or a humidifier in the middle of winter?

Humidity control

An ERV can only help to manage humidity by slowing down the moisture transfer from high to low (latent transfer efficiency of my Zehnder is about 70%, i think.) There is no active moisture removal process. Summer humidity management can only happen via AC or a dehumidifier, which we don't have. The first summer in the house, the RH was a bit higher than I wanted. As I recall, it was often in the 50%+ range This past summer the RH was mostly in the low 40% range, I think because all of the building materials have fully dried out. In a very air-tight house, even on cooler summer days, there is always some demand for cooling because of the interior heat load. (We keep the house closed up all summer to avoid the higher RH.) This small amount of cooling controlled the RH quite well this year. Winter RH runs in the 35-40% range early winter to 30-35% late winter, which we find comfortable.

Log in or create an account to post a comment.

Sign up Log in