Image Credit: Proctor Engineering

If you live in a humid climate (for example, in Florida), you need an air conditioner that does a good job of dehumidification. But if you live in a dry climate (for example, in Nevada), dehumidification is almost irrelevant, because the outdoor air is so dry. In Nevada, all you need is an air conditioner that lowers the temperature of the air in an energy-efficient way.

In theory, air conditioner manufacturers could tweak the design of their equipment to focus mainly on lowering the indoor air temperature (a process known as sensible heat removal), or they could produce equipment that devotes a lot of energy to dehumidification (a process known as latent heat removal). Unfortunately, though, air conditioner manufacturers don’t offer special equipment designed for dry climates. Instead, they sell the same equipment in Nevada that they do in Florida.

Most residential air conditioners sold in the U.S. are designed to operate at a sensible heat ratio between 0.75 or 0.80. (The sum of the sensible load and the latent load is the total load; the sensible heat ratio is the sensible load divided by the total load.) If you live in a very humid climate, this sensible heat ratio might be too high. If you live in a very dry climate, this sensible heat ratio is definitely too low.

John Proctor is the president of Proctor Engineering Group in San Rafael, California, and a nationally known expert on residential cooling. Proctor has always been irked by the failure of air conditioner manufacturers to address regional needs. “Air conditioners are designed and installed the same for Florida and Arizona,” says Proctor. “It makes no sense, since Florida and the Southwest have different climates and different cooling needs.”

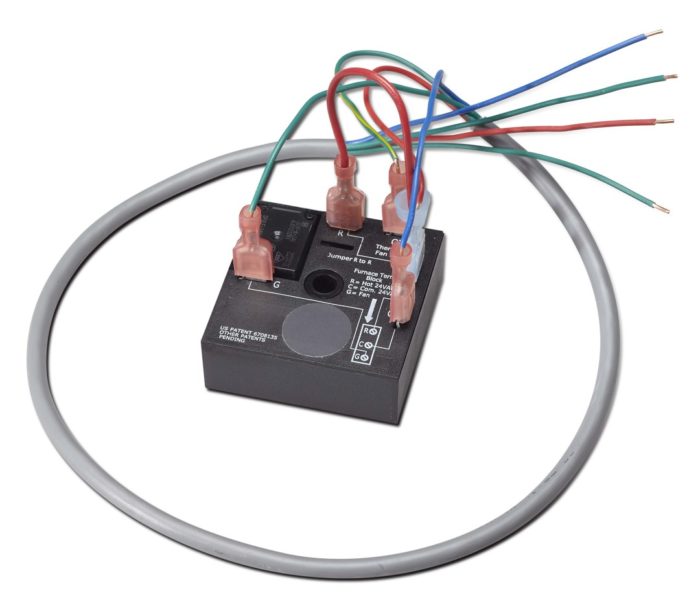

A retrofit control to save energy

To improve the efficiency of air conditioners…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

30 Comments

How to turn off 90 second delay?

We're here in Texas and it's pretty humid during cooling season. I'm pretty sure that we have a fan delay on our blower (it's older but the thermostat clearly clicks well before the blower stops, it's usually a decent length of time from the click until the blower stops. Now that I think about it, though, it's actually not a consistent period of time, is that odd? Perhaps something else other than a fan delay is in play here).

The article (which is great, btw, lots of interesting info) says "With most air conditioners, you can turn off the 90-second time delay if there is one.”

I looked through the manual for our furnace (it's a RUUD up flow GPH), I see settings to set the blower timing at 90, 120,160 and 180. But none to set this to 0. It's a two dip-switch or two jumper setup. Does anyone know if that's common? Is this the setting that the article is talking about?

Thanks,

James

Reply to James Howison

James,

I don't know the answer to your question. If I were you, I would call Ruud Heating and Cooling products in Fort Smith, Arkansas (800-848-7883; 479-646-4311) and ask for someone on their technical help hotline.

Perhaps a GBA reader has some advice for you.

Humid climate blower delay

Ruud - best I can suggest for now is to search for an install manual. Those are geared towards contractors, not homeowners, and may not appear on manufactureers unsecured sites, but many 3rd party sites house such manuals.

My bet is that the delay may not be configured less than 90 seconds since it is nearly always beneficial in heating mode to wring the last Btus out of the heat exchanger and ductwork following a heating call. AC coils are something of an add-on to a gas furnace, and the subtleties of AC and dehu may be lost on the typical furnace designer / specifier / installer.

I differ a bit with John Proctor as to appropriate blower operation at the end of a cooling cycle. I agree that in an arid climate it makes perfect sense to raise CFM per ton to the extent feasible, constrained by ductwork capacity, blower power and noise.

I also agree that it makes sense, in an arid climate, to operate the blower post termination for long enough to re-evaporate condensate, if any, essentially turning the vapor compression refrigeration system back into a swamp cooler for a minute or so. It is also worthwhile to get any remaining cool air out of the ducts and into the rooms.

I disagree with Proctor's advice about blower operation in humid states such as Florida. Continuous fan is a big no-no, not only on humidity grounds, but also a bad idea since most of our ductwork is in unconditioned spaces.

However, the moment the compressor stops, there is still useful cooling available from 3 sources:

1) Fully chilled air in the supply ductwork

2) Sensible cooling from the coil itself, it being comprised of 5-20 lbs of metal at a temperature 5-10 degrees below supply air temperature.

3) Within the coil's tubing - as pressures equalize and with air crossing coil, some of the remaining liquid refrigerant boils off, absorbing yet more heat.

While the numbers would vary for individual systems, 90 seconds seems like a reasonable period to deliver useful cooling from the 3 sources listed above while avoiding re-evaporating too much condensate. Given that the typical on cycle, particularly during mild, part load conditions, may be just 5-15 minutes, judicious blower off delay following compressor termination, offers a sizable bump in system efficiency.

Ideally this would be installer-configurable from perhaps 0-300 seconds, so that an informed installer could account for several system variables such as extent and location of ductwork, whether system is two stage, row depth of coil, base CFM per ton, to name a few. Ideally, different values could be selected for heat and cooling modes.

Trane ECM features

I appreciate the value of adjusting the time before blower stops, at the end of a cooling cycle. And a lower-energy retrofit motor is always valuable.

There was one comment which roused my curiosity:

'...one of the touted (but questionable) benefits of an ECM — the ability to maintain a constant airflow under changing static pressures..."

Why is this a questionable value? I can only see the upside at present. Of course a lazy technician can connect that to a crappy duct system, but they can (and do!) make such a wrong choice using ANY motor, and duct system. To me it seems easy to measure static pressure to check one's design and work, but it is not easy to find a techncian who agrees. It seems many do not really care what the actual airflow is.

Perhaps the scope of this article is meant to exclude actual ECM equipment. But I would like to observe that Trane equipment has long offered an "Enhanced Mode" on its variable speed blowers. The 2004 model I have offers choices including 50% airflow for 3 minutes after a cooling cycle, as well as reduced airflow during the first 8.5 minutes of a cycle in order to enhance humidity removal. At 1000 CFM wattage can be as high as 320W at 0.9 ESP (inches water column), down to 210W at 0.5 ESP or 170W at 0.3 ESP. With a 2-stage AC, first stage often sees the latter value. For what that's worth.

I sincerely wish more of the industry would watch the issues which Mr. Proctor talks about in this article.

Thanks

I appreciate your comments. I have the installers manual, it shows wiring diagrams etc, but it seems there is no option below 90 seconds. I might call them.

I appreciate Curt's response too, I see the point of those sources of cooling, but I also see that there is a trade off against pushing that moisture back into the building. Hard to know apriori what that sensible/latent trade off is. Humidistat definitely seems called for. The operation Tweaking of the Trane are interesting too. Lots of variables in any system, seems that something like the Nest would have the memory, processor and sensors to learn benefits from blower tweaks over time for any one system.

Response to Curt Kinder

Curt,

You wrote, "I disagree with Proctor's advice about blower operation in humid states such as Florida. Continuous fan is a big no-no, not only on humidity grounds, but also a bad idea since most of our ductwork is in unconditioned spaces. [I assume that you understand, Curt, that John Proctor agrees with you on this point.] However, the moment the compressor stops, there is still useful cooling available from 3 sources."

No one is disputing that there is still useful sensible cooling available from the three source you list. The technical question that the article raises is whether, in a humid climate, the useful sensible cooling available from those three sources is worth the accompanying drawback -- namely, less effective dehumidification.

Response to Mark Johnson

Mark,

ECMs are efficient, and they use less energy than common permanent split capacitor motors. That's good.

You questioned my statement that "the ability [of an ECM] to maintain a constant airflow under changing static pressures" is one of its "touted (but questionable) benefits."

Here is one reason that some manufacturers like ECMs: they provide a low SEER rating that is unrealistic under field conditions (because the SEER test is performed with a very low external static pressure).

Here is one reason why you might not want an ECM: when the cable installer clumsily crushes the ductwork in your attic, restricting air flow, an ECM will ramp up its watt draw as it tries to keep the airflow rate constant. That may push more air through the constricted ductwork, but it increases your energy bill.

Under these circumstances, it might be better to have a Concept 3 motor -- so that if the static pressure goes up, airflow goes down and the watt draw remains the same. If the cable installer crushes a duct in the attic, the homeowner is more likely to notice a problem and fix the duct with a Concept 3 motor than with an ECM.

Responses to Curt, Mark and James

James -- generally if the time delay can be extended more than 90 seconds for a furnace it applies only to the heating mode.

Mark -- As noted by Martin in his response, when the airflow is highly restricted, the "Constant CFM" ECMs will ramp up their power draw. Sometimes, but not always this increase in watt draw will overwhelm the benefit of the higher airflow. ECM incidentally refers to Electrically Commutated Motor -- that is what a BPM is. The fact that the motor can be controlled various ways makes all sorts of things possible including various speeds under various conditions, various timing, etc.

Curt -- Like you and Martin, I hate continuous fans. For very many reasons (continuous duct leakage, continuous duct conduction, high kWh particularly with PSC motors, humidity reintroduction in wet climates, etc.) My only comment is if you insist on using a continuous fan you would be out of your mind not to retrofit to a BPM motor.

With respect to delaying the fan off in wet climates, the research by Florida Solar Energy Center and Hugh Henderson pretty clearly shows that any fan run time at the end of the compressor cycle is detrimental --- unless it happens to be drier than usual in the house that day (thus the thermidistat is a good idea).

The laboratory tested improvement in efficiency from a 90 second delay with a totally dry coil is about 3%. At the same time, with a wet coil, the highest reintroduction of moisture occurs immediately after the compressor shuts off.

I spent a half hour or so at FSEC site - no joy

I would greatly appreciate a link or other info guiding me to the post compressor fan run time data

Thanks!

Response to Curt Kinder

Curt,

Like you, I was frustrated by my searches for Hugh Henderson's papers. Many of the FSEC links are dead. Here is one good link, however:

Understanding the Dehumidification Performance of Air-Conditioning Equipment at Part-Load Conditions

Dry Climate design airflow targets

Thank you John and Martin. I'd only like to suggest that 500 CFM/Ton should be the *minimum* design airflow, with 550 to 600 CFM/Ton being optimum for a dry climate like most of CA, Nevada, etc. With proper installation practices, it's easy to move over 1,100 CFM on a two ton system with just 150-200W of fan power while passing it through high efficiency filtration (MERV 8 or better) in 0% leakage duct system. It's remarkable how much moisture removal is taking place at even these aggressive airflow targets, especially when clients like their homes much cooler than 80 IDB.

Clients are often surprised to hear how wasteful and expensive the water is that leaves their condensate drain. For every gallon of moisture removed per hour, it represents about 3/4 ton of cooling capacity squandered, at a cost of about 16 cents per gallon (at 14 cents/kWh) at normal system efficiencies, which is also about 160 times more expensive than what comes out of the faucet.

post-run time

It took a lot of pleading with Daikin's application engineers to

obtain the "secret settings" to *not* continuously run the blower

especially in cooling mode, which my system would otherwise do

by default. Even with that, the ECM has a hardwired post-run

time of three minutes after it's commanded off -- which is barely

short enough to let the coil stop evaporating refrigerant and

warm up to somewhere over the dewpoint but not let too much

humidity come off it and back into the house. But the fact that

Daikin set this system up to *always* have the blower active is

perplexing; the choices given in *any* of the installation or

service manuals do not include complete blower shutdown even

though the settings do exist. And believe me, I read a lot of

those manuals in my research phase.

Other system brands may have similar design stupidities.

_H*

Martin - thanks for the link

From the linked paper:

"The off-cycle evaporation process becomes adiabatic after refrigerant migration inside the coil and system has subsided 1 or 2 minutes after the compressor stops operating. The type of expansion device has some impact on the duration of the transition."

From John Proctor:

"At the same time, with a wet coil, the highest reintroduction of moisture occurs immediately after the compressor shuts off."

I may be splitting hairs, but I don't equate "immediately" with "instantly". Given that at the moment the compressor stops there is still liquid refrigerant in the evaporator coil boiling off, and that the coil's metal is significantly cooler than the dewpoint of return air, there is a period during which continued fan operation will not reintroduce significant moisture into the air.

It may not be long, perhaps 15-30 seconds, but it should at least allow for a typical duct system's internal volume of air to be delivered into the conditioned space without significant humidity penalty.

That paper supports my habit of avoiding single stage systems whenever possible - the lower stage's long run times really help with humidity, especially in part load conditions (i.e, most of the time)

I took a look at Daikin awhile back, but I couldn't make head or tails of the manuals, so I elected to spare myself a headache.

Curt -- you have a good point

Looking at Figure 1 in the paper, there is a time delay between the compressor off and the onset of latent addition -- it is very short. Judging from the graph it might be substantially less than a minute. At the same time it might just be the response time of the instrumentation sensors. I'll stick with turning off the fan immediately if I i'm in a wet climate, but I would not disagree that 15 to 30 seconds might have enough sensible cooling advantage to make it worthwhile.

Concerning the use of two speed machines -- you are right if the ducts are either inside the conditioned space or superinsulated (a rare case).

Great Article

Thank you Martin for providing some great, practical information for us hot-dry climate folks. Any rough estimate regarding a installed price for one of the Concept 3 motors from a qualified installer (Phoenix area)?

Real world test?

I live in SW Florida so I decided to test my ac by standing below the air duct for the cool-delay-fan-off setting after the compressor shuts off. At the 100 sec delay-off setting, the air was still very cool so I increased it to the maximum of 127 sec and it was still cool at the end of the shut-off cycle. I have to say I prefer capturing that cool air rather than worrying about the extra humidity...especially since the system is running pretty much continually during the summer and keeping humidity in check.

A gross exaggeration?

“Running your fan all the time is always a bad idea, but it is even worse in Florida than it is in a dry climate, because it totally eliminates your dehumidification."

I think "Totally eliminates" is a gross exaggeration. I would venture to guess that a system with a continuously running fan would remove 80 to 90% of the moisture removed by an intermittent fan system. I say this because I collect condensate for plants in Georgia.

Response to Brad Carr

Brad,

Q. "Any rough estimate regarding a installed price for one of the Concept 3 motors from a qualified installer (Phoenix area)?"

A. As the article noted, the Concept 3 motor costs around $220. I have no idea what labor rates for HVAC contractors are in Phoenix, so you'll have to call a few contractors to get an estimate for the work. For an extremely rough guide to many types of construction work, you can double the cost of materials. (Needless to say, some types of construction work are much more expensive than this rule indicates.)

Response to Mario Carballo

Mario,

Just because the air in your ducts is still cool when the fan turns off, does not mean that your house doesn't benefit from that cool air.

If your ducts are located within the conditioned envelope of your home -- as GBA strongly recommends -- then the cool air will stay inside your house. Another way of describing what happens is: after the fan turns off, the air in your duct system will absorb heat from your house, with the effect that your house is cooled.

Response to Charles Campbell

Charles,

Thanks for your comment. I think it is fair to say the John Proctor's statement that running the fan continuously in Florida "totally eliminates your dehumidification" was an example of colorful speech intended to underline his point. I think you are right that it is an overstatement.

Nevertheless, running the fan continuously is a very bad idea. Many air handler fans draw 800 watts. You can do the math to figure out how much it costs to run such a fan year round: At 12 cents per kWh, the answer is $841.

Should we believe them, or not?

Thanks for this article. I found it very informative and useful. One bit of advice left me curious, and perhaps Martin or John can comment. In the motor retrofit section, it suggests measuring the static pressure with the old motor, and then adjusting the replacement ECM motor to get the same static pressure. This assumes that the current motor/blower setup is correct for the home. However, in the section on dry climate, John reports data from California, showing that a significant number of homes have airflow that is too low by a significant margin (the reported median 325 CFM/ton is more than 50% below the optimum 500 CFM/ton).

The field tests suggest to me that there is good reason not to accept the original installer's static pressure as being a reliable target figure for after changing to an ECM motor. Is there another approach that could be used to adjust the new motor to a more efficient setting, rather than blindly following the static pressure of the old setup?

Response to Derek Roff

Derek,

Like you, I am interested in John Proctor's answer.

In the meantime, here's my take: I think that it's advisable to avoid cranking up the Concept 3 motor because it makes sense to limit the motor's watt draw. If the airflow rate over the coil is less than desired, the problem is best addressed by making improvements to the duct system.

Martin wrote, "Nevertheless,

Martin wrote, "Nevertheless, running the fan continuously is a very bad idea. Many air handler fans draw 800 watts. You can do the math to figure out how much it costs to run such a fan year round: At 12 cents per kWh, the answer is $841."

OK, but consider that if the fan is not run continuously to mix air in a 2-story house, the hot air upstairs is not brought downstairs to discharge its heat through the foundation slab (typical in the deep south, and via Manual J I believe you can demonstrate that the amount transferred through an uninsulated slab can run as high as 1/6 of the entire cooling load). This means that the compressor comes on instead to remove the heat, and it draws a whole lot more than 800 watts.

AC system dehumidification

I have found that it is most important to have an AC system operate long enough during each cooling cycle (at least 30 minutes) to condense water on the indoor coil and have a significant amount of water drip from the coil and run down the condensate drain. AC systems that cycle on for only 10 or 15 minutes do not run long enough to remove much water (down the drain). With some residential thermostats attempting to maintain a 1F (or less) dead-band, short cycling AC systems are prevalent. If your AC system operates long enough to condense and drain enough water from the air in your house, the re-evaporation of moisture from the indoor coil becomes less of a concern.

Response to Derek

The best approach to fan motors, air handlers, duct work etc is to take a couple steps back and do a proper room-by-room Manual J compliant heating and cooling load calculation. That will yield, if informed by accurate inputs, the air flow each room requires.

With each room's required air flow in hand, configure air handler, blower motor, and ductwork as necessary to deliver the required air flow to within 10% or so.

Don't let the tail, in this case blower motor choices / configuration, wag the dog (what each room / zone / the whole house needs for comfort and efficiency)

Ductwork should accommodate 300-500 CFM / ton as required for both humidity control and system efficiency.

If you get this stuff reasonably dialed in and your house is reasonably air tight so that it doesn't heat and cool the whole neighborhood, you'll be pleasantly suprised how little it costs south of the Arctic Circle to heat and cool your home to a comfortable degree.

OK OK The most common situation is not the exceptional one.

1) Most air conditioners are oversized and run for pretty short cycles -- even in Florida.

2) If you want mixing, put in a smaller air conditioner and if that doesn't do it have the air handler run part time (not all the time and not with ducts in the attic and not with a PSC motor).

3) Evaporating water does cool the air, but it also puts moisture in it.

4) One is obviously free to run their fan whenever they want for as long as they want.

5) Matching the same airflow with lower watts is a conservative approach. One can certainly dial up the speed and get more sensible cooling. In some cases we do that, but mostly we fix the duct systems and then we can get a bazillion (a real precise and accurate scientific number :^} ) cfm with the motor adjusted to low watts. We like having mother nature on our side rather than trying to overpower her. In one study we did in Phoenix only two contractors got even close to adequate airflow. Contractor A used well designed METAL DUCTS. The other used the biggest air handler they could fit. I would recommend Contractor A.

How long a runtime needed?

In response to Tim O'Brien message #24, I would like to put on the discussion how long an AC run time is needed for dehumidification, and how we know that. I submit there can be very good dehumidification with shorter run times. My evidence is two-fold; 1) Trane's "Enhanced Mode" uses reduced air flow for only 8.5 minutes at the beginning of the cycle, and is said to add much effectiveness. 2) In my own house, a new AC is giving objectively good humidity control (~5% less RH than previous AC) using 9-11 minute run times.

The new AC is downsized from the previous one, and is a properly matched system with 13.0 EER. It uses simple controls, no Trane "Enhanced Mode" and an older Honeywell thermostat. The house does have a 2nd AC system with nearly all the good features, but that is a constant in this "experiment". Using a TED 5000 system to view electricity use minute by minute, one can see in the attached file run times far shorter than 30 minutes. I really wanted to attach a JPG file showing behavior from 4-8pm on a 97F day, but that feature failed to do what I expected.

After having this newer system installed, the whole house RH is about 5% lower than before, and I am seeing 45-50% as the summer norm (78F).

This is in Houston where summers are monotonous and dewpoint is 68-72F, sometimes higher and rarely lower. I do believe AC manufacturers are sophisticated enough to shorten the time to get a cold coil and good dehumidification is now possible with much shorter run times than you have said. Thank you.

Only sold to contractors?

Hello. Can a DIY'er purchase the Western Cooling Control? I haven't had any luck finding a source online... I'm in Colorado, and it's *usually* quite arid here in the summer!

Response to Daniel Jacobs

Daniel,

I have sent an e-mail to John Proctor, asking him your question. I'll let you know what he says.

Thank you! I'll keep checking

Thank you! I'll keep checking back.

Daniel

Log in or become a member to post a comment.

Sign up Log in