-

Removing Scale From a Tankless Water Heater

How to flush out the crud that builds up inside your gas-powered instantaneous water heater

-

A New Book for Cob Builders

This new book assembles a huge amount of valuable technical information on cob walls

-

Residential Energy Efficiency: A Look Back on the Last 25 Years

Bit by bit, some mechanical equipment and systems have improved

-

Choosing Window Glazing

How to specify the right U-factor and SHGC for your climate zone

-

Equipment Sheds as Solar Mounts

During a recent visit to France, I discovered “hangars photovoltaïques”

-

Low-Slope Roof Assembly Failures

A consultant for Structural Research Incorporated reports that dozens of new buildings have rotting roof sheathing

-

High Indoor Humidity in New Buildings

Kohta Ueno investigates summertime high humidity problems in new multifamily buildings

-

A Community Responds to the Housing Crisis

A non-profit group in Utah is teaching natural building skills to future homeowners

-

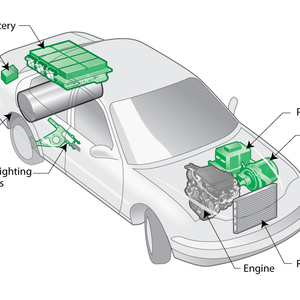

What’s Better: An EV or a Plug-In Hybrid?

Policy wonks warn us, once again, not to let the perfect become the enemy of the good

-

A Few Ways to Lower Your Energy Bills

Revisiting old advice and some new tips for bringing down energy use and costs