Flooring approach in climate zone 3A basement

Hey folks,

I’m planning on finishing by basement and am looking for some advice on the flooring assembly. I posted something similar about the walls a few weeks back. https://www.greenbuildingadvisor.com/community/forum/energy-efficiency-and-durability/101308/basement-wall-assembly-climate-zone-3a

Some quick information: Climate zone 3a, poured concrete slab, no insulation under slab, no bulk water issues so far, new house constructed in 2016.

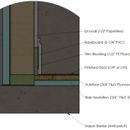

I’ve uploaded a drawing of the approach I’m looking at. Its modeled somewhat after the Steve Baczek article “Build a Risk-Free Finished Basement” and the “Stay-Dry, No-Mold Finished Basement” article. Along with the information I’ve gleaned from GBA. Where on the wall assembly I was 95% sure of what I was doing, and only wanted to confirm the form thickness, on the floor assembly I’m much less sure. Basic approach (if you don’t care to look at the drawing) is concrete floor>3/4″ rigid foam>3/4″ OSB>LVP or LVT. So, with that in mind, I have some questions.

1. Is ¾” T&G foam ok? With no slab insulation requirement by code, I assume it is of sufficient thickness. I’ll be tapnig the seams.

2. The standard approach I’ve read here is two ½” plywood sheets laid perpendicular. I’m using one sheet of ¾” T&G OSB. Any issues with this when it comes to cupping? Would Advantech be a good investment here?

3. Should I leave an expansion gap around the perimeter where the OSB and the walls meet? Right now I have the rigid foam and the subfloor butting up tight against the walls.

4. The standard advice here is to attach the first layer of subfloor to the concrete with Tapcons. Should I attach the ¾” T&G subfloor at all? Is the purpose of anchoring to concrete to prevent cupping? If I should anchor the OSB, can I use powered activated fasteners instead of Tapcons?

5. Based on the article “Build a Risk-Free Finished Basement” I have the drywall terminating 4” above the subfloor, with pressure treated blocking filling the gap between the drywall and subfloor. Does this seem necessary in my approach? While I’m using a PT bottom plate for the walls, the studs are regular KD, so moisture resistance doesn’t extend more than 1.5” from the concrete slab.

6. I’m not designing in a poly layer in the floor assembly. Is this an issue? I’ve seen conflicting advice here on GBA. I do not know for sure there is a vapor barrier under the slab, but the radon remediation contractor I had in a couple months ago says he would have noticed if there was not a poly layer under the slab, as he was drilling the sub-slab depressurization holes, because the house is new (maybe a code requirement now?)

7. With the ~1.75″ build up of the foam/subfloor/finished floor, how are transitions handled to areas where it is bare concrete? I have a mechanical room where it is not practical to finish the floor (water heaters, air handlers, injection pit, etc) and a workshop area where I wasn’t going to spend the money to do so. There will be at least two door/thresholds that will have a pretty big difference in elevations.

Appreciate any and all help,

–Jamie

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Jamie,

First, a general caveat: Anyone who decides to finish below-grade space needs to accept the risk of water damage or flooding. The risk may be high or low, but the risk is always there.

Q. "Is ¾-inch T&G foam OK?"

A. That will work. Of course, the thicker the rigid foam, the higher the R-value -- so thicker foam would be a bit better.

Q. "The standard approach I've read here is two ½-inch plywood sheets laid perpendicular. I’m using one sheet of ¾-inch T&G OSB. Any issues with this when it comes to cupping?"

A. No, as long as you use a sufficient number of TapCon fasteners to attach the plywood to the slab.

Q. "Would Advantech be a good investment here?"

A. Either Advantech OSB or plywood will work.

Q. "Should I leave an expansion gap around the perimeter where the OSB and the walls meet?"

A. A 1/2-inch gap for the OSB or plywood subfloor is a good idea. You don't really need a gap for the rigid foam.

Q. "The standard advice here is to attach the first layer of subfloor to the concrete with Tapcons. Should I attach the ¾” T&G subfloor at all?"

A. Yes.

Q. "Is the purpose of anchoring to concrete to prevent cupping?"

A. Yes. Remember, it can be hard to engage the tongues in the grooves when installing T&G subflooring. In some cases, the tongue won't engage.

Q. "If I should anchor the OSB, can I use powered-activated fasteners instead of Tapcons?"

A. I prefer the TapCons.

Q. "Based on the article “Build a Risk-Free Finished Basement” I have the drywall terminating 4 inches above the subfloor, with pressure-treated blocking filling the gap between the drywall and subfloor. Does this seem necessary in my approach?"

A. That will work. Some people avoid gypsum drywall altogether for basement work. It's up to you to assess your risk tolerance here.

Q. "I’m not designing in a poly layer in the floor assembly. Is this an issue?"

A. On an older house, it's usually a good idea to install polyethylene above the slab. You can't be sure that the contractors who installed the slab knew what they were doing. Polyethylene is cheap.

Q. "With the ~1.75 inch build up of the foam/subfloor/finished floor, how are transitions handled to areas where it is bare concrete? I have a mechanical room where it is not practical to finish the floor (water heaters, air handlers, injection pit, etc) and a workshop area where I wasn't going to spend the money to do so. There will be at least two door/thresholds that will have a pretty big difference in elevations."

A. Either install rigid foam and plywood everywhere, or get used to the high threshold. A small ramp is one approach -- although it will always be a tripping hazard.

You also have to consider what to do with the basement stairs. You need consistent riser heights for safety.

-- Martin Holladay

Martin,

Thanks for all the answers. Your really do provide a wealth of knowledge. Hope to hear you on the FHB podcast again soon. A laundry list of questions I know, but I wanted to follow-up on a few.

2. Would Advantech be a good investment here? I was mainly getting at if the cost premium for Advantech (about 30% in my area) would be worth it in this flooring application. The 3/4" foam should separate it from any moisture from the concrete floor, so I'm leaning towards regular OSB.

4. If I should anchor the OSB, can I use powered-activated fasteners instead of Tapcons? You prefer TapCons, but....would Ramset pins work? I can already feel tears welling up when I think about drilling pilot holes in the OSB, then drilling holes in the concrete floor, and finally attaching the TapCon, 43 million times over my 1500 sqft basement.

5. I have the drywall terminating 4 inches above the subfloor, with pressure-treated blocking filling the gap between the drywall and subfloor. The blocking is a bit more work compared to just bringing the drywall down all the way (leaving the normal 1/4" gap. My question is does the effort of doing the blocking really gain anything if bulk water gets into the basement? After cursing my luck and starting the cleanup, would my life be that much better if the 4" PT blocking was there?

7. With the ~1.75" build up of the foam/subfloor/finished floor, how are transitions handled to areas where it is bare concrete? Are there any products out there that help with this transition? Or do folks build little custom miniature ramps? I had not thought about the stairs...if this assembly causes the rise on the last step to be out of code, what would be a sensible solution? I can't see redoing the entire basement stairs...that would be an expensive and difficult endeavor.

Thanks,

--Jamie

Jamie,

Q. "Would Advantech be a good investment here? I was mainly getting at if the cost premium for Advantech (about 30% in my area) would be worth it in this flooring application. The 3/4" foam should separate it from any moisture from the concrete floor, so I'm leaning towards regular OSB."

A. If I were upgrading from regular OSB, I would probably choose plywood, not Advantech. It's your call.

Q. "If I should anchor the OSB, can I use powered-activated fasteners instead of Tapcons?"

A. It's been years since I've used powder-actuated fasteners, but my memory is that you have no control over the depth of the fastener. Depending on the hardness of the concrete -- whether or not you hit a piece of aggregate a certain way or not -- your fasteners can end up either recessed or proud. That won't work with subflooring.

Q. "I have the drywall terminating 4 inches above the subfloor, with pressure-treated blocking filling the gap between the drywall and subfloor. The blocking is a bit more work compared to just bringing the drywall down all the way (leaving the normal 1/4" gap. My question is does the effort of doing the blocking really gain anything if bulk water gets into the basement? After cursing my luck and starting the cleanup, would my life be that much better if the 4" PT blocking was there?"

A. Again, your call. You are overthinking this. Flooding may be unlikely or likely -- only you know the answer to that. It's certainly true that whenever there is flooding, it's always a mess. And if you plan for 4 inches of standing water, how do you know you won't have 5 inches of standing water?

Q. "With the ~1.75" build up of the foam/subfloor/finished floor, how are transitions handled to areas where it is bare concrete? Are there any products out there that help with this transition? Or do folks build little custom miniature ramps?"

A. This is finish carpentry. If you have a big table saw or you know how to use a plane, you can make a ramp.

Q. "If this assembly causes the rise on the last step to be out of code, what would be a sensible solution?"

A. Remove the stringers and cut new stringers, or remove half of the treads and make custom shims for each tread, with each shim adjusting 1/16 inch or perhaps 1/8 inch at a time. It's not rocket science -- it's just work.