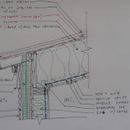

Roof / wall connection showing vent above structural sheathing

I know this has been discussed a thousand times here but each situation is unique and I find that answers seem to vary depending upon the mood of the commentator.

I had previously developed a similar detail as the one shown which had furring strips below the sheathing allowing the vent channel to run below the sheathing but I believe this introduces a whole host of problems not the least of which is an area of loose fabric above my dense packed rafters which overtime could become home to a whole host of critters which might then crawl though it.

I also believe that running the vent channel below the roof sheathing invites bulk water into that space where otherwise it would be excluded. We are then depending upon robust eave details to prevent Wind River and Rain to enter this vent cavity. By closing this off to win driven drain and putting the vent above the roof sheathing we eliminate this possibility.

I am of the opinionthat the risk of moisture in my rafters is potentially reduced by moving the sheathing down and the furring up and making sure that my roof underlayment is a vapor open product such as Mento 1000, roofing felt, or something else similar.

I believe that moisture within the rafters is mitigated by the Intello air and moisture barrier on the interior face of the wall framing.

Furthermore some conversations with local building professionals and building scientists push me in this direction so I don’t think that the opinion regarding location of vent channel in this condition is unanimous.

I understand potential code complications, but I don’t believe that there is enough attention being paid to my project to warrant concern in that area from a purely jurisdictional perspective, actual building science concerns notwithstanding.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Ethan,

I too was concerned about that roof/wall/rafter connection, so we terminated the rafters at the bottom plate keeping it inside the wall sheathing. We site built the soffits and we have a vent channel that is outboard of the exterior roof insulation.

Attached is the detail.

Thanks, Jonathan. Is your insulation foam or Rockwool? How are you creating the vent cavity between your insulation in your roof sheathing?

Ethan,

The roof insulation is polyiso. We used 1 layer of 2" polyiso followed by a ThermaCal nail base panel that was comprised of another 2" of polyiso, a 1" vent cavity and 5/8" CDX. We ran short on the panels and had to replicate the assembly of the nail base for about 10% of the roof area. I prefer this method to the panels because the panels are little cumbersome to try to cut and most roofers are not carpenters. Also the panels are designed to be fastened at 12" spacing so most of the fasteners do not sit in the rafters. We used 5/4" x 3 furring strips and fastened them 16" OC into the rafters.

Jonathan, I appreciate your contribution to this discussion. I do believe that polyiso is a completely different beast than dense pack cellulose, particularly in the manner in which it interacts with water. So I'm curious about the location of the vent cavity specifically in the dense pack cellulose condition. I have a growing suspicion that creating a tighter roof assembly and avoiding bulk water via a robust roof assembly (standing seam, no hips or valleys, over Mento1000 w Ice and Water Shield at eave) is preferable to creating a situation in which an unprotected roof membrane could be ripped or torn into overtime. I believe that this assembly in concert with dense packed cellulose and its hygro... properties will be a robust solution to the situation.

Ethan,

If you are comfortable with Dan Kolbert's position that a well-sealed, dense-packed cellulose roof in contact with the sheathing is safe, than introducing venting above the sheathing will only make it safer.

I've been active in the threads where above sheathing venting has been discussed. I don't know how relatively effective it is versus venting below, and wish someone would comment on that. My concerns have been that many of the proposed assemblies didn't have any effective mechanism to allow the air to enter, move or exit.

Where I lose you a bit is worrying possible bulk-water intrusion if the vent is below the sheathing. How will this water get introduced? How does it get into the soffit vents?

My initial assumption is that any system failure is unexpected. So following from that assumption one could surmise that any unexpected failure would occur in a vulnerable area. When I look at a detail which includes airspace above and unprotected membrane, my intuition is that that empty space is potentially prone to failure at some point in the future. To answer your question specifically, perhaps a high wind event such as we have had many of recently in my area could drive rain into the vent cavity. Furthermore some type of animal such as a bird a squirrel or other beast could have already set up residence in that location and created a hole in the membrane. Voila. Having uninterrupted plywood covered by a vapor open water resistive barrier seems to me to be a more robust system over time. It also seems to be a system which accounts for unforeseen future events.

Ethan,

I think that your worries about water intrusion are unfounded. In my experience, anyway, I haven't heard about wind-driven rain through soffit vents causing problems.

On the other hand, it isn't very unusual to hear of water-entry problems at the ridge vent. If you have a ventilation channel connecting soffit vents to a ridge vent -- either under the roof sheathing or over the roof sheathing -- the air movement through the ventilation channel should be able to handle incidental moisture entering through the ridge vent.

Floris Keverling Buisman and Ken Levenson at 475 High Performance Building have been promoting the idea that you can install dense-packed cellulose in a roof's rafter bays, without any vent channels, and that the assembly can be safe if a smart vapor retarder is installed on the interior. They claim that WUFI software proves the assembly is safe, and there is some monitoring data that shows that the approach can work, if installation is flawless.

So Malcolm is right -- if you believe that (and I'm not sure whether Dan Kolbert still does), then the addition of a ventilation channel above the roof sheathing just makes the system a little safer than if the ventilation channel weren't there.

A caveat to readers: conservative builders prefer to see some kind of ventilation channel when you are insulating with cellulose. For more information on the controversy, see Smart Vapor Retarders for Walls and Roofs.

And I understand, Ethan, that you're not trying to build a roof without a ventilation channel. The question is whether the plywood is vapor-permeable enough to allow outward drying. My gut tells me it is.

We are all indebted to first-adaptors who move building science forward, but I'm puzzled by why anyone would want to include a potentially risky assembly in a new build. I can see the reasoning behind it in a renovation where there are few other options, or maybe where a conventional approach severely affects the architecture, but beyond that why?

The GBA blogs have featured high-performance houses using low-risk assemblies that don't seem to suggest any compromise in cost or architecture. Stephen Sheehy's house is a good example, and there are many others. It's easy enough to get things wrong when building. Increasing the consequences of doing so by starting with a risky assembly just doesn't make sense.

Good points, Malcolm. My advice to Ethan would be to follow one of the tried-and-true cathedral ceiling assemblies discussed in my article, "How to Build an Insulated Cathedral Ceiling."

I don't quite understand the attraction of inventing a brand new approach to designing an assembly -- especially an assembly like a cathedral ceiling, which has 4 decades of various types of failures to instruct us -- when excellent solutions have already been developed.

Martin, I have read that article... I think I'm following your advice (except CDX instead of fiberboard)... I quote at length

"Creating vent channels above the roof sheathing

If you prefer, you can locate your ventilation channels on top of the roof sheathing rather than under the roof sheathing. If you decide to do this, make sure that any roofing underlayment that you install above the roof sheathing is vapor-permeable — for example, #15 asphalt felt, VaproShield SlopeShield, or Solitex Mento — and that your local building department accepts this approach to roof venting. If you install ventilation channels on top of a vapor-impermeable synthetic roofing underlayment, the flowing air won't be able to help dry out the roof sheathing.

If you plan to install ventilation channels above your roof sheathing, it's best to choose a roof sheathing that is vapor-permeable (for example, fiberboard). If you use plywood or OSB, there's a small chance that the sheathing can still accumulate worrisome amounts of moisture over the winter; this is especially true for north-facing roofs.

You can create 1 1/2-inch-high ventilation channels above the roof sheathing with 2x4s installed on the flat, with the 2x4s located above the rafters, 16 inches or 24 inches on center. Although this approach is less fussy than installing vent baffles underneath the sheathing, it usually costs more, because most types of roofing require a second layer of plywood or OSB on top of the vent channels.

In some cases, these ventilation channels are installed above a layer or two of rigid foam. It's also possible to purchase nailbase (a type of SIP with OSB on one side instead of two) that includes integrated ventilation channels between the OSB and the rigid foam; one brand of these panels is Cool-Vent from Hunter Panels.

If you are choosing to build a vented roof assembly, don't forget to include soffit vents and ridge vents."

Ethan,

Just to be clear, my comments were a general observation after seeing the many iterations of wall and roof assemblies that come up on GBA, not in any way directed at your question.

Malcolm, Martin, et al. From my perspective, your conversation about my roof detail as drawn interspersed with generic comments about the desire of GBA readers to invent novel unvented roof assemblies has reached the level of a zen koan: If a man fastens a water resistive barrier directly to his plywood sheathing with a vent cavity above, will it still breathe?

Ethan,

Nicely put.

Here my current take on this: I can't see any significant difference between a roof with air-sealed plywood ventilation channels and one with the ventilation above the plywood roof sheathing. Unless there is some inherent risk of having insulation directly in contact with the sheathing, where the venting occurs shouldn't make any difference.

The only other question I have is whether having the metal roofing as the top of the cavity wasn't asking for more moisture to be introduced into the vent channel when it acts as a condensing surface. While the channel may be able to deal with this, I don't think having bulk water draining from it at the eaves is a desirable situation.

Ethan,

There are really two reasons that your assembly might raise concerns.

The first is one you noted: while my article advises the use of fiberboard for roofs with ventilation channels above the sheathing, you want to use plywood sheathing, which (when dry) may have a vapor permeance as low as 0.5 perm (although most brands are somewhat more permeable, and in all cases the permeance rises as the plywood gets wet).

So that fact slows down the rate of outward drying compared to the example in my article.

The second issue concerns the role of the rafters in redistributing moisture -- a factor that is hard to quantify, even (I assume) for WUFI. If you install site-built ventilation baffles made of plywood under the roof sheathing, the projecting rafters can pull moisture from the top of the insulation layer. The moving air helps lower the moisture content of the rafters. That doesn't happen when the ventilation channels are above the sheathing.

This is a judgment call. My judgment is that your assembly will work, if the workmanship quality is high, but I don't have calculations to back up my judgment.

Reporting back - a lot of this was made moot by the fact that at 3:12 pitch, the metal roof manufacturers want a HT Roof underlayment on the plywood directly under the meta - no Mento (in that location) for me.

Jon, are suggesting that Mento 5000 may be OK under a metal roof? What are your thoughts on Solitex UM? I'm still considering dense pack under unvented plywood sheathing with Solitex UM and metal roof above that. Solitex UM rated 100C.

As I see it:

Grace I&W HT 127C max temp

Mento 5000 120C

Mento 1000 100C

Underlayment under a metal roof: < 90C? Maybe 120C in rare cases (non black color and a furring strip vent channel significantly reduce this). I think plywood is only rated for 93C.

Perhaps the proper thing is to ask the metal roofing manufacturer exactly what temperate they require. "HT" is vague.

I asked PAC-CLAD. Their response was: In order for there to be a watertight warranty for the metal roofing, it must be applied over HT Ice + Water. They did not have an answer regarding technical specs. They did say the metal could be installed over purlins but then there would be no warranty. I think I have seen stanging seam applied over purlins, but I'm not sure I would want to forego the warranty.

I do see that Mento 1000 and UM are water tight with a 33' water column. I can't figure out how Grace and other underlayments are rated as I can't find any water column data on them.