Shed Roof to Wall Flashing

Hello. I’m at the stage of designing the flashing and air/moisture barrier system and the connection between the north shed roof and a vertical wall is giving me concerns.

The roofs are made up of 12 1/4″ SIP panels with a cold roof on top. Asection would show the panel with 30 lb asphalt paper on top, 2×4 spacers on edge with 3/4″ plywood sheathing on top of them, then a layer of Versashield Fire membrane and then a 7/8″ corrugated metal roof.

The walls, however, are standard 2×6 construction ( 2×6 studs, 1/2″ plywood sheathing, Stoguard Air/Moisture membrane, 2″ Roxul Comfortboard, 1×4 furring strips and then LP Smartside siding).

How do I flash the connection between the shed roof and vertical wall? I’m concerned where the edge of the cold roof should stop (against the vertical sheathing, back a couple of inches to allow air to exit)? Should I tie the air channel under the cold roof into the air channel behind the LP Smartside? Should I leave a gap between the bottom of the Roxul Comfortboard and Smartside and the top of the corrugated roofing panel?

I’ve also seen a product from Cor-A-Vent that’s designed for the roof to vertical wall problem. Should I use that instead?

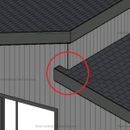

I’m also wondering how to flash the shed roof corners where they hit the vertical side walls.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Scott,

7/8" corrugated is a bit harder to flash than other metal roofing, but the details are quite similar.

Here is a link with examples of what I'll describe for each condition:

http://www.westmansteel.ca/public/File/webfiles/snapLokInstall.pdf

1. You use an end wall flashing. First you install an adhesive backed foam strip, then ideally, an end wall flashing with a 7/8" return you cut to the contours of your corrugated roof panels.

2. Uses a side wall flashing. When I install snap-lock panels I bend up the end at the wall to form a dam ,hen install the flashing over that. In your case the corrugations do the same thing. Make sure to get a side wall flashing with enough width to cover several corrugations, and install a foam strip on top of one of them.

3 + 4 - Are both the same condition, one just has a longer ridge. You start with the end wall flashing as in #1 ,then install the sidewall as I described above, then a peak cap. Again ideally you would contour the ridge flashing return to the corrugations.

Vent the shed roof by installing the end wall flashing on top of strips of your wall strapping cut the same height as the vertical leg of the flashing. Above this install a counter flashing back on your sheathing with a return wide enough to allow air movement. Above this start your wall strapping and cladding.