Anchor bolt issues: bolts too low or too far, need alternatives after pour

First casualty of a custom build : my anchor bolts are not ideal, with some placed too low in the wall, and a few placed too far forward to grab the sill plate per current design. Apparently even after I insisted they placed the bolts in the outside third of the wall (their “siding” position,as i was told), where they really should have been placed on the inner third of the wall. Even though I caught it before the concrete was cured, moving the bolts to an “acceptable” location made a few of them too low to provide enough thread to bolt to.

Even the bolts that were placed correctly, I am not 100% sure if they were clocked correctly to provide sufficient holding power given their close proximity to the inside edge of the poured wall. they should have used offset anchors, and the used standard J bolts, which did not help at all.

The crane operator also managed to blow out of the “good”anchor bolts, likely by hitting it with a cage full of forms (see pic).

Bottom line, I will need brand/model suggestions for after pour bolt options (epoxy in place seems to be the best as i don’t have enough “meat” for expansion bolts).

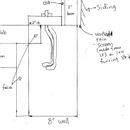

I attached a very crude drawing of the configuration. Only difference is I finally made the foam ledge 6″ deep to avoid thermal bridging at the slab, in both house and garage (garage has 4″ slab). Note that I can “cheat” the entire assembly towards the outside by as much as 1/2″ (drywall would cover the foam on the inside) to help with aligning the sill plate with the bolts, but I would rather not as currently it would expose my EPS foam to ants. Not an issue if I replace the outside EPS foam with Roxul (still undecided, worst this about the Roxul is higher space claim per R-value, and potential for high compression when installing furring strips for the rain screen.)

I have seen some earthquake design anchor plates that seem to grab the sill plate from the side, but I am worried about cost and the plates creating gaps at the OSB layer.

Opinions and suggestions welcome.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Check with Simpson Anchoring Systems (Mechanical Anchors): https://www.strongtie.com/anchoringsystemsforconcreteandmasonry/landing. You probably should hire an Engineer to study your foundation anchoring and give you a solution. It be almost impossible for anyone to give you solutions without visiting your jobsite.

Mai Tai,

Much of the anchoring we do for shear-walls is specced as being drilled after the concrete has cured and is secured by epoxy. Some builders use this method as their standard practice rather than putting the anchor bolts in during the pour.

A hammer drill, some threaded rod and a few tubes of epoxy and you will be back in business. Drilling in the middle of your wall will allow good coverage on each side. You might want to offset slightly to miss any rebar. The bolts don't need to be situated right in the middle of your sill plate.

Edit: If some of the existing anchor bolts are fine except just a bit low, use a spade bit to hog-out the plate so the washer and nut can catch.

The Simpson Side plate anchors are typically used when you don't have vertical access. Adding Epoxy anchors is the way to go. The catalog has tables for design. Is the building design controlled by wind or seismic? What seismic design category is the structure located in?

Thanks for the confirmation this can be fixed by epoxied in place threaded rod.

TIM R No seismic or wind design loads, although we seem to be getting more weather (wind) in Southern Ontario so I would not mind being prudent.

I can see why some builders would just default to epoxied anchors: it makes sense especially if you can use the actual sill plate as a template, no problems with misaligned holes or angled anchor bolts. I did consider the trusty spade bit, but I have not found any info on how much hogging out is too much :)

Two products stood out in my research as a way to mitigate my issues.

Elocone nuts by CanAm would be a quick fix for anchor bolts set too low, certainly faster than welding extensions or even adding a coupling nut. Unfortunately they seem to start at 3/4". Anyone know of a competing/equivalent product available in 1/2" size?

https://www.canam-construction.com/en/construction-products/elocone-nuts/

The other (more likely) product is the square offset washer or slotted washer. That would likely help mitigate of the inevitable off center anchor bolt position in my build. The good? news is I seem to have plenty of anchors (they seem to be 2' OC or so), so maybe the ones that don't make the cut will be cut flush.

Mai Tai,

The required spacing for non-seismic or extreme wind areas is 2.4m oc. Maybe you will end up with enough good ones that you won't need many more.

Epoxied anchors cost way more than a wet set anchor bolt. Do you need to have this approved by a building department?