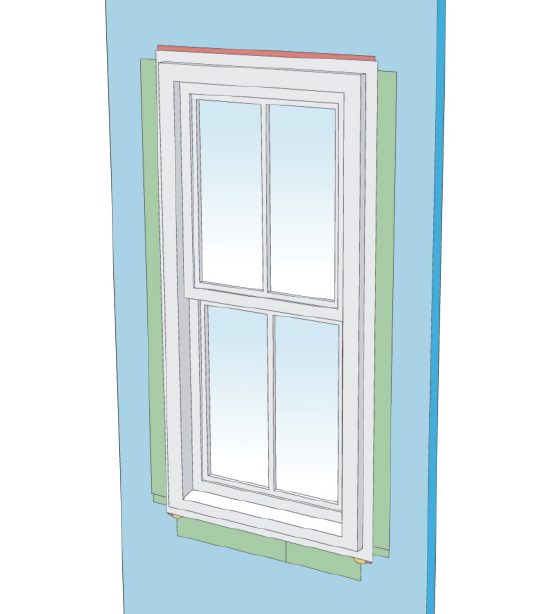

Image Credit: Building American Program

Over 30 years ago, when builders first began installing rigid foam wall sheathing, they had to figure out their own methods of fastening flanged windows. In 1982, when I sheathed my house with 1-inch-thick EPS, I installed “picture frames” of 1-inch lumber around each window rough opening. As it turned out, Joe Lstiburek was also building a foam-sheathed house in 1982, but he used a different approach.

“Back then, we weren’t using OSB or plywood sheathing — just XPS foam sheathing, usually Dow blue board, with diagonal metal strapping for bracing,” Lstiburek told me recently. “At first, we would run a horizontal 1-inch thick board under the bottom flange of the window, to help support the weight of the window. Under the other three flanges, there was nothing but foam. We attached the windows to the studs with screws through the foam. We built thousands of houses this way, using foam up to 1½ inch thick. We never experienced any problems.”

Eventually, Lstiburek realized he didn’t need to install any wood under the lower flange. “In the late 1980s, I took that practice with me to the U.S.,” said Lstiburek. “Then we stopped installing the horizontal board underneath — except for wide windows. If the window was wider than 4 feet, we’d still install a board under the bottom flange. But most of the windows we installed were basically hung from the flange fasteners.”

What about thicker foam?

I asked Lstiburek how he attaches flanged windows on walls with very thick foam. “I don’t have enough of a track record with 2-inch foam, so when we go above 1½-inch-thick foam, I recommend using side straps,” Lstiburek told me. (Side straps are also called masonry clips.) “You attach the windows at the sides of the rough opening with the straps. The side straps work…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

10 Comments

Here in Washington State

Here in Washington State new energy codes require exterior foam (prescriptive requirements) on all buildings in Eastern Washington and all non-residential buildings in Western Washington. With that kind of force promoting energy efficient buildings and the use of continuous exterior insulation as a prescriptive method, window manufacturers should no longer have an excuse to ignore foam installations now that many buildings in Washington State require this type of installation or similar.

A year ago I called up Milgard Windows to get some updated waterproofing details from them and they told me they no longer provide those details because they do not want to be liable for water intrusion issues. If manufacturers can simply ignore water intrusion details, I guess window manufacturers will continue to ignore alternate installations as well and try and pawn off the liability on someone else.

Response to J Chesnut

J,

Thosten Chlupp is a great believer in innie windows -- he asserts that the better thermal performance comes from protecting them from the wind -- pulling them closer to the interior keeps their frames warmer. Of course this must be balanced against possible shading; larger windows are less affected by shading than smaller windows.

I think that Joe believes that medieval windows were inset to protect the glass. If the peasants are throwing pitchforks at your cathedral or castle, the glass in an innie window will not be as vulnerable to pitchforks as an outie window. Of course, the more popular the Pope, the less he has to fear pitchforks.

Minnesota unhelpful

Marvin and Anderson sell too many windows to need to be helpful at this point. That is why I advocate for the superior imports.

When did flanges come about? As I'm working on my 1907 abode its fun to compare the old sashes that were simply pinced between 1/2" thick trim with current day standards - and no header to boot. Frames weren't even fastened to the studs, held in place by the lathe. My 1907 home is advanced stick framing before the term was coined ; ).

I don't quite follow Lstiburek's reasoning for preferring innie windows.

- “For optimal thermal performance, innie windows rock."

The passivhaus literature I think is convincing that the glazing should be set towards the middle of the thermal gradient. Also sometimes innie windows compromise solar heat gains when wanted by shading the opening.

- "Glass windows were expensive — only the Pope and rich people could afford them — and it was important to protect the glass."

Protect the glass from what? Water or reformationists? I assume Joe is talking about the old wood sashes here (which in cold climates suffer more from interior condensation than from rain). Pazen's windows are interesting because the glass covers even the sash on the exterior. Glass itself is very durable for exterior use.

Foam is plenty strong enough

A lot of carpenters seem to be very worried that foam isn't strong enough to hold the window flange. I've installed Andersen and Pella flanged units over foam, the wiggly soft vinyl Andersen will suck in a bit if you overdrive the fastener but they still work fine...the Pella aluminum flange is even easier since it's somewhat rigid to begin with. And the windows feel and act the same as when nailed to wood sheathing.

Conservative engineers

“Structural engineers are conservative, because when they make a mistake, people die,” he said. “That’s why they learn to be conservative.”

I agree that structural engineers, with rare exceptions like the Ove Arup practice, are extremely conservative, but it's not because theor mistakes cause fatalities. Deaths caused by structural engineering failures are so rare as to be almost non-existent compared to those caused by medical mistakes. Structural engineers are conservative because relatively minor failures (think cracks, not collapses) can lead to very expensive lawsuits and huge increases in their insurance premiums. Even spectacular failures like the Tacoma Narrows Bridge (1940) resulted in no human death (a small dog lost its life). The Hyatt Regency atrium bridge collapse (Kansans City 1980, 115 deaths) is the notorious exception that proves the rule. The Hyatt failure, caused by a conceptual flaw in the suspension system, attracted a $3 billion settlement.

That is how they do it in Germany

Martin,

you must have worked with a rough crew in Germany. Using the spray foam is not allowed nor common practice there. I am German and worked as a window installer and later planning a lot of window details following the "DIN NORM" which says that every window has to be secured on each corner and less than 2' 6" o.c..... . As far as the practical approach on site often goes: If the window is so small that your drill does not fit, the spray foam will do it, otherwise you secure it at leased with four screws and if it looks flimsy add a couple more :-).

Innies vs. outies

I think the main reason that it is either innie or outie here in the States, is because the windows are what they are and few people want to change that. I agree with J about the superior imports mounted in the thermal center of the wall (or at least close). It is really nice to keep the frames warm but rather than protecting them against the wind, we should cover as much of the frames with insulation as possible.

Response to Philipp Gross

Philipp,

Thanks for your perspective. I certainly appreciate knowing more about German methods of installing windows.

The crew I was working with was installing windows and entry doors into walls made of a new prototype material, styrofoam concrete. The walls were made of precast panels of concrete mixed with styrofoam beads.

In many ways, the construction method was experimental, although the experienced German builders I was working claimed that their methods have been approved by engineers. The entry doors and windows were foamed in place.

Reengineered windows

Building material manufacturers seem to lag behind better building practices unlike the technology sector that sets and leads new trends. Heck, even the construction tool makers are ahead of users at times; 10 years ago who thought we needed impact drivers, trade-specific gloves, upright orientation tool bags and so on. It's too bad window makers haven't stepped too far forward. It would be nice to see window designs that address the installation challenges associated with rigid foam covered buildings.

I've heard through a reputable source that a couple of window manufacturers are modeling windows with deeper flange to frame face distance. Most clad or vinyl windows have a 1 in. to 1 1/8 in. distance that works fine for planing out with siding applied directly to the wall but leaves siding proud of the window when we install siding over a rainscreen space or foam (when the window is installed at the framing plane).

The distances the window companies are looking into are in the 2 in. to 2 1/2 in. - essentially enough to accommodate about 1 in. of rigid foam and possibly a rainscreen space. I guess those companies are recognizing the trend in energy codes towards exterior layers of rigid foam insulation. Still, going to a 2 in. or 2 1/2 in. frame to flange distance won't address the array of possible installation details that innie / outie, various foam thicknesses and the combinations present.

the problem is the windows, not the exterior insulation

FWIW, working with Inline Fiberglass windows which are configured more like an extruded aluminum commercial window, and less like a clad wood residential window, we found that Inline has exterior jamb and sill extensions that were deep enough for 2" of exterior insulation and allowed the window to be mounted with the nail flange against the sheathing. http://yfrog.com/h248014239p

I think this is a much better solution than hanging the window away from the framing whether backed by plywood or just foam, particularly if you are using something like Zip sheathing which relies on its tape to lap over the nailing flange to establish a reliable water shedding assembly.

But of course most commodity residential windows are not configured this way. It just points to the need for building component manufacturers to update their products to be able to work easier with high performance walls. Every commodity residential window now needs to accommodate a variable exterior stand-off from the sheathing to work with different thickness of exterior insulation. Andersen, Weathersheild, Pella, the lot of them, all need to revisit their product so we don't have to come up with jury rigged ad-hoc solutions such as outlined in articles like this one. The products need to adapt - not us. This is a product design problem, not a construction problem.

New construction windows over foam

I have been planning a energy retrofit of my home in Austin, Texas and here is how I plan on installing my new windows. I am adding 1 1/2 inches of foam with a radiant barrier over my existing T-11 siding. After flashing the window area I am installing 1 x 4 furring strips on top of the foam. 1 x 6 PT is installed around my window openings and will be flush with the furring strips. New construction windows will be attached with the flanges to the 1 x 6 PT. In addition they will be caulked and flashed with butyl tape. After installing the windows, I will install 1 x 4 hardi trim. This will leave a 1 1/2 to 2 reveal on the 1 x 6 PT to attach the hardi lap siding to the 1 x 6 PT.

Log in or become a member to post a comment.

Sign up Log in