Questions about a Lstiburek article on slab insulation

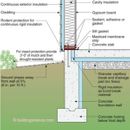

Attached is a figure from a Joseph Lstiburek article on slab insulation, and copied below are two sections of text from the article. I’d be grateful for answers to a few questions.

The entire article can be accessed at http://www.buildingscience.com/documents/insights/bsi-059-slab-happy/

1) “You make the assembly out of three pieces – a footing, a stem wall and the “flat plate” slab part. Then you insulate it under it and on the inside of the perimeter making sure you uncouple the plate from the stem wall at its edge (Figure 1). This edge thing is a big deal – the thermal bridging that occurs if you don’t do it costs you more than half the thermal resistance of the whole deal.”

Why does a slab lose so much heat at the edge as compared to the underside?

In various places the edge insulation is referred to a a “bond break”: what does that mean, exactly, and what is the significance of calling it that, rather than referring to it simply as “insulation?’

Lstiburek cites with approval a project in Chicago that features a 2″ bond break. Would a thinner one suffice in Zone 4C?

2) “Do you really need to insulate the stem wall if you insulate the edge of the slab and insulate under the slab at the perimeter? Yes and no. Yes in climate zones 4 and higher, no in climate zones

3 and lower. Is this based on a hygrothermal analysis? No. Is this based on an energy payback analysis? No. Is this based on minimizing your carbon “footprint”? No. Get serious. It is based on something that is real. We found that in climate zones 4 and higher if you didn’t do it people felt uncomfortable. It is not a good idea to annoy your clients. Especially if they are old – remember you will get old too – sooner than you expect.”

How does the stemwall insulation keep the slab warmer? Does it need to go all the way to the footing?

3) Regarding the stemwall from a structural point of view: it appears that the placement of 2″ slab insulation results in the 2×6 sill being bolted to a stem that is only 3/1/2″ wide. Is that enough?

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Heat losses out the stem wall and slab edges are higher than at center slab since there is less soil-R between that part of the slab and the great outdoors. At center slab the heat losses are more closely related to the deep subsoil temperatures (which are usually close to the average annual or decade-long outdoor air temperatures), whereas at the slab edge and stem wall the heat loads track the daily or monthly outdoor temperature averages (or seasonal average, down at the footing.) The wintertime weekly/monthly average temps are several 10s of degrees colder than the annual average temp, ergo the heat losses are higher near the edges.

Insulating the stemwall all the way down to the footing evens-up the slab temps by coupling it all to the deep subsoil temp rather than the seasonal average temps. The high thermal mass of the soil corralled by the insulated stemwalls keeps it's annual high/low temperature range very tight, whereas with an uninsulated stemwall the perimeter of the slab would be noticeably cooler than the rest by mid-winter, and noticeably warmer than the rest by mid-summer, even through R7-8 of sub-slab foam.

A "bond break" is a layer that keeps the edges of the slab from sticking to the walls to allow it to shrink without mechanical strain while curing. It's related to "expansion joint", which allows the concrete to expand thermally without inducing large pressure on the wall. The foam in this case provides both functions(the bond break being more important here, since the temperature of the slab in a heated conditioned house doesn't change much), as well as an insulating function. Even a 1" XPS as a bond break would be fine from a slab contraction/expansion point of view, but R5 doesn't really cut it from an insulation point of view in zone 4C. In zone 4C it's fine to reduce that to 1.5" if XPS (R7.5) or 2" if EPS (R8), but 1" (R4-5) would be more likely to have a noticeable comfort impact.

Cantilevering a 2x6 studwall plate 2" off the foundation will usually meet code structural requirements.

Thanks, Dana, for the thorough and clear explanations. The image of the stem walls "coralling" the thermal mass of the soil is especially evocative.

Two followup questions, if I may.

Would hydronic radiant heat in the slab call for thicker edge insulation in this particular arrangement?

Regarding the sill plate, I was more concerned about the narrowness and height of the stem into which it is being bolted: 3 1/2" wide and 6" tall. Would that satisfy seismic codes?

Seismic design issues are usually spelled out in local codes, but if you bolt it down as if it were a 2x4 plate (and I presume 2x4 framing would meet code), the fact that there's a 2" cantilever is of little or no consequence. I would think that the tie-down bolts need to be deeper than 6" into the concrete in ANY seismic zone though(?).

If you poured the stemwall full width with an insulating concrete form (ICF) you could use a much thinner bond-break without losing thermal performance, especially if you used Type-IX EPS or Type X XPS under the footings and lower density stuff to fully wrap the footing, thermally breaking the whole thing from the soil. (The width of the footing and the density of the foam need to be specified by an engineer to get this through code, but it's done on high-R houses like PassiveHouses fairly often.)

Any time you're heating the slab it calls for thicker slab insulation (including slab-edge) but won't affect the spec for the stem wall. In zone 4C non-heated slabs do well to have something R7-R8 under the slab, but add about another ~R5 to that for radiant floors. At 3" you get ~R12.5 performance out of Type-II EPS (and a bit more out of denser-tougher Type-IX EPS) which is about right. In colder areas with colder subsoil and colder outdoor temps even more is warranted. Even though some radiant guys prefer to use XPS for better staple retention for fixing the PEX prior to the pour, the HFC blowing agents used for 2.5" of XPS (R12.5) has 200x the lifecycle greenhouse potential of the pentane used for blowing EPS, and probably more than the lifecycle energy-use carbon it's offsetting once you're past the first inch or so in a sub-slab installation, making EPS a greener choice. Both are closed cell, and do just fine under slabs.

Dana,

Thanks for your thorough answer. It looks like you've got this one covered. I appreciate your contributions to the site.

My question is somehow related to this topic, which is why I'm posting it here, please pardon me for "hijacking it". If moderators think I should start a new thread I will.

Assuming the same detail image posted above, but considering 2" of exterior rigid insulation behind a rainscreen.

2 questions:

1- Can I use the same metal termite shield at the bottom of the wall to extend and cover the rigid insulation as a "J" channel , or should I use a separate flashing for that?

2- If rigid is 2" or more, why not create a "lip" on the foundation wall to rest the rigid on? Similar to the one used on brick. Is there a reason for this , other than cost saving. (haven't really seen this detail online, I might be wrong though)

Thanks.

Just to add a little bit to Dana's first response regarding question #1 - heat loss at the slab edge is significantly higher because the edge (at least 8" vertical) is exposed to ambient air, rather than the ground. See attached image.

That's right, John!

There's a remaining bit of thermal bridging at the foundation sill/stud-plate through the concrete to the exterior too, which is why insulating the exterior of the foundation wall is sometimes preferable (if not always practical.) In your drawing that top arrow is a 1.5" tall R2 stripe in what is probably an R15-R20 whole-wall, but if the foam is on the exterior the stripe becomes R12 without increasing the amount of foam used. But with exterior foam comes a foundation-finishing cost adder, it's not a cost-neutral change.

"Cantilevering a 2x6 studwall plate 2" off the foundation will usually meet code structural requirements."

I live in a very cold climate (Zone 7/8). I am assuming I need at least 4" of bond break foam but how do I position a load bearing wall on this region?

I was thinking of this inteior perimeter insulation until my structural engineer told me that the slab serves a structural purpose to 'brace' the footings down low,. i.e. the slab needs to be in direct contact with the footings. This would seem to leave only the exterior insulation option or fancy structural insulation (foamed concrete?).

Can anyone comment on this?