Opinions on wall and basement enclosure for custom house

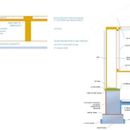

Hi everyone! I’ve been reading this Q&A section for a long time prepping for our custom build. We are currently in the design phase with the architect and I would like the communities opinion on my enclosure I’ve been putting together. Any thoughts or comments are greatly appreciated. Most ideas are taken from what I’ve learned on here! I feel like its going to be a community built house by the time I’m done:)

I am in Des Moines, IA – Climate zone 5. This will be a walkout ranch.

Thanks,

Matt

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Matt,

Comments:

1. The insulation in your walls will have an R-value of about R-20 -- minus the effect of the thermal bridging through the studs. So your walls are OK, but not that great.

2. Your basement slab -- or is it a crawl space slab? -- is well insulated. In fact, it's better insulated than your above-grade walls, since you included R-20 continuous insulation. You'd be better off if you installed some of that sub-slab foam on the exterior of your above-grade walls.

Thanks Martin,

It is a full basement. I should have mentioned that. My bad.

As for adding insulation to the exterior, I was wondering if that would be a good thing to do. I have been researching on whether to add Roxul or EPS. Does anyone have a preference? If I remember right, I would need R7 or greater in my climate zone. I was also thinking to use Roxul in the stud cavities, but really couldn't discern which is a better choice in my situation. I think cost will be the determining factor.

Your detail doesn't show air sealing between the bottom plate of the studwall and the subfloor.

There doesn't appear to be any insulation on the foundation wall above the slab(?), which would be a huge thermal bridge.

Dense packed cellulose offers more moisture protection than Roxul in the cavities. Roxul has somewhat better fire resistance though. Blown fiber will always have a better fill & fewer voids than even the best-installed batts.

For the exterior sheathing insulation 2" Roxul would be more fireproof than 2" EPS, but substantially more expensive. Performance-wise they would be similar, at about R8-8.5. A third alternative would be 2" of foil-faced polyiso, which is in-between from a fire point of view, but runs R12-R13, nearly doubling the performance of a code-min R20 2x6 20" o.c. studwall (which comes in at about R14 after thermal bridging if you include the R value of the sheathing & gypsum.) Roxul doesn't burn, but does allow air to reach the susceptible sheathing. EPS will melt & drip while burning. Polyiso has a highe kindling temp and chars in place rather than drips once fully ignited. Foil facers are pretty easy to air seal, using purpose-made FSK tapes (2" alumium duct tape.)

Even though the R14 whole-wall code-min is legal to build, there's a pretty good rationale for R25+ in zone-5 locations from both a comfort and long-term energy cost savings point of view. The 2" Roxul/EPS wall delivers about R22, whereas 2" polyiso delivers R26-27 at the same wall thickness. And with R8-R12 on the exterior and cellulose in the cavities you can save the cost of the smart vapor-retarder.