Image Credit: Rodenhouse

My file of interesting new green building products is bulging again, so it’s time to highlight a few items that have caught my attention.

The nine products featured here include three insulation products (Amdry subfloor panels, Cornell nailbase panels, and Staycell One Step 255 spray foam), one manufacturer of fasteners to secure rigid foam (Rodenhouse), one window distributor (Zola), a new gasket-in-a-roll for installing windows (Tremco ExoAir Trio), one new type of siding (Apex Ultrex fiberglass siding), one HVAC product (a fan to move heat from one room to another), and one plumbing item (HydroRight Dual Flush Converter for toilets).

Full disclosure: while these products are intriguing, I can’t vouch for their durability or suitability for your project. GBA welcomes feedback from readers who have used these products, so that our reviews can better reflect the collective wisdom of the GBA community.

Another subfloor panel for basement slabs

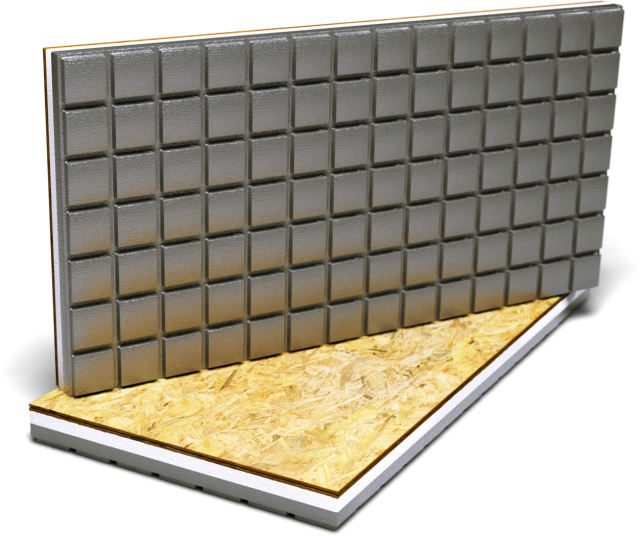

AmDry panels are OSB subfloor panels designed to be installed on a basement slab.

AmDry panels are similar to competing products like DriCore panels and Barricade subfloor tiles. (The DriCore panel is a sandwich consisting of waferboard adhered to a dimpled plastic vapor barrier which raises the subfloor off the slab and permits some air movement between the slab and the subfloor. The Barricade subfloor tile is an OSB panel bonded to a 1/2-inch layer of XPS rigid foam.)

AmDry panels include a dimpled bottom (like DriCore panels) as well as a layer of rigid foam insulation (like Barricade panels). AmDry panels are available in three different thicknesses (R-7, R-9, and R-11), all of which include a layer of expanded polystyrene (EPS) insulation. AmDry panels measure 2 ft. by 4 ft., so they are larger than competing products (which measure 2 ft. by 2 ft.). AmDry panels are sold at Home…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

12 Comments

it's a bit disconcerting zola

it's a bit disconcerting zola won't reveal who makes their windows in poland.

is this because the markup is 3x what it actually costs and once people figure that out, they could get them cheaper on their own?

Response to Mike Eliason

Mike,

I think that most purchasers of European windows want to know something about the manufacturer -- just as any purchaser of a U.S. window wants to know a little bit about the company that makes the windows. How long have they been in business? What's their reputation for satisfying customer complaints? How likely is it that the company will still be around in 10 years if you ever need parts?

These are the types of questions that window purchasers ask. If you are buying a window from Marvin (for example), many of these questions can be answered. Purchasers of other brands of European windows -- for examples, windows made by Holz & Form, Bieber, Energate, Gradwohl, Heinzmann, Internorm, Makrowin, Intus, Optiwin, or Unilux -- can research the companies that make them, if they want.

However, when it comes to "the Polish manufacturer of windows that cannot be named," U.S. buyers remain in the dark.

To Martin Holladay

You hit the nail on the head. Companies like the ones you mentioned openly state who manufacturers their windows. Intus comes right out and openly discloses on their website that the window frames are manufactured by Schuco. Why hide anything?

These mysterious window factories with no names that only the NSA is aware of is beyond silly. When someone spends tends of thousands of dollars on windows they should know where they were made in case something goes wrong and they need to get a hold of the manufacturer. It's not like Zola makes the windows himself, he is the middle man. While there is nothing wrong with that in and of itself, it is somewhat of a negative selling point. The 5 month lead time surely doesn't help either. There are better ways to answer the question of where the windows are made instead of asking the questioner to sign disclosure notices. I bet the NSA knows who makes the windows ;)

Zola etc.

I don't know why Florian doesn't identify his manufacturer. It is a puzzle, to be sure. What isn't a puzzle is the quality of the windows. I've seen them up close only once, a month ago in Olympia, Washington, and they looked pretty awesome to me. The most interesting part of Zola windows, however, is not the manufacturer but that dark band of stuff that's sandwiched into the wood sash in the photo above. It's called "Purenit," a recycled polyurethane product made by a German company called Puren. It seems to be used in a lot of Passivhaus windows. Recently somebody at GBA was remarking on the lack of Passivhaus-qualified doors in this country, and it seems like this product might be used for that. Anyway, I'd be interested in an article about Purenit, not Florian's phantom manufacturer. [BTW, if it uses German hardware (it does) and a German-made foam product in the sash, and it comes from a factory in a country that's right next to Germany, something tells me that, you know...]

It's never a good thing when pricing isn't disclosed.

How do companies stay in business if they aren't up front on the price of their product? Seriously, if I'm planning the siding of a project, how can I even consider a product that has no price information?

How to insulate a cathederal ceiling myself from inside house?

I live in Trenton, Ontario, Canada a 2 hour drive east of Toronto, Ontario, I need expert advice on situation below insulating cathederal ceilings in house built about 1960's.

This house is about 1,180 sq ft floor space, ceilings go from just under 7 ft high on outside walls to 9 -10 ft high on opposite wall. My father in-law bought this house in 1986, has had a musty smell for about the last 15 years.

Neither of my wife's parents smelled it l guess living there even though so many told them, my father in-law went to nursing home 2 1/2 years ago his wife went to same home 5-6 years ago both have altimers decease.( Sorry for bad spelling ).

I tried to upload a few photo's, but they are to big for this site, all ceilings have wooden beams each about 46 inches apart.

Standing inside the house looking up at the ceiling, the ceiling panels are about 2 ft wide, these panels were placed above the beams and were the original roof. On the attic side of these panels, there is black tar and gravel the panels themselves are about 5-6 inches thick.

At some point before my father in-law bought this house in 1986, the roof panels must have been leaking.

The prior owner put on a second roof, above the original roof panels, there is about a 10 inch space between the two roofs. The carpenter who helped me gut and refinish the house called the outer roof a stick roof not sure what that means. But the outer roof outside looks like a reg struss roof, my father in-law about 7-8 years ago being cheap put new shingles on top of old shingles.

The old shingles had a green moss stuff above kitchen area, wish he had removed them.

So having now to remove 2 layers of shingles will be costly, hoping to do a section at a time doing it myself. But due to having to replace about 45 ft or more of outside walls old walls weren't even touching concrete sill plate could slightly push on outside walls and shake them, had to sister allot of floor joices,100% replace all wiring was 50 amp now 200 am in ground, all plumbing replaced and due to walls being so bad had to replace outside siding.list on and on can't borrow anymore just have to save over summer hoping l get some drywall jobs to pay for roof and insulation.

Home Depot sells metal panels, picture in flyer shows these being installed over shingles has anyone used these? I would need to remove both layers of shingles, thinking of strapping roof once shingles removed replacing any bad plywood any thoughts on this product? Thinking of using this for home we live in needing shingles as well with in a few years, home we live in l replaced 80% of plywood and shingles ion 2002, hoping can put these sheets of metal over my single layer of shingles on home we live in.

For my father in-laws home it has never had insulation in the attic just the panels and the outer roof since he bought it in 1986, which is likely why walls were so rotted and black mold on dinning room ceiling panels. I bought a huge pail of stuff professionals use to encapsole mold clear I will paint it on before putting new gyprock over all ceilings. Should l put pink fiberglass insulation between beams on the inside living area of house panels?

I was thinking beams are only 5 1/2'' inches thick, l thought if it is ok to insulate from the inside of the house I would add 2x2's or 2x4's to allow proper thickness of insulation not sure what l need or if the 5-6 inch thick original roof panels would count as insulation. Or should l remove plywood from the outer roof and insulate from outside, either way do l need a 6 mil vapour barrier and if yes where do l put it?

Inside l will l hope before winter putting new gyprock on all ceilings once l know how to insulate roof, either above way need to how how to vent the roof? When l renovated last year was only a vent on peak nof roof not properly installed had carpenter put in 4 of those sq brown vents don't think it is enough. Sorry for length of this message, please anyone who can help me with above roofing, insulating, venting of mess above will be very greatful being on a $ 729.00 month disability pension will be hard to save up to do this but am sure the lord will open doors.

Thanks in advance Jim Reeves, Ontario, Canada

Response to Bill Sweeney

Bill,

Many manufacturers don't like to discuss prices. Instead, they leave pricing up to distributors and retailers.

If a product wholesales for $1,000, some distributors might sell it for $1,200, while others might charge $1,800. The manufacturers don't want to quote a price, since it might embarrass the distributors who have a high markup.

I agree, it's a problem. Wise manufacturers should be willing to give a price -- or at least a price range -- in response to a question from a journalist or an interested builder.

Response to James Reeves

James,

Since your post doesn't seem to be a comment related to the product reviews on this page -- and instead appears to be a request for advice on how to insulate your cathedral ceiling -- I suggest that you post your question elsewhere, on our Q&A page. Here is the link: Q&A page.

How can l correct crawling space, mildew smell, high hummidity?

My name is James Reeves, l live in Trenton, Ontario, Canada l have been working on a house since 2011 my father in-law gave my wife. About mid July/2012 after 4 heart attacks and then a stent in July/2012 we run out of money so now as l get small drywall jobs l try to hope finish this house out to either sell it or rent it. Hoping to complete house and keep it because, of it's location property butts up to our city Trenton city boarder.

Once they start to either upgrade or build a new city sewer system plant, this 3 1/2 acers 160 x 900 plus deep lot will increase in value builders could put apartment buildings or about 20-30 homes but needs a city sewer hook up to do above now on septic.

Crawl space is dirt floor under the spare bedroom about 14 ft wide x 16 - 18 ft long there is a block wall between this area and the main dirt floor crawlspace.

Total house about 1280 sq ft do l need 20 mil vapour barrier or can l put 2-3 layers of 6 mil house vapour barrier?> Can anyone give me advise how to correct this cheapest way but properly that l can do myself with a helper?

Under bedroom crawlspace about 210 sq ft, dirt is about 2-3 feet below floor posts on concrete pads then floor sits on beams. The same in bigger crawlspace about 950 sq ft, dirt in biggest space about 5 ft from floor joices.

Any advise or help anyone can give me l despertly need please and thank you couldn't upload pictures says bigger than 2mb allowed her but could email photo's if anyone wants them to advise me thanks again James Reeves

PS:- If anyone lives in my area who could help me, l would exchange my drywall services in exchange.

Rodenhouse fasteners for rigid foam insulation

A related product which has the benefits of a wide head (3") and reducing thermal bridging through the screw is Dekfast Iso-Tak made by SFS Intec ("SFS" stands for Swiss Fastening System).

It is described as a thermal efficient fastening system, and it allows you to fasten thick panels of insulation with relatively short screws. See http://www.sfsintecusa.com/products/dekfast/

I used the 4 1/8" sleeves with 3 1/2 Grabber wood screws to total a 6 1/2" fastener for 6"-thick EPS panels.

They worked great. I simply pushed the sleeve by bare hand into the EPS and then used a long bit to drive the screws through the sleeves and EPS into the bottom of my floor joists.

For great service and customer support, contact Scott Carpenter [email protected]

High Hummidity after dehumidifier installed

We have always had Hummidity issues in our home. It was built in the 1930s, completed a complete removal 5 years ago. Roof is metal with spray foam insulation. The home contains an attic. Home is only 1,500 square feet. After installing new AC unit with standalone dehumidifier, Hummidity still remains 55%+. Never has reached and stayed at 50% and has not gone lower. the dehumidifier just keeps running and running. The Cooling/heating company who did the install is very well known and does. Great work in the area. They thought it was the dehumidifier not working properly but reinstalled a new unit today. Still same issue with high Hummidity. Forgot to mention this home is in Florida. I did read the post on Hummidity and saw with the foam insulation maybe all the moisture is getting trapped in the attic and can't get out. The dehumidifier can't keep up with the amount of moisture removed from home. The dehumidifier is bigger than we need. Supports 3,000 sq ft home. The heating/cooling company can't figure out why and where the moisture is coming from. Does anyone have any suggestions on the next steps/tests that should be done to figure out why our homes humidity is so high where a duhimidfier can't keep up with the amount of moisture? Thanks

Response to Erica Sayers

Erica,

I think that you posted your questions on the wrong page. I will re-post the questions on our Q&A page. Please click the link below to read the answers to your questions:

https://www.greenbuildingadvisor.com/community/forum/general-questions/58501/high-humidity-after-dehumidifier-was-installed

Log in or become a member to post a comment.

Sign up Log in