Image Credit: U.S. Environmental Protection Agency

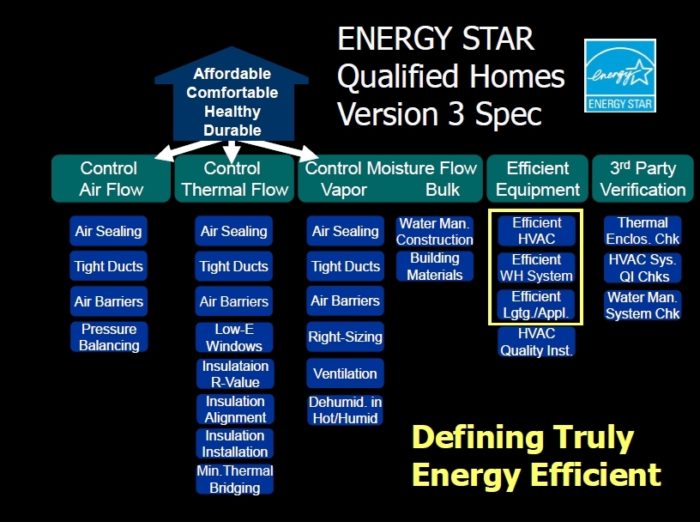

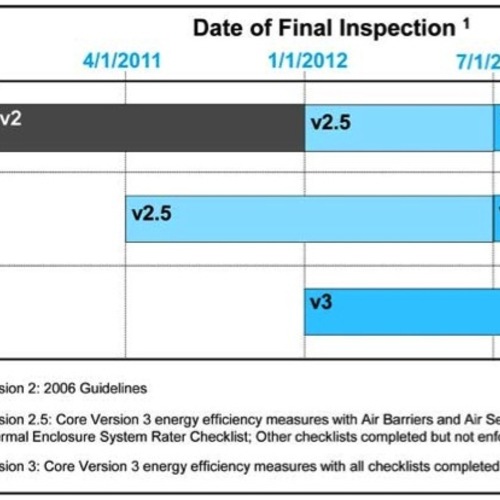

Beginning on January 1, 2012, homes enrolled in the Energy Star Homes program will need to comply with a new specification — dubbed Energy Star Version 3 — that is stricter than the current Version 2 specification.

Version 3 will still offer builders two possible paths to obtaining an Energy Star label: a performance path and a prescriptive path. Since it’s impossible to provide a comprehensive description of Version 3 in a short article, I’ll confine myself to commenting on some of the highlights of the new specification.

More checklists

By now, Energy Star builders are familiar with the Thermal Bypass Checklist. The Version 3 specification has given the checklist a new name: the Thermal Enclosure System Rater Checklist.

Joining that checklist are three new checklists:

- The Water Management System Builder Checklist

- The HVAC System Quality Installation Contractor Checklist

- The HVAC System Quality Installation Rater Checklist

Among the requirements found in the Water Management checklist:

- Builders must install pan flashing on the rough sills of all window and door openings.

- Builders are prohibited from using any materials (including framing lumber) with “visible mold.”

While it’s hard to imagine that builders won’t be tempted to slip in the occasional 2×4 with a spot of mold on it, the checklist probably won’t slow down progress on many building sites, since the entire checklist lacks teeth. The only person required to verify that the builder has complied with the checklist is — drumroll, please — the builder.

Lowering the HERS Index goal

Energy Star builders will need to achieve HERS Index targets that are lower (that is, stricter) than the Version 2 HERS targets. Actual HERS targets will depend on the climate zone — in Vermont, most Energy Star homes will need a HERS Index between 60 and 70 — and the size of the home.

That’s right — Version 3 includes a “size adjustment…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

10 Comments

Air inlets four feet above grade?

"The specification requires ventilation air inlets for supply or balanced ventilation systems to be at least 4 feet above grade. This provision means that many homes will no longer be able to install such inlets through the basement rim joist."

What am I missing here, other than some concern that snow will bury an inlet in heavy snow areas? It would seem that in many cases, with most or all of the foundation having only a foot or so above grade, the requirement will force the inlet to come out through the framed wall, preventing the ventilation equipment from being in the basement, making the connection to a duct system originating in the basement awkward, or compromising the insulation in a piece of the framed wall. The only framing construction I can imagine that would accommodate the requirement is a double framed or otherwise quite wide wall.

My new, superinsulated and exceptionally tight house (not quite finished), with HRV inlet and exhaust ducts already installed, would fail Energy Star Version 3!

Rigid air barrier

Martin - are you sure they will allow a non-rigid air barrier? I heard Sam state at RESNET conference (last year) that they will require rigid air barriers for version 3. All of our current raters we use are requiring rigid air barriers with the current version.

Response to Dick Russell

Dick,

In addition to the problem of 5-foot snow banks, the minimum height requirement for ventilation air inlets may be driven by a concern about proximity to smelly objects on the ground like dog feces. But I'm just guessing.

Response to Danny Kelly

Danny,

I have quoted from the language in the EPA documents: "EPA recommends, but does not require, rigid air barriers."

You are not alone in questioning this provision; it came up during the comment period, but the EPA didn't budge. See comment #129, and the EPA's response, in this document:

EPA Responses to Comments on ENERGY STAR Qualified New Homes Guidelines, Version 3.0

Great article!

Great article, Martin, as usual. Another new aspect of the program, which you almost touched on, is that builders, HERS raters, and HVAC contractors must go through a special training class and pass a test. Raters have to take a two-day class, HVAC contractors have to take a 4 hour class, and builders have to go through a 1 hour online module. Builders and raters must go through these classes to maintain their ENERGY STAR Partner status or to become a Partner if they're not one yet.

Last week, the ES team just released their guidebooks for Thermal Enclosure Systems, HVAC, and Water Management. (You can download them here: http://1.usa.gov/hk5jKM.) They're much better than last fall, when I first saw them, but there are still a lot of missing photos.

ENERGY STAR Version 3 is a big step up in the program, but it certainly has some flaws, as you've documented. I've been writing in our blog (http://bog.energyvanguard.com) about ES V3 since they first released it last April and have also written a white paper about it (http://bit.ly/hGyP1X).

In one respect I think

In one respect I think testing may increase the proformance of the home. On the other hand it may be like appraisals with the auditor doing whatever it takes to keep a client.

Near-grade supply inlets get fouled with yard waste and detritus

I would expect that this requirement is due to the potential for the air inlet of a ventilation supply duct to become fouled with yard waste, grass clippings, etc. Exhaust ducts are not a problem, because they are forcing air out to the exterior. But supply ventilation ducts are sucking air in, and this tends to draw debris. I think experience would bear out that after a year or two (if the supply inlet is not manually cleaned), the whole supply ventilation intake will be covered with debris, which would seriously restrict the air flow through the duct. Essentially, you get a supply ventilation system that is incapable of delivering any fresh air, and you've increased the ventilation fan energy in the case of ECM powered units. In addition to clogging, any debris that passes by the insect screen on the exterior will come to foul the heat exchanger, reducing its efficiency over time. It's hard to say if this problem is entirely eliminated by raising the inlets by 4', but it seems like a logical step. Hope this helps.

Energy Star Version 3 Training

Nice article Martin.

There seems to be a lot of concern out there about Version 3 being too hard, too expensive, etc. Some partners have threatened to back out of their home certification commitments completely. As with most of the general public, it seems many Energy Star Partners fear change.

The largest change seems to be found in the HVAC contractor's scope of work. While the EPA-required course covers what has to be completed, it doesn't teach the attendee HOW to complete these Version 3 requirements.

We've developed an Energy Star Version 3 training for HVAC Contractors that combines the 4-hour ACCA course with an additional 1.5 days of in-depth coverage on diagnostic testing, HVAC design, and Version 3 checklist completion... with an additional (optional) day of in-field, hands-on, training. In-field training for HVAC contractors and technicians will be critical for the overall success of Version 3. We hope that most of our class attendees will see the value in bringing additional staff from their companies out for the field training portion.

We're also offering a 2-day class, Energy Star Version 3 for HERS Raters, where we'll not only focus on the necessities, but spend some time discussing ways for Raters to increase their service offerings as a result of the Version 3 requirements. With an expected decrease in volume, diversification is key.

Lastly, we've designed a 1-day class, Energy Star Version 3 for Builders and Architects, that covers the core changes per trade, covers inspections and diagnostic testing requirements that Raters will implement, and emphasizes the importance of getting their trades on-board early. As with most things, buy-in has to happen at the top of the decision making ladder in order to ensure success throughout. We feel that after attending a thorough training, having their questions answered, and understanding who's responsible for what, some of the builders that were previously "on the edge" will come back over to the Version 3 side of the fence.

Thanks for addressing all of these Version 3 issues. Keep up the great work!

What Version 3 gets wrong - Bullet 1

What Energy Star document says that builders in Climate Zones 4 through 8 can omit interior air barriers at rim joists?

Response to John Ashton

John,

Here's the document:

http://www.energystar.gov/ia/partners/bldrs_lenders_raters/downloads/InspectionChecklists.pdf

And here's the quote:

"Band joists are currently exempt from interior air barrier requirement in Climate Zones 4 thru 8."

Log in or become a member to post a comment.

Sign up Log in