Insulation on the Outside

Creating an air barrier at the sheathing level and insulating on the exterior with rigid foam insulation is key to the PERSIST and REMOTE building strategies as well as Andrew Homoly's "perfect" building envelope.Is there such a thing as a perfect building envelope? One that could be mass-produced from readily available materials, and be appropriate for 90% of all new homes?

Andrew Homoly thinks he’s found one, as he explains in this Q&A post at GreenBuildingAdvisor.

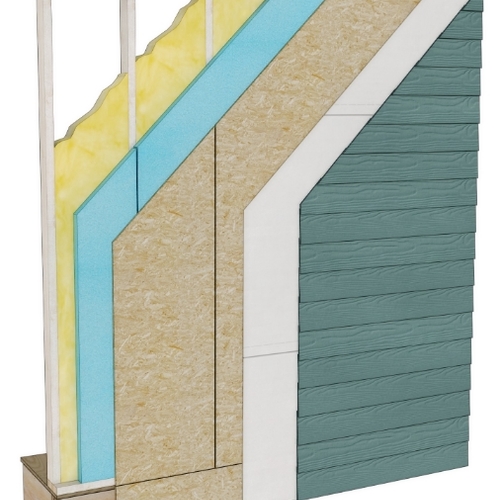

Here are the basic elements:

- A conventional foundation insulated with 2 in. of rigid foam on the outside.

- 2×6 walls sheathed with Zip System OSB with 2 in. of rigid foam on the outside and open-cell spray polyurethane foam in the stud bays.

- A roof sheathed with OSB, insulated on the exterior with 2 in. of rigid foam capped with another later of OSB sheathing over furring strips.

- Soffit and fascia made from OSB sheathing, insulated on the exterior with 2 in. of rigid foam, and topped with furring strips and finish material.

It is this last detail, the insulated and vented soffit and fascia, that has Homoly thinking he’s nailed it. He calls his approach the Homoly-Pedley Perfect Envelope, sharing the credit with his framer, Mike Pedley, who came up with the soffit/fascia detail.

“Note the ‘gap’ goes all the way up the wall, around the soffit, around the facia, and up the roof to the ridge vent,” Homoly writes. “Periodic vent strips could also be added in the soffit if desired. The entire home from foundation to wall to soffit to facia to roof is wrapped in an uninterrupted thermal envelope.

“I believe this system accomplishes multiple goals … and could easily be mass-produced since it utilizes all common building techniques and materials.

“What do you think?”

Sorry, but it’s not especially new

Homoly’s plan hinges on establishing an air barrier at the sheathing level. But as GBA senior editor Martin Holladay points out, that’s…

Weekly Newsletter

Get building science and energy efficiency advice, plus special offers, in your inbox.

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in

19 Comments

These summation blogs are

These summation blogs are great and some like this one are fantastically full of useful information.

Keep up the great work.

Aj

Building Design

A lot of building efficiency can be gained by good building design. Concentrate on low surface to volume ratios and minimize corners, both inside and out. A basic design that would be inherently efficient would be a walkout rambler dug into a hillside with the walkout and the majority of the glazing facing south.

To say you need a bunch of foam or SIPs to make a house efficient is just not true, I would only use foam where no other material will suffice, under the slab and the exterior of the foundation wall.

Context

Some of my comments here (eating bears, driving in circles) may seem nuts when taken out of the complete context. Confused readers should note that my post was riffing on AJ's much nuttier post just before it. This sort of dialogue is difficult to summarize or paraphrase.

LOL, tj..... Too late my

LOL, tj..... Too late my man.... My bear posts (besides yours!) were a bit tongue in cheek too don't yaa think!!? Lol...

Now I have to finish off my bear steak with it's beechnut demiglaise....

Not-So-Foamy

I agree with Doug, Albert and Brett Moyer(NOT Boyer)

I think it is possible to build High Performance with Less Foam

two central european

two central european variations on the 'perfect wall' that use no foam:

solid timber (brettstapel, cross laminated timber)

TJIs or wood truss fixed to solid timber element, filled w/ cellulose

fiberboard sheathing

rainscreen

or

solid timber (brettstapel, cross laminated timber)

mineral wool fixed to timber element

rainscreen

Europeans

Mike,

thanks for bringing up the Euros.... they have a good track record of building High Performance Structures ... with AND without OUTSIDE insulation... correct me if I am wrong ...but I believe the trend in Europe is to AVOID Foam

Response to Mike Eliason

Mike,

Similar walls are built in North America, but (usually) without the cross-laminated timber. It's more common here to use stick framing.

So, the comparable North American walls would be:

Wall #1:

Plywood-sheathed stick-framed wall

Larsen trusses filled with cellulose

Fiberboard sheathing or diagonal board sheathing

Rainscreen (vertical furring strips)

Wall #2:

Plywood-sheathed stick-framed wall

Mineral wool panels attached to the plywood

Rainscreen (vertical furring strips)

Another Not-So-Foamy Example

Thorsten Chlupp calls it "Out-Insulation"

this a darn good thread started by Lucas Durand

https://www.greenbuildingadvisor.com/community/forum/general-questions/19942/sunrise-home?cm_BOlgD%24B7W8pUB8d6p3DiDDMa_B7W8pUw2h-0=1318465631

Lucas is working on his own Not-So-Foamy House right now

He has developed his own system which I hope he will publish soon

sort of a hybrid between Chlupp and Riversong

I think Lucas can visualize a good Air Barrier .... much like Thorsten Chlupp and Robert Riversong and Marc Rosenbaum

John,

Yes and no. For the

John,

Yes and no. For the most part when I worked there, the tendency was to avoid it - but some structures are easier or cheaper to wrap in foam - like existing masonry/concrete retrofits. There is also a much better track record w/ EIFS-like systems (or as the Germans call is Waermedaemmverbundsystem or WDVS).

Usage of mineal wool or foamglas in lieu of petroleum-based foams is pretty common.

Martin,

Yes, those are similar. In the EU systems - the massivholz is shear/air barrier/structure and can be routed out to be MEP chase as well. Or alternatively, add a service wall to the interior. And Thorsten's system is very similar to wall systems I've seen in Europe (including the cellulose-based 'outsulation').

Not in the South

However, here is Georgia it is not common to put rigid foam on the outside of the foundation due to the need to check for termites. I agree with exterior wall sheathing, but for my area I believe damp sprayed cellulose is cheaper, more environmentally friendly, and still meets the required R-value for our climate zone.

I Joists for walls

Why are I joists not being used in walls? With very little thermal bridging and ease of construction, I joists could provide a very efficient wall assembly

Response to Mark

Mark,

Builders of superinsulated houses have been using I-joists as studs for years. That's how Katrin Klingenberg built her house in 2003-2004. In the May 2004 issue of Energy Design Update, I reported details of the wall construction of her house:

"Klingenberg framed the thick walls of her house with vertical 12-inch TJIs (I-joists from Trus Joist). Trus Joist has developed details allowing their TJI floor joists to be used as studs; however, since US builders show little interest in superinsulation, the publication is available only in German. (The document, which has the unlikely title of “Balloon und Platform Framing Details,” is posted on the Web.) According to Klingenberg, when TJIs are used as studs, they require structural sheathing on both sides. For interior sheathing, Klingenberg specified OSB, which functions as a vapor retarder. On the exterior, Klingenberg wanted a more vapor-permeable sheathing; she settled on 1⁄2-inch Stedi-R structural fiberboard (R-1.28) from Georgia Pacific."

“Thinking green, it is better

“Thinking green, it is better also to eat less meat"

I apologize for getting off topic, but this statement is hopelessly false.

Brett Moyer not Boyer

Scott, I tried to point out your typo in an earlier comment...

guess you missed it

Thanks, John

With apologies to Brett, the typo is fixed.

Super-insulated high mass

I know I am late on this blog and new to the site, but when Peter Yost, GBA's technical director, said, ”A concrete (or concrete block) wall with all of the insulation to the exterior, pulling the structure pretty much into the conditioned space, is elegant." I had to comment.

As a custom design builder, I have been building super-insulated homes for thirty years and in 1991 I built my personal home out of concrete block with a Larsen Truss attached and insulated with 7" of sprayed urethane. The foundation has 4" of extruded polystyrene and basement floor has 2" of extruded polystyrene protected with a tu-tuff barrier. The attic has a perfect air/vapor barrier with R-70 blown fiberglass.

Without question my 4000 sq. ft. home does not perform as well as many of my stick built super-insulated homes of similar size. Of course there are hundreds of variables, including location and lifestyle.

I find this site very interesting and could have commented on so many blogs, after thirty years of performing homes, I have seen alot.

Reply to Roger Kjonaas

Roger,

Your comment is interesting. To what do you attribute the lower performance of your home?

In most U.S. climates, a high-mass superinsulated home has no advantages compared to a low-mass superinsulated home. What matters is the quality of the envelope -- airtightness, R-value, and window specs -- not the amount of mass inside the envelope.

So I tend to be skeptical whenever thermal mass proponents brag about the advantages of interior concrete. In that regard, I think we agree. But I can't really think of a reason why your high-mass home should perform worse than a low-mass home. Please let us know if you have a theory to explain your observation.

Reply to Martin

I really haven't been able to figure it out, I have an infrared scanner and have inspected the home, but nothing sticks out.

The reason I used the high mass wall system is because the walls have hydronic heating tubes throughout, it was going to provide the thermal storage, as I was going to build a hybrid heating system with solar and a water stream generator, I live up against the Missouri River, north of Bismarck, North Dakota.

Back in about 1982 I built a super-insulated passive solar home with a wood foundation and wood basement floor, all protected with high ml. rubber membranes. This was a low mass house and the owners called me in January wondering what to do about their house over heating. Mass is important to reduce temperature swings, but exactly how much is always the question.

Log in or become a member to post a comment.

Sign up Log in