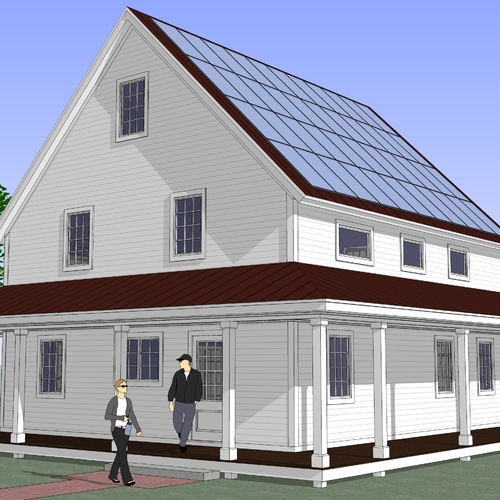

Image Credit: Ben Southworth

Jane Bindley had a dream: to turn her 1978 ranch in central New Hampshire into a net-zero-energy house. How hard could that be?

As it turned out, pretty hard. But with help from a dedicated team of experts and a generous budget, Bindley achieved her dream.

Can a north-facing house be net-zero?

Bindley chose her team wisely. She hired a New Hampshire company, Garland Mill Timberframes, to renovate her home. Ben Southworth from Garland Mill is an experienced design/build contractor. When it came time to choose an energy consultant, Southworth advised Bindley to select Marc Rosenbaum, one of the most experienced designers of net-zero-energy homes in the country.

Southworth doubted that Bindley’s nondescript ranch was worth saving. “I told her, ‘It will cost more money to take it apart than to bulldoze it,’” said Southworth. “But she answered, ‘It’s structurally sound, and I can’t imagine putting the house in a landfill.’ ”

The house sits on the shore of Squam Lake, with a spectacular view of the lake to the north. Most of the home’s windows face the view. “We were killed from a solar perspective,” said Southworth. “The house is up against a big hill on the south side, and the hill has tall trees. We put as many PV panels as we could on the south roof. Since we were aiming for net-zero energy, the PV array defined what our heat load had to be.” The house ended up with a 7.5-kW PV system.

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

52 Comments

Thank you, Martin, for a

Thank you, Martin, for a thorough treatment of this project. One clarification — although the house does not have full-time occupancy, two things make it similar to a full-time house. One is that the first year I had Jane keep the thermostat at comfort temperatures, and even now, it's best with low-temperature radiant floors to not use a deep temperature setback; and two, Jane has a large family and when the house is occupied there could be a lot of people there — one of the rooms is full of bunk beds :-)

After Pictures

Interesting approach, thanks for sharing. Is there a way to see more after pictures?

"After" photos

Armando,

I'm expecting to receive some more photos from Ben Southworth soon. Right now I don't have the photos you request. As soon as they're available, I'll post them to this blog.

Basement insulation

Nice post Martin.

This is more of a question for Marc Rosenbaum if he comes back to the post. I was wondering about Marc's decision making process regarding the insulation of the basement. R-40 is very high and would most likely increase the number of freeze/thaw cycles experienced by the concrete. What was the mitigation strategy (leaving an unexposed area at the top of the wall for example) that was applied here? A discussion of assessing risk to basement walls when doing an insulation job with closed cell foam would be helpful.

Is cold concrete at risk?

Kyle,

I'm not aware of any study that shows that interior basement insulation damages a concrete foundation. After all, think about all of the outbuildings, sheds and unheated barns with poured concrete crawl space or basement foundations — as long as the footings are below frost depth, these foundations are not generally damaged by cold weather.

Taped Sheathing Joints

With closed cell spray foam in the stud cavities, is it necessary to tape the exterior sheathing joints? Perhaps at the rim joist area, but for the rest of the wall?

Just trying to figure out where to save money...

Kyle - no issues that I know

Kyle - no issues that I know of with concrete, as Martin has responded.

Brett - belt and suspenders on this project, because there's a fixed energy budget, and we needed it to get really tight. We're making buildings under 1 ACH50 by taping the sheathing. Spray foam helps but there are plenty of places the foam doesn't get to so it alone won't easily get you to a really tight building.

While we are on the Subject...

Marc,

Did you seal the roof deck joints as well?

And it appears in one the posted pictures that you used a primer (wet areas around the taped joints) before you applied the Grace Vycor strips.

What did you use?

re: Thanks Martin

Martin, this is a great article! Brett, we used a Grace primer that Marc recommended to us. I still have a couple of gallons if you want to buy it from me! The reason I still have it is that we are now using Zip wall peel-and-stick wherever possible because of the excellent adhesion. Obviously on windows and doors the Grace is a little more robust especially with fasteners, but for seams it is all Zip tape without primer now.

Cost

Thank you for the response Ben.

How much did you spend to tape the sheathing joints (walls only)?

I am trying to calculate the amount of tape in linear feet needed for wall joints on a 3,000-ish square foot home.

One more thing

And when you say you are now using Zip wall peel and stick, are you using this tape on regular OSB sheathing?

Interior vs exterior foundation insulation

Given the no holds barred approach to insulation in this project, I wonder why the decision to insulate from inside was taken. a similarly airtight construction could have been achieved with polyisocyanurate or type IX rigid insulation. The added benefit of thermal mass inside the building could have provided some advantages. I suppose costs of excavation could have eliminated this as an option (although given the overall budget I'm not so sure...). Curious. Nice post.

More Info

Marc,

I've done a few gut rehabs to very low HERS scores, however I'm still intrgued why you selected to use SIPS other than you are more comfortable with it. Did you do a cost analisys with other sytems or methods. Can you please elaborate? Forgive me if I'm asking too much, I do fing this job interesting, but too many questions left out.

Questions...

Thanks for the article Martin. A good example of an unlimited budget, net zero home

Just a few questions:

1. Curious about the radiant floor system choice. I thought that was generally a inefficient choice in very tight homes. Maybe with the GSHP, that is the only option....although I thought that you could convert that to hydronic air system. But then you have the problem of installing a duct system that does not penetrate the thermal envelope, exhaust ,etc

2. You said that the client "covers her windows with movable R-7 foam-filled insulation panels at night." Never heard of such a thing. Would love some explanation.

3. A 7.5 Kw PV system....that is a huge system. I thought the solar exposure was minimal? How many panels is that? Approximate square footage? Was it installed somewhere away from the structure? $60,000 costs...is that the actual costs....or does that include any rebates?

Thanks

refrase...

... to many answers left out. I think Martin just gave us a teaser... :-))

Reply to Armando

Armando,

It was Ben Southworth, not Marc Rosenbaum, who preferred using SIPs to rigid foam. Southworth is a timber-framer who has a lot of experience with SIPs.

Here's one advantage to SIPs (at least for the roof): if you're doing a chainsaw retrofit, it's easier to recreate the rake and eave overhangs with SIPs than it is to tack on framing made of 2-bys.

Reply to Ed

Ed,

1. The Warmboard subfloor allowed the use of low-temperature water. That decision made the GSHP much more efficient.

2. You've never heard of movable nighttime window insulation panels? Ed, you must be a young guy. They were all the rage back in the 1970s, when the hippies and solar fanatics (I was one of them) were building experimental low-energy houses. Most people got tired of the twice-a-day chore pretty quickly.

3. No PV rebates were available in New Hampshire when this house was built, so $60,000 is the full cost and the net cost. It's not a huge system for a net-zero-energy house — in fact it's on the low side. Try to do better! I don't think you can sharpen your pencil any better than Marc Rosenbaum.

Solar exposure was not minimal; it was actually pretty good, with just a little wintertime shading. Wintertime shading doesn't matter too much. You don't make much electricity in New Hampshire in the winter anyway.

Reply to Armando's other post

Armando,

Just a teaser? Maybe. Some of my editors think my blogs are too long ... yet it seems I'm leaving some readers hungry for more details. I can't satisfy everybody — except that I'm happy to answer follow-up questions (thereby lengthening my blog....)

SIPs Walls

When you said, “the SIPs were attached to the framing…” as in a “floating wall”? No saddle footings? How were they attached? What type of final cladding? I’m looking forward to the final pics.

PV calculations...

Martin,

I was not doubting Marc's PV calculations. I have 18 PV panels on my roof for a 2.5 Kw system in sunny CA. It just seemed like a large surface area would be needed for a 7.5 Kw system, probably more southward facing rooftop than even a 3500 square foot home has available. But maybe not?

And hey, I actually am not that young, but maybe younger than you.....but obviously, a little under-informed about such labor intensive insulating devices.

SIP attachment details

Armando,

I have just posted a detail (Image #5) the shows how the wall SIPs were attached to the existing house.

SIP Attachment

That's pretty cool. I could have used this technique several years a go. I used a saddle footing and we framed a wall next to the existing wall. The footing part was a pain. This is a good alternative.

Thermal Bridge?

Is the steel L Bracket continuous or is it a series of short brackets?

Either way it ...Is it not a significant thermal short circuit from the rim joist to the outside?

Thermal short circuit?

John,

Most people use the terms "thermal bridge" or "thermal short circuit" to refer to a building component that conducts heat from the interior conditioned space to the exterior. But the steel L bracket you are referring to conducts heat from the exterior to the exterior — it's hardly a "thermal short circuit."

The bracket is nowhere near the interior of the building or the conditioned space. The interior side of the rim joist is massively insulated with closed-cell spray polyurethane foam.

Perhaps "Not-so-Bad"

If the steel angle is not continuous then it seems to be "not-so-bad"

If it is continuous ... then what makes it any different from the "bad" example in the Clint Easwood anology in Lstiburek's paper

http://www.buildingscience.com/documents/insights/bsi-005-a-bridge-too-far

The interior of the rim joist does "appear" to be massively insulated in the illustration.

What if you take a section cut thru the floor joists instead of thru the cavity?

Cavity insulation alone at the rim joist does not address thermal bridging....Eh?

The outsulation at the rim joist seems to be "bypassed" by the highly conductive steel.

Ventilation?

Wondering what ventilation systems were used on this project.; both IAQ and roof ventilation, etc. used?

Ventilation

Mike,

Check the specs: mechanical ventilation is provided by a Renewaire energy-recovery ventilator.

Since the roofing is standing-seam metal over SIPs, I don't believe there is any roof cavity ventilation.

Clint Eastwood thermal bridge

John,

Joe's "Clint Eastwood" examples -- the bad and the ugly -- show continuous steel brackets continuously attached to a concrete slab at room temperature.

I think it's a stretch to say this is the same as a steel bracket which, every 16 or 24 inches, is adjacent to a narrow section of wood sheathing contacting a narrow 1 1/2-inch-wide area of framing that is in contact with room-temperature air about 7 or 9 inches back from the bracket, where the floor joist finally emerges from the foam.

So ... the steel is not continuous

Martin,

I agree that if this is a series of small brackets and not a continuous steel angle....

It is not-so-bad

It was just not clear from the illustration.

Are there any photos of this detail?

New image -- the electric bill

I have just posted a copy of one of Jane Bindley's recent electric bills. Her electricity usage is zero zero zero zero zero zero ....

new definition of "mansion"

Wow, this is an amazing post. The level of detail is terrific - and the story really demonstrates the investment required to get to net zero. Not to diminish this effort, truly, I think we Americans are going to have to come to terms that in our new future, a 3,400 s.f. house that costs $1.19 million to retrofit -- will be known as a mansion. Or, do you think that over time, the costs will come down by a factor of 10 so that we can truly afford this kind of retrofit?

Pam

This is NOT a typical net-zero remodel. There are mamy, many 1,500-2,000 sf net-zero homes built to reasonable costs (±$30K-$50k) in NM, AZ and CA. You do not have to spend $1MM to get there. For what I can tell, her major costs to net-zero were around ±$300K or 25%-35% of the entire cost; which is typical to the up-costs of a net-zero home. We don't know how many other amenities and finishes she had installed in this project.

Response to Pam and Armando

Pam,

Although Armando is correct that most of the cost of this retrofit is not attributable to energy improvements, the cost to bring the house to net-zero performance was nevertheless breathtaking. I don't think the cost of this type of retrofit is ever going to come down by a factor of 10.

The fact is, builders interested in superinsulation retrofits have been performing this type of work since the early 1980s. We know the costs, and they are very high.

Armando: I'm aware of fewer than 10 homes in the US that have documented 12 months of net-zero energy performance. Almost all of them have PV systems ranging in size from 6 kW to 10 kW. (The exception is the David Pill house in Charlotte, Vermont, which has a wind turbine.)

For net-zero-energy performance, you're going to pay $42,000 to $70,000 just for the PV array. That doesn't cover envelope improvements.

Please provide more details on a house with only $30,000 of incremental cost that can demonstrate 12 months of net-zero-energy performance. Until I see more information, count me a skeptic.

Which Half of the Year?

Martin,

Do you know which half of the year the home is mostly occupied?

Is it a weekend retreat or a summer home?

Were the windows covered with insulated panels every night AND during the unoccupied half of the year?

Response to John

John,

The house is occupied three or four days a week, year round.

The windows are covered at night during the winter, but not during the summer. I imagine that the north windows are insulated (night and day) when the home is unoccupied during the winter, but I'm not sure.

Affordable Net-zero

Martin,

I've been in many presentations at green building conferences and events by ConSol and the Davis Group in CA, Artistic Homes in NM, John Wesley Miller in Tucson, BSC, Steve Winter's group, DOE, the Building America and ORNL have demonstrated homes around the country they've been working on affordable NZs for years. Even our buddy Peter did many presentations several years a go about affordable NZs in his BSC days and after. The UCF in FL, they've been working on NZs for a long time, at one time they had a website you could look in real time all their data. I'm sure contacting all of them would be happy to give you details.

ConSol, Davis Group, Artistic Homes, John Wesley Miller...

Armando,

None of the builders or researchers you list have made a net-zero energy home (mind you, I insist on 12 months of documented net-zero performance -- no firewood, no unaccounted for natural gas) that I am aware of. Correct me if I'm wrong by giving me the address of the home and the name of the responsible builder or researcher.

Moreover, if they have done it, I'm sure that the incremental cost was way more than $30,000 ...

Affordable net-zero

Thank you, Martin and Armando, for your responses. I would be really interested in anywhere you could point me that would document how to get to net zero -- in the most affordable way possible. I have this thing about "marginal rate of utility" of each dollar spent being a factor. That is, I am very cognizant of payback times and effective use of our collective (often: incentivized) spending to get at the problem as effectively as possible. I have read... and it kind of makes sense to me... that money is a proxy for carbon. That is, the low-hanging (inexpensive) fruit can be the most... fruitful. That said, I recognize that LCA is really likely the barometer. Anyway, I diverge. Re: affordable net-zero, I am looking for the specific details to get there today. I have been looking and looking online. So far, this website is the best I can find. But I still cannot find detailed "how to's." To be sure, there seem to have been great strides in products in the past year. But I having a devil of a time piecing it all together. Thank you!

Response to Pam

Pam,

You may be interested in reading two blogs that cover the topic of net-zero energy design:

"Equipment Versus Envelope"

"Thinking About Net-Zero Energy"

Here's the basic method: choose a good energy modeling program and run the simulations with many iterations of the house. Each iteration will need to be costed out, at least roughly.

Then you get to compare the energy performance of the different iterations. What happens if you add $5,000 more insulation to the attic? Is the performance better or worse than a house with $5,000 of additional PV modules?

What happens if you switch from double to triple glazing? Is the $10,000 incremental cost worthwhile?

NREL's BeOPT program (not yet widely available) sounds useful. But really, a good designer needs to become comfortable running these energy simulations and costing out the various construction options. Sometimes you have to just sharpen your pencil and do the math.

Thank you

Thank you, Martin. I'm a newbie here as you can surely tell. Your other blog posts - on super insulation and the energy efficiency pyramid are exactly what I am looking for, too. I've been online searching for about 10 days and finally landed here -- exactly where I wanted to be. Many thanks!

Wow

Interesting article. Not for the average homeowner. Good things to take from the retrofit but overall this is at the top of the buying pyramid for both existing and new. Glad to know someone's got money.

Excellent coverage

Well done, Martin.

A very informative and interesting article.

From 80,000 ft, we are at an early stage in the evolution of Net-Zero construction techniques and technologies, and more importantly -- demand.

Costs will come down and energy prices will rise...

Response to Charles -- about the project cost

Charles,

Here's another way to look at this project's cost. Assuming that the project cost $1,190,000, how else could the money have been spent?

Let's say that no energy retrofit work was performed. But perhaps Jane Bindley still wanted to spruce the place up. (Perhaps the 1970s shag carpeting and avacado appliances had to go.) So let's provide a budget that is 50% of the original budget to upgrade the interior finishes. That's $595,000 -- enough to make the interior spiffy -- very spiffy.

Remember, we haven't improved the energy performance of the house yet. Instead, we take the remainder of the original project budget -- the other $595,000 -- and invest it in a long-term investment that yields 4% interest. How much does that nest egg generate? Well, it generates $23,800 a year -- forever.

Do you think that $23,800 per year is enough to pay the energy bills on a ranch house? I think it probably is.

Just food for thought.

PPT on this home

See PPT on this home at: http://www.affordablecomfort.org/ Look under ACI Initiatives, then Thousand Home Challenge, then case studies (4th or 5th link down the page).

Another investment

Of course it's hard to make the financial argument. But hopefully the lessons we learn from projects like this will help push things along, will help us make the goals more affordable.

Net zero

Nice article for an unlimited budget. The insulation package could have been done much less expensive and still achieve good R values. 4 inches of foam on the outside and flash and batt on the inside would get the walls to 45 or so. This also helps with the water plane. Spray foam the ceilings to 7 inches provides a good air seal and R 49, which is in the new 2009 energy code. The basement insulation in my view is overdone. I think what we need to understand is that air sealing is more important than insulation values. If we approached a retrofit from the air sealing point of view and was on a budget, we would be sure to air seal first and then insulate the best we can. PV systems have to be sized to the use, however its not a good idea to oversize a system in NH as putting excess energy on the grid is not paid.

Thanks Carmela for the ACI link

Kudos to Southworth and Rosenbaum for doing what they could with what they were dealt.

It seems to me that the will of the homeowner may have been the component that drove the price tag off the scale.

It looks like Marc Rosenbaum "campaigned" to reduce the sliding glass doors and window area.....

Homeowner did not budge.

No wonder the levels of insulation and the price sound so ridiculous.

Bindley threw a lot of money at this but did not set a good example for others.

Cost of Net Zero

Getting a home as efficient as possible is the first step... and then building the power plant is the second and very expensive next step. Making sure the homeowner doesn't install the $25 beer fridge from 1979 in the garage that makes the home not net zero is the 3rd step.

Education is everything!

On another note the different energy modeling programs give different opinions on how to estimate the near-zero for a building.... I feel that modeling pv output is much easier than modeling average person-habits and energy use within a building... but basing expensive decisions off the numbers can be problematic when we cant decide on which numbers to use!

Check out this presentation comparing some energy modeling tools... depending on which one you choose your home can have a very different 'estimated' energy use!

http://www.bgbg.org/resources/Documents/SB_Modeling_Software_Presentation.pdf

Response to Quint

Quint,

An interesting presentation -- thanks for the link.

Mechanical System

If the building envelope was built to a PassivHaus standard, why was such an expensive mechanical system chosen? One of the big arguments for spending money on the envelope is to save money on mechanical systems, especially with PassivHaus. Were the large expanses of north facing glass a determining factor?

Saving money on mechanical systems

Steve,

You raise an interesting question. It's important to point out:

1. This house may have an excellent thermal envelope, but it made no attempt to comply with the Passivhaus standard.

2. Unlike most Passivhaus buildings, this home had the goal of generating all of its annual energy requirements using a rooftop PV array. That goal drove Marc to specify a ground-source heat pump -- which, as you correctly point out, is probably the most expensive equipment ever invented for heating a house.

3. The idea that Passivhaus buildings have low-cost mechanical equipment is somewhat of a myth. Every Passivhaus building I have ever studied includes a space heating system. It's quite common for a Passivhaus building to have a mechanical ventilation system incorporating an HRV, as well as an air-source heat pump and (often) an elaborate domestic hot water system, sometimes including an expensive solar thermal system.

Recently Posted interior photos

I have to say the Architecture is very nice.

Log in or become a member to post a comment.

Sign up Log in