Zone 5 Envelope Enclosure / Parallel Chord Truss

I’m will be building a home this summer / fall and have started working out the details for my build.

I’m in zone 5, BC, Canada, and intend to build a simple shaped gable end structure with cathedral ceilings. I’ve located a truss manufacture who can build parallel chord scissor trusses for me that will meet my 20′ span without a ridge beam.

I intend to insulate well. I am leaning towards a 2×6 wall, sheathed, tyvek, with 2″ of roxul comfortboard on the outside. I could also consider a double wall if there were significant cost savings, but my research has informed me that it is a little riskier from a vapour diffusion perspective.

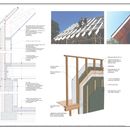

My question is in regards to the roof assembly that I am considering. Which is, ordering trusses with no overhang, and wrapping an airtight vapour permeable roof underlayment straight on top of the tyvek on my walls. This would create a simple plane to create an airtight enclosure for my roof. I would then strap the roof with 2x material on top of the membrane before roofing (and create my overhangs with 2x). The trusses would then be dense packed with cellulose.

I think this system will allow the sheathing to breath to the outside, but am I just adding cost and extra work for a little bit of air sealing convenience?

Should I just install ventilation baffles in the trusses to create the ventilation channel, and have poly on the inside to be my air barrier?

See the attached detail. Any comments are appreciated.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Jeff,

Looks OK to me.

I'll see Martin's "OK" and raise a "it's the simplest, cheapest and most robust high R roof assembly yet developed".

A few months back, we looked at it here at GBA: Just search on David Posluszny

There is a Youtube channel that shows how it was built, called "greasybrothers"

Note the Shirley house used a wrong side vapor barrier, but it still seems to work fine.

Jeff, My one concern is that unlike the photo of a similar roof you have provided, your detail has only an

1 1/2" of meat connecting the rafter tails and the strapping over your plywood. Depending on the overhang, it may fail in shear at the edge of the roof. It's worth running it past either your BI or engineer.

Thanks For The Thumbs Up Martin & Kevin. Malcolm, you make a very valid point. I will look into it further.

- Jeff

Jeff, Another way of skinning the cat is to fasten the 2x strapping/rafter tails directly to the top cords of the trusses with a WRB/ air barrier sandwiched in between. The advantage is using only one layer of roof sheathing. I'd imagine the disadvantage is you'd have to be a monkey to frame it.

I'm curious if anyone wants to recommend vapour permeable roof membranes that are available in Canada. I see Tyvek has a product call Attic Wrap, which is permeable. Could you use any house wrap as a roofing membrane, since it is built similar to a rainscreen?

Jeff,

For the application you are talking about, I would only consider a product that is marketed as a roofing underlayment. High-quality options include vapor-permeable roofing underlayments from 475 like Solitex Mento.

Other options include GAF Deck-Armor, Cosella-Dörken Delta-Maxx Titan, and VaproShield SlopeShield.

To adress Malcom's point, we've also used extended 2X4's flat side up, and installed a horizontal 2x back to a 2X ledger on the house. Takes care of the shear and bending issue, and you can install them above the end of the 2x so the soffit is slightly recessed.