Heat loss calculation and minisplit location questions

I am building a modular energy efficient house in N. Reading, MA. The modular company PBS has a lot of experience building energy efficient homes which is why I am surprised at their heat loss calculations. The house is 3860 sq ft not including the walkout unheated basement. PBS uses the ADA in their building method and the other house details are as follows:

House is oriented northwest-southeast

Paradigm Triple Glazed Windows U-.21 Innie

R-10 under slab

R-20 on front and side concrete basement wall, back and garage are the same as above grade

Above grade details are as follows drywall, 2×6 16″ OC with dense pack cellulose, Zip sheathing/taped, Tyvek Drainwrap, 2 layers of 2″ foam taped(xps or polyiso whichever is available from reclaimed vendors) 1×4 strapping, LP smartside.

Attic floor will either be 18″ loose fill cellulose or a layer of cc foam then cellulose.

PBS says that all their houses will blow at least a 2ACH but going lower is dependant on the GC(Me). Since I have been following this site and others for the past 3 years I feel I have a good grasp on what needs to be done so I am shooting for at least a 1.5ACH.

My questions are does this heat/loss calc seem high and no matter what it may be where would you place the mini splits (type too) that would keep the house comfortable? My wife goes from ok to freezing with a 1 degree change so I don’t have a real leeway with temperature variances. Lastly I must say this site is great. Thanks!

Arthur L

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Arthur,

A couple of reactions:

1. You refer to an "unheated basement," but then you tell us that the basement insulation is on the basement walls. That means that the basement is inside the home's conditioned space. If you want the basement to be outside the home's conditioned space -- and I'm not urging you you to make this change -- you would have to move the insulation to the basement ceiling.

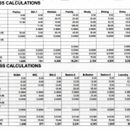

2. You're asking for someone to do a lot of calculations for you, and I don't know if you will be successful in your goal of finding a volunteer to do the work. What's the total heat loss for the entire house? [Later edit: I found the addition, written in pencil in the margin of the document. I missed those pencil marks the first time I looked at the image. It looks like 54,310 Btu/h. Sorry I missed that at first reading.]

Martin,

1. That piece of information was provided because I thought it may have some relevance in the Heat/Loss calc. This space may be finished down the road which is why I am insulating it as it is.

2. Wasnt looking for someone to calc the Heat Loss just to tell me if the the one I paid for seems high. I've seen hundreds of post here where people have posted their total heat loss and square footage and then being told that something seems wrong. Just seeking some advice.....

Arthur,

Without doing any calculations, I'll admit that 54,000 Btu/h sounds high. However, you're building a big house -- 5,790 s.f., according to my calculations, if you include the basement -- so it might be about right.

One glaring fat thumb on the scale:

You claim to be installing U0.21 Paradigms, but the "Door & Glass Factor" U-factor in the spreadsheet is U0.36. If you have insulated exterior doors they would typically come in at U0.25-ish (but there would be spec sheets with the real numbers), and your window U-factor needs to be adjusted down to U0.21 in the calc.

Dana,

Thats what I thought but I wanted to make sure also I felt that the exposed wall factor was a lot higher since we are looking at an R-40 wall. I asked PBS for clarification and if necessary a rerun. In the meantime I actually found a copy of the software they used "Slant/Fin" and I inputed their values with 2 exceptions. I changed the glass/door factor to .21 and the exposed wall factor to .025. This dropped the gross heat loss from 54,310 to 50,872. Now I feel that the increased expense of 4" of external foam maybe a waste of money!

An 2x6/R20 celluose16" o.c. comes in at about R14-R15 whole-wall on it's own. Add R10 foam and you're at about R25, which is about U0.040 . Maybe they misunderstood, and assumed only 2"?

If it's 4" of exterior foam it's about R35 whole-wall (not R40), which is about U0.029. That's about 1.34 x reality.

The the window U-factor a about 1.7x reality.

The infiltration factors in the Slant Fin tools are insane overstatements of reality for a house that meets IRC 2012 code max air leakage. Whatever they came up with for infiltration losses, assume reality is only about 25-30% of that number.

The exterior foam adds a HUGE amount of moisture resilience to structure. You might be able to argue against the last 1-2" on it's net-present-value of future energy cost savings in a low energy cost high labor cost market, but not the first 2". In BA-1005 they posit R30 whole wall as a middle-of-the-road cost effectiveness basis using virgin stock foam. But if using reclaimed foam it's probably still a slam dunk for a longer term financial analysis. See Table 2, p10 of this document:

http://www.buildingscience.com/documents/bareports/ba-1005-building-america-high-r-value-high-performance-residential-buildings-all-climate-zones

The Slant-Fin tool is also an I=B=R calc, which does not subtract out the 24/7 plug loads or those pesky heat-emitting mammalian occupants. Every sleeping human is good for about 250BTU/hr. Look up the annual kwh on your refrigerator, divide by 8760 hours per year, and multiply times 3412 BTU/hr per kilowatt for what to expect out of it. DVR, security systems , phone systems, etc all draw continuous power too. A house that size with R35-ish whole walls and U21-ish windows would usually come in under 10 BTU/hr per square foot @ 0F outdoors. In N. Reading that's about the lowest reasonable outdside design temp, and may be a degree or so lower than the 99th percentile temperature bin for N. Reading. (0F is the 99% outside design temp in Lawrence: http://www.energystar.gov/ia/partners/bldrs_lenders_raters/downloads/Outdoor_Design_Conditions_508.pdf )

Dana,

I investigated the Slant/fin infiltration factor calculation and "insane overstatements" almost doesn't describe it. A .018 infiltration factor in slant fin equates to house ACH50(nat) of 1. Going on this assuming at minimum ACH50 2 converted to ACH50(nat) using a N factor of 17.8=.11235955. That would make the Slant/fin infiltration factor .00202. If I use this number in Slant/fin with your changes to the exposed wall factor of .029 my gross heat loss is cut in half.

Dana,

Good work tracking down all the sources of exaggeration. Thanks.

Just out of curiosity, I know PBS also does double-stud walls dense-pack cellulose to get similar or high R-value walls with no exterior foam needed. Did you consider that option and how did it compare? I'll guess that it would have been cheaper, except that you are using reclaimed foam which makes the approach you are taking cheaper, but that's just a guess. And as Dana says "The exterior foam adds a HUGE amount of moisture resilience."

Charlie,

My original design did use double stud walls. My particular floorplan would require it to be divided into 10 modules(not including the roof) which drastically increased the delivery and setup costs. Changing it to onsite foam installation allowed me to reduce it to 4 modules and reduced the price significantly almost 25%. Once you add in the reclaimed foam installation it will probably be more like a 10-12% saving and if I didn't live in a state with 3 different insulation outlets the savings may have been negligible.

Thanks Arthur. Building projects seem to often hinge on the particulars of an individual project ... in your case a drastic difference in the number of modules. Great that the reclaimed foam option was available.