Blogs

-

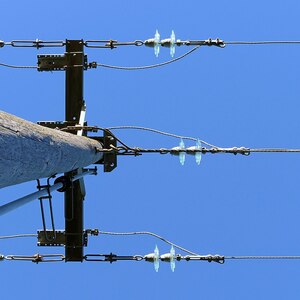

The “Public” in Public Utilities

Maine comes close to having a statewide consumer-owned utility. It failed but not without gaining a toehold for energy democracy.

-

Building Code Meets Building Science

Five ways residential building codes have begun to align with building science–directed best practices

-

Latest Retrofit Standard for Passive House Performance

Phius REVIVE 2024 focuses on thermal resilience and reducing upfront emissions, and is supported by new life-cycle cost calculator

-

Recurring Mold in the Attic

What is the source of moisture in this cold-climate vented roof assembly with cellulose insulation?

-

Windows Before WRB?

Yes, if the flashing details are done right, you can safely install windows before the housewrap

-

Choosing the Right Range Hood Makeup Air System

First know the basics, then consider all the factors that go into a good makeup air system. Then install a modest-size range hood with the right capacity.

-

An Unusual Approach to Low-Carbon Concrete

Waco Independent School District demonstrates the potential of nano-modified concrete

-

Direct Air Capture Ramps Up

The number of facilities removing CO2 from the air is increasing but major hurdles remain to widescale adoption of direct capture

-

Getting Good Results from Fiberglass Batts

This less-favored insulation type will do a good job of slowing heat loss, if key details are attended to during installation

-

Water Quality

No matter how it arrives at the tap, water is vulnerable to contamination and requires our vigilance to ensure it is safe