Image Credit: Image #1: www.BadgerRadiantDesigns.com

Image Credit: Image #1: www.BadgerRadiantDesigns.com The lower the temperature of the return water, the greater the combustion efficiency.

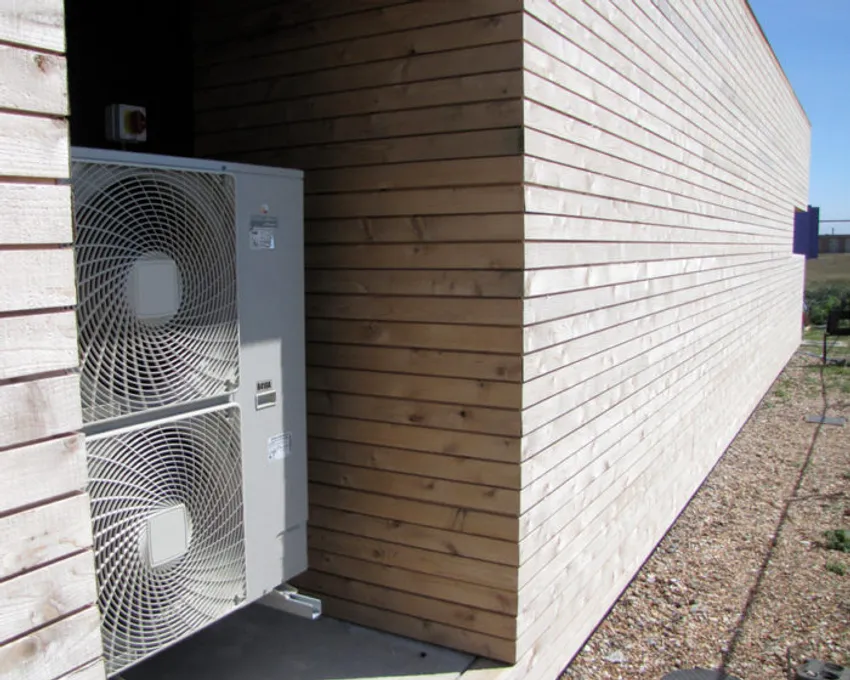

Image Credit: Image #2: GBA The Peerless PureFire is a gas-fired modulating condensing boiler suitable for single-family homes.

Image Credit: Image #3: Peerless

For the past few decades, an increasingly popular space heating option is a system with a modulating condensing (mod-con) boiler. Because these boilers can potentially have a high efficiency (90-95% or higher), they are often promoted by state and utility subsidy programs.

In a well-designed system, the boiler’s efficiency can hit or even exceed its nameplate AFUE. But as installed, most fall well short of their AFUE test numbers and often suffer an abbreviated lifespan. Efficiency problems and lifespan-crippling sizing errors could be avoided with a modest amount of analysis.

With a bit of simple math, the risk of ending up with a modulating condensing boiler that neither modulates nor condenses can be avoided. This math is by no means a substitute for a hydronic system design, but it’s very useful. Don’t just leave the design of your system to your HVAC contractor; be proactive, and pay attention to the details of any contractor’s proposal.

Modulating-condensing basics

To improve combustion efficiency, mod-con boilers take advantage of the fact that a major combustion byproduct of hydrocarbons is water vapor. Water as vapor contains latent energy (the “heat of vaporization”), which is about 970 BTU/pound. When water vapor condenses back to a liquid, it releases that heat.

With condensing equipment the key is to operate the appliance so that the water vapor in the exhaust condenses on the heat exchanger (not in the flue, and not outdoors) so that the heat of vaporization is delivered to the heating system water.

Without condensation of flue gases, the highest combustion efficiency that a gas or propane boiler can achieve is about 88%. Most non-condensing gas boilers are set up to run at about 82-86% efficiency. They are tuned to a lower combustion efficiency to avoid excessive flue condensation or damage to the boiler from the acidic condensate, and as a result give up even more source fuel heat to the atmosphere.

Condensing boilers are designed with materials tolerant of the condensate, but must be operated at a sufficiently low temperature to maximize condensation.

At typical air/fuel mixtures, the dew point of natural gas exhaust is in the low 130s Fahrenheit. No materials conduct heat perfectly. Films of gas next to the heat exchanger insulate the main exhaust, and films of water films on the water side impede the heat exchange as well. Usually, the entering water temperature (EWT) at the boiler needs to be 125°F to 127°F or lower before condensation occurs on the heat exchanger. But below about 125°F EWT, efficiency climbs rapidly, flattening out as the EWT drops to 100°F or lower.

Most mod-con boilers are designed so that the highest efficiency is at the low end of the firing range, below which point insulating laminar flows on the exhaust side impede heat exchange even further. At lowest fire and a 100°F EWT, most condensing boilers are operating at 94-95% combustion efficiency, but some are a bit higher. To operate with maximum condensing efficiency, these boilers come equipped with “outdoor reset” controls that sense outdoor temperature as a proxy for heat load, and vary the operating temperature of the boiler to the lowest temperature that actually meets the load. These controls have to be set up and programmed to find the fine line between higher efficiency and not quite keeping up.

The single most common error is failing to set up the reset curve properly, but that’s easy to deal with even after the equipment is installed. Other common errors can be much thornier to fix, and are better to simply avoid.

The most common errors

Modulation ranges are not infinite. The common screw-ups to avoid are related incorrectly sizing for the minimum output capacity firing rate rather than the maximum. There are two common variations to this error:

1. Oversizing the boiler for the heat load. When the boiler is oversized for the heat load, it spends most of the heating season cycling on and off rather than ramping the system temperature and firing rate up and down in response to outdoor temperature changes with nearly continuous burns. With every burn cycle there is some fuel lost during ignition cycles, and some amount of heat extracted from the heat exchanger with every (necessary for safety) flue purge. Fewer burn cycles adds up to less fuel thrown away, higher efficiency, and less wear on the boiler.

To avoid oversizing for the heat load, the first order of business is to get a reasonably accurate load estimate using either a Manual-J type calculation (using aggressive, not conservative assumptions) or, for replacement equipment, a fuel use load analysis. The boiler at high-fire at an assumed 88% efficiency needs to cover the calculated load, but it doesn’t need to be more than 1.4 times the load to cover even the 25 year extreme temperature events.

When the 99% design load is known, you’ll want to calculate the load at the average wintertime temperature. Pull up a WeatherSpark temperature graph for the area, zoom out to cover the 3 or 4 coldest months, and use the cursor to estimate the median wintertime outdoor temperature. If the minimum firing rate of a prospective boiler is more than the calculated load at the median wintertime outdoor temperature, it will be out of its modulation range most of the season. It’ll still heat the house, and maybe it won’t even short cycle (see problem #2), but it won’t be as comfortable or as efficient when it’s cycling on and off rather than firing nearly continuously, modulating the firing.

2. Oversizing the boiler for the radiation (and microzones). To keep the boiler from excessive cycling on calls for heat from the zones, there has to be sufficient radiation on each zone to elicit the minimum fire output of the boiler, at condensing temperatures.

The heat rate emitted by the radiators or baseboards varies with the average water temperature (AWT) and the length. Typical fin-tube baseboard might be emitting ~600 BTU/hour per foot of baseboard at 180°F AWT, but at 130°F AWT (the beginning of condensing) it’s delivering only ~250 BTU/hour per foot, and at ~120°F AWT (where it edges into the mid-90s for efficiency) only 200 BTU/hour per foot. The magic number for decent condensing efficiency is 200 BTU/hour per foot or less.

Similarly, cast-iron radiators deliver about 170 BTU/hour per square foot equivalent direct radiation (EDR) at an AWT of 180°F, but that drops to 70 BTU/hour per square foot EDR at 130°F AWT, and 50 BTU/hour per foot at 120°F AWT. With cast iron, the thermal mass will lengthen the burn cycles, but anything over 70 BTU/hour per square foot needs more analysis.

If the zone radiation can’t deliver the boiler’s minimum fire output at condensing temperatures, it may still heat the room, but the boiler begins to cycle as water temperatures drop. With more heat going into the water than is coming out, the water temperature rises, and is eventually above boiler’s outdoor reset curve temperature, at which point the burner turns off, even as the water continues to circulate. The burner re-fires only when the water temperature drops below the reset temperature. The cooler the water temperature, the greater the combustion efficiency (see Image #2, below), but at some point the losses from excess cycling exceeds any condensing efficiency gained, and high cycling rates prematurely wear out the boiler.

The more zones, the harder it is to have sufficient radiation on every zone to balance with the minimum-fire output of the boiler, and the more difficult it is to avoid short cycling. With high thermal mass radiation, micro-zoning can often work, but with low-mass emitters like fin-tube baseboard, it often requires adding a buffering thermal mass of water to extend minimum burn times.

The greater the available thermal mass, the longer it takes to raise the water temperature. With more thermal mass, the number of cycles drops. If the minimum burn times for the buffer are long enough that calls for heat from multiple zones are more or less guaranteed to overlap, modest cycling won’t reduce efficiency or boiler lifespan. At minimum burn times of less than 3 minutes or more than 5 burns per hour, the boiler is on the edge of a longevity and efficiency problem. One-minute burns and 10 burns per hour are on the edge of an efficiency and lifespan disaster.

An example

Take a hypothetical case from a prior article. In this case, fuel use analysis of a house in Washington, D.C., projected a realistic heat load of somewhere between 29,155 BTU/hour and 31,400 BTU/hour at an outdoor temp of 20°F. The house in this example was previously heated with a cast-iron boiler with an output of 88,000 BTU/hour.

Assume that this is a two-story house with a full basement. The house is divided into three zones, with fin-tube baseboard of the following lengths:

Top floor: 70 feet

First floor: 60 feet

Basement: 15 feet

Total: 145 feet

At an AWT of 180°F, the 145 feet of baseboard could emit 87,000 BTU/hour at an AWT of 180°F, which balances reasonably with the 88,000 BTU/hour cast-iron boiler. If all zones call for heat at the same time, burn times would be quite long.

Eyeballing it on a Weatherspark graph, the average winter temperature in Washington, D.C., is in the low 40s F, or halfway between the 60°F to 65°F heating/cooling balance point and the outside design temperature. So the average seasonal heat heat load is only about 15,000 BTU/hour, half the estimated 30,000 BTU/hour heat load previously determined.

The duty cycle of the old boiler at the average winter load is in the 15-18% range. Calls for heat from the first floor and top floor would often overlap, but not always. Basement zone calls would short cycle.

Ideally, the replacement boiler would fix those problems.

At 1.4x oversizing for a 30,000 BTU/hour load, a non-modulating cast-iron boiler would have an output of about (1.4 x 30,000 BTU/hour) = 42,000 BTU/hour. The existing radiation would emit that much at an AWT of about 140°F — which is above the condensing zone, and would not need to be protected against condensation.

Operating at 180°F AWT, the smaller first-floor zone would still be emitting 36,000 BTU/hour of the 42,000 BTU/hour boiler output, and cycling on single zone calls would be reasonable utilizing just the thermal mass of the boiler. The basement zone would still cycle on its own, but it would sometimes overlap with calls from the upper floors.

So what happens if the replacement is a small mod-con boiler like the Peerless PureFire PF-50 (see Image #3, below)? That boiler delivers 47,000 BTU/hour at condensing temperatures and about 43,000 BTU/hour at its maximum operating temperature (assuming high-80s efficiency). As a system it can deliver the 42,000 BTU/hour at 1.4x oversizing, but isn’t ridiculously oversized. Sound about right?

Maybe, maybe not. Let’s find out!

Testing for condition #1. The minimum fire input to the PF-50 is 16 MBH (=16,000 BTU/hour) so at 95% efficiency, its minimum fire output is 0.95 x 16,000 BTU/hour = 15,200 BTU/hour. That happens to be the approximate seasonal average. The boiler will modulate some even during the shoulder seasons, and all the time during the coldest weeks. Not ideal, but not terrible — modulating about half the time.

But can it condense?

With 15,200 BTU/hour of boiler output going into 145 feet of fin-tube radiation, that’s 15,200 BTU/hour divided by 145 feet = 105 BTU/hour per foot, which is well below the 200 BTU/hour per foot needed for condensing. So it definitely will be able to condense most of the time.

Testing for condition #2. Will it short cycle in condensing mode?

At 120°F AWT, the zones can emit:

Top floor: 70 feet x 200 BTU/hour per foot = 14,000 BTU/hour

First floor: 60 feet x 200 BTU/hour per foot = 12,000 BTU/hour

Basement: 15 feet x 200 BTU/hour per foot = 3,000 BTU/hour

The minimum-fire output is 15,200 BTU/hour, only 10% higher than the radiation is emitting, so the top floor will be fine — it’ll cycle some when it’s the only zone calling for heat, but the cycles will be long, and likely to overlap with calls from other zones.

With about 27% more heat going in than being emitted, the first floor zone would also probably be fine, but at an AWT any lower than 120°F it could hit short-cycling territory pretty quickly if it’s the only zone calling for heat. If it short cycles, the short cycling can be limited by raising the low temperature of the reset curve a bit, without taking a large hit in average combustion efficiency.

OTHER BOILERS

Are there more appropriate options for the example house and radiation than a PF-50? Absolutely! Many new generation mod-con boilers with fire-tube heat exchangers or dual heat exchangers can modulate efficiently over a wider range than the PF-50. The lower modulation range would fix both common errors (Error #1 and Error #2) with more of a margin. Here are examples of these new generation boilers:Boiler Model Min. input Max. inputNTI Trinity TX51 7,100 BTU/h 57,000 BTU/hNavien NHB 80 8,000 BTU/h 80,000 BTU/hHTP UFT-80W 8,000 BTU/h 80,000 BTU/hLochinvar CDN040 9,000 BTU/h 40,000 BTU/hIBC HC 13-50 13,000 BTU/h 50,000 BTU/hNote that the first three boilers have considerably more output at maximum fire than the 42,000 BTU/hour necessary for the 1.4x oversizing factor, yet they still have a very low minimum output — literally half (or less) that of the PF-50. Those are suitable solutions for 19 out of 20 homes in the U.S. with hydronic heating systems, and better candidates for systems that are broken up into smaller zones.

The basement is again hopeless on its own, of course. If it short cycles on basement calls one could add another 40 to 50 feet of baseboard at a lower cost than a buffer tank, but it’s probably not going to be worth the expense and effort since the long cycles from other floors means that basement calls usually overlap with calls from the other zones.

Success! From the simple-math sizing, the PF-50 makes it using the existing radiation. With some tweaking, monitoring, and fine-tuning of the reset curve, the boiler can probably come close to hitting its AFUE numbers. But breaking it up into smaller zones would clearly be a mistake, since it’s already coming close to short cycling on zone calls.

The sad reality

Most homes in the U.S. have true heat loads in the 20,000 to 35,000 BTU/hour range. While there are numerous boilers with comparable ratings (minimum and maximum output) to a PF-50, there are more 100,000 to 120,000 BTU/hour mod-con boilers being installed in those homes than 50,000 BTU/hour boilers, and that’s a shame. Oversized boilers cost more up front, cost more to operate, and don’t last as long as when the sizing is correctly proportioned to both the load and the radiation.

Unless they start with a careful heat load analysis, some installers would be inclined to install the PF-80 and still worry that with “only” 75,000 BTU/hour of output it wouldn’t deliver as much heat as the boiler it just replaced, and might fall short. Others would simply insist on a boiler with at least as much output as the old boiler, installing something as big as the PF-110 “just to be sure.” Either one of those would be a mistake, failing both Test #1 and Test #2.

The minimum-fire output of the PF-80 is about 19,000 BTU/hour, well over half the design output. That means it would only be modulating during the coldest weather, and would be prone to short-cycling on the zone calls at condensing temperatures.

The minimum output of the PF-110 is about 26,000 BTU/hour, which is fully 85% of load and about twice the amount of heat that either of the two main zones can emit at condensing temperatures. This guarantees that it will never operate above 90% combustion efficiency without short-cycling, and would only modulate during the coldest hours of the coldest days. This is more commonly seen than a right-sized boiler — it’s the rule rather than the exception.

Appropriate additions of thermal mass can mitigate short cycling, but it won’t magically make an oversized boiler right sized. Adding large buffer tanks re-invents the high-mass boiler, which is more conveniently done with a condensing hot water heater. There are many ways to screw up hydronic system designs beyond mere sizing, but unless sizing is right, the system can never be optimal.

Dana Dorsett has lifelong interests in energy policy, building science, and home efficiency. He is currently an electrical engineer in Massachusetts.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

26 Comments

Thanks, Dana, for this important article

Dana,

This is the type of useful article which will stand as a reference piece to help GBA readers for years. I expect that this topic will come up in future questions on our Q&A page --- and now, we'll be able to link to this article.

Don't be discouraged by the paucity of comments. While most Americans use furnaces, not boilers, readers in New England are grateful for your advice on boilers and hydronic systems.

What, me worry? :-) (Not a bit!)

Given that fewer than 25% of homes in the US are heated with hydronic systems, and only a bit more than half of those use fuels that can take advantage of condensing efficiency, and only about 3-4% of those boilers are going to be replaced in in a given year, this is by definition a somewhat esoteric topic. I view it as something akin to a cheat-sheet on a textbook chapter- a quick way to avoid egregious sizing errors that lead to higher cost, lower comfort & efficiency. In my limited experience in the field an on web forums I'd hazard that MOST condensing boilers currently installed are oversized for both the load and the radiation.

On another forum I recently read of a ~3300' house in PA with an 80,000-200,000 BTU/hr mod-con ( Dunkirk 95M-200 : http://www.dunkirk.com/sites/default/files/372_0.pdf ) installed 7-8 years ago that is short cycling on zone calls even at 160F+ output. The design heat load on that place is probably about 50K, and it's broken up into four zones, two of which are radiant slabs, the other fin tube baseboard. The tested AFUE is 95% for that unit, but there is no way it is getting more than 85% as-used AFUE. It literally never modulates OR condenses.

The homeowner isn't interested in replacing the boiler, is currently dealing with leaks in one of the radiant slab zones, and will be installing alternate radiation in that zone. Unfortunately it isn't physically possible to install enough radiation to suppress the short-cycling, and with the lower mass radiation the short cycling will be worse than it already is. If he's lucky the short-cycling beast will go another decade before succumbing, but I wouldn't bet the farm on that. Another 5 might even be optimistic. Had the homeowner run a heat load analysis and done the napkin math in this piece a right-sized boiler would last 2x as long, and the difference in operating cost over that 20 years would more than pay for the right-sized replacement. I suspect there were even state & local subsidies paid for installing that "96% efficiency " boiler, a total waste. This house would have done fine with a boiler with an 80,000 BTU/hr MAXIMUM input rather than an 80K minimum.

I WISH this was just an outlier, but unfortunately it's not. The design heat loads of average homes in climate zones 5-7 is under 50,000 BTU/hr, but there appear to be far more 100K-150K (or bigger) mod-cons in service than 50K-80K versions. With hydronic boilers bigger is definitely NOT better, and hopefully having a dumb-math crib sheet like this will help people avoid falling into that all too common trap. With condensing gas furnaces the output heat exchanger is built into the equipment and they will at least condense at any oversizing factor. Not so with boilers.

Mr Dorset -Your comments are always detailed and through…. are you an HVAC/energy consultant ?if so I would like to consult with you about a new build.

I need to replace a 2009 Buderus GB 142 gas boiler. Considering HTP. Not comfortable with any of the local contractors properly performing a manual J and would like to hire someone do help. Anyone??? I am in CT (not that this matters for the calc). Thanks

Andy

Spot on

I had to convince my installer to go with a 60MBTU/hr boiler, not 110, when his own heat loss calc showed 48MBTU/hr. To be fair, we have an indirect water heater attached as well. But the 60 has been fine.

Setting the reset curve was definitely an issue as well; the installer left with it set to whatever default was, and it was not at all correct. With some math & monitoring, I was able to get it tuned pretty well.

Speaking of monitoring, some boilers have ModBus interfaces which let you monitor them on an ongoing basis; I don't know if this would be of general use to many homeowners but attached are some fun examples from my boiler.

Mod Con Boliers

Great piece. Here in New Zealand it's impossible to get low output mod/con LPG boilers. Our house (270m²) has a heat requirement of 10kW at 0°C, but generally, because it is a modern build, only one zone is needed. This zone on the cold side of the house (South West) has a modulated demand of < 2kW at 5°C. Currently the hydronics are heated by an early (2011) 18kW Navien with a modulation ratio of 2:1 - all that was available at the time. Veissman, a German manufacturer make a really nice model range in the 300-W series, with one model able to modulate between 1.9 - 19kW. Large modulation ratios are essential to getting maximum efficiency from these boilers. Also, most manufacturers can supply 'system' and 'combi' units, with the 'combi' units able to supply domestic hot water as the primary function, then reverting back to central heating demand after the call for DHW is satisfied. As a rule, these 'combi' units have DHW heating outputs way above what is required for hydronics, and as such, I believe, are not suitable for hydronic UFH. There are so many efficiency gains to had by correct sizing, model choice and high modulation ratios, that they should not be ignored.

They're out there, but you may have to hunt (@ Michael Clarke)

The current model Navien NHB-80 dual heat exchanger boiler can modulate down to about 2.2 kw output. They make a smaller version too (the NHB-55) , but it has the same minimum firing rate, so the smaller size doesn't give it a modulating advantage.

The fire-tube HTP UFT-080 can go that low too. It is manufactured by the Korean company Kiturami, who exports it under their own nameplate as "HomSys" see: http://gd.kidp.or.kr/eng/product/eng_product_view.asp?idx=19408 I'm not sure if there is an LPG version available, or whether there is a way for a kiwi to buy it without going grey market.

Low mass combi systems rarely modulate below ~3.5-4 kw out, most are much higher. Navien makes at least one that runs that low. It is sold in the US under the model name NCB-180, and it comes in an LPG version.

Eric: The notion that you would have to upsize a boiler to manage the domestic hot water is rarely true, but apparently many installers in the US seem to believe (against all evidence) that the size must increase when the hot water load is added. It's generally better to size the indirect for the domestic hot water load (typically the biggest tub you have to fill) and the boiler to the space heating load. Zoned as a priority zone, a 60K condensing boiler delivers heat to the indirect about 2x as fast as a typical non-condensing 50 gallon standalone hot water heater. Suppressing space heating zones during the abbreviated recovery period for the indirect will never impinge on comfort unless one opted to schedule an "endless shower" for the coldest hours of the coldest nights of the year.

Default values on the reset curve are almost never a good fit, but with a fuel use analysis from a prior boiler (or from the trend line of the fuel use you nicely graphed out of the Solo-60), it's possible to find reasonable starting points and tweak it in over time.

Modulation has limits. For very low load homes or for micro-zoned homes it's often easier & better to use a condensing tank type hot water heater, utilizing the thermal mass of the water in the tank to suppress short cycling.

Tweaking the curve

@Dana - it sure seems like with a season's worth of data from the boiler (FWIW, heating degree days were gleaned directly from the outdoor reset temps, and heating therms were separated out from DHW therms) I should be able to set the "perfect" curve. I'll have to think about that some more in anticipation of next winter.

For non-geek homeowners, though, I wonder if there's any efficient method for an installer to get a better curve than default without requiring too many visits. I don't think your article elaborated on setting up the curve; maybe another article for another day?

Setting up the reset curve is outside the scope of this article.

To max out the efficiency of the curve you would need to estimate out the 99% design water temperature requirements on a room-by-room basis for the available radiation in those rooms. The room with the highest water temp requirement at the 99% outside design temp defines that point on the curve. If one room needs 130F water to keep up at design temperatures and all others only need 110F water, it either needs to be set to 130F at the design temperature or add enough radiation to that room to bring it's water temp requirements in line with the others.

Then estimate at which outdoor temperature at which the min-fire output equals the whole house load, and the water temperature required by the radiation to deliver that heat, which defines a second point on the curve. You also have to keep in mind at what water temp the boiler begins to short-cycle, and establish a low-limit on the water temp there independent of load.

Very few mod-con installers will even take a stab at it, let alone make multiple site visits to tweak it in for you. (Hell, it's hard enough to find one who will even size it correctly!) Better installers are willing to take a first cut estimate on programming the curve, and maybe talk you through how to adjust it over the phone if it's not quite keeping up or starting to short-cycle.

I'm not sure it's worth another blog article, but maybe. Different manufacturers have different approaches to outdoor reset, and the programming conventions vary (a lot). Some even include non-linear curves to compensate for non-linearities of heat emitter output with temperature at low temp. (Fin tube baseboard is very non-linear in output below 110F water temps, but tall radiators and radiant slabs are fairly linear even in the 90s F water temps.)

As with anything else, if you want the most out of it you have to read the manual and do some experimenting. It's usually better to start with tweaking in the water temp at the cold outdoor temp end of the curve first, dropping it 5F at a time until it's not keeping up overnight, then bumping it up a degree at a time until it keeps up with the setpoint. This is easy to do early in the heating season when the nights are getting colder, but may need some fine tuning at mid-winter. Finding the right water temp at the warmer weather end of the curve is a bit squishier, and more prone to being skewed by day to day differences in solar gain, etc.

Interesting but complicated

Very good read, Dana. But far too complicated for most. Having lived with hydronic heat the last 6 winters, I know it's not easy to get everything optimized. It get's even worse when there are not enough zones--that is the temp near your thermostat is not representing all areas within the zone it controls. I do have a couple easy questions: (1) Is there a maximum ratio of heat load requirement of smallest zone to lowest output of boiler that you would recommend? (2) Assuming someone got everything correct, do we know how long we can expect these mod-con boilers to last? I've had one the last three winters, and it beats the heck out of the old inefficient 1954 cast iron dinosaur it replaced, and the new boiler is probably oversized. I tweaked the curve many times the first winter and could never quite get it right, but a lot of that has to do with heat loss rates being so different in different parts of this old house--one room toasty, another okay under a blanket.

There are no simple answers. (@ Antonio Oliver)

Far too complicated? And this was about the 4th draft, AFTER simplifying it! :-)

To anwer your questions:

1) It's not really the ratio of the heat load of the zone to the min-fire output that's important, but rather the ratio of the RADIATION output (at condensing temps) to min-fire output of the boiler. Even in a micro-zoned system you want the smallest zone radiation to be able to emit the lion's share of the min-fire boiler output to limit the cycling. There's no one answer, but if the zone radiation can't deliver at least 2/3 of the min-fire output at condensing temps it's short-cycling potential is pretty high, unless you add thermal mass.

When you micro-zone a house you can sometimes do just fine with under-radiated zones as long as the boiler isn't oversized for the whole house load by utilizing a thermally massive hydraulic separator (eg Boiler Buddy http://www.boilerbuddy.com/ ) or some other buffering technique. When a boiler is right-sized for the whole house load the calls for heat from different zones will usually overlap, and the boiler will modulate as calls for heat from different zones come & go. By having the thermal mass of a high-volume hydraulic separator or buffer tank involved with every burn it establishes a minimum burn time, increasing the frequency and likelihood of zone calls overlapping. The napkin math analysis of how that works goes like this:

It takes 1 BTU to raise a pound of water 1 degree F. Most mod-cons won't turn off the burner until the water is 5-7F over the set point on the reset curve, and doesn't re-fire until the return water temp has dropped something like 10F from when it turned the burner off. A gallon of water weighs 8.34lbs, so to raise the temp of a 20 gallon buffer 10F takes 8.34lbs/gal x 20 gal x 10F= 1668 BTU. If the min-fire output of the boiler is 15,200 BTU/hr (like the PF-50 example in the blog article), the minimum burn time is then 1668 / 15,200= 0.11 hours, or about 6.5 minutes, even if the radiation isn't emitting anything. If the zone radiation is emitting say, 2500 BTU/hr then there is only (15,200 -2500=) 12,700 BTU/hr, and the burn time is roughly 1668 / 12,700= 0.13 hours or close to 8 minutes.

In reality even fin-tube has some water volume and other thermal mass as does the boiler itself, and you could add that all up for a first-order approximation of the burn times. It's never quite as simple as the napkin-math analysis, but that's the gist of it.

If you have old fashioned high volume cast iron boilers it has quite a bit of thermal mass in both the water and the iron. The specific heat of cast iron is about 0.11 BTU/lb-degree-F, so it takes ~9.1 lbs of cast radiator to add up to the thermal mass of a pound of water (or ~76 lbs of cast iron to be equivalent to a gallon of water), but if you've ever had to move them you'll know those suckers can be HEAVY. It adds up. Even 5" x 20" SunRad type radiators (popular well into the 1950s, and hopefully in your house) weigh ~5 lbs per section (dry), and contain ~1.25 lbs of water per section, so the cast iron itself is about 30% of the thermal mass of the radiator, and it's several times the thermal mass of fin-tube baseboard of equivalent output. Many of those houses can be safely micro-zoned without buffering, but you really need to run the math (at least the napkin-math) to get a handle on it. Minimum burn times based on the zone's thermal mass much shorter than 3 minutes run a short cycling risk.

2) Properly sized and maintained a mod-con with a stainless steel heat exchanger should go for at least a couple decades. Some of the aluminum HX versions are more sensitive to system water chemistry, and have higher failure rates. Some of the more recent stainless fire-tube HX designs look like they should go the distance without a lot of TLC, unlike many of their water-tube cousins. We'll see.

Very helpful, need guidance

Thanks Dana for this and your other article 'Sizing a ModCon Boiler'.

These have been extremely helpful wading through the wide and various options and opinions. I recently had my 20+ year old oil boiler fail. I would like to switch to and maximize the efficiency of propane which is the only gas option in my area. More than a half dozen contractors have visited our house and made proposals. Only one of them did a calculation which ended up being about twice the BTU/hr that I got when using your suggested Whole House Load Calc. I'd very much appreciate feedback from you and any other GBA experts that want to chime in on my heat load calc's as well as guidance on sizing and selecting a boiler.

Heat Load Calcs

I have a 1970's bi-level modular dropped on to a basement with half wall height above grade in front & one side, with on grade walk out for back & other side. The upper level is 1100 sq ft with currently 48 ft of fin tube and basement is 1100 sq ft currently unheated to which I want to add a zone. The walls on both levels are R-13, attic R-26, windows 1st gen double pane(which I calc as single pane) and basement floor uninsulated.

Using the Whole House Load Calc (screenshots in attached file) for 99% at -3 F, I get 39,583 BTU/hr for current condition. I plan on adding R-30 & filling all air leaks in attic, adding storm windows and/or treatments and insulating basement floor with R4-5 EPS under laminate. These changes result in 32,613 BTU/hr. Eventually I might re-side, add insulation and possibly replace windows but am not currently planning nor have the budget.

Using the Fuel Usage and Degree Day method for Jan 22 to Mar 11 at Manchester, NH Airport, I get 21,195 BTU/hr Base 65 and 23.351 BTU/hr Base 60:

125 gal oil x 140,000 BTU/gal x 65% efficiency = 11.375 MBTU

Note: I used 65% since boiler was running dirty and producing HW barely before dying.

11.375 MBTU / 1520.6 HDD / 24 Hr/Day = 311.7 BTU/Degree Hr * (65F - -3F) = 21,195 BTU/hr Base 65

11.375 MBTU / 1278.7 HDD / 24 Hr/Day = 370.7 BTU/Degree Hr * (60F - -3F) = 23,351 BTU/hr Base 60

I am not sure what to make of this compared to the Whole House Load Calc since a) only the upper floor is currently heated, not the whole house with basement, b) the thermostat was set to 50 at night (boiler didn't turn on at night until thermo reset to 64F in morning) and c) HW has been only for dishes and clothes since we have been showering at the gym not at home.

Equipment Sizing for Heat

Based on the Whole House Load Calc for the house without updates and using ASHRAE sizing factor, the maximum/top range of the boiler should be at least:

39,583 BTU/hr * 1.4 = 55,416 BTU/hr

Based on Radiation and Zones, my understanding is that I would want a boiler that modulates down to a minimum/bottom range of at least the smallest zone which is 10,400 BTU/hr or less:

Upper Level: 62 ft * 200 BTU/ft/hr = 12,400 BTU/hr

48 ft fin tube currently, planning 62 ft by adding 4 more ft (2100 BTU towel racks equated as 3.5 ft fin tube) in 2 baths plus 10 ft (or radiator) in currently unheated front hall

Basement: 52 ft * 200 BTU/ft/hr = 10,400 BTU/hr

52 ft per quotes, including a 2800 BTU towel rack in bath equated at 4.5 ft fin tube

Equipment Sizing for Hot Water

Based on my reading to date, my understanding I should go with an indirect for a house with 3 baths, 2 kitchens and a W/D and that the indirect should be sized (not the boiler) for the biggest demand which is typically the biggest tub or in my case when up to 6 adults want to take a shower in the morning during middle of winter:

Worst Case: 6 people * 7.5 min showers @ 2.0 GPM HW from indirect = 90 Gal in ~20 or more minutes

2 sets of (3) 7.5 min showers plus 5 min in between = ~20 or more minutes

Quotes so far have recommended indirect or combi units. I have eliminated the combi's as an option due to capacity, efficiency and longevity concerns.

Equipment Selection

My current thinking is I would like to buy a boiler that ideally 1) always runs (or nearly as possible) at high efficiency to minimize yearly and potentially higher propane expense; and that 2) is a quality design and build that lasts 20 to 30 years. I am wondering about the a) boiler sizes being proposed, b) boiler manufacturer reputations and c) the design and build quality. I realize I may need to make a compromise in build quality (ie 316Ti vs 439 stainless) in order to get more and higher efficiency across the heating season. I am guessing/hoping the payback in fuel savings over a estimated shorter life will likely make up for earlier replacement, on top of lower initial cost.

Proposal 1: Veissman BH-2B 26-94 with 60 gal SuperStor

One of the more reasonable estimates, coming in $1000 over the lowest quote for a Navien combi. He came highly recommended, is an authorized installer and been one of the best on listening and responding. I like the manufacturer reputation and solid 316Ti build of the boiler and the indirect. My concern is that it only modulates down to 19K BTU/hr (18 effective). I have asked the contractor about using the smaller BH-2B 19-68 which modulates down to 12K BTU/hr (11.4 effective) and am waiting to hear back on willingness and price.

Proposal 2: IBC VFC 15-150 with 40 gal IBC BTI

About $1000 more than #1, he's an authorized installer recommended by IBC regional rep. I like the manufacturer reputation, support, sensible design and solid 316Ti build. This boiler seems to come closest to my ideal with the only and major concern of it not modulating low enough - 15k BTU/hr (14.25 effective). A positive is it's on demand water capacity, tho that is not as important to me as boiler efficiency and economizing. Another concern is that the indirect is not as high quality with 444 vs 316L of the SuperStor, tho it comes with temp control. Not sure if this is a functionally superior point or just a parts cost one. Boiler also comes with built in internet access.

Proposal 3: IBC SL 10-85 with 55 gal IBC BTI

About $1000 lower than #1, he's an authorized installer recommended by IBC regional rep. I like the manufacturer reputation, support and sensible design but am not as keen on the 439 stainless build. This boiler tho comes closest to my efficiency ideal - 10k BTU/hr (9.5 effective). Same concerns on indirect as #2 and boiler comes with built in internet access.

Out of the options above, I'm leaning toward the IBC SL 10-85 boiler due to lower min modulation and sensible design that might last as long as the quality build of the Veissman. For an indirect tho I'm leaning towards the SuperStor for better stainless and assuming it integrates just as well with IBC boiler as the IBC BTI.

Guidance Needed

Am I on track in calculations and sizing boiler for max load? At what point is the minimum modulation a diminishing return in my situation? Is minimum modulation below 10k BTU/hr worth trading off for perceived/likely manufacture, design and build quality? Are my reading/perceptions/understanding of reputation, design and quality off?

I know there are other boiler manufacturers that offer even lower minimum modulation. However none of the boilers quoted so far have matched the IBC SL 10-85 minimum and the quotes with other brands have not been dramatically less (in many cases are actually quite more) for what seems like not as good reputation, design and build quality.

Thanks for your and everyone on the forum's help,

Anthony

Looks like you've done your homework!

Who ran the Manual-Js? What tool is that?

The Manual-Js are using 70F as the indoor design temp, which is quite a bit warmer than your 64F daytime, 50F overnight set back scheme.

If the average indoor temp of the house is really about 60F, you should be using base 55F weather data ather than base 60F or 65F to come up the BTU/degree-hour constant, but then adding ten heating-degrees (for a 65F balance point base) to come up with code-min 68F indoor temp load. My seat of the pants guess would be about a 400 BTU/degree-hour constant, x (65F- -3F)= ~27K heat load at a code min 68F indoors, -3F outdoors. To compare the fuel use calc to the Manual-J's results add a couple of degrees and it'll be about 28K.

If your presumed 65% boiler efficiency is lower than reality, your heat load result will be too. A combustion efficiency of 65% isn't just a bit dirty, it's REALLY bad. Most burners in a new boiler would run ~85%, and near end of life might still be tunable to 80%, and probably more like 75% if running a detuned. That would make the 28K heat load more like 28K x 75/65= ~32K (which seems about right for 2200' space, where the lower floor is half below-grade) but not 39K. Something seems a bit screwy with the Manual-Js but it's hard to say what without more detail. Is there literally NO insulation on the above-grade portion of the block foundation?

Don't down-grade the combustion efficiency to compensate for the hot water use error. Hot water use would be offsetting the error in the other direction from solar gains.

The smaller IBC looks reasonably sized for your radiation and loads, as is the smaller Viessmann.

The bigger IBC is overkill but can deliver 24/365 shower while simultaneously serving your space heating load (no priority zoning necessary.) With the reset curves dialed in to the nth degree the zone calls will tend to overlap, so the fact that it's min-fire output is 40% more than the smallest radiation zone can deliver shouldn't be a big deal, if you run the zones in "set & forget" mode rather than running setbacks. Since it looks like you can deliver ~23K at condensing temperatures with the existing radiation without cycling and that's more than 2/3 of your design heat load, it should be able to run in condensing mode most or even all the time, and you'd use less gas by fine-tuning the curve to run at the lowest water temperature/maximum condensing efficiency than you'd save by using setbacks, with a higher-temp recovery ramp from setback. But the min-fire output of the bigger IBC is still something like half your design heat load, which means it will cycle quite a bit more than something with a min-fire half that much.

The inexpensive ~80 KBTU Kiturami 10:1 turn down mod-cons are actually pretty good, imported by HTP, sold as the UFT-080W (or WBRUNG-080W under a Westinghouse name plate.) HTP's headquarters is an afternoon's round-trip drive from Manchester NH, and support regionally is pretty good. (I know an installer in ME who was a bit nervous about them at first, but is installing them by the dozen now. Reliablity seems high, by his reckoning.) Kiturami is a first tier Korean manufacturer that competes head to head with Navien in their home market, but has taken an OEM strategy for the north American market rather than building support network from scratch. A number of US & Canadian manufacturers are selling & supporting their mod-cons and tankless water heaters, etc. It might be worth getting a comparative quote. The 80K boiler modulates down to 8K-in 7.6K out in condensing mode, which should work great with your radiation, even without fine-tuning the curve to the nth degree.

If the shower is on the upper floor and the drains are below basement slab level it's going to be worth installing a drainwater heat recovery heat exchanger (the biggest that fits is the right one) to cut the BTU/hr load from showers in half. (My boiler never modulates over ~60K simultaneously serving both an endless shower and all zones calling for heat, thanks in good part to a 4" x 48" drainwater heat exchanger. I would have installed a taller one if it would have fit.)

Thanks, I’ve got great instructors!

I really appreciate all that you do. This is quite a learning curve, sometimes feels like I’m trying to wrap my mouth around a firehose.

I ran the Whole House Load calculations from the LoadCalc.net website referenced in one of the GBA articles. I attached their input and output details to my first post. I just re-ran and attached the details for the current and improved structure for 65F. I'm ok tho with designing to 68 or 70F for max load.

I re-ran the Fuel Usage calc using 55F weather data, getting 456.2 BTU/Degree Hour with 26,458 BTU/hr for 55F inside temp and 31,109 BTU/hr for 65F inside temp, both at -3F 99% outside temp. The LoadCalc is for both upper level and basement while the Fuel Usage is only the upper level, does not include the basement. So shouldn't the Whole House LoadCalc be significantly more (not sure by how much tho) than the Fuel Usage and HDD calc?

The oil burner was REALLY dirty, unable to heat hot water to temp and was blowing black smoke. Upon having it inspected and cleaned, the fire chamber(?) was full of soot with a failing power venter. I wasn’t trying to downgrade the efficiency bc of hot water use. Just taking a guess based on the boiler being rated 78% efficient when previously cleaned. I trust your judgement at what efficiency to use. The upper level house and basement walls are insulated R-13 with basement being more like ¼ below grade. The basement floor is not currently insulated tho.

I hear you on the IBC VFC and have taken it off the list. I am also leaning towards taking the Veissman off as well. I’ve been reading recent reports of Veissman support being subpar along with costly recurring Vitoden issues, while hearing IBC and HTP being responsive in support and owning product issues. And I’ve also not heard back from the Veissman contractor yet after 5 days.

I am reaching out to IBC and HTP for authorized installers. I spoke with an HTP installer who confirmed many if not most the points you and GBA have raised. He is the most knowledgable contractor so far, spending the time on the phone to discuss design point pro & cons for my situation. He believes a higher thermal mass is likely needed with the HTP UFT by either 1) replacing current upper fin tube and installing basement with low temp base board; 2) adding a buffer tank if keeping upper fin tube & installing basement with high temp fin tube; or 3) installing an HTP Pioneer instead of buffer tank in scenario 2.

He doesn’t believe the old/inexpensive high temp baseboard can emit enough BTUs at low temps to keep the boiler condensing as often. Is that true? I asked and he agreed that adding more length of less expensive hot temp bb in basement would help as long as done consistently across rooms.

Seems cheaper to add 10-20% more hot temp bb than pay 2+x more for low temp bb. As previously described I am planning on adding 25% more emitting capacity to upper level with either a 6000 BTU pan rad or 10 feet of fin tube in entry hall along with 2 heated towel racks in bathroom that are roughly equivalent to 4 more ft of bb. Would adding 25% more high temp bb to basement, for a total of 130 ft, not be enough? Or do I need to add enough emitter capacity (like 50% more for 150 total ft) to match or exceed the 99% load?

Another thing that was pointed out was that much of the baseboard is behind furniture, not as open and exposed to emitting heat. How much will this affect the heat emitting capacity of baseboard, whether high or low temp?

Two of the three showers/tubs are on the upper level along with a dishwasher and the stack goes down into the slab. Great idea, thanks! What should features and brand should I look for?

Thanks again for the help,

Anthony

More radiation doesn't hurt.

You can count on getting 200 BTU/hr per foot out of old-school baseboard and low-90s condensing efficiency out of the boiler. With 114' of baseboard that's enough to cover the load whenever the load is 23,000 BTU/hr or less, which is probably more than 90% of the time. (You'd have to do a temperature bin analysis along with a better heat load analysis to know for sure.) Do you NEED more radiation? Probably not, but it won't hurt, and you'd buy a little bit more in efficiency.

To go any lower in water temperature you'll need low-temp baseboard, but it's going to buy at best another 5% in fuel savings (probably less) It'll only need a buffer tank if you're running temps low enough that the zone radiation can't emit enough heat. So there's a trade-off. If it's only saving you $50/year in higher efficiency and it costs another $5K in buffer+ radiation is it "worth it"? The $5K might buy you more fuel savings and comfort by insulating the foundation better, cutting that 8K of calculated basement wall load down to something like 4KBTU/hr.

Panel rads are a real uptick in comfort level, and may be "worth it" on that basis, despite the high expense. Low temp baseboard is cheaper, gives more consistent performance at sub-120F temps than old-school baseboard, but not a big difference in additional comfort.

Like most Manual-Js the loadcalc.net tool tends to overshoot reality by a good amount. It's less sophisticated than the pro tools so there's only so much fine-tuning you can do with it. If it's giving you a ~30K design load number for the "after" picture, your real load is likely to be 25K, or a bit less (sometimes a LOT less.)

Nate Adams knows how to run a pro Manual-J tool, and even his Manual-Js over shoot a bit. See his discussion of calculated load vs. measured load on a retrofit project heated with a heat pump on his blog here:

http://energysmartohio.com/case_studies/1917-net-zero-ready/

He worked it pretty hard on every factor to bring the calculated load down to 27,719 BTU/hr. Measured reality after the fact was about 25,000 BTU/hr, about 10% lower.

ort.

The fattest and tallest drainwater heat recovery unit that fits is the right one. Home Depot sells Renewability's PowerPipe series, but it's usually cheaper (even with shipping) to buy them direct from the manufacturer.

https://usa.renewability.com/collections/r4-series

EcoInnnovation used to sell comparable performance ThermoDrain series units online at competitive pricing, but they only seem to be available through distributors now (and only in Canada).

http://ecoinnovation.ca/where-to-buy-homeowner

I've generally only kept track of those two, since only those two vendors are on the Massachusetts pre-approved plumbing fixtures list (I live in MA), and others would require a code waiver. (In my limited experience some the folks at EcoInnovation have a history of talking trash about the ethics of Renewability, but whatever the food fight was about 10 years ago they should be over it by now, but if not, take it all with a grain of salt, eh?)

For apples to apples efficiency comparisons model by model, Natural Resources Canada maintains third-party tested efficiency lists, tested to a protocol they developed for that purpose. You can look it up by vendor and model here:

http://oee.nrcan.gc.ca/pml-lmp/index.cfm?language_langue=en&action=app%2Esearch-recherche&appliance=DWHR&attr=0

or you can download the spreadsheet for comparison here:

http://oee.nrcan.gc.ca/pml-lmp/index.cfm?action=app.download-telecharger&appliance=DWHR

Thanks again... how much is too much?

What is a temperature bin analysis and what can I use to get a better heat load analysis, room by room more accurately correct?

What I think I’m hearing for boiler brand and model is that I’m better off with HTP UFT 80 unless it’s price installed is significantly higher to make up for the IBC SL 10-85’s higher 10k BTU/hr minimum?

And what I’m hearing is that I am close/likely to covering my design day requirements. Given the high price of propane and it’s yearly recurring cost, I would like to get the maximum efficiency and effectiveness per dollar of the system installed. Since baseboard is being installed in the basement anyhow and it is a 10-20% portion of the cost it seems worthwhile to spend 10-20% more or 1 to 4% more overall to get the best efficiency out of the boiler going from 114 to 130 or 140 ft, no? And since the bb piping in the basement needs to be cleaned up as well (currently portions are dangling below a drop ceiling), the cost will likely be marginal as well to tactically increase bb in the upper level. The question I have is whether I should use all bb or can a pan rad be added at the end of each zone and be better at increasing thermal mass and reducing RWT? The pan rads you referenced in another article at eComfort are reasonable enough.

I completely agree and appreciate your point on where to spend the next $5k. The basement walls appear to have 2x4 against the foundation with R-13 inbetween. I was figuring it’s not worth tearing them down to put 2” of EPS but better off putting the 2” on the outside of the whole house when/if I reside. Thoughts? I am planning on putting down at least 1” EPS on the uninsulated floor tho. Is it worth the extra $ to put 2” down if code allows reduced room height? There is currently R-13 in the basement ceiling. Should I keep or remove it?

Thanks for the recommendations and the Natural Resources Canada sight. Looks like I will be able to get a 54 or possibly even a 60” DWHR in. According to the NRC worksheet, EcoDrain V1000-4-60 has the best Heat Recovery Rate for 60”. The next best is the EcoDrain V1000-4-48, better than all other brands’ sizes up to 60” Is this right? And while R4-54 PowerPipe is best for 54”, it’s surprisingly close to R4-60.

Not to make this more confusing but is my house a candidate for a heat pump? I previously ruled it out based on varied feedback and what looked like the need for a super insulated house to work in my climate.

Temperature bins & heat loads

Hiring a certified professional engineer or RESNET rater to do the heat load numbers works. It used to run about $500 in my area, but it's probably a bit more now, but it depends on the complexity of the job and how much on-site work the evaluator has to do for measuring all of the relevant areas (windows doors, walls, ceilings etc.) and R-values/U-factors of what it will be AFTER any intended up grades.

A number of organizations maintain 25 year weather data sorted into hourly temperature bins. A year has 24 x 365= 8,760 hours, and when the hourly temperature readings are sorted by temperature it creates a profile of the local weather that's useful in HVAC specifications. The 99% outside design temperature is the 99th percentile temperature bin for the location- in other words only 1% of the 8,760 hours in a year are colder than that. But you'd have to look up what the 90th percentile or 93rd percentile bin etc and run the load numbers at those temps to determine the outdoor temperature at which you would need a high enough water temperature that you would lose condensing efficiency.

If this is PROPANE and not natural gas you'll almost always be better off (sometimes 3x better off) going with mini-split heat pumps than a propane fired boiler. In most of New England propane vendors are mini-monopolies- they own & maintain the tank and the sole right to fill it, and usually have a very steep charge in the contract for removing it, which puts a real damper on competition. Low volume users often get dinged for a very high price, well above the l;pcal average. I personally know of a situation in MA where a woman in a 600' house was stuck paying $5/gallon when the state average was running $3.50, and it would have cost $2K to go with a different supplier. I've read of a situation in NH where the homeowners stopped using propane altogether after installing a geothermal system. The propane delivery company first accused them of picking the lock and letting a competitor fill the tank. When they explained that they no longer used propane and wouldn't be refilling the vendor insisted they pay a removal fee (again multiple thousands). They refused to pay the fee, and it turned into a pissing match for a couple of years with the tank still in the back yard. (I'm not sure how that was ever resolved- maybe it's still there?)

There are a number of heat pumps with sufficient capacity to handle your sub 30K @ -3F load. If mini-splits it's usually better to zone by floor, using two separate units. There are both ducted and ductless solutions. Hot water using a heat pump water heater can work too, and with drainwater heat recovery you won't run out of showering capacity as quickly with a 50 gallon tank as you would with an 80 gallon and no heat recovery. Explain to whomever is doing the Manual-J that you're interested in a mini-split heat pump solution, and don't even start soliciting proposals until you have the room by room load numbers- HVAC contractors are often pretty terrible, oversizing the equipment to the point that it's less efficient and less comfortable. One of the guys in the office here has a ~1700' 1920s bungalow in Arlington MA (99% design temp +9F), and got all sorts of insane proposals until I sat him down and forced him to run the load numbers. He ended up with a three mini-split solution, a pair of 1-ton Mitsubishi FH12NAs and a 3/4 ton FH09NA, for about $12K (before state rebate subsidies), less than it would have taken to install gas fired mod-con, since it would have needed all new radiation. Depending on your floor plan you may want do do mini-ducted units, one per floor. It's easier than you might think if you're starting from scratch and completely re-doing the lower floor.

A pair of Fujitsu 18RLFCDs or a 12RLFD + 18RLFCD mini-ducted would almost certainly have sufficient capacity. That series has better air handlers than most of the competition, and have a fully specified capacity down to -5F, but keeps on going even at -20F at some unspecified output, but there are others.

http://portal.fujitsugeneral.com/files/catalog/files/18RLFCD1.pdf (More than 25,000 BTU/hr of capacity @ +17F, and more than 15K @ -5F)

http://www.fujitsugeneral.com/us/resources/pdf/support/downloads/submittal-sheets/12RLFCD.pdf (More than 19,000 BTU/hr @ +17F, 12-13K @ -5F.)

But there are also options, some with full sized air handlers, and options with fully specified capacities at -13F or -15F.

Efficiency Vermont maintains a list of cold climate heat pumps that qualify for subsidy in VT here:

https://www.efficiencyvermont.com/Media/Default/docs/rebates/qpls/efficiency-vermont-cold-climate-heat-pumps-qualifying-products.pdf

I'd DEFINITLEY be looking hard at this type of solution before going with propane.

One advantage EcoDrain V1000 has over a PowerPipe is llikely to be an extremely low pressure drop at high flow, due to their fatter multi-path tubing design. But at 4x60 or shorter or with low-flow shower heads it usually doesn't matter much. The PowerPipe design had for a long time had the lowest pressure drop units on the market. I have no idea what the pricing is like on the EcoDrain V1000 series is- it's relatively new to the market whereas PowerPipe and ThermoDrain have been around for at least a decade or more.

Heat load software and heat pumps

Can I do the heat load room by room myself with software? I have an engineering background along with some architecture. My father is a professional mechanical engineer as well who worked in the energy industry designing refineries and power plants. If so, what software or website would you recommend?

I have the weather data and can do the analysis. Do I really need to tho if I am confident that a system will cover at least the 99% temp efficiently?

I hear ya on propane! One of my big concerns has been that I may lock myself into a significantly more costly annual energy cost. Hence wanting to have the highest boiler, system and building efficiency. I am not sure I would be able to put ducts in tho bc the ceilings are 7’6” with the joists running perpendicular to the ends of the house where I expect the units would be installed. I suppose I could run ducts in the attic for the upper level. Each floor layout is open on one half end with 3 bedrooms at the other half end, with the floors having opposite layouts. Would this type of layout work for ductless? How would I identify a competent heat pump contractor?

I’m sold on the EcoDrain if its not overly priced. Thanks again for this suggestion.

Heat Pumps, Loads and Contractors

Hi Dana,

Any feedback on looking into heat pumps, heat loads and contractors?

Thanks,

Anthony

Doing heat loads well takes some experience

Most newbies end up being too conservative on all the input assumptions, and oversizing it almost as badly as the HVAC contractors using the same tools.

One of the most popular set of professional Manual-J tools are from Wrightsoft, but you can usually get an experienced engineer to run the numbers for you for less money than the price a full software license:

https://www.wrightsoft.com/nortekhvac/purchase.aspx

Sometimes the engineer will have to calculate some of the U-factors from scratch if the assembly type isn't found in the tool's menu.

https://www.greenbuildingadvisor.com/articles/dept/musings/all-about-u-factor

With any load tool (loadcalc included) make sure to specify a pretty tight house. Most of the default settings are on the extremely air-leaky side of reality for houses in cold climates. (They presume much higher air leakage than is even allowed by current IRC code.)

Figure out your loads first, thencome up with some of your own model selection possibilities before starting down the contractor search road. With a printed out Manual-J in hand you'll have something to push back on them with. Most start out with over sized (and often climate-inappropriate) proposals when left to their own devices.

Progress and obstacles

Thanks Dana, I searched for PE's and HER/RESNET raters but only found one for southern NH who does commercial, not residential. He did refer me to one in RI as well as ReVision Energy for installation. In the process I found room by room Manual J software online for $49 ( http://www.hvacloadcalculator.com ). Any experience with this one?

I am also looking into NHSaves HPwES audit and rebates, tho the audit does not sound like it will provide much specific sizing info other than whole house and perhaps more accurate infiltration #'s.

Initial contractor searches indicate they are aligned with typically one heating pump manufacturer, with Mitsubishi and Fujitsu being more common so far. Are there any manufacturers to lean towards (or away from) for heating or hw heat pump systems? Any words of wisdom on selecting a heat pump contractor?

Any other suggested for improvements for having a greener home and bank account? I am considering backup heat and power for the eventual and sometimes often NH power outages, as well as replacing the roof within 5 years.

Any and all insight and guidance is very much appreciated.

Local support matters.

The big three from an overall quality & support point of view are Daikin (the world's largest manufacturer of variable refrigerant volume cooling and heating equipment), Fujitsu, and Mitsubishi. But local support matters. If there are 2 dozen Fujitsu installers within an hour's drive of your house and one Daikin installer, would you go with a Daikin that has marginally better specs? Daikin installers are pretty rare in these parts.

Gree is the largest Chinese manufacturer of this stuff and OEMs a lot of equipment under US company nameplates. They have some cold climate equipment with good specs and Home Depot sells them, but I'm less convinced that the quality of the support in NH would be as good as Mitsubishi (which has a large presence in New England, including a regional design center in MA) or Fujitsu.

There seems to be a growing number of LG installers in this area, but I'm not sure how well supported they are by the distributors. Most of them seem to be doing it as a sideline to their primary "heating and plumbing' type businesses.

Factory training and certification sometimes matters too. A Mitsubishi "Diamond" or Fujitsu "Elite" installer has installed more than just a few, and have taken at least some of the training, which may not be the case with a air conditioning outfit that only does mini-splits as a side line and would rather sell you a 2 -3 ton Carrier or Trane traditional split system.

A contractor who will listen to what YOU think the house needs and will trust the Manual-J is important. Many will have their own ideas about what it's going to take (to make their next boat payment, not to heat/cool your house. :-) ) What, you have 10 rooms? That means you need an 8 zone 4 ton system with a ductless head each in six rooms and a couple of mini-duct cassettes supporting 2 rooms each. (They're out there!) Finding an installer competent to design and install mini-ducted solutions takes a bit more vetting, but they're around. Sometimes the design might have to be specified by a third party, but a competent installer should be able to follow the spec. It's good to have a VERY good idea about what it actually needs before soliciting proposals, which is why you need the load calculations first.

I have no experience with that particular load tool, but it's probably good enough for your purposes. (A Wrightsoft license isn't cheap.)

There is always another layer of house efficiency to tap. Checking back with the forums on this site when considering different approaches to parts of the renovation process doesn't hurt. There is quite a range of experience (professional and other) weighing in on this site.

HPWH and Appliances

Thanks Dana, very helpful. I have identified 2-3 Elite/Diamond contractors each for Fujitsu and Mitsubishi that have good social media and BBB reviews. I am working through on the Manual J, learning A LOT!

One issue though is what water heater to use. I will not have oil or gas, only electric. I read your comments on Martin's 'Heat-Pump Water Heaters Come of Age' article. Should I not use a HPWH? I will have a freezer in the same room and could possibly draw heat from a frig in the next room over.

Another issue is electric stoves(2) and dryer. I previously planned on replacing them with propane gas ones when I was previously planning on moving to propane with $200/yr estimated savings vs electric. Do I stay with electric or still move them to a smaller propane tank system? One of the positives of having propane was that I was considering gas fireplaces in upper LR and lower Great Room for enjoyment and backup heat during power outage. Would I be better off putting money into either a generator or solar?

Response to GreenGreenie

Green,

If the room where your heat-pump water heater will be located meets the minimum volume requirements set by the manufacturer of the heat-pump water heater you want to install, a heat-pump water heater may be a good choice. For more information, see this article: Domestic Hot Water: No Perfect Solution.

When it comes to the choice of propane vs. electric for heating appliances, most green builders are preparing for an all-electric future and getting rid of propane. This choice acknowledges that fossil fuel burning is contributing to climate change, and that our electricity grid is gradually integrating more renewable energy sources.

Follow up

Thanks Dana,

The article and your response is helpful and confirms my approach. Given the higher UEF for smaller HPWH units and DWHR recovery %, can I go with 50 and 66 gal HPWH? How does the DWHR recovery % translate into increasing a HPWH 1st hour capacity?

In meeting with contractors, the ducted units may not support all the ducts/rooms (LR, DR, Kitchen, 3 BR) on each floor, will be more expensive to install and have ~2 HSPF deficit (about $300 more operating cost per year) compared to wall units. Given their feedback along with other readers comments, would two wall units (one for each floor) make more sense?

Each floor is roughly half open living space with a hall down the middle going to bedrooms on other half. I am ok and actually like bedrooms being cooler than living areas. I'm thinking worst case is if the heat distribution ends up being a problem I can then later install small ducted units to feed the 3 BRs on each floor. Does this make sense? I'm wondering if I am getting the same level of advice as the contractor who installed the ducted systems you referred to. How many rooms did each unit support?

Thanks,

Greenie

I'm wondering about your calculation where you add a buffer tank to your system. You suggest that the boiler will fire at it's minimum rate. I would think the boiler would target a specific output temperature. If there is a small load from a secondary loop, it only has to add as much head as the secondary loop is taking out in order to get to that temperature. I would think it would see 20 gallons of cold water in the primary loop as a heavy load, and modulate all the way up until all the water in the primary loop hits the target temperature. This is bad because it doesn't lengthen the firing time much and the boiler is less efficient when it fires at 100%. The buffer will lengthen the cycle time only because it will discharge its stored heat into the active zone over a longer time. Do you agree?

One solution would be to attach a buffer tank that circulates water with a low flow rate, presenting enough of a load equal to keep the boiler firing at its minimum rate. That rate varies with the difference between the boiler target temperature and the temperature in the tank, so you would want have to have a fancy control system that targets the right certain load. The control system could monitor the temperature differential across the boiler, and, if it has a fixed primary loop pumping speed, it could target a specific temperature differential as a way of presenting the right load. When the boiler shuts off, it would keep pumping at full speed as long as one of the zones is active, unloading it's stored heat into the active heating zones. Or you can use a bigger buffer, skip the control system, and use a fixed speed pump, which is probably the cheaper option.

This seems like the right solution to me, but I haven't seen it in the heating literature.

Log in or create an account to post a comment.

Sign up Log in