Cold bedroom fix?

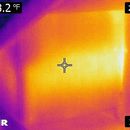

Climate zone 6A, my daughter-in-law’s 1990s half of a duplex. Cold bedroom juts into garage (see photos). Fiberglass (6″?) that’s below bedroom subfloor isn’t in contact with it – about a 2″ gap as far as I can tell.

To take the photo that looks up at the subfloor, I reached my camera through the gap below the wall sheathing, while simultaneously pulling the fiberglass aside. So, basically no access to push the fiberglass up against the subfloor.

Any ideas on how to get the existing fiberglass in contact with the subfloor? Maybe slide a series of pre-cut pieces of rigid foam between the bottom chords of the trusses to raise up the existing insulation?

I can also attach rigid foam insulation to the wall sheathing with adhesive and cap nails.

Thanks.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Jonathan,

There are two issues here: air sealing and improving the insulation.

I can't quite visualize the geometry completely, but it's clearly important to seal all air leaks between the cold garage and the bedroom. If you can either see or visualize all the possible cracks and air leaks, you need to come up with an air sealing plan, which may involve caulk, tape, canned spray foam, or sealed blocking.

If you have access to the gap between the subfloor and the fiberglass batts, stick a hose in there and dense-pack the bay. If the bedroom has carpeting, pull up the carpeting so you can drill holes in the subfloor for your cellulose hose. Pack those bays tight.

Once you air seal and insulate the edges, I wouldn't worry too much about the lack of contact between fiberglass insulation and floor. See below (fig 7) where it is apparently considered a benefit.

https://buildingscience.com/documents/insights/bsi-009-new-light-in-crawlspaces

Current IRC code minimum for floors over unconditioned space in zone 6 is R30, or a full cavity fill if the joists aren't deep enough for R30. Filling it up is clearly the right thing to do, from both an air-tightness and R-value point of view.

It appears that there is a thermal bypass path between the floor joists that communicate freely with the unconditioned garage attic(?), and possibly a gap in the insulation (or none at all) in that wall cavity at the corner that juts into the garage attic?

Most box store rental blowers don't come with dense-packing hoses, but if there's a ~2" air space between the subfloor & fiberglass you can still get there if you can snake the 2.5" hose the full length (or at least within a foot or two) you can still do it. You may have to tape a stiffening stick (say, a 10' piece of 1" PVC pipe) to be able to get it all the way to the end. Cut cardboard air dams stapled to the joist framing to keep the blow-back reasonably controlled. Mark a circle about an inch or sobigger in diameter than the hose, cut an X into the circle with a utility knife to allow you to insert the hose. Run the blower on "air only" when inserting the hose to keep it from catching and binding on the pre-existing fiberglass.

When it hits the end, back up about 6-8" and start blowing the cellulose, but pay close attention to the sound of the blower. As soon as it stalls back out a foot or so to allow it to pack more in. You may have to do a few quick push-pulls each time it stalls to un-plug the packed cellulose that formed at the end of the hose, but if you're really quick about backing out when the blower begins to stall. Mark the hose about a foot from the end to know when you're getting close. With this method you won't be able to hit 3.5lbs with a single-stage blower, but in most cases it'll be 2.8-3lbs. When you're done, caulk the edges of your cardboard air dams and tape over the blower-hole X with a high quality tape such as housewrap tape or a temperature rated aluminum duct tape.

Before inserting the hose, take a cut-off sweatshirt sleeve and thread the hose through it. Use the sleeve as an o-ring gasket to limit the amount blow-back in your face from the insertion hole while blowing.

Drill an inspection hole into the OSB of the wall section to verify that it's insulated. If it isn't you can drill a 3" hole with a hole saw and angle the cellulose hose in there (insert it the whole way, if you can, but that's hard to do if it's 2x4 framing.

Thanks, all, for your thoughtful responses. Access from the garage attic side is so difficult that I think dense packed cellulose is the only practical solution. Even that might be tricky, as bet these two bays are open to each other, making one big four foot bay below the subfloor.

I posted to GBA Q&A because I don't think I can successfully DIY dense pack. I've never done it, and I've heard that rental machines don't work well. (Plus I'm old. Just inspecting left me creaky;)

I suspect hiring a contractor for such a small area may make the setup fee unattractive, but I'll check with a couple of good local dense packers, such as the one featured in this Home Energy magazine article: http://homeenergy.org/show/article/nav/buildingenvelope/id/1772

If they ever replace the carpeting, that will be their best chance at access from above, as Martin mentioned. There's also a recessed light above the front door, which complicates things.

Even without dense packing filling the 2" with cellulose would make a real difference. No matter what there will have to be air dams in the joist bays where they cross under the walls, and that too will make a difference.

Rental machines can usually dense pack just fine up to the 3lb range they're just slower (but more forgiving) than 2-stage machines.