Insulating at the ridge

We finished framing the roof and are getting ready to start sheathing tomorrow. I have a structural ridge (7 x 20 LVL) over a cathedral ceiling and a non-structural ridge (1 3/4 x 11 7/8) with collar ties over the rest of the roof. The roof assembly calls for 5/8″ gypsum, Siga Majrex vapor control membrane, 2×10 rafters packed with DPC, 5/8″ Zip sheathing, 5 1/2 ThermaCal1 nail base panel (4″ of polyiso with a vent channel on top) and shingles (probably cedar). If I de-rate the polyiso to r-5 and assume r-3.5 for the DPC, that should provide me with an r-62 and 32% of the total r-value coming from the exterior foam which is adequate for CZ-4. I have some concerns/questions about this assembly as follow:

1) While I am in CZ-4, I am only about 2 miles from CZ-5 and the ridge sits at an elevation of about 440′. I am thinking that I may need to adjust my insulation ratios to meet those required for CZ-5.

2) The architect’s detail shows the vapor control membrane attached to the rafters all the way to the ridge, which is not possible where I have collar ties. Instead the membrane will have to go up one rafter and then across the bottom of the collar tie and then down the opposite rafter. It will be very difficult to try to seal and dense pack the rafters above the collar ties. It would be rather easy to dense pack the entire area including the collar ties, but that will reduce my exterior to total r-value ratio dramatically in the most vulnerable part of the roof. While I am trying to avoid closed-cell foam as much as possible, would the solution be to add 2″ of CCF to the underside of the sheathing and then dense pack? Would I need to do this for all of the sheathing or just for the sheathing from the bottom of the collar ties up to the ridge?

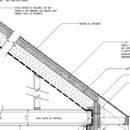

3) On the side where I have the structural ridge and no collar ties, the architect’s membrane detail is fine. My concern here is that top of the rafters are flush with the top of the ridge which will leave a large triangular air gap above the ridge when the sheathing is applied. Should I have my sub apply the sheathing tight to the top of the ridge (so no air gap in the sheathing) and then when the nail base panels are added, we can cut a triangular piece of polyiso to fill the gap that will be created? In retrospect, we should have attached the rafters to the top of an architectural Power Beam which would have eliminated the gap and looked really good.

Thanks.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Jonathan,

Q. "While I am in Climate Zone 4,...I am thinking that I may need to adjust my insulation ratios to meet those required for Climate Zone 5."

A. Relax. You are in Climate Zone 4.

Q. "It will be very difficult to try to seal and dense-pack the rafters above the collar ties. ... While I am trying to avoid closed-cell foam as much as possible, would the solution be to add 2" of closed-cell spray faom to the underside of the sheathing and then dense pack?"

A. You are probably overthinking this, but overthinking is better than underthinking. Above the collar ties, you could just omit the cellulose. Instead, you could install open-cell spray foam on the underside of the roof sheathing. (Remember, you have rigid foam above the sheathing, so you don't have to worry about moisture accumulation.) Open-cell spray foam is environmentally preferable to closed-cell spray foam, and it's cheaper.

Q. "Should I have my sub apply the sheathing tight to the top of the ridge (so no air gap in the sheathing) and then when the nail base panels are added, we can cut a triangular piece of polyiso to fill the gap that will be created?"

A. It's good to think through this detail above the LVL carefully. This location is often a source of air leakage. If I were you, I would bring the sheathing just to the top of the rafters, leaving the top of the LVL exposed, and I would use spray foam on top of the entire "triangle" area. (A small two-component spray foam kit would do it.) Then use a long bread knife to cut the cured foam in a triangle shape. At that point, you will be ready for the nailbase.

Alternatively, you could buy some wide Siga Wigluv tape, and run the tape from one side of the roof to the other -- from the sheathing on one side of the roof, over the top of the LVL, and down to the sheathing on the other side.

Martin,

Thanks for your responses. I will use the open-cell foam in the ridge above the collar ties and keep my ratio as needed for Zone 4.

We cut the sheathing as you suggested and I plan on taping over the top with Wigluv.

Jonathan,

Sounds good.