Should I be concerned with these wall and roof insulation details?

Hi,

I am a weatherization contractor located in coastal MA, climate zone 5. After reviewing countless articles here and from Joesph Lstiburek’s website, I’m concerned that the plans I received for a new construction project are not optimal and may pose problems down the road for the homeowner. Specifically, I’m looking to see if my concerns are accurate or if the plans are acceptable. My questions/concerns are (images for walls and ceiling as attached):

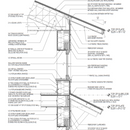

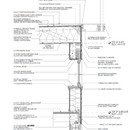

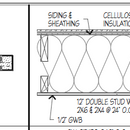

1. The plans call for double stud walls with 2×6 exterior and 2×4 interior framing (24″ O.C.) for a total of 12″ of dense packed cellulose. A continuous layer of polyethylene vapor barrier is called on the interior wall, covered by 1/2″ GWB. My concern is excessive moisture levels in the exterior sheathing (either 1/2″ plywood or Zip System) and potential failure in years to come. To further heighten my concerns, no rigid foam is called for on the exterior sheathing nor are furring strips. So my question is: Are my concerns accurate? If not, great, but an explanation why would be appreciated. If they are, and assuming cost is not an option, what would be an ideal assembly? Two that came to mind are below.

Option 1 – Joseph Lstiburek’s ideal double wall

http://buildingscience.com/documents/enclosures-that-work/high-r-value-wall-assemblies/high-r-value-double-stud-wall-construction?topic=doctypes/enclosures-that-work/etw-high-r-value-enclosure-assemblie

Option 2 – Rigid foam on the exterior, per Martin Holladay’s recommendations. https://www.greenbuildingadvisor.com/blogs/dept/musings/calculating-minimum-thickness-rigid-foam-sheathing

If option 2 and given the double stud wall assembly is 12″, minimum exterior foam would need to be in the neighborhood of R16-R18, correct?

2. For the roof assemblies, the plans are calling for an unvented cavity containing 18″ of dense packed cellulose. Once again, I’m concerned about moisture levels in the exterior sheathing (Zip System). The plans do call for a smart vapor barrier on the interior; however, no exterior rigid foam or furring strips are called for. The main roof is covered in galvalume (sections of 5 and 8 pitch) as well as a flat roof, covered in an EPDM rubber membrane. My first question here is if this is even code, and my second is this is extremely risky, correct?

My understanding would be to use closed cell foam to treat the underside of the roof sheathing or a combination of air permeable insulation (open cell spray foam, but not cellulose) with R20 rigid foam on top of the roof sheathing.

Thank you for reading my post and providing useful feedback.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Corey,

Concerning the walls, this article should answer your question: Exterior Rigid Foam on Double-Stud Walls Is a No-No.

Concerning the roof, you're right. It is a code violation to insulate an unvented cathedral ceiling with cellulose (unless there is an adequate layer of rigid foam on the exterior side of the roof sheathing). There are two possible fixes: (a) install the required exterior rigid foam, or (b) install ventilation gaps between the underside of the roof sheathing and the top of the insulation. For more information, see How to Build an Insulated Cathedral Ceiling.

Martin,

They appear to also have an unvented flat roof with just DP cellulose inboard, same issue? They are using spray foam for the wall to roof connection. Cost and carbon aside, would they have been ok if they continued with 2" of spray foam between the roof sheathing and cellulose?

Jonathan,

You're right. This article explains what should have been done: Insulating Low-Slope Residential Roofs.

In Climate Zone 5, 2 inches of closed-cell spray foam on the interior side of the roof sheathing isn't enough to keep you out of trouble. The foam insulation layer needs a minimum R-value of R-20 -- and 2 inches of closed cell spray foam is only R-12.

It's possible that this designer has been convinced by salespeople at 475 High Performance Building Supply that these details, which violate code, are acceptable. For more on the controversy, see Smart Vapor Retarders for Walls and Roofs.

.

What's the reason for the 2x6 exterior wall?

Just guessing, but 24" o.c. spacing a 2x6 wall has about the same structural capacity as a 2x4 16" o.c. wall, and about the same board feet of lumber, less lumber if one can then drop back to single top plates by aligning rafter with the studs, advanced framing style. If it were 2x4 it would have to be 16" o.c.

My architect was fine with a double stud 2x4 wall, 24" o/c, although it's a single level house.

The floor insulation detail is a bit confusing, showing 2x10 joists and 12" of cellulose dense-packed against the rim. Unless someone is careful, the cellulose will end up in contact with the top of the foundation. The label for the bottom plate of the wall says 2x12 but the drawing appears to show 2 pieces (a 2x4 and a 2x6?) with foam sealing the outer plate to the subfloor and the sheathing. These types of confusing details will have the contractor improvising during construction, unless he feels like calling the architect for clarification.

Anyone else concerned about the sketchy connection of the roof deck cantilever to the interior roof structure?

Whoa - missed that!

I noticed that, but assumed that it's supported somehow at the ends or perhaps by posts that are not shown. No way it can cantilever as drawn.

Corey,

To return to your questions about double-stud walls:

1. As I noted in my article, you don't want to install exterior rigid foam on a double-stud wall.

2. In your climate zone, the interior polyethylene isn't a good idea, especially if the house will be air-conditioned during the summer. A so-called smart vapor retarder (like MemBrain) is better in this location than interior poly.

3. A ventilated rainscreen gap between the siding and the WRB is always a good idea with a double-stud wall, because it helps damp sheathing dry quickly.

Thank you for the clarification Martin. For the roof, I failed to consider R20 of closed cell spray foam against the sheathing, covered by cellulose, essentially a giant flash and batt. I'll weigh the flash and batt against the ventilation method you mentioned in your article and discuss these options with the GC.

As for the walls, yes, I thought an interior polyethylene wasn't a good idea as well. And yes, the house will be air conditioned in the summer time.

Thank you again,

CRM

In a flash & batt the "flash" needs to be a minimum of ~30% of the total R in walls or ~40% for roofs in a zone 5 location for dew point control at the foam/fiber level. If it's less than that you'll need a class-II vapor retarder or a "smart" vapor retarder such as 2 mil nylon on the interior side. R20 is the prescriptive minimum for roofs at a presumed R49 code-min total. If it's higher R than that, the foam-R needs to grow proportionally.

Corey,

For more information on Dana Dorsett's point, see Combining Exterior Rigid Foam With Fluffy Insulation.

Dana, thank you very much for the additional information. Martin, thanks again for the link to the article. It's great knowing there's a community of likeminded people who are willing to help each other. I truly appreciate everyone's comments and insights.

CRM

The detail showing the unvented DP cell roof is not to code. Simple soffit and ridge vents with vent baffles stapled to the sheathing will solve this. To compensate for the room the vents will take and keep you at R63, you will have to raise da roof.

Stephen,

Corey is designing a low-slope (flat) roof, so your suggestion about soffit vents and ridge vents isn't relevant. Low-slope roofs need different approaches, which is why I suggested in Comment #3 that the correct details are explained in an article called Insulating Low-Slope Residential Roofs.