I will be adding a room to my house this summer and I am looking at a couple different wall configurations.

Any comments / suggestions / criticisms more than welcome.

Obviously these are not wildly original, they are based on so many great posts here and also on recommendations from BSC.

Thanks!!

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Greg,

There seem to be a few peculiarities to each wall. Maybe you can explain your thinking?

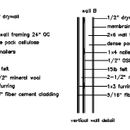

Wall A has 2x6 studs without any exterior sheathing. You will be attempting to install dense-packed cellulose, and you expect that #15 asphalt felt on the exterior of the studs, held in place with a few horizontal 1x4s, will resist the force of the cellulose when installed with a blowing machine. I think that won't work. The asphalt felt will rip, and the cellulose will escape to the exterior.

With Wall B, what is the purpose of the horizontal 1x4 nailers installed on the exterior side of the 1/2-inch OSB? Won't those horizontal 1x4s make it more difficult to install the mineral wool?

Wall A looks good to me. Martin I think the cellulose gets blown in after the mineral wool and strapping are up.

Greg, follow directions... what zone are you in?

Good morning and thanks Martin and AJ.

As AJ said per wall A, I had intended to include information that the exterior sections would be completed prior to blowing in the cellulose. Using the mineral wool and cladding to keep the cellulose from passing thru the structure. Unfortunately I was interrupted while posting and didnt get it done. Definitely important additional information!

Per wall B, I totally missed that I put the nailers on the wrong side of the OSB in the drawing that I posted (thanks for the catch Martin). The intent of the nailers was to be between the studs and OSB in order to decouple the OSB from the studs and leaving the 3/4" space to fill with either rigid EPS or else cellulose as it's blown into place - if there was a particular advantage to either in the small area.

I was also considering using 2x4 rather than 1x4 in that application which adds a little more space for cellulose fill and a little higher R value.

AJ, I am in northwest Wisconsin, Zone 6, not too far south of zone 7.

Any thoughts on using the membrain inside?

thanks again!

Greg, there is an interesting post of Four Seven Five Building supply website which is very similar to your proposed wall assembly. There are exterior smart membranes that would work. The one on the website above is Solitex Mento.

Also are you using mineral wool batts or mineral wool "boards" like Roxul Comfortboard? The Comfortboard would resist deformation much better than the mineral wool batts.

http://www.foursevenfive.com/blog/2012/09/vapor-open-exterior-without-sheathing-maximizes-outward-drying-potential/

See what you think.