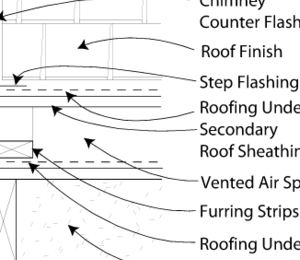

Flashing is any piece of water-resistant material installed at transitions to keep rain and snow melt out of roofs and walls. There are as many different types of flashing materials as there are uses for flashing. Lead is a traditional flashing material that is still used today around chimneys. More modern flashing materials include the peel-and-stick tapes commonly used during window installations. You can buy boots to flash plumbing vents and gaskets to flash electrical penetrations. Commonly used metal flashing for horizonal building details like the top of the casing around windows and doors are usually copper, galvanized steel, or galvalume and are available in many colors. These materials can also be used to make your own kickout flashing, as shown in this detail.

Kickout flashing is an often overlooked and critically important piece of flashing at roof-to-wall intersections. Whenever a sloped roof abuts a vertical wall, there is the possibility of water pooling, penetrating, and rotting the wall and roof structures. At these intersections, step flashing is placed under the roof shingles and extends up the vertical wall to prevent water from entering the wall while directing it down the roof. When the roof ends before the wall, the final piece of step flashing should be a kickout flashing that directs water away from the wall and into the roof gutter.

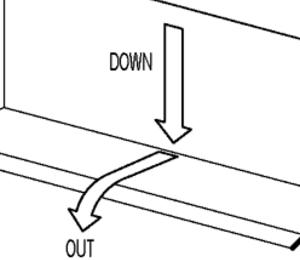

Kickout flashing is easily bent on-site out of a piece of step flashing, or there are pre-made products that can be purchased. To make your own kickout flashing, draw a square line from the outside edge of the roof leg in to the center seam on a piece of step flashing. Draw another line from the bottom outside corner of the roof leg to meet the first line at the seam. Cut the square line. Bend the lower…

This article is only available to GBA Prime Members

Sign up for a free trial and get instant access to this article as well as GBA’s complete library of premium articles and construction details.

Start Free TrialAlready a member? Log in