How best to insulate a traditional slab paired with a wrap-and-strap timber frame?

Hey folks, been reading the site for a while during our planning process and its time to start asking some questions.

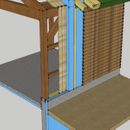

We are doing an owner-builder timber frame barn-home which will also serve as my workshop with a wrap and strap insulation scheme and I have been getting a lot of conflicting advice on how to insulate our frost walls. We will be building in Southern Vermont, zone 6. We are aiming for what we consider pretty decent levels of energy performance, but not a passive house. (4-6″ polyiso in walls, 8″-9″ on roof, 4″ XPS under and around slab, triple pane intus windows, obsessive air-sealing details… etc.)

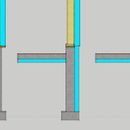

I was planning on using 4″ of XPS on the exterior of the frost walls, as per the REMOTE/PERSIST system, but have run into some trouble with how to detail the slab perimeter foam with a large barn door (either an overhead or DIY carriage doors) without the tractor tires or just general traffic destroying the exterior foam edge. Placing the foam on the interior of the frost wall would allow us to protect that foam with a sacrificial something or other bridging between slab and frost wall where the frost wall would bear the weight of tires and such rather than the foam getting caught between tractor tires and the slab all by its lonesome.

The only solution we’ve found for protecting the exterior foam for the barn door is to build a fully frost-protected ramp that would essentially mirror the interior foam option at that doorway. The downside is that is isn’t a particularly inexpensive soltution in terms of concrete and labor.

Interior foam means we get stuck with a rather large shelf of foam covered by 1x T&G on the interior that we aren’t too terribly thrilled with. Even with only 3″ of XPS we end up with a 9.75″ deep shelf which makes furniture and workbenches trickier.

An benefit of the interior insulation is that I can extend the PT sill out to protect the underside of the wall foam. However a benefit of the exterior foam (assuming I can find a decent solution to protect it from toes and weedwhackers) is that it can be made much thicker without an excessively large interior shelf.

Most insulation details I can find deal with insulation between the studs or a SIP panel resting on the frost wall. Our timber frame shunts the wall insulation out past the frost wall so we are running into a thermal break at the sill with most standard details due to the offset.

Any advice on how to detail this would be appreciated.

I have attached two visual references. One is an isometric of our wrap and strap plan. The triple cross-section shows the interior insulation option (which would need to be covered on the vertical interior side somehow) followed by a simple exterior insulation option which does have a thermal bridge through the frost wall from underneath the slab. The 3rd is a sort of jury-rigged possible solution to mitigate that thermal bridge (which could extend up to slab surface to act as a joint between slab and frost wall)

In all cases the timber posts would bear directly on the sill plate and frost wall. We would not be placing such point loads on any interior foam. In the case of the interior foam, the foam would be cut to fit around the post bases (another argument in favor of the exterior IMO)

Thanks folks!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Erik,

You might want to read a few earlier threads on this topic:

Slab at garage door. How to insulate?

Retaining heat at a garage door; part 2.a.07x

Inverted thickened edge slab