Image Credit: All images: Sean Maxwell — Graph: Steven Winter Associates

In a previous article, I explained why it’s important to prevent air leaks between individual apartments in multifamily buildings — a type of air sealing known as “compartmentalization.” With my compartmentalization rant over, let me tell you how we can change our building codes to find a solution to the problem of leaky apartments, and why you should support a change to the language of the International Energy Conservation Code.

Code-required blower door testing

Blower door testing is a great verification tool, and it should be included in energy codes. The 2015 International Energy Conservation Code (IECC) calls for residential buildings to be tested with a blower door and verified as having an air leakage rate not exceeding 3-5 air changes per hour at 50 Pascals, depending on climate.

A little while back, my home state of New York decided to adopt the IECC and its blower door testing requirements, but when I was at Steven Winter Associates I recommended some changes to the language. These recommendations were adapted and adopted into the New York State Energy Conservation Construction Code, and just recently were signed into law.

I’ve recently submitted a proposal for change to the IECC based on the New York language. I’ll tell you why I think you should support that change.

A variety of test methods

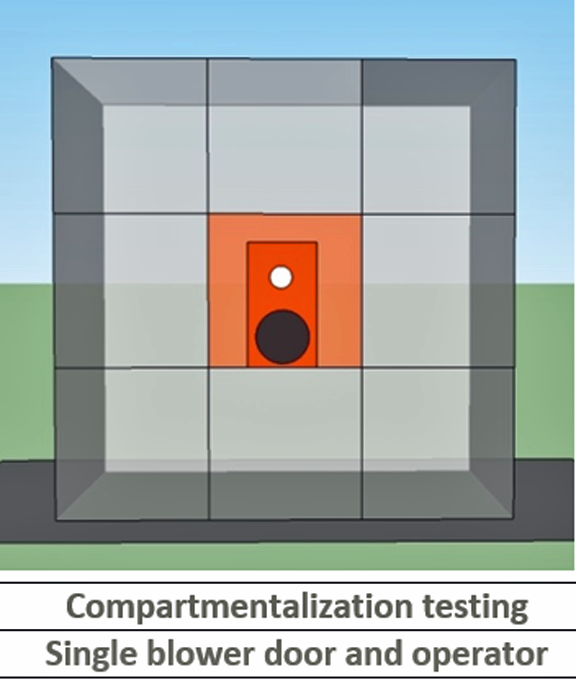

There are several valid ways to test a multifamily building’s air leakage with a blower door. Before we discuss these test methods, let’s first review some terminology.

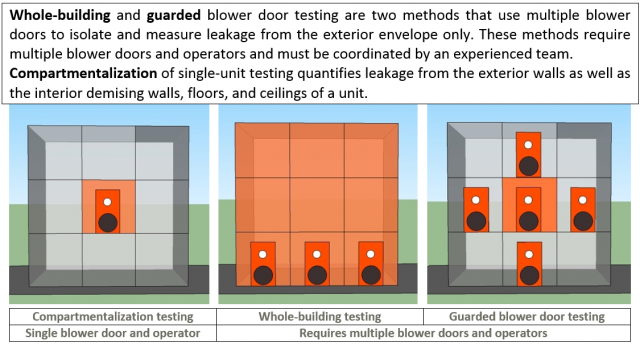

The simplest blower door test on a single family home measures only the leakage of the exterior envelope, which can be referred to as “exterior leakage.” In multifamily buildings, there are lots of other air leakage pathways besides from the exterior, and a blower door test on a single unit will measure some leakage from outside and some “inter-unit” leakage from other spaces. Multifamily buildings typically have lots of inter-unit leakage, but it’s exterior leakage from the outside that relates most directly to energy consumption.

Similar to a single-family home test, whole-building leakage testing uses one or more blower doors to pressurize or depressurize the entire building at once, measuring all the exterior air leakage in one shot. Because all spaces in the building are under the same pressure, inter-unit leakage is negated. For a larger building this method often requires multiple blower doors and experienced technicians to conduct properly. Factors such as building height, design, stage of construction, and especially weather on the testing day can make a whole-building test a challenge. Still, this test is quite popular, particularly in Europe, and for large commercial buildings, it may be the only option.

Another method is guarded blower door testing, which also requires multiple blower doors and experienced technicians to perform. It also aims to measure exterior envelope leakage by manipulating inter-compartment pressures with multiple fans.

The figure below illustrates this technique in more detail. It’s called guarded testing because it uses secondary “guard” blower doors placed around the target unit. These are maintained at the same test pressure as the target unit, which neutralizes any inter-unit leakage. The result is that only exterior leakage is recorded from the target unit.

By moving the doors around a building like a tic-tac-toe board, the exterior leakage of all the spaces can be isolated and recorded. The time-consuming process requires experienced operators, a good plan, and several blower doors even for a small multifamily building. This method is often used for research, but it is also a practical way to test some townhouse building configurations.

By comparison, single-unit or compartment testing (the terms are used interchangeably here) is simpler than other methods. A single technician with a single blower door moves around the building and tests each unit individually. Because no steps are taken to nullify leakage from other apartments as in whole-building or guarded testing, this test quantifies leakage from the exterior walls as well as the interior demising walls, floors, and ceilings of a unit. Experienced technicians will tell you that it is common for this inter-unit leakage to rival or even exceed that of the exterior leakage. Because exterior leakage is really what matters for energy use, this test is not very useful for energy cost calculations.

Which test is best?

Each test has its merits, but I believe that single-unit tests are most appropriate for residential buildings. Guarded blower door testing is more useful as a research tool, and whole-building testing can be too complicated and expensive to require on a wide scale.

One might argue that a compartment test yields a number that is essentially useless for energy models because it measures mostly interior leakage. That is largely true. But the goal of an energy code requirement is to save energy, and testing compartmentalization will do that. The reasons are both practical and forward-thinking.

Above all, for a code provision to be beneficial, it needs to be enforceable. More than the other methods, single-unit testing is easiest to introduce on a nationwide basis. It requires less training, experience, and equipment than whole-building tests. Many of the U.S. network of HERS raters and BPI professionals are all already qualified for it. As described below, the additional cost to builders in many cases will be less for single-unit tests than for other methods, when sampling protocols are used.

There are several complications with conducting whole-building tests on a wide scale that make it more troublesome to require by code. First, these large tests have high mobilization costs, and there are fewer companies that own either high-powered fans or multiple blower doors for bigger buildings. Second, the entire building has to be prepared (central exhaust registers taped, windows locked, central fans switched off, etc.) before the test can be conducted, and for a large building this can take several hours. Workers also cannot enter or leave the building during the test; it must be “locked down.” For this reason, it is virtually impossible to do a big blower door test early in construction during normal hours because work on the building cannot stop. Punch list time is ideal because fewer workers are present, but fixing big problems at that stage is much more expensive.

A single-unit test can be more useful to builders; it can be used to check progress and identify problems very early in construction when they are cheaper to fix. A tester can leapfrog and work around other trades in the building, reducing the disruption to regular workflow. If a unit passes the blower door test early on, the job is done; if not, fixes can be applied and a retest can be done in minutes.

The possibility of demonstrating compliance early is very attractive because it reduces uncertainty and potential cost at the end of the project. In fact, a higher-volume builder may decide to purchase a blower door kit and self-check periodically. Wouldn’t it be a very positive side-effect if the blower door became a common tool of the builders of tomorrow?

As for utility incentive programs that reward tight building exteriors, the builder may have to do a whole-building test at the end, but this is a much less worrisome prospect if smaller tests have been used to check progress along the way.

Compartmentalizing individual apartments is a good goal

Alternatively, some attempts were made by Steven Winter Associates to find links between single-unit, guarded, and whole-building blower door test data, and to arrive at “factors” for converting results from single-unit tests to exterior leakage figures that are more useful to energy models. This is as complicated as it sounds, and the best summary of that research is that more research is needed. One might argue for an alternative compliance option in the code that allows whole-building testing. But compartmentalization is a valuable goal in itself, and whole-building and guarded blower door tests do not take it into account.

Compartment testing leads the building industry in the right direction. It fosters a natural alliance between fire safety, health, and energy conservation professionals that other test methods may not. It is easy to explain and understand even for someone who has never seen a blower door, and the immediate benefits are apparent to builders, residents, and landlords alike. It also takes the building industry as a whole in a progressive direction by actually quantifying compliance with requirements for unit separation.

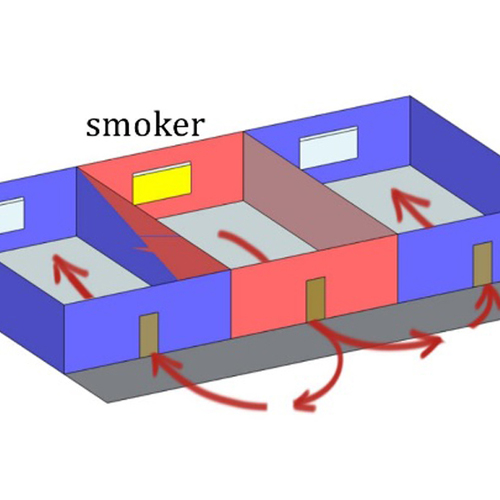

For example, consider fire-stopping. Passive fire protection includes stopping the passage of smoke and hot gases between compartments in a building. Manufacturers often color their products red, to make it easier to breeze through a code-required visual inspection of fire-stopping measures. Most inspectors see the red and check a box.

Look at the picture of the wall on the right. Does it look fire-stopped to you? It passed inspection in New York, but when we tested it, these low-rise multi-unit residential homes were very leaky. If it were my home, I would like to make sure that my fire-stopping actually stops fire. A blower door test can verify what a visual inspection cannot, because a passing grade is a number, not an opinion.

It is easy to imagine the next steps from here. One obvious step is to require blower door testing of apartments in larger residential buildings. It is also possible to look forward a decade to when compartmentalization of other major spaces — boiler rooms, trash rooms, and even separate leases in commercial buildings — is verified with a blower door.

Who would not like to verify that a boiler room is isolated from the rest of a large building? A quick test with a blower door will do that. This is the direction the industry should go.

Changing the International Energy Conservation Code

Many states have adopted various versions of the IECC but have shied away from its provisions requiring blower door testing. Mostly likely this is because the prospect of requiring whole-building tests on all new residential buildings, particularly multifamily buildings, seems daunting. Many code councils probably didn’t see a productive way to introduce it. New Jersey, for example, took the requirements for inspections of the air barrier and blower door tests and changed it to inspections of the air barrier or blower door tests.

Looking at some of the other currently recommended changes to the IECC regarding the blower door testing requirements, there are a range of approaches. Some are meant to strengthen the requirements, while others seek to weaken them or remove them entirely. But most seem to grapple with the difficult question of how to actually do blower door testing on larger residential buildings. Donald Surrena of the National Association of Home Builders in the U.S., a powerful industry group, attached the following comments to his proposal:

“Air tightness testing for single-family detached homes is very straightforward; however, it is much more difficult to accurately test attached dwelling units, including multifamily buildings. Currently the IECC treats low-rise multifamily buildings of three stories or less like single-family homes and multifamily buildings of four stories or more like commercial buildings. Regardless of height, all multifamily buildings have the same airtightness testing complications, such as: Does the entire building need to be tested at one time? What about multifamily buildings with open corridors? Does every dwelling need to be tested? Can the leakages be averaged between units? Is the leakage tested only to the ‘outside’ or should it include leakage to adjacent units?”

These questions and the resistance they cause are precisely the reason that an alternate approach to testing multifamily buildings is needed.

Defining an appropriate building code requirement for compartment testing

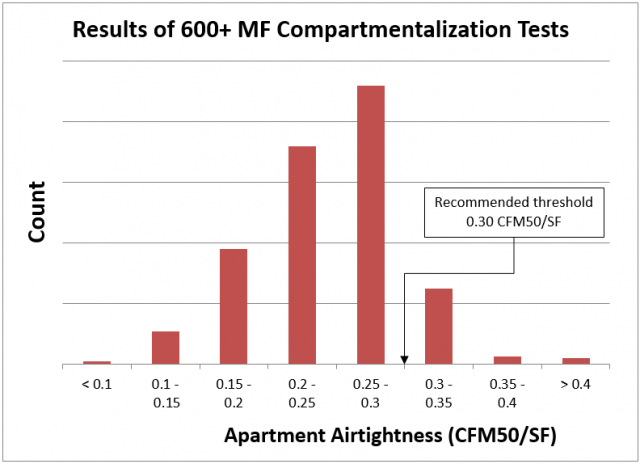

The language in our IECC proposal is largely aligned with language from ASHRAE 62.2-2013, LEED BD+C: Multifamily Midrise, and the EPA’s Energy Star Multifamily High Rise program, which recommend or require a maximum leakage rate of 0.30 cubic feet of leakage per minute at 50 Pascals per square foot of apartment envelope area (0.3 cfm50/sf), which includes the floors, ceilings, and interior and exterior walls of an apartment.

Will this threshold be difficult to meet? I can tell you that a builder should not have trouble passing the test unless something really big is missed. What fails apartment tests are typically big mistakes: the drywall doesn’t go from floor to ceiling between compartments; there are big holes in the fire separations where plumbing and electrical pipes run through; service chases are not fire-stopped between floors like they should be.

Steven Winter Associates maintains a database of multifamily blower door tests that it has conducted over the past five years in the course of certifying thousands of units of green and high-performance housing in New York State, and it shows that the threshold of 0.3 cfm50/sf is generally achievable. The graph at right shows the results of over 600 of these tests.

In the database, 88% of units tested in the Steven Winter Associates portfolio meet this threshold. While most of the projects participated in some sort of utility program that required compartmentalization, and therefore are not fully representative of typical practice, it clearly shows that the threshold is within reach for builders that make an effort.

Perhaps one of the main benefits of compartment testing is that for larger buildings, doing a series of smaller tests may end up saving money over a whole-building test. Using a hypothetical 50-unit building as an example, we estimated that it may cost less than half as much to test a building by compartment testing as for whole-building testing. (The IECC proposal has more information about how this cost estimate was made.) For this to be widely adopted by states, I believe this is a welcome option.

A testing approach that is easier and cheaper

The proposed changes to the IECC should make it easier and less expensive for builders to comply with the new code mandate to conduct blower door testing on most residential buildings. It will also make buildings safer, healthier, and more comfortable. Furthermore, simple compartment tests are easier to implement on a wide scale, are more enforceable, take advantage of a very large and already-qualified workforce in the form of HERS and BPI testing specialists.

Please view the proposal here and submit public comments by July 22. Look for Proposal RE56-16 on page 101. Anyone can view the proposed changes, but you’ll have to register with CDP Access to make comments.

Sean Maxwell formerly worked as a senior energy consultant at Steven Winter Associates in Norwalk, Connecticut. He now lives in Australia.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

3 Comments

What about common areas?

I agree that it makes sense to compartmentalize, and I agree that it makes sense to test compartmentalization with the simple low-cost test. Among other benefits, it might be that if you test the first unit that gets completed, and learn where the quality problems are, those aspects can be done right on the remaining units rather than needing to go back and fix them after completion.

But here's my question: What about the common areas, particularly stairwells, elevators, and hallways? If there is no air barrier between floors, you'll still build up stack effect of the full height of the building, and that pressure difference can drive flow through the common areas, as well as out of the lower units and into the upper units. I am not familiar with best practices in that regard and am curious what people try to do. From an energy conservation perspective, the ideal would be to leave those spaced unconditioned, such that the temperature would be close to the outdoor temperature, and no stack effect would develop, but I haven't heard of that being chosen deliberately, and I'm not sure it would be allowed by code or accepted by tenants.

Testing Methods

Sean, great article and I totally agree that testing is better than visual inspection. The benefits from reduced sound transmission, cooking odors, ETS contamination, fire separation, IAQ and comfort are too many to ignore.

LEED experience confirms

I recently worked on five multi unit residential, LEED Canada certified buildings in which smoking was permitted. For LEED compliance purposes, all units were sealed, and confirmed by blower door testing. However, benefits exceeded merely control of tobacco smoke. The quiet and lack of odor noticeable in the hallways of fully occupied buildings was remarkable. The LEED approach is to conduct testing in a representative selection of units (at least 10%, including all exposure conditions) - which might also be a reasonable indication of total building airtightness, given that all units are intended to be highly airtight.

Log in or create an account to post a comment.

Sign up Log in