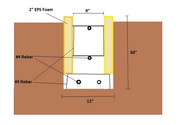

Creating ICF / Foxblock-style Footing Using EPS Sheets + Rebar

Greetings everyone –

I am trying to figure out an economical ICF design using 4×8 sheets of EPS rather than expensive manufactured ICFs.

After some hunting, I came across a product called the foothold, but they only make them 20″ wide. Could be useful for folks building ICF walls or other alternative methods: http://thefootholdicf.com

I was scheming about creating some type of rebar structure to hold the foam in place, with the trench walls providing exterior support. This drawing was based on using 2xrebar L’s, tied together to form an 8″ rebar “box”, but I was also considering 8″ pieces of lateral rebar with caps or even a course of elevated concrete blocks every few feet. Sorry this is a bit stream of consciousness, but I’m curious what other ideas are out there.

Do most folks here on GBA use ICF footings/stem walls? If so, what techniques/products do you use?

Cheers,

Zane

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Looks like my image didn't work...

https://s22.postimg.cc/mlkryife9/EPS_Footing.jpg

Bump? Bad idea?

Zane,

It looks like a nightmare to form, keep straight and pour.

Thanks Maclolm - I can't say I'm surprised to hear that.

What about putting a course of blocks every few feet to hold the foam in place? Sort of a hybrid block/poured foundation?

Could it be done? Probably, with enough time/effort/money. Is it economical, efficient, or sensible? Not really. Traditional forming and then attaching the foam afterwards would save you a world of pain. You will also run into problems with your rebar being at the surface of the concrete. There are requirements for how deep in the concrete it needs to be to slow spalling. Maybe look towards some more traditional methods of forming. This is something that would work much better in AutoCad world than real site conditions.

Zane,

If you managed to get the form all backfilled and straight as shown in your drawing, as soon as you begin filling the footings the concrete will push the foam upwards. (As a side note, have you confirmed you can use a 12" footing on your build? That seems very small.)

Starting to frame off a bowed or uneven foundation just makes everything a lot more difficult, I'd urge you to use one of the conventional ways to form walls and go with that.

If you did manage to pour the walls, i'm curious as to how you then proceed. Excavate on the exterior for perimeter and storm drains? Excavate on the interior for the slab? Seems like a lot of work to avoid some other work.

If this sounds a bit harsh, it's intended to save you the grief I experienced early in my building career. I tried mimicking what I saw on other sites and had my first foundation turn out pretty wavy. The difference between working on it, and the ones I did subsequently was considerable.

Good luck!

No no please, harsh is good! I appreciate it! I would rather hear this feedback now than deal with the fallout.

I got on this train because my cousin is a contractor and had left over fox block ties. They routered out the foam to create channels so they would lock together and it was successful. Then again, they actually know what they are doing. Who knows how many foundations they've poured but it wasn't just a half baked idea dreamed up while sitting at a computer.

In the realm of convention foundations, I've heard block foundations filled with rebar and concrete can be easier to get right for a novice. Seems like a lot more work, but I'd be curious to hear some opinions.

Cheers,

Zane