Image Credit: Fine Homebuilding

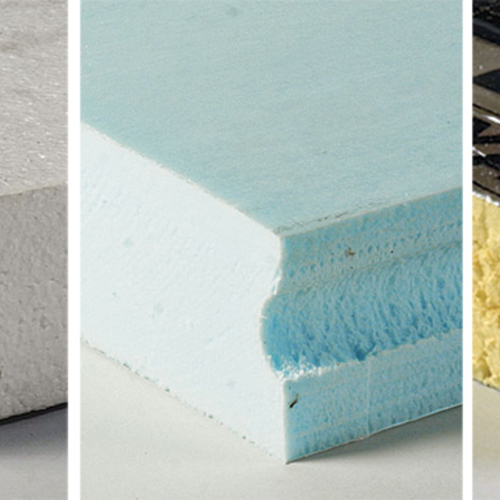

Researchers have known for years that most types of insulation — including fiberglass batts, extruded polystyrene (XPS), and expanded polystyrene (EPS) — perform better at low temperatures than high temperatures. The phenomenon was described by Chris Schumacher, an engineer and researcher at Building Science Corporation, at a conference in 2011: “If you measure the R-value of an R-13 fiberglass batt, you’ll get different results at different outdoor temperatures. If the outdoor temperature rises, the R-value goes down. If the outdoor temperature drops, the R-value rises. Why? Because as you move to a higher temperature, you get more radiation happening, and therefore a lower R-value. But at lower temperatures, there is less conduction, less convection, and less radiation — and therefore a higher R-value.”

Polyisocyanurate does not follow the usual pattern for other types of insulation. When tested at mean temperatures below 50°F, polyiso performs worse than it does at a mean temperature of 75°F. The reason for this declining performance, according to Schumacher, is that “the trapped blowing-agent gases start to condense at cold temperatures.”

R-value is defined by law

The standard ASTM test methods for determining a material’s R-value are performed at a mean temperature of 75°F. According to the Federal R-value Rule, the U.S. law that regulates how insulation products are labeled and marketed, R-value claims for insulation must be based on these ASTM tests. It could be argued that these test procedures tend to favor polyisocyanurate (which ends up with a labeled R-value of about R-6 per inch) over XPS (which ends up with a labeled R-value of R-5 per inch). Many builders probably specify polyiso because of its high R-value per inch, without considering the fact the the performance of polyiso suffers at low outdoor temperatures.

Achilles Karagiozis, the director of building science at Owens Corning, decided…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

74 Comments

What about mixing foam layers?

Martin I remember reading about the 'polyiso penalty' some time over the past year and seeing the idea of layering xps on top of polyiso to reduce this effect. Did you and Karagiozis discuss this option?

I'm imagining the first layer(s) of exterior rigid foam being polyiso, but to keep those layers warmer/protected to reduce this effect, it could be topped with a final layer of xps before installing the cladding. It would be interesting to see this scenario modeled to know what an ideal ratio might be, when mixing the two foams.

Response to Mark Fredericks

Mark,

Your suggestion make sense. However, it's hard to guess exactly how such a wall would behave without resorting to WUFI or field measurements.

My own philosophy is aligned with the Pretty Good House movement. It's very easy to spend too much time sharpening our pencils and not enough time building.

So here's my advice: include plenty of insulation when you build. If you're worried about the performance of your insulation at cold temperatures, make it a little thicker.

Interior temperature

I agree with Martins response. Though it is always good to theorize, and this is a great place to do just that. Having so many informed individuals in one place has spurred some pretty enlightening ideas in the comments section. And of course the main blog articles are just as informative.

On that note, I wonder how this affects people in Maine or extreme cold climates living in PERSIST or REMOTE houses. Ones with most/all of the insulation being rigid foam (often polyiso). It's typical to have a programmable thermostat in new homes, and to set the temperature back at night. Given the precipitous drop in polyiso's insulating performance, is there a point where it actually makes sense to set the interior temperature higher? In order to keep the mean foam temp a little higher.

There are a lot of factors involved in this idea to be sure. Air leakage, window/door losses, internal heat gains, etc. But it could be a good critical thinking practice at the very least.

Response to Daniel Young

Daniel,

Thermostat setbacks always save energy. It always requires less energy to heat a house to 58°F than to heat a house to 72°F.

Remember, cold polyiso still has an R-value, and still slows the flow of heat. It just isn't performing as well as some people assume. It makes no sense to heat up your house just to heat up the polyiso. Such an approach will waste energy.

This discussion of thermostat setbacks doesn't take several factors into account, including the performance of your heating equipment. Some types of heating equipment -- notably air-source heat pumps -- don't respond well to thermostat setbacks, and generally perform best when kept at a constant setting.

A Hydro Quebec representative told me that it was a bad idea to reduce night heating by more than 3 degrees C. Apart from Hydro's concern about peak demand in the morning, is there any break even point where the energy required to reheat the house in the morning is more than that required to keep it warmer at night?

Nils,

Q. "Is there any break even point where the energy required to reheat the house in the morning is more than that required to keep it warmer at night?"

A. No. If you lower the temperature of the building, you consume less energy. That said, it's important to realize:

1. Thermostat setbacks save more money in a poorly insulated building than a well insulated building. After all, if you turn off the heating system in a very well insulated building, the indoor temperature barely drops.

2. Some types of heating equipment will take several hours to bring the indoor temperature back up to 72 degrees F if you let the indoor temperature drop too far. Oversized heating equipment does a better job of quickly raising the indoor air temperature than right-sized equipment.

3. In most cases, here at GBA we recommend a very tight, very well insulated thermal envelope and right-sized heating equipment. If you follow our advice, there's no reason for nightly temperature setbacks. But if you've got a typical house -- with air leaks, insufficient insulation, and an oversized furnace -- feel free to set back your thermostat as much as you want.

the middle climates, and EPS

In zone 4, I guess the performance of XPS and polyiso would be pretty similar.

On a different note, since EPS, like polyiso, is blown with pentane, this seems even more damning for EPS. Its already lower R-value of 4 might be more like 3 in a cold climate. Although, if it is used sub-grade where it is protected from frigid temperatures, it should stay warm enough to perform as expected.

Response to Nick Welch

Nick,

EPS behaves like XPS, not polyiso: as the temperature drops, the performance of EPS improves. This can be seen in the graph in Image #4 on this page. The black line on that graph is the line for EPS.

EPS

Martin, if the performance curve of polyiso is caused by the blowing agent condensing, and EPS uses the same blowing agent, why would EPS not suffer as well? Does the blowing agent leak out of EPS very rapidly after manufacturing?

Response to Nick Welch

Nick,

I think your guess is correct: after manufacturing, the pentane in EPS is replaced by air.

What I'd really like to see, however, is EPS manufacturers -- and all insulation manufacturers -- release more of these temperature-dependency graphs, so we can be sure we know how these products behave at different temperatures.

I'm surprised at the severity of the non-linearity.

The knee of the hockey stick starts at a mean-temp of about +15C, but note that it's conductiviey literally doubles by the time the mean drops to +5C (it's performance is cut by half?)

That is a dramatically more severe derating curve than others I've seen for polyiso, but it may have been polyiso blown with different blowing agents than the sample tested.

Mind you, looking at the English units conductivity scale on the right edge of figure 4, the R-value of the iso at +15C is about R7.5-R8 (considerably more than R6), but it falls to a mere R3.5 @ +5C (+41F) mean temp, falling to a mere R2 at -15C (+5F) mean temp.

If truly representative this has severe dew-point consequences for builds in climate zones 6 & higher, where the mean outdoor temps are below -5C, when using anywhere near the IRC prescriptive minimums for exterior insulating sheathing: http://publicecodes.cyberregs.com/icod/irc/2012/icod_irc_2012_7_sec002_par025.htm

At a mean outdoor temp of -5C, a 2x6 wall with R20 cavity fill and a presumed R11.25 insulating sheathing with a 20C interior temp the temp gradient of about (25C/R33.25=) 0.75C/R. With R11.25 on the exterior that puts the mean temp at the sheathing at about (-5C + (R11.25 x 0.75C/R) =) +3.4C But that would also make the mean temp of the exterior foam about -1C, a temp at which it's performance is already below R3/inch, call it R2.5/inch in stead of R6/inch, meaning the presumed R11.25 is actually about R5.

Doing a crude first-order correction, that means at the mean winter temp of -5C the total R is now R25 instead of R33, and the degrees/R ratio is about 1C/R, and the mean temp at the sheathing is actually 0C (yes, freezing), not +3.4C (38F), and WAY below the dew point of healthy 30%RH/20C air.

If that's the case, it isn't like you have to just add 20% more foam to pad it out, you'd have to add about 100% more (double it!) for cold/very-cold climates.

Just eyeballing the curves, at a mean temp of -5C in the foam EPS has 2x the R-value of polyiso, but at 0C the iso is still outperforming EPS with some margin. If one were to double-layered the foam and put 1" iso (labeled performance ~R6-6.5) next to the sheathing, and 1.5" of EPS (labeled performance R6) as the exterior layer you would have met the IRC minimums and you'd still be getting a true R12+ at an outdoor temp of -5C and the sheathing would be fine.

But you would be in dire straits if you went with only 20% more than the IRC prescriptive minimums by going with 2" of polyiso (labeled performance R12-R13), since the true average performance would only be about R6 at outdoor temps that matter from a sheathing moisture accumulation point of view.

Since he was simulating the heat flow analysis with WUFI, I'm wondering if he did the moisture flow at the sheathing at the same time(?). (I'm guessing not.)

Grey eps, phenolic foam and foam/batt combinations

What about grey EPS? If understand correctly, the point of the graphite in grey EPS is to reduce the radiation. Do the findings you report imply this is unnecessary in very cold climates?

Also, what about phenolic foam? How does the r-value of that vary with temperature?

In some climates, it would actually be desirable to have no insulation in the summer (if the wall albedo is high, there is some thermal mass, and the average outdoor temperature is lower than the interior temperature). This would reduce cooling load or remove the need for cooling. So would an insulation material that was *more* insulating at low temperatures be ideal here?

Overall it seems to me that in a cold climate the reduction in r value will be more important when there is another insulating layer interior to the foam (e.g. foam outside a batt insulated frame wall) than if the foam is the only insulating layer (e.g. "no batt" REMOTE/PERSIST, or SIPs). This is because if you have another insulating layer interior to the foam then all the foam will be fairly cold, whereas if the foam is the only insulation, the innermost part of the foam will be warm, and so on average the foam will be less affected.

I have read elsewhere that batt insulation is less effective at lower temperatures (or maybe it's at higher delta-t?) because of natural convection.

So maybe a frame wall insulated with batts, sheathed with polystyrene foam on the outside is actually ideal in a sense, as then both insulants are placed optimally: the polystyrene where it's cold and the batt insulation where it's relatively warm, with a low temperature difference across it.

Fibreglass batt

Looking at your chart again, I now see that it claims that the performance of fibreglass batt improves as temperature drops. So now I am confused! Maybe what I read is a myth?

We've discussed this several time in the past ...

We've had a few arguments and discussions about this in the past ..

What about the AGE of the product ?

I asked several time about this in our prior posts, and never actually got any return.

Dana: weren't you the one pointing to recent change in blowing agents to lessen this effect,

and on how blowing agent in XPS and Poly have different escape speed which will affect this derating of the poly much at lower temp ?

We need to see how aging polyiso performs after several years under the same low temp situation.

Then as pointed, using polyiso on the inside of a multi layered insulation strategy would surely help with the situation.

Until we can clarify the situation with AGE and diff. blowing agents of polyiso vs temp

i'll continue using clean and cheap EPS in our climate.

( currently doing a 10" recycled EPS PERSIST type project )

Response to Dana Dorsett

Dana,

You raise some excellent questions, most of which are unanswerable at this point.

First of all, when it comes to the implications for dew point analyses in cold-climate walls, I agree that this "hockey stick curve" raises serious concerns. You are correct that my advice to "just make the insulation a little thicker" does not address all possible concerns, and should probably be modified. I'll probably be editing my article to reflect that important point. Thanks for bringing it up.

Second, it's possible that this polyiso curve is not typical. We just don't know at this point what the curves look like for different brands of polyiso. Last week, when I was attending the conference at which Achilles Karagiozis presented his findings -- the official name of the confenence was "Conference on Thermal Performance of the Exterior Envelopes of Whole Buildings XII" -- I had a conversation with Kohta Ueno, the researcher from the Building Science Corporation, about Karagiozis's conclusions. Ueno speculated that other brands of polyiso might have difference curves.

It's frustrating that the manufacturers of these products aren't working with designers and builders in a more cooperative fashion, so that we can all build better wall and roof assemblies.

Response to F W

F.W.,

Q. "What about grey EPS? If understand correctly, the point of the graphite in grey EPS is to reduce the radiation. Do the findings you report imply this is unnecessary in very cold climates?"

A. That's an excellent question. (I assume that you are talking about BASF Neopor). Let me know when to schedule the demonstration in front of BASF headquarters; I'll meet you there with a homemade sign that says, "Release the temperature-dependency graph for Neopor!"

Q. "I have read elsewhere that batt insulation is less effective at lower temperatures (or maybe it's at higher delta-t?) because of natural convection."

A. The convection-loop problem is entirely separate from the phenomenon discussed in this article. In a sealed cavity, fiberglass batts actually perform better at cold temperatures than at warm temperatures, as explained in this article and the attached graphs. Convective looping is a separate phenomenon that is most pronounced in horizontal applications of fiberglass (for example, on an attic floor), when the insulation is installed without a top-side air barrier (as is typical) in a very cold climate. Cold temperatures giveth, and cold temperatures taketh away. The bottom line is that it makes sense to install a cap of cellulose on top of fiberglass batts when the fiberglass is installed on an attic floor in a cold climate. The cellulose warms up the top layer of fiberglass and greatly reduces convective looping.

Response to Jin Kazama

Jin,

You are correct that the R-value of many types of rigid foam drops over time. When I spoke to Achilles Karagiozis about his work, he raised the issue of aging polyiso, and noted that we don't know enough about the interaction between aging effects and cold temperature effects. There are polyiso questions for many years of research.

I wrote an article about the "thermal drift" issue that was published in the April 2003 issue of Energy Design Update. Here are some excerpts from that article:

"The thermal performance of closed-cell foam insulations -- including polyurethane, polyisocyanurate, and to some extent extruded polystyrene -- drops as the insulation ages. The cause of this “thermal drift” is the gradual dissipation of gaseous blowing agents, which are replaced by air as they exit the foam. (Expanded polystyrene, an open-cell foam, is not affected by thermal drift.)

"Until recently, R-value labels on polyisocyanurate have been based on a testing protocol developed by the Polyisocyanurate Insulation Manufacturers Association (PIMA), the PIMA 101 test method. Although PIMA 101 values accurately reflect an insulation’s performance during its first months of life, in-service R-values are significantly lower ten years down the road.

"US polyisocyanurate manufacturers, wounded by years of criticism that their published R-values are unrealistic, have finally agreed on a new test method for determining the R-value of some of their products. The new value, dubbed “long-term thermal resistance,” or LTTR, was implemented in the US by industry consensus on January 1, 2003 for polyiso insulation that is either unfaced or that has a gas-permeable facing. ...

"The agreement to adopt the LTTR method applies not only to polyisocyanurate insulation, but also to extruded polystyrene and polyurethane.

"Much of the credit for needling manufacturers to adopt a more realistic basis for labeling polyiso belongs to Mark Graham, executive director of technical services at National Roofing Contractors Association (NRCA). “The whole debate about the R-value of polyiso goes back to the 1980s, when the NRCA did some research into the issue and published a technical bulletin,” says Graham. For decades, polyisocyanurate manufacturers have been trumpeting R-values of up to 7.5 per inch, in spite of evidence that after a few years, the in-service thermal performance of polyiso was considerably worse. The NRCA tested a variety of polyiso insulation products, and concluded in 1987 that “an R-value of 5.6 per inch thickness is a reasonable value to be used when calculating thermal performance [of polyisocyanurate or polyurethane insulation] over the anticipated life of the roof.”

"The LTTR method results in polyiso R-values ranging from 6.0 to 6.25 per inch. But according to Graham, the NRCA’s 1987 recommendation still holds. “NRCA is not backing away from our recommendation concerning R-5.6 per inch,” he says. “The new ASTM standard is a basis for comparing products. PIMA and the whole polyiso industry have come a tremendously long ways, and we have made a substantial step in the direction of achieving a consensus on how to rate the thermal resistance of polyiso. Hopefully we’re on the final chapter, but I don’t think the book is closed yet.” ..

"Of course, no test method is perfect, and standard methods are arrived at after a series of technical compromises. “The LTTR test method has only been used for the past year or two, and there are some concerns that the test might be biased -- giving higher numbers at lower thicknesses,” says Mike Londrigan, program leader at Dow Building Products. “Because of these concerns, the test may be refined in the future. But any labeling changes resulting from future refinements will probably be very minor.”

"Understanding the recent changes wrought by the adoption of the LTTR method is further muddied by simultaneous changes in the polyisocyanurate manufacturing process. Because of the Montreal Protocol requiring the phase-out of ozone-damaging HCFCs, US polyisocyanurate manufacturers recently switched from HCFC 141B to a more ozone-friendly blowing agent, pentane.

"Some polyiso manufacturers insist that the switch to pentane has not affected polyiso R-values. According to Tom Rowe, vice president of sales and marketing for Atlas Roofing Corporation, “The changes in the polyiso R-values that customers are seeing today are totally unrelated to the change to a hydrocarbon blowing agent. Using the LTTR test, our polyiso with the new blowing agent has exactly the same R-value as our polyiso with the old blowing agent.” John Geary, marketing services manager at Firestone Building Products, agrees with Rowe. “Our products have the same R-value or thermal performance whether the blowing agent is 141 B or pentane,” says Geary.

"Yet, for whatever reason, not all manufacturers join Atlas and Firestone in denying that the switch to pentane carries any performance penalty. According to Reed Larson, market manager for the building insulation division at Johns Manville, “The new blowing agent results in slightly lower polyiso R-values on average.” The only polyiso manufacturer to provide data on R-value changes due to the switch to pentane is Dow Building Products. According to a Dow Web page (www.dow.com/styrofoam/na/iso/thermax_s.htm), “Dow is transitioning to a new blowing agent. As a result, current R-values are changing.” The Dow chart shows that the switch to pentane has caused R-values for 1-inch Thermax to drop from 7.2 to 6.5, and for 2-inch Thermax to drop from 14.4 to 13.0. Because Thermax is a foil-faced product that does not fall under LTTR labeling requirements, this drop in R-value represents an actual performance reduction rather than merely a change in testing procedure.

"For the average builder comparing insulation labels, it makes little difference whether recent changes in R-values are due to new blowing agents or new test procedures, as long as they feel confident that the values on the label are trustworthy. In fact, the R-values provided today by polyisocyanurate manufacturers are more accurate than ever, and can be reasonably used to make comparisons between competing insulation materials.

"In the last few months, many polyiso products have seen R-value labeling reductions in the range of 10% to 17%. It can be expected that these values will hold, on average, for about 15 years. Beyond 15 years, it is probably prudent for conservative designers to continue to figure on a long-term value for polyiso of R-5.6 per inch, as the NRCA advises.

"Although the LTTR method is not yet being applied to aluminum foil-faced products, polyiso manufacturers are aware that the current PIMA 101 method probably needs some tweaking. Technical committees are now looking at the issue, and several industry sources predict that once consensus is reached on a new LTTR-type test method for foil-faced products, the R-values on their labels will be dropping as well."

What i wanted to address is more ...

about the cold temperature behavior of an aged polyiso.

If its blowing agent has escaped for the most part, how is it's sub 5c behavior is modified ?

We discussed about phase change of blowing agent going from gazeous to liquid in that range of temp, not helping with the therm resist. , but if the blowing agent is not present anymore, will it exhibit the same type of behavior as with EPS/XPS ?

I also remember we discussed about blowing agent for XPS and its release timing,

being different from here and euro where XPS is mostly blown using CO2 if i remember correctly?

The pentane encapsulated in the EPS granules totally escapes to air ( quasi totally ) in a few hours/days while the manufacturer usually have the freshly expended granules resting in aerated bins/bags.

We had the curves for the different blowing agent used in XPS and POLYiso last year nah ?

How about XPS on the Interior?

My house in Barrie, Ontario (1 hour north of Toronto) has 2x4 construction with dense pack cellulose, plaster then 3/4" foil faced insulation glued to surface with drywall over top.

How do you assess the potential performance of this assembly?

Response to Richard Speare

Richard,

Q. "How do you assess the potential performance of this assembly?"

A. The three most common ways would be:

(a) with WUFI, a hygrothermal modeling program;

(b) with a full-size guarded hot box that can handle wall assemblies measuring at least 8 ft. by 8 ft. (Note: This method is good for a thermal assessment, but not a moisture assessment.);

(c) by building a house with this type of wall and monitoring it for a few years.

The type of wall you describe has no ability to dry to the interior. Such walls usually perform well, especially if they have siding that dries readily, and are equipped with a ventilated rainscreen. This type of wall might be problematic if you have a cladding that traps moisture or dries slowly (like stucco).

Response to Richard Speare

Re: (c) by building a house with this type of wall and monitoring it for a few years.

The type of wall you describe has no ability to dry to the interior. Such walls usually perform well, especially if they have siding that dries readily, and are equipped with a ventilated rainscreen. This type of wall might be problematic if you have a cladding that traps moisture or dries slowly (like stucco).

I had thought about that as I was doing the work. The good news is that my house is brick exterior, tentest on studs, dense pack celluose, then the gypsum board with plaster, and then my foil faced insulation & drywall. So there is likely good drying to the outside, but I was wondering about the plaster/gypsum board. Do you think there is potential for that to trap moisture? I think that the foil face would act like a vapour barrier that I did not have previously.

Your thoughts?

Response to Richard Speare

Richard,

Yes, the foil facing on your rigid foam is certainly a vapor barrier. It sounds like you have plaster on the exterior side of the foil-faced foam, and drywall on the interior side of the foil-faced foam. Is that correct?

The drywall is at interior conditions -- warm and dry -- so there is no reason to worry about the drywall.

Most of the wall's insulation is on the exterior side of the plaster, so it should be fairly warm and dry, too. If the plaster ever gets damp for any reason, it will need to dry to the exterior. I don't think that either foil layer will ever get cold enough to encourage condensation.

Response to Richard Speare

Correct. It certainly made the room warmer, I'm planning to do the same to the rest of the house.

Thanks!

.

An anomaly in the brick graph?

All the graphs show fairly smooth curves of increase and decrease across the seasons, except for July in the second graph in the section, "Brick veneer softens the differences...". This graph of the percentage differences in heat loss between Polyiso and XPS show July as having the opposite sign and a very different magnitude from the surrounding late spring and summer months. For July, XPS shows better performance by about 28%, the greatest of the entire year, while in June, it is worse by about 8%, and in August, it's worse by about 4%.

The graphs for the other location and other thicknesses do not show such a discrepancy for July. Is this an error in generating the graphs, or is there another explanation for the seeming anomaly in this graph? It seem odd to me that polyiso would perform worst during only one of the warmest months, and only when under brick veneer.

Response to Derek Roff

Derek,

The anomaly is due entirely to the fact that the heat flow through the wall in July is so tiny. Look at the graph that shows the heat flow in watt-hours per square meter (instead of as a percentage). The heat flow is close to zero -- so low that the percentage graph represents noise rather than a significant flow of heat.

A little confused

So, the pentane blowing agent condenses at about 15C. Then, does it become a thermal conductor? I can't imaging how microscopic "droplets" of pentane in somewhat larger voids can really impact insulation value. Isn't it the cells that provide the thermal resistance, not the blowing agent?

If I am not getting this, then using a CO2 blowing agent (or any other gas with a lower evaporation temperature) seems to be the ideal solution, would it not?

Gas thermal conductivity drops with temperature

In the opening paragraph of this blog, the quote by Schumacher seems to suggest that radiation is the primary reason why the R of many insulation materials is seen to improve with colder temperatures. While radiation effects may be part of the reason the R of a fiberglass batt or other translucent insulating material increases at colder temperatures, I suspect that for opaque materials the primary mechanism is the lower thermal conductivity of the trapped gas.

In an insulation layer, conduction will be partly through the solid particles and partly through the myriad small bubbles or regions of immobile gas. In an effective insulation, the solid material serves to create those small pockets of gas and thus essentially eliminate convection as a transport mechanism. If the gas moves, the material isn't effective, and thus we have the need to have an air barrier on all six sides of the insulation if it is air-open, like a FG batt.

Truly "dead" air itself has an R value of about 6 per inch, as calculated from its thermal conductivity. The R of inert gases is even higher, and it goes up in order of their atomic numbers, so that for example krypton has a higher R than that of argon, and indeed window glass units with krypton fill perform better than those with argon. Best would be with a radon fill, but then the window might glow in the dark and give you radiation poisoning!

The thermal conductivity of a gas typically drops as does temperature, and over modest temperature ranges is fairly linear. For air, the decrease in conductivity from 40 to 0 C (104 to 32 F) is about 11%. From image 3 above, the corresponding change in XPS conductivity over the same range is, hey, about 11%! On looking at the slopes for cellulose (largely air cavities), EPS, and XPS, we see that the lines are nearly parallel. So we shouldn't really wonder about why R gets better at lower temperatures. The wonder is that oddball polyiso.

Response to Steve Young

Steve,

I don't know the answer to your question, and I welcome a comment from any insulation expert who does.

I do know this: the pentane blowing agent in polyiso raises the R-value per inch of polyiso (compared to rigid foam products with air) when the polyiso is tested at a mean temperature of 75°F. That's why manufacturers try to limit the dissipation of the pentane with a variety of facing products. Keeping the pentane in the polyiso raises the performance of the polyiso, at least when it's warm, and the manufacturers don't want the pentane to be replaced by air.

Foam fun

I have to question whether a model is truly representative of the real world situation.

It certainly makes sense that there can be some effect from condensation within the polyiso cells, but

wouldn't it seem likely that the warming of the foam would reach a point where the condensation ceases or is minimized.

Wouldn't a hot box test be more representative than a computer simulation?

Effective R value has been bantied about in EDU since the 1980's. We certainly need more work on this topic. Or do we?

Response to Tom Gocze

Tom,

The temperature-dependency curve for polyiso shown in Image #2 was not developed by a computer model. It is based on real-world measurements made by the type of heat flow meter used in the ASTM C518 procedure ("Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus").

You can see a photo of the type of device used for this measurement on this GBA page: Understanding R-Value.

Response to response

Thanks Martin,

I still wonder about the temperature gradient through a given thickness of polyiso not being linear. One would need to account for the relative temperature as you go through a given thickness of foam. At some point, I suspect not too far in, condensation should stop and insulation value would be higher. No?

Certainly a thicker piece of foam would maintain a higher average R value than 1" or thinner.

That being said, polyiso manufacturers still offer many varying values from 5 to 7+ per inch, just to keep it fun.

Response to Tom Gocze

Tom,

You wrote, "I still wonder about the temperature gradient through a given thickness of polyiso not being linear. One would need to account for the relative temperature as you go through a given thickness of foam."

The "heat flow meter apparatus" mentioned in my previous answer measures actual heat flow at different mean temperatures. If the center of a piece of rigid foam performs differently from the section of foam near the surface, that phenomenon is obviously accounted for when heat flow through a sample is measured.

In other words, we are talking about measurements, not energy modeling software. "It is what it is."

2 questions::

Where is the geographical dividing line in the US between hot and cold climates? And why does brick veneer have the effect described?

Response to Charles Campbell

Charles,

Achilles Karagiozis plans to run more modeling exercises to estimate the polyiso penalty in a variety of climates. The short version is that the polyiso penalty still exists in mixed climates, but that the penalty is much smaller in mixed climates than in cold climates. When more information is available, GBA will publish it.

Brick veneer heats up when exposed to sunlight. Moreover, because of its thermal mass, it retains heat for hours, even when the weather is cloudy -- softening the highs and lows of the outdoor air temperature. That means that the wall sheathing behind brick veneer never gets as cold as the wall sheathing behind vinyl siding. If the air temperature drops to 0 degrees F on a cold night, the brick veneer may never get any colder than 12 or 15 degrees F.

Another response to Charles Campbell

Charles,

Perhaps I misunderstood your question. Perhaps you were simply asking for access to a map that shows the areas of the U.S. that are considered to have climates that are cold, mixed, and hot.

The usual source for these designations is the Building Science Corp. I will reproduce the BSC climate map below.

.

Thanks, Martin

Thanks, Martin.

I was just trying to simplify by dividing the whole country into cold and hot, so that builders could quickly distinguish whether they should pay attention to this issue or not. As more data are gathered, eventually I suppose a bit more complicated map could be drawn. Until then, how far north of Miami would you think polyiso has the advantage?

You wrote, "Brick veneer heats up when exposed to sunlight." I wonder if white brick (or white concrete veneer) would show the same effect? Or darker colors on north elevations that never see sun?

Also, has anyone had success taping the edges of polyiso so that the pentane never escapes?

Another response to Charles Campbell

Charles,

As I wrote before, the thermal mass of the brick veneer will lead to this "softening" of the polyiso penalty, whether or not the bricks are exposed to sunshine.

Q. "Has anyone had success taping the edges of polyiso so that the pentane never escapes?"

A. No. Polyiso's "thermal drift" phenomenon is an unavoidable fact.

Relative humidity and condensation

The potential effect on dew point/condensation in cold climate walls is a valid concern, but any actual impact in the real world will almost certainly depend directly on relative humidity. The wall assembly in our retrofit 1890's-era Victorian consists of 4" of dense blown-in cellulose in the stud bays, with 2" of fiberglas-faced polyiso (claimed R value of 12) over the sheathing. Nothing impedes the wall assembly from drying to the interior, and it also has a well vented rainscreen.

Thicker foam would have been nice, but wasn’t practical: any thicker walls would have severely messed with certain architectural details. But using the simplified dew point calculation presented several years ago at GBA (https://www.greenbuildingadvisor.com/blogs/dept/musings/are-dew-point-calculations-really-necessary?utm_source=email&utm_medium=eletter&utm_term=energy-efficiency&utm_content=20111228-energy-efficiency-payback-calculations&utm_campaig), I determined that there was little risk of developing wet sheathing (or cellulose) as long as the inside RH stays below 50% most of the time.

Possibly the information in the present post changes that equation…but assuming that is the case, conditions are mitigated to a significant extent by the fact that relative humidity tends to be much less in my northern climate during the same cold months when the thermal performance of polyiso may be most compromised. According to my hygrometer, inside relative humidity seldom strays from a range of 32-42%, from December through February…significantly less than the assumption I used in the calculation. Ergo, I don’t perceive a problem to exist. I would feel much more concerned if RH actually was consistently running at 50% (or greater).

What about spray foam?

I understand that spray foam wasn't studied in this research. But based on the chemical makeup of spray foam, would you expect its cold weather performance penalty to be more like XPS or polyiso?

Response to Dave Frank

Dave,

The graph in Image #4 answers your question -- at least for the (unidentified) brand of closed-cell spray foam tested by the Building Science Corporation. The orange line is labeled "2 pcf ccSPF," which stands for 2-pounds-per-cubic-foot closed-cell spray polyurethane foam."

You'll notice from the graph that the spray foam behaves more like XPS and ESP than polyiso. So it should perform well at cold temperatures.

this is all pointless...

unless we can access a similar test result for 10 -20 years aged polyiso.

If you are planning for less than 20 years you can forget ur "green" glow at home please.

Has any of the studies on polyiso behavior informed us on the reason why polyiso cold temp thermal value drift ? is it really only related to blowing agent factor ?

Still looking for information on how fast are the blowing agents getting out of the polyiso.

Taping every sides of insulation is labor intensive on any sizable project and renders the R /cost value of polyiso pointless.

I don't see how i would have people taping of the edges of every panels on large flat roof job

with hundreds of panels being installed.

If we can't understand how time affects this behavior, i will personally

have to revised some near future projects to include a certain layer of EPS/XPS to replace

last layer of polyiso .

charles CAMPBELL" look for HDD VS CDD for each location to determine smart use of polyiso.

If "heating degree days " has a large margin over cooling , switch to XPS/EPS .

roxul ..

we sometime forget to include their product in our discussions.

something i just found on roxul website about their roofing boards vs PIC boards .

http://www.roxul.com/files/RX-NA_EN/pdf/tech%20data/TB-%20extreme%20temps.pdf

probably biased on the PIC curve

but i wonder how high the stone wool curves would go at -20c ??

Response to Jin Kazama

Jin,

Thanks for sharing the link to the Roxul document. I have added the Roxul graph to this article as Image #7.

Response to Dana Dorsett (Comment #9)

Dana,

You wrote, "Looking at the English units conductivity scale on the right edge of figure 4, the R-value of the [poly]iso at +15 C is about R7.5-R8 (considerably more than R6), but it falls to a mere R3.5 @ +5C (+41F) mean temp, falling to a mere R2 at -15C (+5F) mean temp."

Something is odd about the hockey stick graph (Image #2) that Achilles Karagiozis used as the basis of his modeling exercises. It doesn't correspond to other published graphs; for example, look at the polyiso line in the Roxul graph published as Image #7 -- it shows a cold-temperature performance of R-4.7.

I will be contacting Achilles to ask him to comment on the discrepancy.

Along the same lines...

Martin,

Regarding the apparent inconsistency with the Roxul graph... It seems there is the same inconsistency with the BSC graphs themselves. For example, Image #5 doesn't show the performance penalty shown in #2 and #4. Am I reading these charts right, or is there some explanation for this discrepancy?

Also, are the graphs in #2 and #4 published on the BSC website (so we can see any accompanying commentary)? I was able to find #5, but not these.

Thanks!

well ..

After a few hours of research using google on "old" polyiso cold performance and blowing agent release rate i give up ..

Someone will need to find a direct informative party as it seems as if nobody has ever looked into the performance of polyiso at sub 0c temp VS its age .

The only thing i was able to find are from Huntsmangroup about realease rate of pentane and other blowing agents ...

They found out that R value ( stadard test ) was pretty much in line with the previous estimation for 5 and 15 years aged products ( 5 years real aged and 15 was artificially accelerated .. )

And it went on average down to begining of R5 @ 15 ( different products from diff manufacturers seem to play a role in the variances )

I can only conclude with very little assurance, that if it reaches R5 value after 15 years,

it must be near neutral stage of blowing agent release ( i have no knowledge about it, but i guess it works on a pressure equlaization ?? so probably tapers off to very slow release/replacement after a faster period ? )

as it then reaches XPS value .

But we aren't much interested in learning that, since it was pretty obvious it would get to that kind of value and everybody already know this.

Unfortunately still missing its cold temp performance at this "equalized " age .

My apprentice guess is that its cold performance is not hindered as shown in recent studies once it has aged. It might be up to a stable R5 at that point ...but who knows for now..i don't still .. :(

I've inquired to Roxul about the performance of their insualtion at -20c .

Response to Dave Frank

Dave,

Q. "Am I reading these charts right, or is there some explanation for this discrepancy?"

A. I have sent an e-mail to Achilles Karagiozis, asking him this question. I will post any information that I learn.

Q. "Are the graphs in #2 and #4 published on the BSC website (so we can see any accompanying commentary)?"

A. Not to my knowledge. I obtained the graphs from Achilles Karagiozis.

Response to Jin Kazama

Jin,

You aren't the only person asking these questions. Achilles Karagiozis is asking the same questions as well. When I interviewed him, he said, “This temperature dependency is not very straightforward. There are also the effects of aging. But in many of these applications, we do not have big variations in performance in short periods of time. But we might have it in other applications -- for example, if you have cold and hot temperatures going through a pipe. I think that this information has to be disclosed to the public. People need to know what they are using. As a scientist, I want to understand it more.”

We need clarification

I read your blog entry and the many comments with great interest. And also with some confusion…

1 - Image 5 at the end of the blog entry is the same graph as in BSC’s Info-502 published in April 2013, “Temperature Dependence of R-values in Polyisocyanurate Roof Insulation.” The range of R-values shown for these 2-inch samples at the lowest mean temperature (25°F) is from 4.35/inch to 5.6/inch (all eyeballed off the graph). Image 4 at the end of the blog entry, which forms the basis for the WUFI modeling, shows the R-value at the mean temperature of 25°F to be about 2.3/inch. Do we know what is different in these tests or samples? Does the data presented in the blog entry comprise one manufacturer’s product or is it an amalgamation of several products?

2 - In further testing described in Info-502, BSC tested 4 inches of polyiso, down to outdoor (not mean) temperatures of 0°F. The three products tested had R-values per inch ranging from 4.35 to 5.1. In the footnote, they speculate that the increase in conductivity may be due to condensation of the trapped gases in the cells and that further research is warranted. Is the data presented in the graph in the blog entry a result of this further research?

3 - In the WUFI modeling, is the R-value of the polyiso varying according to the results shown in this graph based on both mean temperature and temperature difference? (At a given mean temperature, the total temperature difference across the polyiso can be different, and we don’t know if the R-value is the same at a 25°F mean temperature with 50°F total temperature difference vs. a 25°F mean temperature with a noticeably lower total temperature difference, as is the case when the foam is used outside of an insulated 2x6 wall.)

4 - If it is true that the R-value of polyiso degrades this significantly at low temperatures, wouldn’t we see this in the heating energy usage of the many buildings constructed with 4 inches of polyiso outside of an insulated 2x6 wall?

As you have called for, we really need clarification as to whether this is a uniform issue or confined to certain products; better insight into the physics of the issue; and a better understanding of the consequences on whole building performance, both in terms of assembly condensation issues, and energy performance.

Response to Marc Rosenbaum

Marc,

Thanks for your comments. I agree completely that Achilles Karagiozis's modeling study raises more questions than it answers.

Q. "The range of R-values shown for these 2-inch samples at the lowest mean temperature (25°F) is from 4.35/inch to 5.6/inch (all eyeballed off the graph). Image 4 at the end of the blog entry, which forms the basis for the WUFI modeling, shows the R-value at the mean temperature of 25°F to be about 2.3/inch. Do we know what is different in these tests or samples?"

A. I also noticed the discrepancy, which is why I wrote (in my Comment #42), "Something is odd about the hockey stick graph (Image #2) that Achilles Karagiozis used as the basis of his modeling exercises. It doesn't correspond to other published graphs; for example, look at the polyiso line in the Roxul graph published as Image #7 -- it shows a cold-temperature performance of R-4.7. I will be contacting Achilles to ask him to comment on the discrepancy."

I sent Achilles an e-mail with questions on December 21, but have not yet heard back -- no doubt because he has been celebrating the holidays. I'll let you know when I hear more.

Q. "[BSC researchers] speculate that the increase in conductivity may be due to condensation of the trapped gases in the cells and that further research is warranted. Is the data presented in the graph in the blog entry a result of this further research?"

A. I don't know. I have left a voice mail message for John Straube; I will report back when I know more.

Q. "Is the R-value of the polyiso varying according to the results shown in this graph based on both mean temperature and temperature difference?"

A. An excellent question; I doubt it. But we'll wait to hear from Achilles Karagiozis on this point.

Q. "If it is true that the R-value of polyiso degrades this significantly at low temperatures, wouldn’t we see this in the heating energy usage of the many buildings constructed with 4 inches of polyiso outside of an insulated 2x6 wall?"

A. Yes, clearly. If we know that cold-climate homes insulated with polyiso are performing well, then we know that modeling exercises won't change the energy bills of existing houses. If GBA readers have built homes with exterior polyiso, and have a year of energy bills to contemplate, then they already know the bottom line. Still (like you), I would like to have more answers to the unanswered questions raised by this modeling exercise.

Thanks for your comments, Marc.

Response to Marc Rosenbaum (Comment #47)

Marc,

Here are some answers …

Q. "I read your blog entry and the many comments with great interest. And also with some confusion…

Image 5 at the end of the blog entry is the same graph as in BSC’s Info-502 published in April 2013, “Temperature Dependence of R-values in Polyisocyanurate Roof Insulation.” The range of R-values shown for these 2-inch samples at the lowest mean temperature (25°F) is from 4.35/inch to 5.6/inch (all eyeballed off the graph). Image 4 at the end of the blog entry, which forms the basis for the WUFI modeling, shows the R-value at the mean temperature of 25°F to be about 2.3/inch. Do we know what is different in these tests or samples? Does the data presented in the blog entry comprise one manufacturer’s product or is it an amalgamation of several products?"

A. The data is from Chris Schumacher’s test data (Presented at Summer Camp). The data is from one manufacturer. The data show a very low R-value at low temperature. The point to be made is that they are actual measurements.

Q. "In further testing described in Info-502, BSC tested 4 inches of polyiso, down to outdoor (not mean) temperatures of 0°F. The three products tested had R-values per inch ranging from 4.35 to 5.1. In the footnote, they speculate that the increase in conductivity may be due to condensation of the trapped gases in the cells and that further research is warranted. Is the data presented in the graph in the blog entry a result of this further research?"

A. No.

Q. "In the WUFI modeling, is the R-value of the polyiso varying according to the results shown in this graph based on both mean temperature and temperature difference? (At a given mean temperature, the total temperature difference across the polyiso can be different, and we don’t know if the R-value is the same at a 25°F mean temperature with 50°F total temperature difference vs. a 25°F mean temperature with a noticeably lower total temperature difference, as is the case when the foam is used outside of an insulated 2x6 wall.)"

A. The data from building science corporation (plot from Chris) was at mean temperature (temperatures of plates were not shown). No other information was available. This was our question too: Did they actually measure thermal conductivity or something else (the temperature difference can make a difference in the results as well as time)?

Q. "If it is true that the R-value of polyiso degrades this significantly at low temperatures, wouldn’t we see this in the heating energy usage of the many buildings constructed with 4 inches of polyiso outside of an insulated 2x6 wall?"

A. The walls contribute (a fraction) to the whole house energy use at high insulation levels. The effect would be smaller in terms of whole energy that just looking at wall performance. As noted, different products can have different behavior, some may have weaker effects than others.

Q. "As you have called for, we really need clarification as to whether this is a uniform issue or confined to certain products; better insight into the physics of the issue; and a better understanding of the consequences on whole building performance, both in terms of assembly condensation issues, and energy performance."

A. We agree, further research is needed, e.g. ORNL/BSC needs to do standardized testing at different temperatures for different products and report the results as derived thermal conductivity.

-- Achilles Karagiozis

Thanks Achilles

I think we all agree that what we need is standardized testing and identification of which products do what at the range of temperatures.

Some more references

Here are two references from the appliance industry (refrigerator insulation), both of which show a general trend of low thermal conductivity (high R value) at low temperature for polyurethane foams with HFC and similar blowing agents. One shows pentane doing the same; the other shows pentane leveling off at low temperatures, maybe getting a little worse. This doesn't really resolve anything but at least these are a few more data points in an area where we have little data, and at least they include the details on what the blowing agents are.

http://www.appliancemagazine.com/ae/editorial.php?article=2149&zone=215&first=1

http://www.honeywell-blowingagents.com/?document=cpi-2012-paper-continued-evaluation-of-blowing-agent-solutions-in-pour-in-place-panel-applications&download=1

Response to Charlie Sullivan

Charlie,

Thanks for the links. I agree that these data points are certainly interesting.

Have you any idea why links to tech bulletins etc. almost always end up with a page not found message?

Nils,

The GBA web site is huge, and it's more than 10 years old. Many of our links no longer work because the organizations we link to have changed the URL addresses for their pages.

GBA strives to repair all dead links. If you find a dead link, post a comment and I'll do my best to fix it. Be specific -- tell me exactly where the dead link can be found.

One other problem concerns the change several months ago from a Drupal platform to a Wordpress platform -- this occurred during the GBA site re-design. The switchover was imperfect, and I am still hand-correcting errors introduced by the new software.

Rain screen over polyico foam.

I have always wondered if it is better to vent the top of the rain screen or leave the top closed. I realize the drying potential is greater if open. I have 3/4 inch strapping over 1 inch foil faced polyiso. My thoughts are drying is still going to take place with a 3/4 gap behind claps even if the top is blocked. Yes not as well as if open but still much better than no rain screen at all. My question is the thermal benefit if any of the foil facing the back of the claps with a 3/4 space. I am assuming it would be better from a thermal performance with the top closed rather than open. If so how much do you think and does it out weigh the drying potential.

Response to Terry Grube

Terry,

I don't have a technical response to your question. But my instinctive answer is that the difference in thermal performance between these two options -- a rainscreen gap with open vents at the top, versus a rainscreen gap without venting at the top -- is trivial.

Interior insulation upgrades at/below grade in cold climates

In a 1950's era house in seacoast NH (HDD ~= 7000), an energy audit suggests we will realize an improvement in energy use with, among other things, installation of 4' of 2" polyiso at the top of the basement walls along with 3" SPF in the rim/band joists. Given the discussion above, given that we are talking about interior of a heated basement, does polyiso still make the most sense or should we consider an alternative?

Response to Michael McCann

Michael,

First of all, if you intend to install insulation on the interior side of your basement walls, I strongly suggest that the insulation should extend all the way down to the footing. You don't just want a narrow band at the top of the wall, because if you install your insulation that way, you have left a massive thermal bridge (the lower section of the concrete wall) allowing heat to bypass your insulation.

For more information on this issue, see How to Insulate a Basement Wall.

Q. "Given the discussion above, given that we are talking about interior of a heated basement, does polyiso still make the most sense or should we consider an alternative?"

A. I wouldn't hesitate to install polyiso in this location (because the temperature of your concrete wall will never be as cold as the outdoor air), although you may prefer to install EPS after reading this article. If you choose polyiso, it's safe to assume that its R-value will be in the range of R-5.5 to R-6.0 per inch.

Interior insulation upgrades at/below grade in cold climates

Hi Martin;

That makes total sense, AND the power company is picking up half of the cost to 4' but none of the cost below that. I have no idea why they ignore the thermal bridging. I suspect when they do their thing, I can add the additional 4' if and when cash flow permits.

Keeping my polyiso warm

Martin,

I am returning to timber frame shell in northern Minnesota that I started 5 yrs back. At the time, I thought that I had installed a smart roof system which consisted of 2X6 T&G over the timbers overlain by a vapor barrier and 3 layers of 2" polyiso panels with overlapping seams. Because I've always been told to avoid hot roofs, I placed 2X4's on edge parallel to the roof pitch (2' OC and 18' long) before attaching the sheating and shingles and vented the soffit and peak. This article apparently refutes the wisdom of choosing polyiso.

I'm wondering about the wisdom of opening the peak and trying to add another layer of insulation in the 3.5" gap between the polyiso and the sheeting? What options do I have? How do I prevent problems with a hot roof?

Thanks for your response.

Response to Wade Srock

Wade,

The nominal (rated) performance of your roof insulation is about R-36 to R-39. That's OK, but it's less than minimum code requirements (R-49). That's too bad.

Normally I would say, "Don't worry". Only the topmost layer of polyiso is exposed to cold temperatures. Maybe the top 2 inches sometimes performs at R-3 or R-4 per inch -- so what? It's enough to keep the lower layers warm enough for them to perform closer to R-6 per inch.

However, it would be easier to live with if you had started out with a code-compliant roof, instead of one that was shy of the code.

My own advice is, "Live with it." It's still probably better than your neighbor's roof.

What about roxul?

Does mineral wool suffer from temperature based performance detieoration?

Response to Andrew Bennett

Andrew,

Q. "Does mineral wool suffer from temperature-based performance deterioration?"

A. No.

Love that answer. I would worry about melting the foam under the tin roof in a warm roof. It can get too hot to touch depending on the colour of the tin. Because of that and the usefulness of the snowload as insulator in the winter I am planning a low slope warm roof with roxul over peel and stick membrane on the roof deck with tin on top. Because the snow load will end up bowing the tin over time between supports, how could I achieve an R60 and a durable and straight roof?

Nils,

Metal roofing is steel, not tin. The steel roofing is separated from the rigid foam by either (a) continuous sheathing like plywood or OSB, or (2) purlins (for example, 1x4s or 2x4s). I've never heard of rigid foam "melting" under steel roofing.

Are you planning to install plywood, OSB, or purlins over your semi-rigid mineral wool? The roofing won't "bow" if the purlins are properly spaced.

Make sure that you specify a type of metal roofing which works on low-slope roofs. Most metal roofing manufacturers require a minimum slope for their products.

If you plan to achieve R-60 on a flat roof with mineral wool alone, you had better talk with the mineral wool manufacturer and the roofing manufacturer to come up with acceptable details. That's an "outside the envelope" installation.

Has there been any update to

Has there been any update to this excellent work? I've been told that the new formulations of polyiso are not as susceptible to the R value drift at low temps? Truth or fiction?

Response to Edward Cambridge

Edward,

Q. "Has there been any update to this excellent work?"

A. Yes. This 2013 article was updated by a follow-up article in 2015 called Cold-Weather Performance of Polyisocyanurate.

Q. "I've been told that the new formulations of polyiso are not as susceptible to the R value drift at low temps. Truth or fiction?"

A. Mostly fiction. That said, I know that engineers at the polyiso companies are working on this problem and hoping for a breakthrough. The problem is tough, and there haven't been any new products released yet. I heard a presentation at a technical conference by John Letts from Firestone on this issue, and I will be reporting on his presentation soon.

I live in the Montreal area of Quebec, Canada. Last fall, I completed a complete renovation of the exterior walls of my house. The house dates from 1955 and has a frame in 2 x 4 covered with bricks. In the cavities there is a kraft vapor barrier with aluminum, mineral wool (4 '') a 1/2 wood fiber board coated with tar, a felt # 15 and brick.I removed the brick, I put a thru wall flashing in self-adhesive membrane, and I added 2-inch IKO Ener-Air polyisocyanurate panels, I sealed the joints with a vapor permeable tape, I added wooden furs and a composite wood cladding. Last winter the average temperature in December was -18 degrees Celsius. How is it that my heating bill has decreased by 25% if polyisocyanurate is so inefficient in cold weather? I think the studies are still in the speculative research stage, but on the right track, but there is a lack of elements in the equation to rule on anything with precision. Anyway, I got a very satisfactory energy performance given the 25% decrease in heating costs. Maybe it would have been better with XPS or EPS, but I'm not convinced, at least it would have been pretty much the same. In the choice of insulation, the aspect of fire resistance determined my choice and this point is really not negligible. Ener-Air insulation is coated with fiberglass and acrylic and the insulation does not melt when subjected to temperatures exceeding 225 degrees F. What I'm sure is that no matter what type insulation, each has strengths and weaknesses.

> Last winter the average temperature in December was -18 degrees Celsius.

That's simply not true. The hourly binned mean temperature for the month was much higher than that in December 2017. The last 5 days of December may have averaged something like -18C/0F , but the monthly average was SUBSTANTIALLY warmer than that. Most days of December 2017 even the low temperature was much higher than -18C, let alone the average temperature for those days.

https://www.timeanddate.com/weather/canada/montreal/historic?month=12&year=2017

Five days of cold-snap doesn't move the monthly average by that much!

>How is it that my heating bill has decreased by 25% if polyisocyanurate is so inefficient in cold weather?

That is because even derated for temperature adding 2" polyiso roughly doubles the R-value of the assembly from what you had, and the membrane surely cuts the air leakage through the walls by well OVER half. With half the total (labeled) R-value on the exterior the mean temperature through the foam layer is higher than if it were a simple 1" layer over even deeper cavity insulation. Even derated to R4.2/inch the R-value of the framing fraction would have tripled.

At Montreal's ~18F mean temperature for the month of January with a +68F indoor temperature and R12 in the wall cavities the warm side of the foam will be at least 32F even with the worst performing polyiso samples and the mean temp through the foam north of 25F. At a mean temp through the foam of +25F the 2" foam will deliver at least R8.5-R9 even if it were a lower grade 2lb roofing foam labeled at R11. Being lower density wall sheathing goods it's probably delivering R10 or better even in January, and higher during warmer months.

https://weatherspark.com/m/25077/1/Average-Weather-in-January-in-Montr%C3%A9al-Canada#Sections-Temperature

>I think the studies are still in the speculative research stage, but on the right track, but there is a lack of elements in the equation to rule on anything with precision.

Research, yes, but "...speculative research..."- not really. This is a well known phenomenon that all polyiso manufacturers have been working on for decades, tweaking their blowing agent mixes and manufacturing processes behind the scenes. Dow claims to have beaten the temperature derating game with their Thermax line:

http://msdssearch.dow.com/PublishedLiteratureDOWCOM/dh_098a/0901b8038098a7e2.pdf?filepath=styrofoam/pdfs/noreg/179-00379.pdf&fromPage=GetDoc

Note the derating curve for the 2lb roofing foam in the sample, compared to Thermax, the top line in black. The roofoing foam is good for only R5.5 at 75F mean temp through the foam, but still R4.3/inch even at 0F/-18C through the foam (which will never occur in Montreal with your stackup.)

Mifranc,

If you read the article, you'll discover that:

(a) Cold weather affects the outermost thickness of exterior rigid foam the most; the rigid foam layers that are closer to the interior aren't as cold, because the outermost layers of foam keep the innermost layers warmer. In other words, the coldest inch of foam is the outermost inch.

(b) Even when it's cold, polyiso performs at about R-5 or so.

So of course polyiso works.

Further to my idea for R60 roof with Roxul mineral wool. In my research I found that that Comfortboard has a resistance to compression of 743psf and is suitable for use underneath cement foundations. So Insulated box beams around the perimeter of the roof, many layers of Comfortboard with roofing OSB screwed on top directly through to the roof deck (covered with peel and stick waterproofing) could support the metal roofing without sagging. I made 14 inch deep box beams of 2x4's, 2 layers of quarter inch OSB and insulation between, for a cathedral roof with a 5/12 slope, peaked, over a 12 ft span that has held up just fine over the last ten years.

I wonder what the thermal bridging effect would be for that type of box beam.

"Comfortboard has a resistance to compression of 743psf and is suitable for use underneath cement foundations."

Comfortboard has been successfully used under non load-bearing slabs, but 743 psi is less than 1/3rd of the typical minimum capacity necessary for foundations.

Log in or become a member to post a comment.

Sign up Log in