Condensation forms on a surface when the temperature of the surface is below the dew point of the air. During the winter, when the coldest surface in a room is often the window, it’s fairly common to see water droplets or ice on window glass — especially in a room with elevated indoor humidity.

Condensation is more likely to form when indoor relative humidity is high. That’s why it’s more common to see condensation on a bathroom window than a bedroom window.

Condensation is more likely to form on cold surfaces than warm surfaces. That’s why it’s more common to see condensation on a single-glazed window than a double-glazed window.

Older Americans who grew up in the days of single-glazed windows remember the joy of waking up on a cold winter morning to see beautiful frost patterns — swirls, vines, and lacy leaves — on their bedroom windows. And who can forget the frost-covered windows in the Hollywood version of Dr. Zhivago?

On today’s low-e windows, however, such frost patterns are extremely rare.

Thermal bridging

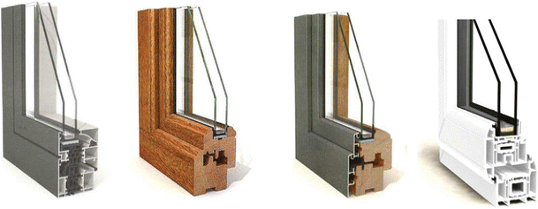

In theory, a window with a high R-value (that is, a low U-factor) should do a good job of resisting condensation. However, even a low-U window can have a condensation problem. That’s because a window’s U-factor is an area-weighted average of the U-factors of the different window components. Window condensation is a thermal bridging problem, not an average U-factor problem.

The coldest part of most modern windows is the bottom half-inch of glazing. (Although the width of the space between the panes of modern insulated glazing units has been optimized to minimize the effect of convective looping in the gas between the panes, convective looping still occurs. Naturally, the gas at the bottom of the gap — whether air or…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

21 Comments

condensation on the window exterior

With good performing windows, doesn't it make sense that you could also get condensation on the exterior of your windows in the Fall when there is a high diurnal temperature range and high outdoor humidity? Basically the outside of the window isn't warmed quickly enough so it drops below the outdoor air dew point.

Response to John Semmelhack

John,

You wrote, "Removing the screens also slightly increases solar gain and winter daylight."

To me, the difference in daylight (and visibility) isn't slight; it's significant. I would never want to go through a northern winter with insect screens on my windows. The world is gray enough without them.

Response to Aaron Smith

Aaron Smith,

There are two circumstances that can lead to condensation on the exterior of a window.

The first circumstance happens during humid weather in the summer, when condensation can form on the exterior of single-glazed windows on an air-conditioned building. I saw this at Independence Hall in Philadelphia. The exterior moisture buildup was so bad that it had stained the bricks under the windows.

The second circumstance occurs on the exterior of triple-glazed windows that face open patches of sky. Condensation can occur on the exterior of such windows, under the same weather conditions that causes dew on grass. Because of night-sky radiational cooling, the window glass can get colder than the air temperature, leading to the formation of condensation.

The second type of exterior radiation usually won't happen if your window faces an adjacent building or a patch of woods. It's most likely to happen on a window facing open sky, especially if the house is on a slope and the window faces downhill.

Fortunately, most windows are designed to handle water on the exterior, so exterior condensation is no more problematic than rain.

correlation between U-factor and condensation resistance

I don't buy the supposed lack of correlation between U-factor and Condensation Resistance. If you look at Figure 3, there is a very good correlation (higher CR with lower U-factor) except for one window (Glazing 4). If that were my data, I'd check the measurements for Glazing 4 to see if they were done correctly.

David

Response to David Fay

David,

Actually, there are two anomalies in the graph: Glazing #4 and Glazing #7.

Here's the bottom line: if you build a window with a highly insulated frame, and low-e double glazing with argon fill, but you choose an IGU with an aluminum spacer, the spacer can be a thermal bridge that leads to a low condensation resistance (CR) value -- even if the window's overall U-factor is relatively low.

once again passivhaus, leads

once again passivhaus, leads the way? the certification requirements from the passive house institute in darmstadt require temp factor for condensation risk (fRSI) - and that goes beyond just window certification as well (e.g. the schoeck isokorb also lists an fRSI factor).

Reponse to Mike Eliason

Mike,

While it's true that Passivhaus-certified windows are highly resistant to condensation, the window certification process established by the Passivhaus Institut in Darmstadt, Germany is not yet a useful tool to guide American window shoppers.

So far, not a single U.S. or Canadian window manufacturer has managed to get any of their windows certified by the Passivhaus Institut. (However, I've heard that at least one U.S. manufacturer is getting close to having some windows certified.)

The cost of Passivhaus-certified windows (for North American buyers) is so high, and the hurdles of importing windows so daunting (case in point: the difficulties experienced by Roger Normand) that -- for the time being, at least -- the Passivhaus certification process is irrelevant to American window purchasers.

In the future, if a number of North American window manufacturers get some of their windows certified, and if these certified windows can be sold for a reasonable price, then it might make sense for American buyers to look for Passivhaus-certified windows.

Interior insect screens

Interior insect screens (for casement and awning windows) have a similar effect as curtains or shades. Removing screens in the winter time lessens the risk of condensation. It's a twice a year mild pain-in-the-butt. Removing the screens also slightly increases solar gain and significantly increases winter daylight.

At a friend's house, removing the screens in winter made the difference between condensation (and moldy window frames) and no condensation.

Screens

You're right, Martin. While the solar gain increase is slight, the increase in visual transmittance is significant.

Martin,

"Finally, remember

Martin,

"Finally, remember that curtains or shades keep windows cool at night, thereby increasing the chance of condensation. If one of your windows is regularly wet, try opening up the curtains before you go to bed."

I just wanted to reemphasize your closing paragraph because that one factor, blocking or allowing air movment across the glass surface, is often the holy grail of reducing or eliminating surface condensation on windows.

I cringe when I see people suggesting the use of themal shades (not window quilts, that is a different critter) or other loose coverings for increasing the R value of a window system specifically because of the effect that the coverings will potentially have on window condensation.

I am a fan of using the stretch films over existing windows, when necessary, for both adding insulating value as well as reducing or eliminating condensation issues - even if I'm not a fan of the "use it once and throw it away" mentality that often is part of using such products.

I am curious if you have had any thoughts about a follow up blog on window condensation when using surface 4 coatings? That could make for worthwhile discussion point as well.

At the GANA (Glass Association of North America) conference in June, in Minneapolis, Jim Larsen and Tracy Rogers had an interesting debate on the potential for increased condensation when using surface 4 LowE coatings. The gist was that while surface 4 coatings do lower the interior glasss temperature, what is the potential effect on condensation resistance when using them? There was quite a difference of opinion and a lot of charts and graphs.

As a quick aside, Joe Lstiburek was the opening presenter of the conference and I'm not sure that all the window guys knew how to take him (personally, I thoroughly enjoyed his presentation. I had a front row seat).

And back on track, I would suggest that anyone reading Tracy Rogers' full article on condensation resistance take the spacer comparison graphs and statistics with a grain of salt - and unless someone has a specific question about the article or the graphics, I will leave it at that.

Slipping over to Roger Normand's blog on his passivhaus windows, the spacers used in the picture of the Bieber passivhaus certified triple pane that accompany the latest installment of his blog happen to be aluminum; while as near as I can tell (the picture isn't totally clear to that detail) from the picture of the badly condensating window in this blog, the spacer is not aluminum. So using aluminum spacers can land a passivhaus certification and using non aluminum spacers can result in serious condensation issues due to thermal bridging...both are true.

When dealing with window condensation, people often quote relative humidity. In fact it seems people always quote relative humidity, yet as you already pointed out, its the dew point that is the real consideration while relative humidity is...relative.

I have a simulation example of two homes, in a power point presentation that I use, one has an RH of 29% and the other has a RH of 40%, yet it's the home with 29% RH that has a window condensation issue while the home with 40% RH the windows stay clear. While the homes have a significantly different relative humidity as shown, the dew point is the same in both homes. RH is not the significant factor, dew point is.

As always, great article Martin, I thoroughly enjoyed reading it, and thanks.

Regards,

Oberon

Response to Oberon / Greg Smith

Oberon / Greg,

Thanks for you comments.

A note to GBA readers about "surface 4 coatings": Greg is referring to a relatively new type of double glazing: one that includes a hard-coat (pyrolitic) low-e coating on surface #4 (that is, the innermost surface of glass facing the interior of the house). The use of a surface 4 coating allows double-glazing to have two low-e coatings, thereby lowering the U-factor of the IGU.

Somewhat paradoxically (counterintuitively?), a surface 4 coating reflects radiant heat energy back into the room, and IGUs with surface 4 coatings have a colder interior surface than conventional low-e double-glazing without the surface 4 coating. The glazing performs better, but the surface is colder. However, if you are sitting near the window stark naked, the glass will feel warmer (even though it is colder). OK -- enough with the paradoxes.

IGUs with surface 4 coatings will have a slightly increased risk of condensation compared to other types of double glazing. Will homeowners care? Stay tuned...

Martin,

I have windows with Low-e on s4 and windows without. Those with hard coast on S4 consistently have condensation - not just in extreme cold conditions. I have even experienced ice on one. Condensation is along the bottom for the frame. Why occasional condensation might be tolerable, constant condensation has resulted in moisture damage and mold. I have an HRV and my indoor RH in winter is between 40 - 45%. In our December average lows are -4 degrees C.

https://weatherspark.com/y/1603/Average-Weather-in-Kelowna-Canada-Year-Round

Dewpoint vs humidity

Dewpoint vs humidity. Sort of misleading leaving out the temperature corollary.

Dewpoint and humidity are linked via what we all read on our tstats, temperature.

What ever became of the water filled solar gain windows? I have always intended to build a fish filled window just for the hell of it.

earlier tech

Top of the line single-glazed steel casements used to happily deal with condensation by means of tiny gutters at their base with drainage channels leading to the exterior. Ah, life was so much simpler then.

Window style and condensation

I have found casement windows to be more prone to condensation than double hung of the same brand and specifications. Has anyone else had a similar finding in a cold climate?

Why no CRF data?

Why doesn't Rogers share any CRF data? Is it not available?

Response to Nick Sisler

Nick,

I'm not sure why Rogers didn't share any CRF data.

For residential windows, it's hard to find any published CRF values. That's because manufacturers of residential windows are focused on NFRC labeling requirements. NFRC promotes the CR metric, not the CRF metric.

As far as I can tell, the only published CRF values are for commercial windows. For example, here is a data sheet for Efco commercial windows that includes CRF information:

http://www.efcocorp.com/images/products/arch_guides/3450,3460.pdf

With the glazing specified in the data sheet, that particular Efco window has the following ratings:

CRF-Frame: 44

CRF-Glass: 59

Window Tech Systems of Malta, New York published CRF values for their windows here:

http://www.windowtechsystems.net/windowdb/windowsearch.cfm?sort=crf

These values range from 47 to 63.

yep, it's a spacer issue

The main issue (to me) does seem to be that most American window manufacturers are using a less than ideal spacer. The manufacturers could do better if they wanted to, without a significant cost increase.

"So far, not a single U.S. or Canadian window manufacturer has managed to get any of their windows certified by the Passivhaus Institut."

To which I respond, because they haven't tried. Large manufacturers don't see a market yet for high performance components in the U.S. Case in point: Velux manufactures skylights in South Carolina to a much lower standard that what they make and sell in Europe. One cannot even buy their European product from their North American sales representatives.

Smaller manufacturers, like Thermotech in Canada make windows that are used in Passive Houses in North America - good u-frame, u-glass, and good spacer being the critical components. FYI, there will be a workshop for window manufacturers interested in PHI certification in San Francisco following Greenbuild. Clearly some companies see this as an opportunity in high performance. More information here:http://www.aphnetwork.org/events-schedule/phi-window-certification-workshop

Response to Martin: higher cost ≠ higher performance

Martin,

I want to address your cost and import comments. My experience purchasing windows this year for a passive house retrofit has been very different from Mr. Normand's. Mostly because the project budget must be significantly smaller than his (Optiwin aluminum-clad wood windows might be the most expensive PHI-certified windows in the US), but partly because I wear multiple hats on this job and can do energy modeling on the fly during design and review.

I experienced no hurdles importing from Europe. The entire transaction was with an American sales representative and was very similar to other experiences that I have had specifying and reviewing windows. The lead time was longer by about 4 weeks, but I was aware of that up front, so it wasn't a surprise. As for delivery, the sales rep. is taking care of that too. My windows are due on site in about a week, so perhaps i should get back to you then about delivery.

Regarding window selection, there was a learning curve. Aesthetics, performance and cost vary considerably. The most important thing to take away is that higher cost ≠ higher performance.

I received quotes from several manufacturers, for at windows with different levels of performance (all would have worked for the project) and different materials (wood, insulated wood, aluminium clad wood, PVC, etc.). The difference between the high and low quotes was about 30k. Since the performance was comparable, I decided to go with the new Schüco ThermoPlus window for the project (my own house, actually). It's very solidly made, and my 12 year old nephew has been unable to break the corner sample yet, despite some serious effort. I loved the more expensive wood windows. but money is an issue. I chose to compromise on aesthetic rather than performance. That 30k can purchase enough PV to make the project net-zero, fyi.

On a side note, i never did get a quote for the Optiwin wood windows that Mr. Normand used. Beautiful to be sure, but the wide frames significantly reduced glazing area and therefore solar heat gain. This wouldn't be an issue in new construction, but it can be a problem when one is retrofitting using existing rough openings.

Reply to aj Builder

"Dewpoint vs humidity. Sort of misleading leaving out the temperature corollary.

Dewpoint and humidity are linked via what we all read on our tstats, temperature.

What ever became of the water filled solar gain windows? I have always intended to build a fish filled window just for the hell of it."

aj,

I left my comment on dew point open-ended in hopes of more questions/comments in follow up posts. You are absolutely right of course that temperature is what determines the relative humidity.

Dew point is defined as saturation vapor density or 100% relative humidity and relative humidity is simply the ratio of the level of moisture in the air versus the maximum possible level of moisture that can be in the air prior to evaporation. Dew point is the transition temperature between evaporation and condensation.

Per the water-filled IG's, I have heard of them, but no clue if anyone (outside of independent inventors) is actually taking the concept seriously.

reply to Doug McEvers

"I have found casement windows to be more prone to condensation than double hung of the same brand and specifications. Has anyone else had a similar finding in a cold climate?"

Doug,

I happen to agree with you and I chalk it up (my opinion) to the fact that casements as installed are outside of the exterior wall which results in colder glass/frame components.

In addition, because of how casements are installed there is less interior warm air movment over the glass, and the interior screen (if not removed) also contributes to blocking warm interior air from the window.

The advantage of casements, of course, is that they typically close much tighter than slider windows (vertical or horizontal) and they are less likely to be prone to cold air infiltration that can plague loose fitting sliders resulting in condensation as well.

I am not a big fan of casements, but that is just personal preference.

Log in or become a member to post a comment.

Sign up Log in