Dense-packed cellulose in low-height attic?

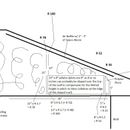

The roof of a one room addition built in 1951 will be sealed, insulated, and re-shingled (northern Zone 5a, almost 6). Three sides slope for about three feet until the slopes meet the flat part that makes up the majority of the roof (Attic Cross Section.jpg) The ceiling is plaster, penetrations will be sealed, the joints between the polyiso boards used near the perimeter to compensate for the lower height will be staggered and sealed, air baffles allowing 2 – 3″ of air flow beneath the slopes will be installed, we’ll leave 2 – 4″ of space under the flat roof for ventilation but the rest (about 24″ under the ventilation space under the flat part + whatever will fit over the polyiso) will be filled with cellulose (Proposed R Profile & Materials.jpg). The flat part of the roof will be re-built at a very slight angle so water doesn’t pool and Ice & Water Shield will be installed. I’m aiming for a pseudo Passive House structure that is durable.

Air sealing is important for ice dam prevention and general efficiency, but I’ve read it’s impossible to seal old homes up super-tight. Fine Home Building published an article (by Mr. Holladay) saying “When blown-in insulation is installed in a closed framing cavity, it’s possible to achieve higher insulation densities than can be achieved on an attic floor… In a closed cavity, cellulose should be installed by the dense-pack method—that is, to a density of at least 3-1/2 lb. per cu. ft.” Dense pack provides a partial air barrier too.

But with this short attic (29″ height max), maybe it makes sense to consider it a closed cavity and use dense packed cellulose above and to the interior of the polyiso – packing up to the air baffles on the sides and leaving 2 – 4″ of ventilation space below the flat roof. This would increase R some, AND will impart the partial air barrier qualities of dense packed cellulose to a house that needs all the help it can get.

Generally, are there problems with using dense packed cellulose where “cellulose” is seen in “Proposed R Profile & Materials.jpg” as far as moisture, insulation value, convection, etc.???

If sound from those angles, maybe there are structural considerations. I don’t want any chance of plaster between joists sagging, bowing, etc. I can’t see if nails or screws hold the board to the framing but do know the boards are 16″ wide (can’t tell know how long). Assuming the weakest scenario – nails instead of screws and boards of unknown strength, is it obvious the plaster ceiling can hold 7.6 lbs per square foot (2 cubic feet high x 3.8 lbs cellulose/cu. ft. = 7.6 lbs over each sq. ft, assuming an overshoot on density to be safe) without bowing??? Or is this a question someone like an inspector or engineer should see in person???

If a dense packed short attic is a good idea, is it technically feasible – attach Insulweb across the rafters then fill in the large area underneath??? Other ways of dense packing this space?

Thank you very much in advance.

GBA Detail Library

A collection of one thousand construction details organized by climate and house part

Replies

Gordon,

When you pile cellulose onto an attic floor, the bottom of the pile of cellulose is somewhat compressed by the weight of the cellulose on top. The top few inches will be a little fluffier. The thicker the pile, the more compression on the bottom.

If you are planning to install 20 to 24 inches of cellulose, the difference between loose-fill and dense-packed cellulose isn't that significant. Your R-values are high; I wouldn't worry too much about getting an extra R-1 or R-2 from dense packing.

It sounds like you will be paying attention to air sealing, so I don't think the reduction in air flow rates attributable to air sealing will make much of a difference.

So -- this issue isn't too important. But, to answer your question: if you want to dense pack the area, only one person can tell you whether it is feasible, and that is your chosen contractor. Every contractor is different. Some cellulose contractors have a lot of dense-packing experience, and others don't.

So, ask your contractor.