Image Credit: Lyndon Than

Editor’s Note: Lyndon Than is a professional engineer and Certified Passive House Consultant who took a year off from work to design and build a home with his wife Phi in North York, a district of Toronto, Ontario. A list of Lyndon’s previous blogs at GBA appears in the sidebar below. For more, you can follow his blog, Passive House Toronto.

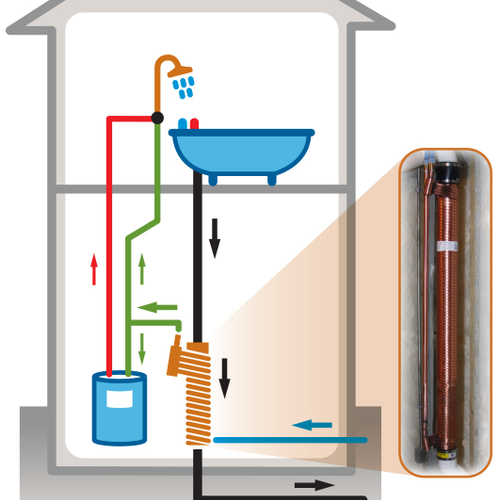

Drainwater heat recovery is a simple way of capturing some of the energy in hot water that’s headed down the drain — energy that ordinarily is thrown away.

Here are a few points to consider:

- The cost is $500 to $1,200. Installation is extra.

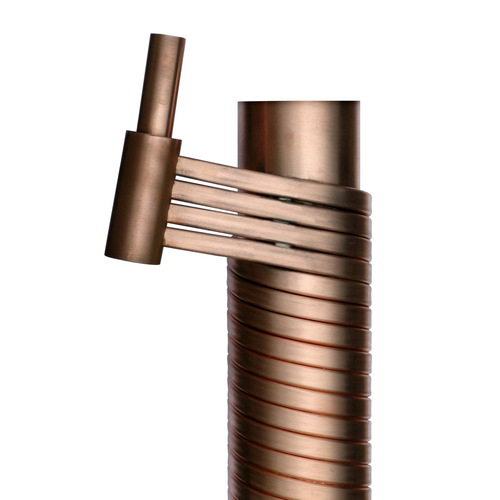

- Go with the largest diameter and longest exchanger you can fit into your plumbing, assuming a vertical installation. There are horizontal units available from Ecodrainalthough I believe they are available in just one size. Leave at least a 12-inch run of straight drain pipe above the exchanger to smooth out the flow. (You can see we’ve done this from the photos. We’ve used 4-inch pipe.)

- It is still worthwhile to pump shower drains in the basement back up so they can drain into the heat exchanger. The cost of these Gulper pumps with a kind of control that senses the water level in the drain is something like $300.

- Gather all your drains to one place, if possible. In our case, we’ve done this with all the shower drains in the house, which all happen to be clustered together in the building.

- Savings of about 20% or more on water heating energy is possible, depending on how things are plumbed in the house.

- Hot water recovery times can be dramatically improved. This, to me, is a very sure sign of energy being saved.

- The design requires a double-walled heat exchanger. In other words, there must be a (tiny) air space between the copper pipe carrying the drain water, and the copper pipe carrying the potable water — this severely limits the efficiency of the unit, and increases the costs (more on this later).

- Surface tension effects cause the drain water to stick to the drain walls in a thin film. This is why heat exchange is arranged at the surface of the drain pipe.

- Simple payback periods range from two years to 10 years.

Why not just leave the water in the tub?

One comment I’ve read is this: Recover your hot water heat simply by leaving the shower water in the bathtub and letting it cool to room temperature before allowing it to drain away. This is an excellent measure, and no cost to install, but it has some issues. First, it adds moisture to the house — good in winter, probably, not so good in summer. Second, it’s only possible with bathtubs because showers can’t hold much water. Third, consider the ring around the tub. Fourth, it gets difficult to have multiple showers in a short period of time, such as on busy mornings with a family of four.

And fifth, don’t assume it is 100% heat recovery. The water in the tub cools only to room temperature, which is almost the halfway-point from the cold water inlet temperature to the 40°C (104°F) or so needed for a shower or bath. So, heat recovery is something like 60%, similar to a good drainwater heat recovery installation.

Efficiency could be improved with another design

The best units are limited to something like 60% efficiency, measured in terms of inlet and outlet water temperatures. Industrial heat exchangers are good for over 90%, even over 95% in some cases. A much more effective design would be to have a copper drain pipe inside of a larger, plastic pipe filled with pressurized, cold water. This would increase heat exchange efficiencies a lot (to probably above 80%, easily more), and reduce the cost of the units greatly as well. It would also reduce the pressure drop incurred by the units we use today.

Given the huge potential for energy saving across a nation like Canada, one would think it is possibly worth the very small contamination risk. After all, if ever there were a leak, the pressurized water would go into the drain, not the other way around, and it would be fairly easy to detect: just check the water meter while all fixtures are turned off. Perhaps an annual check would be worthwhile.

Imagine if we could recover 95% of the energy used to heat hot water for bathing. Small electric point-of-use hot water heaters would be so much more viable; they could be built right in to shower fixtures, and this could lead to all sorts of interesting plumbing configurations (just plumb one line, for example — no need for both hot and cold?).

An alternate strategy

One way around this is to avoid the issue altogether. Instead of directing reclaimed heat to the domestic hot water system, transfer it to the space heating system instead, i.e. to a non-potable heat sink, such as a hydronic heating component, or directly to refrigerant in a heat-pump system. This avoids the water contamination issue, and can recover much closer to 100% of the energy used for heating water. Sadly, I know of nothing on the market that does this as yet, but it would be very easy to build something. A coaxial pipe heat exchanger is all you would need.

Another approach involves using an auxiliary tank and a pump. We recover heat even from processes like clothes-washing and dish-washing, in which the hot drain water is not expelled at the same time cold water is being drawn in.

Installation

You can see there is a lot of copper in these things. The one we installed was a good 60 lb. We came up with a simple way to mount the item effectively. We used a 4-inch water closet flange. We removed the small groove inside this flange so the 4-inch ABS pipe could be passed right through. This is basically creating a bulkhead fitting on your pipe, but there is no break in the pipe. Glue it on with solvent, and then mount it to a couple of wood runners, which make good supports. Notice also we’ve installed unions around the exchanger. This will let us more easily check its insides from time to time and clear out any build-up.

Water pressure losses

Something not mentioned very often: What about the pressure losses? The unit we chose to install uses a single 3/4-inch copper tube (about 60 feet of it) wrapped around the 4-inch drain. In choosing a product, it is a matter of heat exchange performance and this is measured by the Canadian government testing apparatus. After finding units that perform well, we looked for designs that retain the most water pressure.

So, how to plumb in order to retain water pressure? If you have high water pressure, this may not be an issue, but keep in mind, water pressure is not free. Someone, somewhere, must provide it, and I feel we must always think of our buildings as off-grid, so we want to minimize energy losses at every opportunity. Therefore, buy a unit that performs just as well, but results in the least pressure loss. Then, I would plumb everything through it. After all, we heat a lot of water to just room temperature via space heating — it sits there in the toilet, in the pipes, etc. But to recover that heat using the drainwater heat exchanger, the cold side must flow. Therefore, as per manufacturer recommendations, just plumb everything through it. I would still provide a small line to a drinking water fountain or ice maker, however.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

23 Comments

Tall heat exchangers can do better than 60%

"The best units are limited to something like 60% efficiency, measured in terms of inlet and outlet water temperatures."

Not exactly so. The NRCAN test protocol has a flow rate of 2.5gpm, which would be very high for a low-flow showerhead. Heat exchange efficiency improves at lower flow, since the gravity films on the drain side are then thinner, and the contact time in the potable side higher. A 1.75 gpm flow rate adds between 5-10% to the heat recovery efficiency of something that tests ~50% under NRCAN test conditions. see:

http://terrylove.com/images/power-pipe_recovery.jpg

Also, if there is room for a 9-10 footer (which may require putting the shower on the second floor) a 4" unit that long will typically test at about 70% efficiency, even at NRCAN's 2.5gpm flow rate (and likely north of 80% with a single 1.75 gpm shower running.)

Ecodrain also has a long horizontal copper heat exchangers (not relying on gravity film) but no listed third party NRCAN protocol test data on performance.

https://ecodrain.com/en/products/B1000/

Payback period?

What is the payback period? I spend less than $20/month for a natural gas water heater for our family of four (two teenagers).

Or maybe PV?

Thanks for the article. I love the idea of reclaiming drainwater heat, but the cost and complexity of the systems is a barrier. I wonder if, like the solar thermal collectors which Martin has often written about, the cheaper, more efficient, and more energy conserving solution would be adding a little more PV. One PV panel will generate more renewable energy each day than the drainwater heat exchanger can recover, for an average number of showers, in a reasonably sunny climate. It would cost a lot less, and have more flexible installation options.

Payback & complexity (response to #2 & #3)

Installing a gravity film type drainwater heat recovery heat exchanger (DWHR) rather than complex, is ULTRA simple, suitable for DIY installation in a single afternoon for someone with basic plumbing skills.

In new construction payback can be nearly instantaneous in situations where it allows down-sizing the other mechanicals, since it shifts the capital cost from the water heating systems, with typically sub-20 year lifecycles, to the heat exchanger with a 35+ year lifecycle, and a reasonably high scrap value at end of life. If the water is heated with a heat pump water heater (HPWH) the down-sizing of the water alone pays for most of the DWHR. The energy savings is just additional gravy on the top to seal the deal.

Even at 6 cents/kwh (under half the lifecycle cost of rooftop PV) most families heating water with resistance electricity will see a "payback" on energy savings alone in under 10 years for a mid-sized gravity film DWHR, and under 5 if they can fit a 9 or 10 footer. At 12 cent electricity (roughly the US average) simple payback is on the order of 5 years or less. One (of many out there) short analysis of the economics can be found in Table 3 of this document.

http://www.sustainabletechnologies.ca/wp/wp-content/uploads/2015/06/DWHR_TechBrief_June2015.pdf

This clearly beats the economics of just adding more PV panels at current residential rooftop pricing in the US.

But building out more complex systems than a gravity film DWHR the raw economics relative to rooftop PV are likely to go off the rails pretty quickly, perhaps as quickly as the extra foot of EPS under a PassiveHouse slab.

The natural gas energy savings gravy (for Mike):

Assuming 2-teenager 4 person showering family spends only $20/month for hot water, even on a fuel-only basis. That's only 65 cents/day, which at the US average retail price of about a buck a therm is only 65,000 BTU/day input energy. For a 50 gallon Energy Star EF0.67 hot water heater would deliver 0.67 x 65,000= ~45,000 BTU of the source fuel energy into the water, after flue & standby losses.

At a relatively low temperature rise of even 50F (say 55F incoming water, 105F at the showerhead) a 2 gpm shower uses 50,000 BTU/hr. The average showering time in the US is ~8 minutes, so with 4 people showering you're looking at (24/60= ) 0.4 hours, times 50,000 BTU/hr is 20,000 BTU per day. which takes (20,000/0.67=) 30,000 BTU/day of fuel input. That's nearly half of all hot water use (assuming buck a therm gas).

Saving half of that with mid-sized DWHR saves 15, 000 BTU/day x 365 = 55 therms/year assuming if your average incoming water temp is 55F (say US climate zone 4). A a buck a therm over 10 years that's $550, which is roughly the purchase price of a mid-sized DWHR unit if you shop carefully. eg: https://www.amazon.com/Power-Pipe-R4-42-Drain-Water-Recovery/dp/B00FZHTVSA (That one is only ~44% efficiency at the NRCAN tested, 2.5gpm, but will be nearly 50% efficiency at 2 gpm used in the payback discussion.)

If you have to upsize to a bigger tank to be able to serve up back-to-back or overlapping showers for 2 adults + 2 teenagers, deduct the additional cost of the bigger tank (and 2-3 replacements over the lifecycle of a DWHR). The burner size of a standard 50 gallon tank is sufficient to support a 24/365 shower at 2 gpm with a ~50% DWHR at 55F incoming water temperatures, and with 50 gallons of buffering thermal mass, overlapping a couple of showers for 8-16 minutes will work out fine, most of the time. During simultaneous showers the recovery efficiency drops a bit, but it's like adding another 25-35,000 BTU/hr of burner capacity to the water heater (but it's a burner that uses no fuel.)

Thanks, Dana

I appreciate your taking the time to respond. This article says a DWHR system costs $500 to $1,200, plus installation. You are calculating at $530 with no installation cost, so that is a contrast. My previous mention of complexity was in relation to retrofitting an existing house, with the plumbing likely already enclosed in the walls. Obviously, that is more challenging with the simplicity of installation during new construction.

I recognize that you understand vastly more than I about every aspect of this question, and I would be grateful if you added a few words of comparison with the PV side.

Your example DWHR saves $550 in ten years. How much electricity could you generate/save in ten years, if you spent $530 today on one or more solar panels? Assuming the simple case of a homeowner, who is planning to install a solar system, and is debating whether to add one or two panels to the plan, or to install DWHR. I found a calculation that $500 of PV today would generate about $1000 in electricity savings in 10 years. Do you find this credible?

Derek

Taking Dana's number of simple payback in 5 years at 12 cents per kWh, we find he is predicting saving 4400 kWh. That's with a heat pump water heater. With a regular electric one, it's 8800 kWh.

If you spent $530 on PV, at $2/W, you'd get one 265 W panel, and you'd produce maybe 320 kWh per year. After 5 years you would have produced 1600 kWh. $2/W is very optimistic.

So Dana is quite right when he says the drainwater recovery is a better deal.

Note that in many existing houses with basements, there's a vertical section of drain pipe sitting exposed, ready for easy installation of a drainwater heat recovery system, with no need to open any walls.

Perhaps, Charlie...

I appreciate your response, Charlie, but the Internet gives me very different numbers. Dana bought his DWHR on Amazon, picking the cheapest example. If I do the same for a PV panel, I can get a choice of many PV panels at $1/Watt. Like the DWHR example, they aren't the best, but they are genuine PV panels for sale by the nation's most available retailer at half of your "optimistic" cost estimate. NREL tells me that more than half the US averages over 5 hours of PV-harvestable sunlight per day, and various online solar calculators say that this calculates out to about 1.5 kWh per kW of rated peak PV output per year. So $530 will buy me roughly 500 kW of rated solar output, which will produce roughly 750 kWh per year. 10 years will produce 7500 kWh, and at 12 cents per kWh, that's about $900.

But why would I buy from Amazon, when my local Craig's list offers "New Panasonic 255w solar panels - $102", with full warranty. Now my $500 buys me 1275 Watts, good for 1912 kWh per year, and $2295 in electricity, over ten years. Whereas Dana said that the Amazon DWHR was paying back its $530 cost in about 10 years.

I'm not claiming that these numbers are the ones we can bank on, but they are real examples of products for sale and NREL-endorsed calculations. If these numbers aren't right, then what are the most credible numbers for this kind of calculation?

https://albuquerque.craigslist.org/fod/6062670389.html

Response to Derek Roff

Derek,

You haven't mentioned the cost of permits, aluminum racks for roof mounting, wiring, or an inverter.

A realistic cost in the U.S. is $3/watt, installed.

To determine how many kWh of electricity per year your PV system will generate, visit the PVwatts web site. (The answer depends on your geographical location.)

An apples-to-apples comparison needs to compare the actual installed cost of a drainwater heat recovery device, installed by a plumber, with the actual installed cost of a PV array, installed by an electrician.

Back-of-the-envelope calculation: If you have a gas water heater and inexpensive natural gas, you should invest your extra money in PV. If you have an electric water heater, you might want to install a drainwater heat recovery device (especially if you can install it yourself, or can install it inexpensively).

-- Martin Holladay

No need to throw away energy

Thanks for some very detailed and insightful comments.

Dana's inputs are right on. Given the energy content of water, drainwater heat recovery represents quite a lot of energy. If we are paying for domestic water supply, why let it leave the house at 20deg C or higher? If it comes in at 10deg C, let it leave at 5 deg C! No need to stop at 100% recovery.....

Personally, if we rely on full costs for calculating everything, I wouldn't be installing half the stuff I do. Sometimes it seems like high labour rates are totally bad for the environment.

The good news on the payback periods, is a sign that this is a low hanging fruit. Recirculating showers (like this one https://orbital-systems.com/) seem like an excellent idea to me, though the ones offered right now may be ridiculously expensive - but these use about 10% of the energy, AND about 10% of the water.....I figured this would make drainwater heat recovery obsolete, but some time has passed now and there is no sign of the units getting into the NA market, nor do I see any code agencies taking a look.

Even at $1200 installed cost it's cheaper than $3/watt solar

Remember, the avoided cost of larger water heaters ( x 2-3 water heater replacements over the lifecycle of the DWHR unit), less the residual scrap value of that much copper are at least as important as the energy cost savings.

I won't take up the space to run net present value calculations at different price points, but one can also include at the hedge value on potential energy price inflation too (with both PV & DWHR.) The complexity of the financial model can be as messy as you like too, eh? :-)

There are other $500-600 DWHR units out there, and it's not a lot of plumber labor to install in new construction (less than 2 hours additional), and it's a dead-easy DIY as a retrofit if your drain plumbing is exposed. Even at full retail:

http://www.retherm.com/ProductsAndPricing.htm

http://www.renewability.com/order_powerpipe_online.html

http://ecoinnovation.ca/pricing/

Sometimes it take a bit of digging to find the street price, but most listed prices at manufacturers are well above the actual prices available through distributors & plumbing supply houses catering to the trades, so as not to compete head to head with those outlets in their respective markets.

With heat pump hybrid water heaters the additional value of the smaller water heater can be nearly the full cost of the DWHR, and the efficiency of the water heater itself goes up, since it'll be less necessary to engage the resistance heating elements to keep up, running a larger fraction of the time in heat pump mode.

What is incremental cost in New construction?

Three dollar per watt is probably typical. But adding an extra panel or two may not cost that, since the inverter, wiring, permits, administrative costs, etc. are probably not increased by much. Panels are available for less than a dollar per watt.

Another DWHR data point

I estimated the potential savings for DWHR in my home. They were influenced by the layout of the house which resulted in the drains for the three showers being separated from one another. DWHR only made sense for one of them. One of the showers is in the guest bedroom and is rarely used, so DWHR doesn't have a good ROI. The kids bathroom is in the basement, so DWHR would require a pump. Besides, the kids are college age, so I don't plan on them living there full time indefinitely. (Reality may be different.) The master bathroom only has two users. The ROI was financially rationale but not a no-brainer. I estimated $65/year in energy savings. There is a big +/- range on that estimate depending on water usage assumptions. DWHR didn't reduce the tank sizing because the high usage scenarios involve people showering in the other bathrooms. Since the drain is exposed, I decided to save DWHR as a potential DIY project.

And another solar datapoint: We just installed rooftop solar for $2.55/watt before tax incentives.

I shower at < 1 GPM (doesn't

I shower at < 1 GPM (doesn't bother me with high pressure), which significantly effects DWHR payback calculations.

PV direct to water heater (ie, no inverter, no grid-tie) is something to keep an eye on.

Thanks for the additional info.

I appreciate all the additional comments, which give me a more complete picture of the costs on both the PV side and the DWHR side. I'm sure this information will be useful to other readers, as well.

I agree with Stephen Sheehy, that in this comparison, it makes more sense to consider the incremental cost of adding one or two additional PV panels to a larger solar system (new or expanded). It's a safe bet that few homeowners are considering installing a new solar system comprised of only two PV panels (or a $500 budget). Racking cost is relevant, but I doubt that there is an incremental cost in the permitting, between a 5 kW and a 5.5 kW system, for example. We aren't calculating the cost of plumbing permits, on the DWHR side of the equation.

I agree with Martin, that a person must consider local solar production, which varies with location. Where I live, and across many states in the southwest, NREL gives a multiplier of ~1.8 for converting rated PV output in watts to yearly production of kWh. In Hawaii, it might be 1.6, in Florida, 1.5, in Little Rock and Saskatoon, it's 1.4, Burlington and Edmonton, it's 1.3. Those are important differences.

Even though the drain water pipe from my shower is partially embedded in an adobe wall, the information in this discussion gives me enough data to consider adding DWHR. I'll invite Dana over to show me how easy chipping out an adobe wall is as a DYI project, but even if he doesn't show up, I think I could do it in a couple of days. That's probably worth it to me, although not for financial reasons. We already heat our domestic hot water with PV panels directly connected to an electric water heater (no inverter, batteries, nor heat pump- also mentioned by John R, comment #14). We needed to switch on the 240 VAC backup power during parts of five days during the last year, and eight days the year before that. I'd spend $500-$600, to reduce that even further- hopefully to zero.

I would welcome additional links to recommended US DWHR vendors and manufacturers.

At <1 gpm the recovery efficiency is ~75% or higher (@Jon R)

Yes, lower hot water use affects the payback time, but lower flows increase the recovery efficiency (by quite a bit) too. That needs to be factored into the analysis. A second-generation Retherm that tests at a mere 45% efficiency @ 2.5 gpm delivers better than 55% efficiency at 1.5 gpm, and would likely hit well north of 65% at 0.75 gpm. A 3"x 60" PowerPipe testing at 54% @ 2.5gpm delivers over 66% @ 1.5 gpm and is likely to be north of 75% @ 0.75gpm. See:

http://terrylove.com/images/power-pipe_recovery.jpg

Regarding Derek's comments:

The incremental cost of bumping a 5 kw system to 5.5kw isn't always clear, but just in raw hardware cost it's going to be over a buck a watt (installed) for first-tier vendors' goods, even if the panel cost is under a buck a watt. A large fraction of the $/W is "customer acquisition", which doesn't change too much with a 10% increase in system size, but re-spec the system components or re-running the design numbers adds some design cost, and there is incremental rooftop labor as well.

Yes the capacity factor of your PV changes dramatically with location, orientation & shading factors, so it's important to get that figured out pretty well before plugging a capacity factor number into NREL's levelized cost calculator.

I'd imagine that it doesn't take pneumatic tools to make quick demo work on adobe. A heavier-duty hammerdrill with a 1" chisel bit will take a couple of hours to accomplish what takes couple of days with a hammer and chisel, but I won't be testing that thesis with you. ;-)

At this point most DWHR vendors are in Canada (where the incoming water temps are pretty cool), though GFX (one of the original vendors) is located in New York:

http://www.gfxtechnology.com/index.html

I'm not aware of any other US manufacturers of DWHR units of any type.

In Canada there is

Watercycles: http://www.watercycles.ca/

Econinovation: http://ecoinnovation.ca/

Renewability: http://www.renewability.com/

All of the above have third party tested standard protocol efficiency data on their products listed in NRCAN's database.

In addition there is:

EcoDrain: https://ecodrain.com/en/ (multiple types, not just gravity-film)

Retherm: http://www.retherm.com/ (another gravity-film HX vendor)

Be careful!

Read this excellent research report http://www.regie-energie.qc.ca/audiences/3637-07_2/DDR3637_2/RepDDR/B-12-GI-23Doc1-2_RepDDRSE-AQLPA_3637-2_28sept07.pdf . It is the best, practical, relatively thorough study I'm aware of analyzing the performance of various DWHR units in actual tests.

One of the most important things, in my opinion, is the dramatic difference in pressure loss among the various units. The "Power Pipe R3-60" unit provides not only the best thermal performance, but also substantially lower pressure losses than most of the other units. The Power Pipe R3-60 has an insignificant pressure loss of ~ 2 psi compared to many of the other units with pressure losses as high as 12-14 psi at 2.25 gpm flow rates!

This is primarily caused by the size of intake piping around the heat exchanger. If you have 1/2" diameter copper piping instead of 4 x 3/8" copper piping (Power Pipe R3-60) you only have approximately 50% of the cross sectional area for water flow. The result is substantial pressure losses and lower capacity.

My conclusion is that DWHR units are a no-brainer. Especially if you don't have access to cheap natural gas. If you're running propane or electric resistance hot water, a good DWHR will pay for itself in 5+ years. Not to mention the significant improvement in "first-hour" hot water capacity.

But if you choose the wrong model, you may be disappointed because of significant pressure losses in your system - especially if you're on a well system with maybe only 40 psi.

Subsidies DO skew the results (@ Reid, #12)

At a 5% discount rate and a 25 year analysis assuming a 15% capacity factor (don't know what it actually is in your location & orientation & shading factors) the levelized cost of $2.55/watt PV is about 14 cents/kwh.

Reduce the discount rate to 4% and raise the capacity factor to 18% and it's a bit over 10 cents/kwh.

But if you're getting a hefty subsidy reducing the installed cost to $1.75/watt (not sure what's available to you) the levelized cost of that 5% discount/15% capacity PV drops to 9.5 cents, and the 4% discount/18% capacity drops to about 7 cents/kwh.

Play around with this online calculator a bit, and see if you can't figure out what your actual capacity factor is likely to be as well as what discount rate makes the most sense for your situation. (If you financed it, using the interest rate might be a starting point):

http://www.nrel.gov/analysis/tech_lcoe.html

Even at 7 cents/kwh, for most showering families DWHR is still financially rational, but it's a decade long rather than 5 year (simple, not NPV) payback. At an unsubsidized 14 cents/kwh, DWHR will still be financially rational over a decade or so even if only two people are showing daily.

Clearly at some installed $/W price point more PV rather than DWHR will be financially rational even when there are no impacts on the other mechanical systems, assuming there is sufficient additional rooftop/other real estate available for photon-farming. But that price point would be less than half the current ~$3/watt (pre-subsidy: https://openpv.nrel.gov/ ) US average. That day is coming, but it's not going to be next week.

In the US the federal income tax deduction on mortgage interest also skews the financial model for new construction, making both rooftop PV and DWHR more financially rational when the costs can be rolled into a low interest tax code subsidized mortgage.

Some US states and utilities also subsidize DWHR, usually only for homes heating water with electricity, but details vary a lot (and often change) eg:

http://www.oregon.gov/energy/At-Home/Documents/2017%20RETC%20Water%20Heaters.pdf

https://www.mnpower.com/ProgramsRebates/DrainWaterHeatRecovery

http://www.masssave.com/~/media/Files/Business/Approved%20Technologies/Drain-Water-Heat-Recovery-2016-03-25.pdf

http://vermontgas.wpengine.com/wp-content/uploads/2017/01/RER-Application-through-June-30-2017.pdf

Almost all subsidy programs depend on the efficiency of the unit per NRCAN's listed efficiency for the particular unit. NRCAN's listed products can be downloaded in spreadsheet format (which is good for apples-to-apples & price/performance comparison purposes):

http://oee.nrcan.gc.ca/pml-lmp/index.cfm?action=app.download-telecharger&appliance=DWHR

Payback on our solar system (@Dana, #13)

The financial analysis we did on the solar system was based on cash flow. We financed the cost, after incentives, over 10 years under a program called Michigan Saves. The monthly payments on that loan are $148. The expected electric bill reduction averages $114 per month based on pvwatts and current electric rates. So, it isn't quite cash flow positive in year 1. If electric rates go up much, we will be ahead. Although the future of net metering isn't certain, we expect to be grand-fathered into the current rules for 10 years. After 10 years, the net metering rules will probably become less favorable, but the system will be paid off, so we will definitely be ahead then. That is a good enough financial case for us.

My analysis of DWHR was based on a HPWH, so I factored in both electric rates and gas rates (we heat with gas). The ROI is good enough. The project has not reached the top of my list because the $/month numbers for water heating are relatively small and the list of projects is still pretty long.

Recirculating showers

Echoing Lyndon's comments above... Recirculating showers seem like a great idea... I'm curious how expensive the filters are and whether a system could be built (or reverse engineered) to retrofit an existing shower. Throwing hit water down the drain is certainly wasteful, even if some heat is drawn off of it.

Recirculating showers, Ethan #19, Lyndon # 9

The Orbital Systems recirculating shower link that Lyndon posted says that the system is well-suited to retrofits. Lots of statements about NASA technology and the showers that will go to Mars. I suspect that NASA won't allow the generous assortment of shampoos, conditioners, and body washes that the average residential shower faces. Nor, during the flight to Mars, will the astronauts come in for a shower after working in the garden, changing the oil, or covering themselves with sawdust.

Add pet hair, a family member or two with long hair, dry skin, and/or a tendency to use lots of makeup and skin lotions, and I think the homeowner would need to change the filters once a week, if not once a day. If the filtration problem could be solved affordably and sustainably, a recirculating shower sounds great to me.

This makes a lot of sense for

This makes a lot of sense for multi story builds with a basement, less so for a slab on grade configuration. I would basically lose half my shower potential, unless I went with the horizontal setup, which sounds daunting and headache prone (embedded in concrete, no easy way to service). Gulper pumps don't seem to be a viable option, more failure points and energy usage. One of the advantages I can see for this system is the lack of maintenance and moving parts, I would not want to stray from that.

The recirculating shower does sound interesting, especially for properties who do not have a source of water and pay dearly for it (trucked to a cistern). Like most cool high-end systems, cost of filters would likely kill the deal for most "normally serviced houses". At 240$ a year for 1 15min shower a day, I suspect i would be closer to 600$ a year in filters. But even with very reasonable water and energy costs (3$/m3, 0.08$ kw/h), they are claiming 1335$ savings. That would make it a 7 year ROI, assuming it's dependable.

Tank-type

Instead of a coil on the waste pipe, howabout a large (40-50 gal?) tank in the basement akin to an indirect water heater. 4" pipe in, 4" pipe out - with the outlet near the top. Copper coil inside the tank to preheat makeup cold water. This would store waste heat in the mass which if not used to preheat HW would at least cool off to the interior of the building providing a benefit in heating season.

Only obvious objection I can think of is that you'd essentially have an indoor septic tank, more or less. Hrmmm

Derek, this Hamwell's recirculating shower...

seems to be better designed in that it doesn't need $240/yr in filter replacement... https://www.hamwells.com/fresh-cycles

It seems to have cleanouts and a uv filter.

Log in or create an account to post a comment.

Sign up Log in