Image Credit: Green Building Advisor

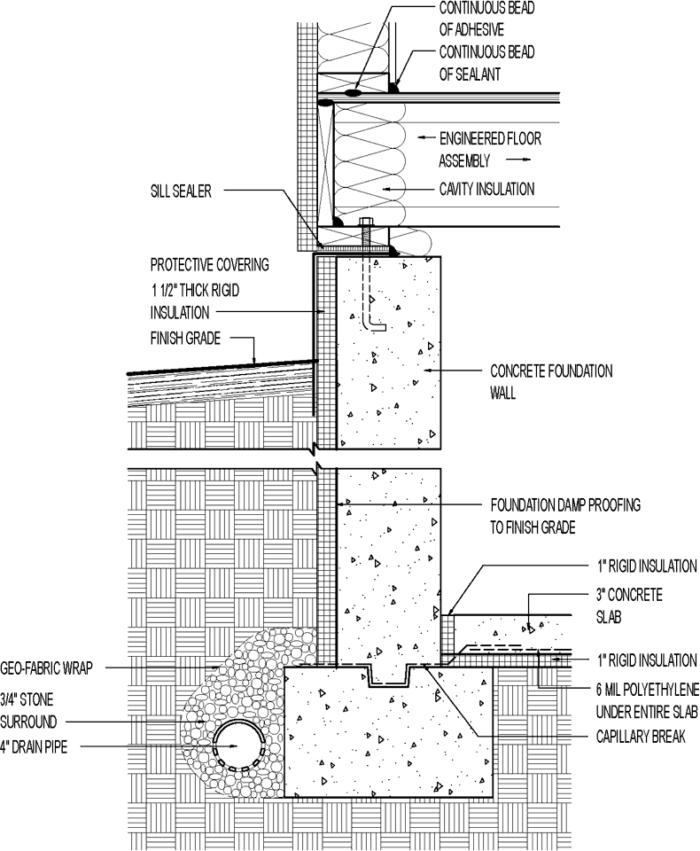

Energy gurus and building codes routinely recommend these days that foundation walls be insulated. One way of accomplishing that is by adding a layer of rigid foam insulation on the outside of the foundation.

And that’s exactly what William Poole is planning to do.

Most of the rigid foam insulation will be underground and out of sight. But what do you do with that stretch of exposed insulation above grade?

“I just can’t get excited about options for covering the insulation in the space between the top of grade and the bottom of the siding,” Poole writes in a Q&A post. “Has anybody completed a project with this detail and come up with a material that is both practical and, for lack of a better term, ‘good looking’?”

Here’s a list of options

GBA senior editor Martin Holladay is first out of the gate with a list of not just a few but 10 potential solutions.

He lists four possible generic products: pressure-treated plywood, fiber-cement panel siding, stucco, and surface-bonding cement. There also are a number of proprietary products worth looking at, Holladay says, including Insul-Guard 2 fiberglass from Diversified Composites, Ground Breaker fiberglass covering from Nudo Products, FP Ultra Lite Panels from Styro Industires , and Protecto Bond membrane, a peel-and-stick product from Protecto Wrap.

Robert Riversong has used surface-bonding cement with “excellent success.” He adds extra acrylic mortar modifier to the mix to improve plasticity, adhesion and water resistance. And for a “belt-and-suspenders” approach, he runs 1/2-in. hardware cloth from the sill to a few inches below grade before troweling on the cement.

“It leaves a highly water-resistant and very tough ‘stucco’ coating that looks great and has excellent tensile strength and crack-resistance because of the fibers,” Riversong writes.

The coating should be vapor permeable even…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

53 Comments

Energy Edge

Here is an awesome product for your foundation: http://www.energyedgeform.com. They are from Wichita, KS, but its my understanding they are in the process to have their product distributed by a national chain. You can contact Tom Campton there and he'll work with you. I highly recommend it.

Response to Armando

Armando,

The product you link to appears to be intended for new-construction slabs -- not for basement foundations or retrofit insulation.

Metal?

What about metal cladding? I've seen a home in N MN use a metal cap (not sure if aluminum or stainless) on the top of the insulation with the sheeting held on with metal straps and then another sheet of metal slid up under the cap the continues below grade by a bit. It is in a sand/gravel soil situation.

Energy Edge for retrofits

Martin, They do have a retrofit and top of basement walls products as well. They have a pretty extensive list of drawings on their wesite, but let me contact them and ask them to post some drawings or pics or if you have anything more specific.

Fastening PT plywood

Martin, (if you're reading) how would you fasten PT plywood to a concrete wall through 4-6 inches of EPS or possibly rock-wool?

Lucas

The best way that I

Lucas

The best way that I know off is to include the PT plywood and the insulation as part of the outside forms for your concrete pour. Simply run some long screws or nails right through the assembly and into the space where the concrete will be. Obviously, this would not work as a retrofit.

Hmm

Thanks Garth. That definately sounds like the easiest way. The PT plywood would only extend say, 24" below grade (while the insulation continues to the footing). Could the formwork be jigged to accomodate an extra 1/2" of plywood at the top?

Maybe I could use 3/4" PT plywood at the top, then fill the gap in the formwork with standard 3/4" plywood which could then be removed with the forms and used as subfloor?

Have you had a good look at

Have you had a good look at the thermomass system? They will sell their proprietary spacers to DIY'ers...

Metal for retrofit

Jeff,

I would be more than a little surprised if it was stainless.

I have used 20 ga. aluminum and it has done well for 2 years so far. The house started out with 6-12 in. band of foundation above grade, aluminum siding over 1 in. foam over studs with steel let-in bracing. Sheet metal shop bent 10-ft. long Z sections. One-inch vertical leg gets nailed to the bottom 2-by plate, through the 1 in. foam. Middle, "horizontal" leg that is not horizontal covers the thickness of foundation foam, and the last leg extends well into the ground. Just needed hand brake and shears to work the corners in the field. The painted aluminum is complimentary to the siding and is holding up very well against the weed eater. Automatic termite shield is built in. More, added layers of exterior wall foam with furring strips extend down to the top of the foundation cladding. Screened venting between furring strips is hopefully using the chimney effect to draw off some summer heat from the claddilng. Disadvantages are minor to me: Relatively small thermal bridge, the aluminum will dent easily. If I had it to do over again, I might choose a lighter color for the foundation cladding---I have wondered, even with the venting, if my xps under the cladding is getting a little hot on the south side.

Response to Lucas Durand

Lucas,

Although I have interviewed builders who have protected rigid foam with PT plywood, I have never done it myself, so I'm not sure which type of fasteners are best. In addition to a few fasteners, it's always possible to use an adhesive.

If I had to do it, I would call up some manufacturers who specialize in masonry and concrete fasteners and ask for the best fasteners for this application.

Insulation

I imagine that the purpose of the insulation is to help keep the home warm?

With this in mind and as heat always moves to cold.

Surely the logic is to have the insulation as close to the comfort zone as possible?

Therefore, the insulation needs to be tight under the floor.

What point is there, in letting your heat escape into the crawl space, where much diluted it is very slightly slowed on its journey to the sky?

Response to Perry 525

Perry525,

There are several reasons why it might be desirable to insulate a crawl space wall or a basement wall instead of the floor above:

1. If it is a basement, it might be desirable to heat the space, since many homeowners use basements for living space.

2. If it is a crawlspace, insulating the walls prevents the pipes from freezing.

3. Most crawl spaces include heating ducts. Insulating the crawl space walls brings the heating ducts inside the conditioned space of the home, saving energy.

4. When crawl space walls are uninsulated, the crawl space is often moldy.

EnergyEdge Insulates, Protects & Finishes Concrete Edges

EnergyEdge is a product that has specifically been designed to address this exact problem. The transition from below grade to above grade insulation systems has traditionally left a gap in the buildings thermal envelope. We have photos and details of installations, both for new construction and retro-fit applications, for slab-on-grade and basement construction. For slab edges, our product actually functions as the form, insulation, protection & finishing system, saving time & wood resources while reducing construction waste.

We are not a new company but are new in the CertainTeed distribution network. We will be on exhibition with them at the USGBC Green Build Show in Chicago beginning tomorrow. Please visit either of our web pages, http://www.EnergyEdgeForm.com or http://www.CertainTeed.com/products/foundations , for information. You can also contact your local CertainTeed sales rep. If you would like for us to send you specific information on your application, please contact Casey Barbour at [email protected] .

Terne-Coated Stainless

TCS might be a better metal for these types of details, compared to aluminum.

In addition to being much stronger, therefore more likely to look decent after a few decades of bumps and weedwacking, it also has a lot lower thermal conductivity.

Further it's much more resistant to corrosion from alkaline masonry products.

I still find this part of a house to be a real head-scratcher. Well over half the houses I've renovated have termite damage, and covering the foundation up to the framing seems like an open invitation. But, running something termite-resistant and durable through the insulation creates such a thermal bridge that it seems questionable also.

Anyone tried vinyl trim coil? (I know, I know...but if durable, thermally low-conductive, and prevents future use of termiticides might be a net benefit.)

TCS more

Forgot to mention that in our area, better roofing companies often have a leftover coil of TCS sitting in their shop. It's used as a high-end roofing. Two years ago when copper pricing went nuts, it became less expensive than copper and is probably more durable.

It's only a little bit harder to work compared to copper, a bit harder to bend and a bit harder to cut.

We get essentially comparable pricing to copper, so we have been using it for flashings quite a bit, anywhere that copper's color or eventual verdigris dripping would be less preferred to the soft gray color of TCS.

Response to Doug

Doug,

One of the products I suggested, Insul-Cap, is a vinyl product made to protect foam insulation. It is manufactured by the Wisconsin Poured Wall Contractors Supply, a company that does not maintain a Web site.

Here is a Web page that provides contact information for the company:

http://www.akama.com/company/Wisconsin_Poured_Wall_Contractors_Supply_af9f31469753.html

Galvanized roofing

I have recently used standing seam coil stock provided by a local roofer. It comes in multiple colors, and can be bent to tuck under the siding with a break. I also hemmed the overlaps or where butting up to items like an exterior chimney. This reduces the 'oil canning' that can occur. To secure, used PL 200 construction adhesive. It fast to install and looks great!!

How to Finish Exterior Foundation Insulation

We just finished a job. The foundation is block on an addition we are just finishing. It was covered with an inch and a half of Foamular foam by the foundation contractor as per the drawing specs. We used the acrylic modified base coat used with Dryvit with a fiberglass mesh emebedded in it. Then top coated with Dryvit. Our local Dryvit dealer OK'd the installation.

We use rigid insulation outside of the foundation and outside of the sheathing to prevent thermal bridging. One of my workers calls it outsulation instead of insulation. I have had good success with this and my clients like the added comfort with no air leaks. All the seams get taped and the window flanges get taped to the foam. I use cellulose insulation in the walls and roof.

Termites in Heaven

Guys, the solutions I've read here, and the detail sketched in the article all share one serious drawback, I'm all with you about insulation, but I'd be scared to death to not have some way to keep an eye out for termites coming up into the house from the crack between the foundation wall and the foam board. The termites will be thanking you till hell freezes over for giving 'em the 'cover of darkness'. Believe me, I want to be wrong because I'm a tree hugging environmental carpenter and builder and that goes hand in hand with going all out on insulation, but.........

Foundation cover

Here is a vote for galvanized wire lath nailed with large washers through the foam into the CMU, and then parged over with mortar. A strip of aluminum coil stock under the PT sill plate and extending out over the foam has (as far as I can tell) prevented termite attack (in our house here in Connecticut) for the last 30 years. There are a few hairline cracks in the parget because this was done prior to the availability of acrylic latex additive which I would add to the stucco/mortar mix if I were doing it today.

Continous Insulation Solution

We suggest using ProGuard Cement Faced Insulated Sheathing. This material is rigid insulation with a cement board facing. The advantages include: continuous insulation, durable substrate, simple installation (Fomo adhesive and screws), waterproofing membrane over all attachments, perfect substrate for thin brick, thin stone and stucco, 15 year system warranty and is manufactured in USA Midwestern states (as opposed to overseas for some of the products mentioned herein). You can find more information at http://www.centerlinematerials.com

Styro Industries

We've just started using Stryro Industries Tuff II trowel on coating which was recommended by Dow. It's very durable and fairly easy to apply.

Insulation for pier built home

I recently bought a log cabin built on cement piers in N. H. There is an opening of about 18 inches between the ground and the bottom log. I had new unfaced insulation put in between the floor joists and plywood put under that. I would like to put a skirt around the house from the ground to the bottom log (should I go below ground level). Should I use plywood with a blue board backer? Obviously, I know very little about this and I am getting different suggestions from each person I talk to.

Response to Barry

Barry,

A durable skirt can be built using pressure-treated 2x4s and pressure-treated plywood. Just build a mini-wall. If you want to keep the crawl space warm, sandwich some rigid foam between the stud wall and the PT plywood.

Exterior insulation benefit vs cost

While exterior rigid foam insulation has its benefits, it's really expensive to protect, regardless of how you do it. EIFS, with the fiberglass mesh is expensive and not that durable. T-Mass is about 1.5 times as much as spraying closed-cell urethane foam on walls furred and insulated inside. (Joe L's objections notwithstanding.) I agree that stone or masonry is esthetically pleasing, and it's wonderful if the owners want to afford it, but is still one of the most costly. I have a hard time justifying the benefit of exterior foam when what we're after is saving energy and providing comfort. While I hold my nose in recommending interior framed walls for insulation, in my eastern Iowa location it's the best value to the client.

Basement Insulation

I have an insulation company in N.H. and when I go over options for my customers we usually opt for spray foam insulation on the interior of the foundation.

Here are my reasonings

1. We can do a thermal barrier that is maintenance free inside the home and dont have to worry about someone backfilling against our insulation and damaging it.

2. As one other poster stated if there is no break of the rigid insulation you are inviting a problem with termites or ants or whatever. There is no food value to the foam but it is a very good home for insects.

3. As a minimum value is the fact that the rigid hast to go on as soon as possible with spf it can be applied later and if any cracks in basment wall happens we can spray and them while not a garunteed water stopper it is pretty good.

4. last one that comes to mind is the spf is done after everyone else mechanical or plumber or whoever and we can make sure the penetrations through the envelope are sealed properly.

Generaly speaking it seems like most people want to do it yourself which is great but a general contractor is under the gun to meet budget and time and the exterior insulation is good but it seems to me alot of maintenance down the road and potential for problems.

That what i think lol Doug

In 1982 I built my 2 story

In 1982 I built my 2 story house with outside insulation from the foundation to the roof line. The 1 inch insulation at the outside of the block wall is covered with embossed aluminum sheets. After 28 years it still looks great. The upper walls have vertical 1x4 T&G western cedar siding over the outside insulation. I am very pleased with this design.

Question and comments

I have a question about the detail drawing in the article. A line, which represents some kind of material is shown covering the insulation and extends from below the sill plate to below grade. Everything else in the wall structure is called out except that item. I am assuming that it represents the hardware cloth discussed in the article. Am I right?

I also noticed that flashing is not shown over the top of the insulation in about the same location as the item that is not called out. I am thinking that flashing would be needed to prevent water penetration between the insulation and concrete. Such flashing could also act as a termite shield listed as a concern in the messages.

After reading all of the discussions, I see no easy answer to this issue and this article and comments pushed that boat farther from the shore. In our area, I would say our three main concerns are freeze/thaw, weed-whackers and moisture. I can see using metal panels over the insulation as long as it goes below frost grade. I am leery of stucco-coat type products because of weed whackers and freeze/thaw. PT plywood is a no-no because, over time, the treatment leaches out of the wood and exposes the wood to decay and insects. Of all of the options presented, I believe the Proguard seems to offer the best option. Its product information says it can be used below grade, although I would prefer to see more assurance than a line or two in the product literature. If this product could be used as the exterior insulation, that would be ideal.

Still, in our area, insulation is not installed often on the exterior foundation other than concrete insulated forms. Basement foundations are usually insulated from the grade line up to the sill plate on the inside rather than outside. Relatively rarely do I find insulated crawlspace foundations. So, we are pretty much left with the CIFs for now, and I am not really crazy about the stucco finish usually used on them; but time will tell about the durability.

Repsonse to Matthew Klein

Matthew Klein,

I agree with you -- it is best to include metal flashing that extends from the gap between the mudsill and foundation, out over the protective covering installed over the foam. The flashing should have a 45-degree lip (drip edge) to kick out any moisture away from the house.

I have used copper sheet for

I have used copper sheet for this detail.It ages to a nice patina that seems to blend in between ground and wall finish and it will probably outlast any surface-applied cement finish.A bit pricey for a detail people tend to ignore.but it is worth it to me to avoid call-backs.

ICF manufacturers appear to recommend parging cement

According to at least a few manufacturers that I looked at before using ARXX ICF blocks for my house, a favoured solution is parging cement to 6" below grade. I haven't got to the stage of needing to apply it yet and given the sudden appearance of snow I might not get there 'til next spring!

Need steps laid out on how to insulate exterior foundation

Guys I could see the solution for my application from your notes, some partial, some not. Here is the problem, I understand there is great benefit to insulating the exterior foundation that is above grade.

1. it is a 100+ yo two story wood framed on a rubble foundation. We are in northern VT (so cold climate)

2. vinyl siding comes down to about 8-12” from the top of finished grade.

3. the sill looks to be in decent shape but it not airtight on the foundation.

4. the exterior foundation face is a mix of rubble stone, faced with some stucco. Lots of stucco has broken and crumbling, as is some of the rubble.

5. I like the suggestion of facing it with cultured stone – but how? How I can reasonably secure lath to the loose crumbled areas of the wall, strapping? In this application would you remove the old loose masonry, repair it, cover it with blue board insulation, cover the insulation with lath, fasten the lath through the blueloard and deep into the masonry ? if so, using what fasteners? And would this require Z flashing from behind the siding over the top of the stone?

6. How about blueboard with PT sheets and lath and parge right to that?

Response to Steve

Steve,

For a rubble foundation, I think your only choice is closed-cell spray polyurethane foam, followed by stucco. It would also be possible, but more expensive, to prepare the cured foam for adhered manufactured stone veneer.

Response to Martin

Martin, thanks. In that solution, stucco directly to the foam (no board, no lath, etc)? Any Silpro products come to mind to address this?

Second response to Steve

Steve,

The synthetic stucco used for EIFS is applied directly to EPS foam, but most EIFS systems require fiberglass netting as well. Traditional stucco requires wire lath, which would need to be mechanically fastened somehow.

Your best bet would be to consult with a stucco contractor or an EIFS contractor.

Skirting

I've done this several times and just used aluminum off a gutter machine roll. You have chouce of colours and can just nail it to the cantalivered framing. It is still working on a passive solar house I built in 1981

stucco

I think SBC would probably work better, but it is harder to come by (and probably more expensive).

I've done a parge coat with type N cement and soft sand, and I've also tried a mix with straight portland. The type N gives a lighter-colored finish, and doesn't seem to get shrinkage hairline cracks as much as the portland. It's not as strong as the portland mix though, so it needs to be thicker to avoid cracking it if you bump it with a lawnmower.

The foam needs to be clean, or the stucco will eventually flake off; when exposed for a couple months the surface of the polystyrene degrades to a yellowish powder, which leads to poor adhesion of the stucco and flaking off.

A local EPS manufacturer also sells a product specifically for parging over foam.

http://www.truefoam.com/en/home/insulationproducts/forfoundations/pargeplus.aspx

Protecting exposed rigid foam with parging

20 years ago, I had my exterior rigid foam insulation parged. The parging went over stucco wire. It is still hanging on. This is in Edmonton, Alberta.

agree with Tom Southern

Don't know if that's your real name, Tom, but, yes, here in the south we do have a termite problem. Ants, too. They don't eat the foam but they sure like living in it. I've done a number of foundation (not lately) where we parged the foam down to the footer with a finish coat above grade. We've done it with and without reinforcing mesh. The latex modified stucco sticks pretty good to a roughed up surface.

It's a lot of work but seeing what I have, I don't feel good about leaving any foam unprotected below grade. The foam glass is nice, but pretty darned expensive.

On my own house, I initially protected the slab edge foam with aluminum flashing. It rotted away after 10 years or so - acidic soil, I think. I replaced some of the deteriorated foam with slabs of AAC block. Not as insulating (it does some) but seems like a long lasting product. I used thinset to stick it to my slab, then stuccoed it.

Seal with a peel and stick membrane and cover with colored metal

Greetings. I realize this is an old thread, but was just trying to see if there were coals to stir.

I was proposing to lap a peel and stick membrane up from my monolithic slab stem foundation foam (incl. vertical to horizontal foam transition) onto my wall foam. Then cover the foam with a colored metal or Galvalume type metal. I would then tape (SIGA type) metal flashing to vertical foam at the base of the flashing where it terminates below grade.

What kind of compatibility issues will I have with using an asphalt based peel and stick membrane on EPS or XPS foams, or should I look for another product??

Is there any value in using a 15mil vapor barier (Stego Wrap type) below the sub slab foam? Seems like the right product as it might be great for termite and radon protection if detailed properly.

Thanks for any ideas.

Jim

Response to Jim Boyd

Jim,

To determine the compatibility of any peel-and-stick product with a particular substrate, you should contact the manufacturer of the peel-and-stick product. As far as I know, rubberized asphalt products are compatible with XPS foam.

Here is an example of a manufacturer's compatibility statement -- one from Protecto Wrap: "Protecto Wrap self-adhered products are often applied directly to and are compatible with exterior sheathing such as plywood, fire-treated plywood, oriented strand board (OSB), exterior gypsum board, glass mat surfaced gypsum board, concrete, and extruded polystyrene."

It's always important to install a vapor barrier under a slab. In my experience, 6 mil polyethylene is adequate for this layer, but you can use Stego Wrap if you want. For more information, see Polyethylene Under Concrete Slabs.

Exterior Rigid Board Insulation Aesthetic Finishing

Hi all,

I'm working on a new construction that's completely grade: first floor garage, second floor, third floor, attic.

We added underslab insulation and plan to insulate the garage to keep everything inside the thermal envelope.

We also added rigid board insulation to the exterior of the foundation. But now we have the problem of how to properly finish this area.

Stucco and metal cladding seem to be the most straight-forward options. Stone veneer is extremely attractive, but seems to be much more risky and complicated.

Mainly trawling for ideas or opinions. Will appreciate either, or both.

Thanks.

Response to Alexander K.

Alexander,

In the article on this page, I list 10 options. The options are also discussed in this article: How to Insulate a Basement Wall. (Scroll down to the paragraph with the heading that reads "If I insulate on the outside, how should I protect the above-grade foam?")

I honestly think these are fairly complete lists of your options. It's up to you to select one.

Termites and Mineral Wool

Would using something like Roxul help alleviate the termite concerns, and if so by how much? The Roxul would reportedly not provide a home for the bugs, and perhaps it would leave less of a crack between the insulation and wall due to its inherent sponginess. But it would still provide cover for anything that found or made a path through it.

Vertical Edge of Exterior Foundation Insulation

Above grade, how would you treat the vertical termination of the insulation where an attached garage starts? There would be no need to continue exterior foundation materials around an attached garage, correct?

Response to BryanW511

Brian,

If you terminate the insulation, you would install trim at the vertical line where the insulation ends. You would need to choose a durable trim that won't rot when in contact with the ground -- probably solid PVC trim, stiff metal flashing, or something similar.

Boral TruExterior

An option not listed is the Boral TruExterior product line - it's a polyash composite that is rated for ground contact, is highly termite resistant, and has a much lower coefficient of expansion than PVC, fiber cement, and other composites. They have a wide selection of trim and siding profiles.

Response to Nathan Bean

Nathan,

Thanks for your comment. Indeed, the manufacturer of Boral TruExterior siding and trim products states that these materials are rated for ground contact.

I dont like any of the suggestions found here, except maybe cultured stone, on a brick ledge though?.. I dont have a answer, but I'll say the public knows what a poured foundation looks like, and anything short of exposed concrete might make your high performance home look like a pole barn or mobile home.

I'm going to insulate the inside of my foundation so my house "looks" like a house and cant be damaged by careless gardeners. But I'm unclear how to tie exterior wall insulation, to the interior foundation insulation. The sill plate would be sitting on a unconditioned concrete stem wall, so how could we break the thermal conductivity between these two?

Hmm, you never see "concrete foundation" on high end homes.

I've seen $20,000,000 new homes with exposed concrete foundations. How much higher-end do you have to go for people to not want to see concrete?

Very "high-end" houses often have concrete walls above grade and in their interiors too.

I am considering Corten steel for this application, does anyone see any issues with that? Thank you in advance for your time and consideration.

Log in or become a member to post a comment.

Sign up Log in