Image Credit: Image #1: Air Conditioning, Heating & Refrigeration News

UPDATED on April 15, 2016.

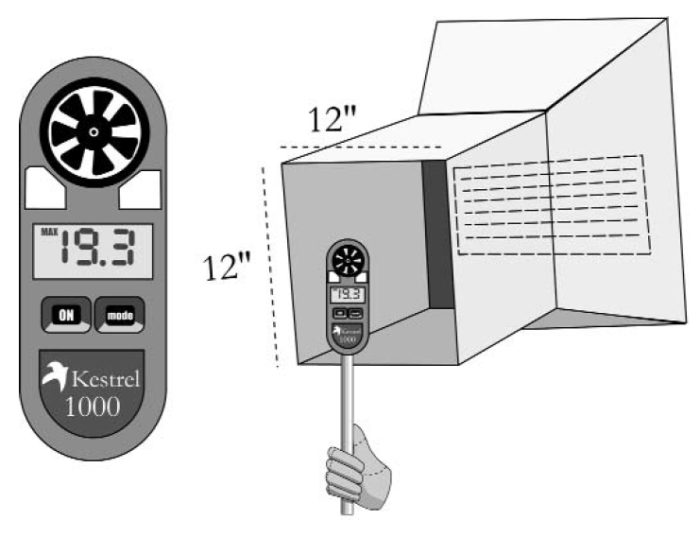

To commission a ventilation system or a forced-air heating system, or to troubleshoot problems with these systems, it’s essential to be able to measure the rate of air flow through registers and grilles. Most home performance contractors measure air flow with a flow hood. Flow hoods vary in accuracy, but they all share one attribute: they are expensive (generally $1,600 to $3,200).

If you want to measure air flow, but you can’t afford a flow hood, you may be interested in using one of the inexpensive approaches to air flow measurement described in this article.

Are flow hoods accurate?

Iain Walker, Craig Wray, and Max Sherman, three scientists at the Lawrence Berkeley National Laboratory (LBNL), examined the accuracy of commercially available flow hoods in a 2002 paper, “Accuracy of Flow Hoods in Residential Applications.” Although most of the flow hoods they looked at provided fairly accurate measurements in commercial buildings with large HVAC grilles, they were often inaccurate when used in homes. “Potential errors are about 20% to 30% of measured flow, due to poor calibrations, sensitivity to grille flow non-uniformities, and flow changes from added flow resistance,” the researchers wrote.

When it comes to measuring air flows, the researchers noted that the level of accuracy required to identify room-to-room residential pressure imbalances is +/-25%, and for ensuring room load and comfort requirements it is +/-20%. For such purposes, a flow hood with a potential error of 20% to 30% isn’t ideal.

Robert deKieffer, an energy consultant from Boulder, Colorado, has also looked into the problem of flow-hood accuracy. “The Shortridge flow hood I used wasn’t anywhere close to accurate,” deKieffer told me. “They charged $75 to calibrate it, and I still got a bad number after it came back. I thought, ‘Wow — I spent a couple thousand bucks for…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

15 Comments

How about ductless heads?

Is there good and accurate way measure air flow through a ductless head, for the purpose of diagnostics (say, to compute the heat output)? The ACEEE Pacific Northwest study used a small vane anemometer in some fashion, but no mention of an apparatus to constrain geometry to a known quantity (like the cross-sectional area of a flow hood), and I could not find any specific comments on the accuracy or %error of their measurements. The geometry of ductless heads (with long, narrow "supplies" and "returns" spaced relatively closely together) would seem to constrain the kinds of techniques one could use.

Response to Aaron Birkland

Aaron,

I don't know of any techniques for measuring air flow through a ductless minsiplit head, although I can imagine ways to make a custom tube or chute out of cardboard, plywood, or sheet metal (with appropriate gaskets) to funnel air flow to a measuring device.

There aren't many reasons for performing this type of measurement -- other than the one you mention, computing heat output, which is chiefly of interest to researchers -- since there is no need to balance the air flow through a ductless minisplit with airflow through any other appliances in a house.

kiss...

I tried building a flow hood; it was pretty much a lose because of

the turbulence/nonlinearities still present at the exit end. I got

better results by doing an even scan of a whole register opening

with the anemometer in averaging mode, and measuring the opening.

MPH times 88 gives FPM, over the aperture sqf gives CFM. While a

moving scan might not have given the precise *average* airflow, it

got plenty close enough for the redneck math I was doing.

_H*

Testing and tuning ductwork

Terrific topic, one I've struggled with. Here are a few comments;

First, Retrotec is selling the European Flow Finder MK2, not manufacturing it.

Secondly, Corbett Lunsford has a terrific video demonstrating 8 different testing devices: http://homeenergypros.lbl.gov/video/airflow-diagnostics-8-ways-to-test-airflow-with-corbett-lunsford

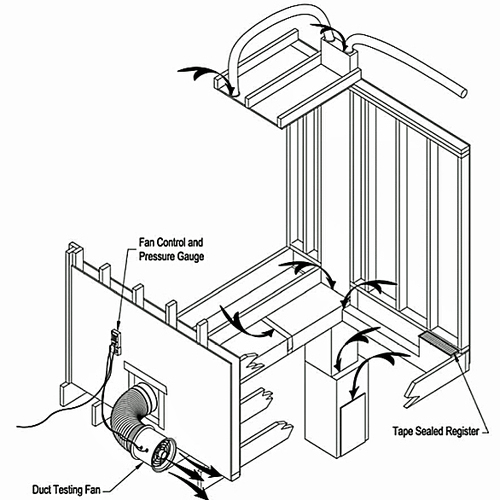

Finally, just getting pressure readings of ductwork with a good manometer is very useful; static pressure, house pressure changes when the furnace turns on, pressure differences across bedroom doors, etc.

Response to Jim Baerg

Jim,

I have corrected the reference to the Flow Finder MK2 that is available from Retrotec; thanks for informing me of my error.

Thanks also for the link to the great video from Corbett Lunsford. It was interesting to see that the result of his garbage-bag test was fairly consistent with his other test methods -- a good indication that the garbage-bag method is accurate enough for many uses.

Measuring Mini Split Airflow (Response to Aaron Birkland)

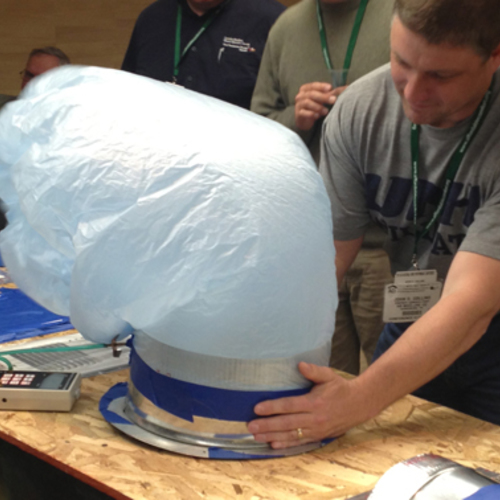

Aaron and Martin--the usual methods I have seen other do on measuring mini split airflow is some type of a capture bag or chute on the return side--NREL (who runs Building America) published a monitoring protocol for this work:

http://www.nrel.gov/docs/fy11osti/49881.pdf

I believe that some of my colleagues at Steven Winter also did some work along these lines, but I'm drawing a blank on any written documentation--it might have come up over beers at a conference.

Hobbit_

Fascinating. Did you observe a significant difference between sampling the velocity at a single arbitrary point, vs sweeping the anemometer along the entire length of the outlet whilst in averaging mode?

With regard to a flow hood, I would also worry about any static pressure it introduces influencing the result, as they are designed to operate in free space, without any significant static pressure at all.

Response to Kohta Ueno

Kohta,

Thanks for the link. When faced with the daunting task of developing a new testing protocol, I'm glad to see that the researchers used the usual materials -- garbage bags and duct tape.

.

NREL Protocol

Kohata,

That was quite informative, especially the sections that describe the apparatus used to measure flow during initial calibration. It would seem that the NREL method is sensitive to anything that would change the relationship between fan RPM and airflow (such as a dirty filter), but the protocol addresses that.

The method that Hobbit_ ended up with seems much easier for ad-hoc measurements by homeowners, but it's nice to know that there's an accepted protocol for long-term monitoring.

to Aaron ..

At any given supply register, for example, I'd find significant

variance as the duct boot behind it certainly wasn't delivering

laminar flow. Thus an average over the whole thing.

There's the issue of the grille, of course, but for narrow slats

I ignored it and didn't have opportunity to think about compensating

for wide ones like in the GreenDream bathroom-fan video. I figure

if the anemometer *spans* a couple of runs of grille it'll get

part higher airflow and part far less, probably averaging to about

the same as if the grille wasn't there. Holding a little farther

away might let the streams re-combine, too. One could always remove

the grille to be sure. There's also the question of just how far

off the edge to scan -- the anemometer doesn't have a zero radius,

so I can't stop at an exact place. Hanging maybe a third of its

radius off the edge and then going back seemed to suffice. Again,

just a hack for ballpark figures, not hard science...

_H*

Great Article

Great article Martin you seem to have read my mind as I have been trying to conceive of a homemade contraption to balance mechanical/ERV's.

I have been using Hobbit's approach with an anemometer but I have been thinking about cutting a plastic 1 gallon milk jug in half and then slitting some rubber tubbing to create a gasket to make a small homemade flow hood.

I am not familiar with air disturbance but I figured for the 4, 5, or 6" round ducts I use I should be able to get a fairly accurate measurement.

This article brings out the inner MacGuyver in all of us.

I'm quite pleased with our Alnor 6200

We do quite a lot of airflow testing in connection with residential duct systems. Nearly all registers we encounter and specify are designed to flow 10 - 200 CFM especially with new construction homes coming in at 1500 - 2000 SF per ton. Those flows are too little for the big commercial flow hoods intended for 2x2 commercial diffusers flowing up to 2000 CFM (That and the $3k price for one of the big boys is a major deterrent)

Before investing $1400 I diddled around with cardboard and anemometers along the lines suggested in this blog, but they are slow, unsatisfactory, and, quite frankly, too amateurish for professional / production use.

While I support the innovations described here for DIYers it's hard to imagine a pro willing to spend kilobucks on blower door rigs, duct blasters, and IR cameras piddling around with propellers and pizza boxes...just sayin'.

Response to Curt Kinder

Curt,

You wrote, "It's hard to imagine a pro willing to spend kilobucks on blower door rigs, Duct Blasters, and IR cameras piddling around with propellers and pizza boxes."

True enough. But the equipment you list would cost about $9,000 or $10,000 to purchase -- possibly more. That type of equipment is certainly required if you are a home performance contractor.

But not everyone who reads GBA is a home performance contractor. Some of us are owner/builders without much money in the bank -- but with a burning interest in building science and diagnostics.

Evaporative cooling indirect/direct

I have a climate cooling problem I need to cool about 50000 BTU/hr peak with an IDEC such as an Ultracool/Mastercool II 7112 with IM-70 precooler in conditions of 0.4% occurrance of 112F DB and 70F WB. I think the current ducting 18" diameter and up duct venting (4 units) is undersized. How can these be used to determine the needed fixes?

Response to James Rikevich

James,

I think that you have posted your question on the wrong page. Your question belongs on GBA's question and answer page. Here is the link:

http://www.greenbuildingadvisor.com/qa

If any GBA readers want to tackle James's question, we'll need some decoding first.

DB= dry bulb temperature

WB = wet bulb temperature

IDEC is a stumper, but probably means "indirect/direct evaporative cooler."

Log in or become a member to post a comment.

Sign up Log in