Attic and wall insulation

I know these questions are asked continuously and I have read for days to try and answer this myself but I can’t find a clear answer.

For several different reasons I won’t go into I am leaning towards a polebarn structure for the exterior. I am located in E TN.

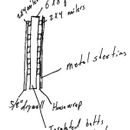

I am not happy with their typical insulation application. Their typical wall assembly is drywall>plastic sheeting>batt insulation>metal exterior sheeting. I am thinking of using drywall>batt insulation>1″ spray foam>house wrap>metal exterior sheeting. If the wrap is secured tight against the 2×4 nailers this should give me a small air gap in between the metal ribs. Does it matter which type of foam (open or closed)? Does this work for moisture and air sealing?

Part 2:

Roof assembly. They typically use metal sheeting>air gap(vented roof)>blown in loose fill>plastic sheeting>drywall. I am thinking of using metal sheeting>felt>osb>air gap(vented roof)>blown in loose fill>dry wall. Does this work for moisture and air sealing?

I am thinking it best to remove their plastic sheeting in both locations.

Thanks for the help,

Travis

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

You are planning to occupy the pole barn? If so, will you have air conditioning?

Travis,

Steve Knapp's questions are relevant. I'm going to assume that the answers to his two questions are "yes" and "yes," until I hear different.

The basic problem with a pole barn is establishing an air barrier. It's certainly easier to establish an air barrier if the wall assembly includes sheathing (OSB or plywood), like a regular house. This would be especially appropriate if the building will be insulated and occupied by people (rather than tractors or horses).

It's especially tricky in this type of building to create a good air seal between the concrete slab and the wall, unless you include wall sheathing.

Travis,

Your drawing does not show any spray foam, in spite of the fact that your description reads as follows: "I am thinking of using drywall>batt insulation>1 inch spray foam>housewrap>metal exterior sheeting."

That raises a few questions:

1. What is your intended substrate for the spray foam? Do you intend to install spray foam against the housewrap that is stretched between the horizontal nailers?

2. Please describe the order of assembly so we can understand when the spray foam would be installed.

Sorry, I thought about that after I hit send. Yes and yes. I am looking at a high seer energy efficient variable speed whole house unit.

The air barrier (or lack of) is a large part of why I didn't like their application. I didn't draw in the spray foam because I guess that is partially my question. My initial thought was to spray it against the house wrap to leave an air gap between the wrap and metal. If I remove the house wrap I could spray closed cell directly against the metal but I am afraid of moisture building up between the 2x4s and the metal sheeting. I could do OSB sheeting with house wrap instead of spray foam with a slight drop in R value. My other thought was to use rigid board insulation instead of OSB but this definitely cost more.

Travis,

I don't think it's a good idea to install spray foam directly against the housewrap. Nor do I think it's a good idea to install spray foam directly against the metal cladding. (If you ever get rust near the bottom of a piece of cladding, you'll never be able to replace the rusted panel if it is glued in place by spray foam.)

So I advice you to install a layer of sheathing -- either OSB, plywood, or rigid foam would work.

Good call on spraying against the metal. What is the concern of spraying against the house wrap, it flexing?

Does the roof assembly look good?

Travis,

As you guessed, my concern about using housewrap as a substrate for installing spray foam is that it is too flexible. After you install one inch of spray foam against the housewrap -- assuming that a contractor would agree to perform the work -- it would be easy to crack the spray foam by leaning against it. That makes is too fragile to be a good air barrier (in my opinion).

Your description of a vented roof assembly is confusing.

1. Do you intend to install the insulation along the sloped roofline, or do you intend to install the insulation on the horizontal floor of an attic?

2. If you intend to install the insulation along the sloped roofline, what materials will you use to create a ventilation gap above the insulation? And how do you intend to support the blown-in insulation?

I was thinking you would install the house wrap, then the metal, then come back and spray foam so you would have the "structure" in place but I still think it is kinda iffy.

I don't have a cutaway or cross sectional of their assembly yet so I am at a disadvantage until I get further along. They way I understand it, they use 2x4s and suspend the ceiling below the top chord so it is still sloped but supported like a horizontal ceiling. I didn't like the metal being directly above the blown in insulation even with the air gap. I have seen it "rain" inside every metal building I have ever been in. I wanted to use the felt and OSB under the metal to address the moisture problem. I am still in conversations with them about getting enough space for over R-40 blown in insulation. They are raised heel trusses. Assuming they create enough cavity for the correct amount of insulation, is taped OSB or sheetrock an acceptable air barrier in this application?