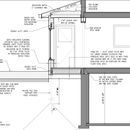

Small addition with helical pile foundation in Toronto Canada

Hi GBA,

I am an architect in Toronto. My client is a contractor who wants to build a small one storey addition using helical pile foundation instead of continuous foundation to save on cost.

The finished floor is raised above the grade by about 21″.

My questions:

-Can I use chicken wire to support the fibreglass insulation in the floor joists as it would be difficult to finish the underside of the floor with plywood I think

-Do I need a air-barrier like tyvek under the fibreglass insulation

-I am detailing 2″ of XPS rigid foam on top of the floor joist for a thermal break, will this work?

-Can I use electric radiant floor to heat this small addition?

Attached wall section and proposed floor plan.

Thanks much,

Lowell Lo

Architect

http://www.lowelllodesign.com

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Lowell,

I believe that crawl spaces should be high enough to allow for human access and repair work. Can you lower the grade?

The short answers:

1. Chicken wire is a bad idea (and an invitation to rodents). You need OSB or plywood.

2. Yes, you need a tight air barrier on the underside of the floor assembly.

3. Rigid foam cannot be sandwiched between floor joists and subflooring because the tops of the joists dig into the rigid foam. The rigid foam belongs on the bottom of the assembly, between the bottom of the floor joists and the protective OSB or plywood.

4. Yes, you can use electric resistance heat for this addition, but electric resistance heat is expensive to operate.

Thanks again Martin.

I think it will be difficult to lower the ground under the addition even If I can do that under it how does one get into the space? I would need to lower the grades around the addition as well.

Can I put an additional plywood on top of the joist then the rigid insulation on top?

I still get figure out how to put the exterior plywood and tyvek under the joist?

The contractor is trying to do minimal construction if we do a continuous foundation it will need to step down to meet the existing basement foundation. You would recommend that and insulate the crawl space floor and insulated the continuous foundation?

Lowell

Lowell,

Practical concerns aside, there are two code issues you may be bumping up against.

The first is that I haven't see any distinction between the height requirements for unenclosed crawlspaces and those that are - meaning you need to provide the minimum height for access to the underside of the addition. That height depends on whether there are services in the floor or not.

The second is that all wood elements within the height of your floor need to be pressure treated. How far that requirement extends is a bit unclear to me. It would certainly include all the framing, and the plywood on the underside. Whether it extends up to the various subfloors you are proposing I don't know.

These low un-enclosed additions are a headache to build, and a continuing headache over time. I'd be inclined to use a frost protected shallow foundation and slab instead.

All that said, I'll confess to building similar ones. What I did to get around the problems of access was to frame the floor upside down, fasten the foam and plywood to the bottom, and then flip the whole thing. Once it is in place, and secured to the house and piers, you can insulate the cavities, run any services, and then lay the subfloor (or floors).

Thanks Malcolm for your tips. I will reread your message again tonight. Are you an Architect in Toronto as well?

Lowell,

No. I practiced in Ottawa during the late '80s. For the past few decades I've been here on Vancouver Island doing more construction than design.

Edit; One other small point. Have you thought of how you will vent the top of the roof space in the addition?

No Malcolm. Can I get your email to correspond for a solution?

Sure, although you will probably get a better range of advice if you ask the questions on this board. There are lots of very experienced posters here.

If you send an email to Martin, I'm sure he will be kind enough to forward it to me.

I was hoping to not inundate Martin with my postings. I am not sure how or if I should email Martin directly. You worked in Ottawa and still working in Canada so I thought to inquire directly with you.

Lowell,

I'd be happy to email you. I just don't like posting my address on public forums. In the past when this has come up Martin has acted as an intermediary as he has my email. If you don't mind posting your e-mail, I'll reply directly.

Edit: the other areas that needs some further detailing are where the patio meets your cladding, and how your roof is supported and flashed at the existing brick.

Thanks for the additional reminders.

My email is: [email protected] There are six L's in all in the email.